- •VOLUME 1

- •CONTRIBUTOR LIST

- •PREFACE

- •LIST OF ARTICLES

- •ABBREVIATIONS AND ACRONYMS

- •CONVERSION FACTORS AND UNIT SYMBOLS

- •ABLATION.

- •ABSORBABLE BIOMATERIALS.

- •ACRYLIC BONE CEMENT.

- •ACTINOTHERAPY.

- •ADOPTIVE IMMUNOTHERAPY.

- •AFFINITY CHROMATOGRAPHY.

- •ALLOYS, SHAPE MEMORY

- •AMBULATORY MONITORING

- •ANALYTICAL METHODS, AUTOMATED

- •ANALYZER, OXYGEN.

- •ANESTHESIA MACHINES

- •ANESTHESIA MONITORING.

- •ANESTHESIA, COMPUTERS IN

- •ANGER CAMERA

- •ANGIOPLASTY.

- •ANORECTAL MANOMETRY

- •ANTIBODIES, MONOCLONAL.

- •APNEA DETECTION.

- •ARRHYTHMIA, TREATMENT.

- •ARRHYTHMIA ANALYSIS, AUTOMATED

- •ARTERIAL TONOMETRY.

- •ARTIFICIAL BLOOD.

- •ARTIFICIAL HEART.

- •ARTIFICIAL HEART VALVE.

- •ARTIFICIAL HIP JOINTS.

- •ARTIFICIAL LARYNX.

- •ARTIFICIAL PANCREAS.

- •ARTERIES, ELASTIC PROPERTIES OF

- •ASSISTIVE DEVICES FOR THE DISABLED.

- •ATOMIC ABSORPTION SPECTROMETRY.

- •AUDIOMETRY

- •BACTERIAL DETECTION SYSTEMS.

- •BALLOON PUMP.

- •BANKED BLOOD.

- •BAROTRAUMA.

- •BARRIER CONTRACEPTIVE DEVICES.

- •BIOCERAMICS.

- •BIOCOMPATIBILITY OF MATERIALS

- •BIOELECTRODES

- •BIOFEEDBACK

- •BIOHEAT TRANSFER

- •BIOIMPEDANCE IN CARDIOVASCULAR MEDICINE

- •BIOINFORMATICS

- •BIOLOGIC THERAPY.

- •BIOMAGNETISM

- •BIOMATERIALS, ABSORBABLE

- •BIOMATERIALS: AN OVERVIEW

- •BIOMATERIALS: BIOCERAMICS

- •BIOMATERIALS: CARBON

- •BIOMATERIALS CORROSION AND WEAR OF

- •BIOMATERIALS FOR DENTISTRY

- •BIOMATERIALS, POLYMERS

- •BIOMATERIALS, SURFACE PROPERTIES OF

- •BIOMATERIALS, TESTING AND STRUCTURAL PROPERTIES OF

- •BIOMATERIALS: TISSUE-ENGINEERING AND SCAFFOLDS

- •BIOMECHANICS OF EXERCISE FITNESS

- •BIOMECHANICS OF JOINTS.

- •BIOMECHANICS OF SCOLIOSIS.

- •BIOMECHANICS OF SKIN.

- •BIOMECHANICS OF THE HUMAN SPINE.

- •BIOMECHANICS OF TOOTH AND JAW.

- •BIOMEDICAL ENGINEERING EDUCATION

- •BIOSURFACE ENGINEERING

- •BIOSENSORS.

- •BIOTELEMETRY

- •BIRTH CONTROL.

- •BLEEDING, GASTROINTESTINAL.

- •BLADDER DYSFUNCTION, NEUROSTIMULATION OF

- •BLIND AND VISUALLY IMPAIRED, ASSISTIVE TECHNOLOGY FOR

- •BLOOD BANKING.

- •BLOOD CELL COUNTERS.

- •BLOOD COLLECTION AND PROCESSING

- •BLOOD FLOW.

- •BLOOD GAS MEASUREMENTS

- •BLOOD PRESSURE MEASUREMENT

- •BLOOD PRESSURE, AUTOMATIC CONTROL OF

- •BLOOD RHEOLOGY

- •BLOOD, ARTIFICIAL

- •BONDING, ENAMEL.

- •BONE AND TEETH, PROPERTIES OF

- •BONE CEMENT, ACRYLIC

- •BONE DENSITY MEASUREMENT

- •BORON NEUTRON CAPTURE THERAPY

- •BRACHYTHERAPY, HIGH DOSAGE RATE

- •BRACHYTHERAPY, INTRAVASCULAR

- •BRAIN ELECTRICAL ACTIVITY.

- •BURN WOUND COVERINGS.

- •BYPASS, CORONARY.

- •BYPASS, CARDIOPULMONARY.

366 BIOMATERIALS: TISSUE-ENGINEERING AND SCAFFOLDS

BIOMATERIALS: TISSUE-ENGINEERING AND SCAFFOLDS

GILSON KHANG

Chonbuk National University

SANG JIN LEE

MOON SUK KIM

HAI BANG LEE

Korea Research Institutes of

Chemical Technology

INTRODUCTION

Tissue engineering offers an alternative to whole organ and tissue transplantation for diseased, failed, or abnormally functioning organs. Millions suffer from end-stage organ failure or tissue loss annually. In the United State alone, at least 8 million surgical operations are carried out each year at a total national healthcare cost exceeding $400 billion annually (1–4). Approximately 500,000 coronary artery bypass surgeries are conducted in the United States annually (5). Autologous and allogenic natural tissue, such as the saphenous vein or the internal mammary artery, is generally used for coronary artery replacement. The results have been favorable for these procedures with patency rates generally ranging from 50–70%. Failures are caused by intimal thickening due largely to adaptation of the vessel in response to increased pressure and wall shear stress, compression, inadequate graft diameter, and disjunction at the anastomosis. Also, successful treatment has been limited by the poor performance of the synthetic materials used, such as polyethyleneterephthalate (PET, Dacron) and expanded polytetrafluoroethylene (ePTFE, Gore-Tex), which are used for tissue replacement due to plaguing problems

(6). For example, in cases of tumor resection in the head, neck, and upper and lower extremities, as well as in cases of trauma and congenital abnormalities, there are often outline defects due to the loss of soft tissue, this tissue is largely composed of subcutaneous adipose tissue (7). The defects lead to abnormal cosmesis, affect the emotional comfort of patients, and may impair function. A surgeon would prefer to use an autologous adipose tissue to sculpt contour deformities. Because mature adipose tissue does not transplant effectively, numerous natural, synthetic, and hybrid materials have been used to act as adipose surrogates. Despite improved patient outcomes, the use of many of these materials results in severe problems, such as unpredictable outcomes, fibrous capsule contraction, allergic reactions, suboptimum mechanical properties, distortion, migration, and long-term resorption.

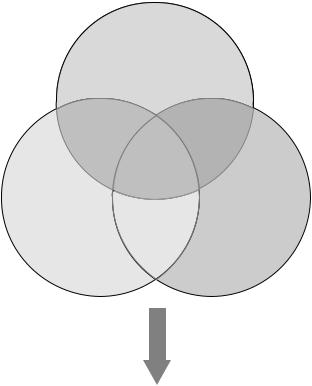

To offset the short supply of donor organs as well as the problems caused by the poor biocompatibility of the biomaterials used, a new hybridized method of ‘‘tissue engineering’’, which combines both cells and biomaterials has been introduced (8). To reconstruct new tissue by tissue engineering, a triad of components are requried: (1) harvested and dissociated cells from the donor tissue including nerve, liver, pancreas, cartilage, and bone as well as embryonic stem, adult stem, or precursor cell; (2) scaffolds

made of biomaterials on which cells are attached and cultured, then implanted at the desired site of the functioning tissue; (3) growth factors that promote and/or prevent cell adhesion, proliferation, migration, and differentiation by up-regulating or down-regulating the synthesis of protein, growth factors, and receptors (see Fig. 1). In a typical application for cartilage regeneration, donor cartilage is harvested from the patient and dissociated into individual chondrocyte cells using enzymes as collagenase, and then mass cultured in vitro. The chondrocyte cells are then seeded onto a porous and synthetic biodegradable scaffold. This cell–polymer structure is massively cultured in a bioreactor. The abnormal tissue is removed and the cell– polymer structure is then implanted in the patient. Finally, the synthetic biodegradable scaffold resorbs into the body and the chondrocyte cell produces collagen and glycosaminoglycan as its own natural extracellular matrix (ECM), which results in regenerated cartilage. This approach can theoretically be applied to the manufacture of almost all organs and tissues except for organs such as the brain (3).

In this section, a review is given of the biomaterials and procedures used in the development of tissue-engineered scaffolds, including: (1) natural and synthetic biomaterials, (2) natural–synthetic hybrid scaffolds, (3) the fabrication methods and techniques for scaffolds, (4) the required physicochemical properties for scaffolds, and (5) cytokinereleased scaffolds.

Cells

(e.g., chondrocytes, osteoblasts, stem cells)

|

Tissue |

|

Engineering |

Scaffolds |

Signaling |

(e.g., collagen, |

molecules |

gelatin, PGA, PLA, |

(e.g., growth |

PLGA) |

factors, |

|

morphogens, |

|

adhesins) |

Time

Appropriate

Environment

Regeneration of

tissues/organs

Figure 1. Tissue engineering triad. The combination of three key elements, cells, biomaterials, and signaling molecules, results in regenerated tissue-engineered neo-organs.

BIOMATERIALS FOR TISSUE ENGINEERING

The Importance of Scaffold Matrices in Tissue Engineering

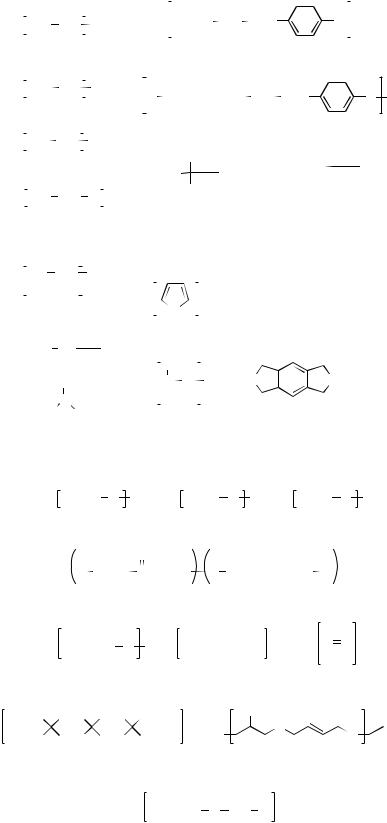

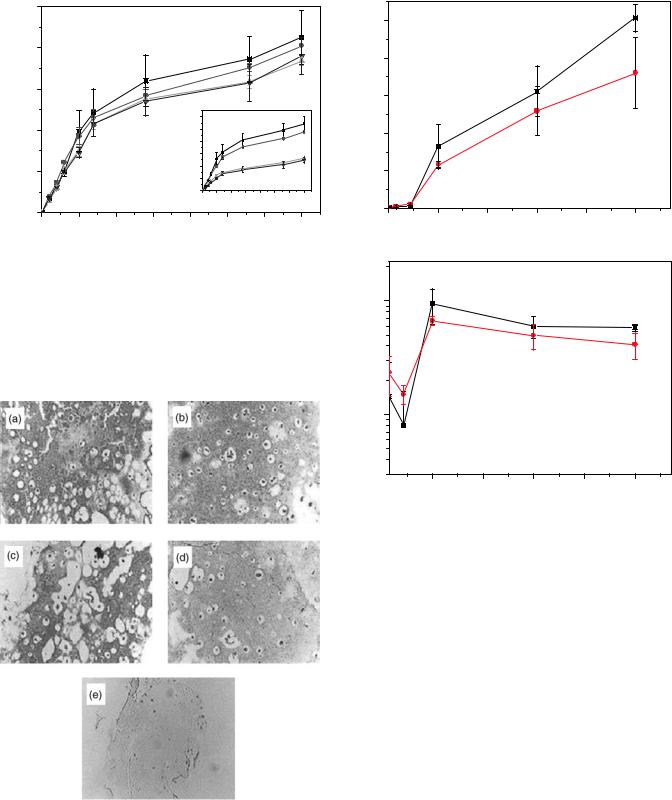

Scaffolds play a very critical role in tissue engineering. Scaffolds direct the growth (1) of cells seeded within the porous structure of the scaffold, or (2) of cells migrating from surrounding tissue. Most mammalian cell types are anchorage dependent; the cells die if an adhesion substrate is not provided. Scaffold matrices can be used to achieve cell delivery with high loading and efficiency to specific sites. Therefore, the scaffold must provide a suitable substrate for cell attachment, cell proliferation, differentiated function, and cell migration. The prerequisite physicochemical properties of scaffolds are (1) to support and deliver the cells; (2) to induce, differentiate, and promote conduit tissue growth; (3) to target the cell-adhesion substrate, (4) to stimulate cellular response; (5) to create a wound healing barrier; (6) to be biocompatible and biodegradable; (7) to have relatively easy processability and malleability into the desired shapes; (8) to be highly porous with large surface–volume; (9) to have mechanical strength and dimensional stability; and (10) to have sterilizability (9–16). Generally, three-dimensional (3D) porous scaffolds can be fabricated from natural and synthetic polymers (Fig. 2 shows these chemical structures), ceramics, metal, and in a very few cases, composite biomaterials and cyto- kine-releasing materials.

Natural Polymers

Many naturally occurring scaffolds can be used for tissue engineering purposes. One such example is the ECM, which is composed of very complex biomaterials and controls cell function. For the ECM used in tissue engineering, natural and synthetic scaffolds are designed to mimic specific function. The natural polymers used are alginate, proteins, collagens (gelatin), fibrins, albumin, gluten, elastin, fibroin, hyarulonic acid, cellulose, starch, chitosan (chitin), sclerolucan, elsinan, pectin (pectinic acid), galactan, curdlan, gellan, levan, emulsan, dextran, pullulan, heparin, silk, chondroitin 6-sulfate, polyhydroxyalkanoates, and others. Much of the interest in these natural polymers comes from their biocompatibility, relatively abundance and commercial availability, and ease of processing (17).

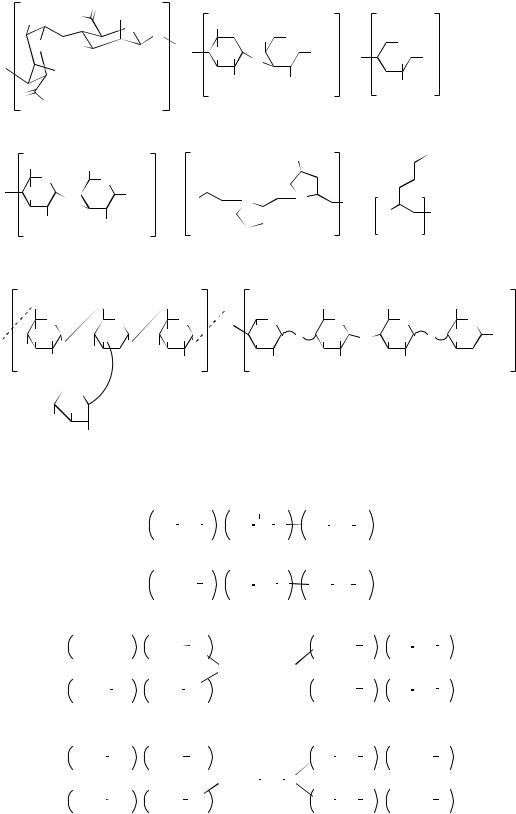

Alginate. Alginate (from seaweed) is composed of two repeating monosaccharides: L-guluronic acid and D-man- nuronic acid. Repeating strands of these monomers form linear, water-soluble polysaccharides. Gelation occurs by interaction of divalent cations (e.g., Ca2þ, Mg2þ) with blocks of guluronic acid from different polysaccharide chains (as shown in Fig. 3). From this gelation property, the encapsulation of calcium alginate beads impregnated with various pharmaceutics, cytokines, or cultured cells, has been extensively investigated. Varying the preparation conditions of the gelation can control structure and physicochemical properties. Calcium alginate scaffolds do not degrade by hydrolytic reaction, whereas they can be degraded by a chelating agent such as ethyleneaminetetraaceticacid (EDTA) or by an enzyme. Also, the diffusion

BIOMATERIALS: TISSUE-ENGINEERING AND SCAFFOLDS |

367 |

of calcium ions from an alginate gel can cause dissociation between alginate chains, which results in a decrease of mechanical strength over time. One of the disadvantages of an alginate matrix is a potential immune response and the lack of complete degradation, since alginate is produced in the human body (10). For these reasons, the chemical modification and incorporation of biological peptides, such as Arg-Gly-Asp cell adhesion peptides, have been used to improve the functionality and flexibility of natural scaffolds and their potential application (18).

Many researchers have studied the encapsulation of chondrocytes. Growth plate chondrocytes, fetal chondrocytes, and mesenchymal stem cells derived from bone marrow have been encapsulated in alginate (19). In each system, the chondrocytes demonstrated a differentiated phenotype, producing an ECM and retaining the cell morphology of typical chondrocytes. In addition, novel hybrid composites, such as alginate/agarose (a thermosensitive polysaccharide), alginate/fibrin, alginate/collagen and alginate/hyaruronic acid, and different gelling agents (water, sucrose, sodium chloride, and calcium sulfate) were investigated to optimize the advantages of each component material for tissue engineered cartilage (20–22). It was found that this hybrid material provides a reason why the microenvironments of composite materials affect chondrogenesis.

Collagen. At least 22 types of collagen exist in the human body. Among these, collagen types I, II, and III are the most abundant and ubiquitous. Conformation of the collagen chain consists of triple helices that are packed or processed into microfibrils. Molecularly, the three repeating amino acid sequences, such as glycine, proline, and hydroxyproline, form protein chains resulting in the formation of a triple helix arrangement. Type I collagen is the most abundant and is the major constituent of bone, skin, ligament, and tendon, whereas type II collagen is the collagen in cartilage. Collagen can promote cell adhesion as demonstrated by the Asp-Gly-Glu-Ala peptide in type I collagen, which functions as a cell-binding domain. Due to the abundance and ready accessibility of these tissues, they have been used frequently in the preparation of collagen (23).

The purified collagen materials obtained from either molecular or fibrillar technology are subjected to additional processing to fabricate the materials into useful scaffold types for specific tissue-engineered organs. Collagen can be processed into several types such as membrane (film and sheet), porous (sponge, felt, and fiber), gel, solution, filamentous, tubular (membrane and sponge), and composite matrix for the application of tissue repair, patches, bone and cartilage repair, nerve regeneration, and vascular and skin repair with/without cells (24). The Physicochemical properties of collagen can be improved by the addition of a variety of homogeneous and heterogeneous composites. Homogeneous composites can be formed between ions, peptides, proteins, and polysaccharides in a collagen matrix by means of ionic and covalent bonding, entrapment, entanglement, and coprecipitation. Heterogeneous composites, such as collagen–synthetic polymers, col- lagen–biological polymers, and collagen–ceramic hybrid

368 BIOMATERIALS: TISSUE-ENGINEERING AND SCAFFOLDS

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

CH2 CH2 O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

CH2 |

CH2 |

|

|

n |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

n |

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

CH2 |

CF2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CH2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

n |

|

|

|

|

|

|

|

O CH2 |

|

|

CH2 CH2 |

O |

|

|

C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

|||||||||||||||||||||||||||||||||||||||||||

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

CF2 |

CF2 |

|

n |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CH3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CH3 |

|

|

|

|

||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CH2 |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CH2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

CH2 |

CH2 |

|

|

O |

|

|

|

|

|

|

|

|

|

|

C |

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

O |

|

|

|

|

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

|

|

|

|

|

|

|

n |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CH2 |

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CH3 |

|

n |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CH2 |

|

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OH |

n |

|||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

CH |

CH2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OH |

|

|

|

|

|

|

|

|

n |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

n |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

CH |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CH3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

CH2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

C |

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Si |

O |

|

|

|

|

|

|

|

|

|

|

|

N |

|

|

|

|

|

|

|

|

|

|

|

|

N |

|

|

|

|

R |

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

NH |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

CH |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CH3 |

|

n |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

H3C |

|

|

|

|

|

CH3 |

|

n |

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

13 |

|

|

|

|

O |

|

|

|

|

|

|

|

|

n |

|||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

(a) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CH3 |

O |

|

|

|

|

|

|

|

|

|

R |

|

O |

|

|

|

|

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

CH2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

CH |

|

|

|

|

|

|

|

|

O |

|

|

|

|

CH |

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

|

|

C |

n |

||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

n |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

n |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

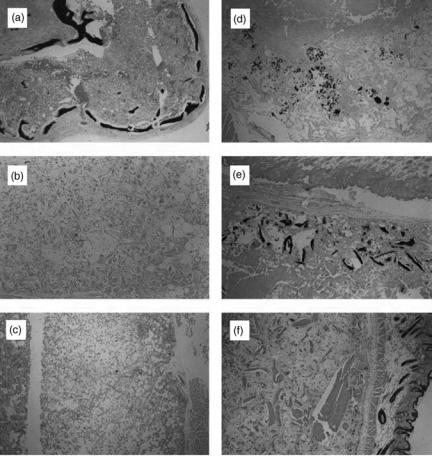

Figure 2. Chemical structures of some commonly used biodegradable and nondegradable polymers in tissue engineering. (a) Synthetic nondegradable polymers: (1). polyethylene, (2). poly(vinylidene f- luoride), (3). polytetrafluoroethylene, (4). poly- (ethylene oxide), (5). poly(vinyl alcohol), (6). poly- (ethyleneterephthalate), (7). poly(butyleneterethphalate), (8). poly(methylmethacrylate), (9). poly- (hydroxymethylmetacrylate), (10). poly(N- isopropylacrylamide), (11). polypyrrole, (12). poly(dimethyl siloxane), and (13). polyimides. (b) Synthetic biodegradable polymers: (14). poly(glycolic acid), (15). poly(lactic acid), (16). poly(hydroxyalkanoate), (17). poly(lactide-co-glycolide), (18). poly(e-caprolactone), (19). polyanhydride, (20). polyphsphazene, (21). poly(orthoester), (22). poly- (propylene fumarate), and (23). poly(dioxanone).

(c) Natural polymers: (24). alginate, (25). chondroi- tin-6-sulfate, (26). chitosan, (27). hyarunonan, (28). collagen, (29). polylysine, (30). dextran, and (31). heparin. (d) PEO-based hydrogels: (32). Pluronic, (33). Pluronic R, (34). Tetronic, and (35). Tetronic R.

|

|

|

|

|

|

|

|

|

|

|

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

O |

CH3 |

|

|

O |

|

|

CH3 |

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O C |

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

C |

CH |

|

|

|

|

CH |

|

C CH2 |

|

|

|

|

|

C |

|

CH2 O |

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

n |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

m |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

17 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R |

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

(CH2)5 |

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

C |

|

|

R |

|

|

C |

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

P |

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

n |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

n |

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

19 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R n |

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CH3 |

|

|

|

|

|

|

|

|

|

|

O |

|||||||||||||

H3CH2C |

O C C O CH2CH3 |

|

|

|

|

|

|

|

HO |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

O |

|||||||||||||||||||||||||||||||||||||||

|

O |

O |

|

|

|

C |

|

C |

|

|

O |

O |

|

|

R |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

n |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

n |

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

21 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

22 |

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

(CH2)2 |

|

|

|

O |

CH2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

n |

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

(b) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

23 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

n

OH

CH3

CH3

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BIOMATERIALS: TISSUE-ENGINEERING AND SCAFFOLDS |

369 |

||||||||||||||||||

|

|

–O |

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OH |

|

OH |

|

|

|

|

|

COOH |

|

CH2OSO3H |

|

|

|

CH2OH |

|

|

|

|

|

|

|

||||||||||||

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

O |

|

|

|

HO |

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

O HO |

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

O |

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

OH |

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

OH |

O |

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

OH |

|

|

|

|

|

|

|

|

|

|

|

|

|

HNCOCH3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

n |

|

NH2 |

|

n |

|

|

|

|

|||||||||

O– |

|

|

|

|

|

|

|

|

|

|

|

|

25 |

|

|

|

|

26 |

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

n |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

24 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NH2 |

|

|

|

|

||

COOH |

|

CH2OH |

|

|

|

|

|

|

|

|

|

|

|

HO |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

O |

|

|

O |

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

OH |

O |

|

O |

|

|

H |

|

N |

|

|

N |

|

|

|

N |

|

|

OH |

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

HO |

|

|

|

|

|

H |

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

|

|

|

|

|

|

|

|

|

|

|

|

OH |

HNCOCH3 |

|

|

|

O |

|

|

|

|

O |

|

|

|

H |

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

n |

O n |

|

|

|

|

||||||||||||

|

|

|

|

|

n |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

27 |

|

|

|

|

|

|

|

|

|

28 |

|

|

|

|

|

|

|

|

|

29 |

|

|

|

|

|

|

|

|

|

|

|

CH2 |

|

|

CH2 |

|

|

CH2 |

|

|

|

|

|

|

CH2OSO3H |

COOH |

|

|

CH2OSO3H |

|

||||||||||||||

|

O |

|

|

O |

|

|

O |

|

|

|

|

O |

O |

|

O |

|

|

|

O |

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

COOH |

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

||||||

|

OH |

|

|

O |

|

|

OH |

|

|

|

OH |

|

|

O OH |

|

O |

OHH |

O OH |

|

|

|

||||||||||||

HO |

O |

|

HO |

O |

HO |

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OH |

|

OH |

NH2 |

|

|

|

|

OSO3H |

HNSO3H |

|

OH |

|

|

|

HNSO3H |

|

|||||||||||||||||

|

|

|

|

|

n |

|

|

|

|

|

|

||||||||||||||||||||||

|

CH2OH |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

n |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

O |

31 |

|

|

OH |

|

HO |

|

OH

30

(c)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CH3 |

|

|

|

|

|

|

|