- •VOLUME 1

- •CONTRIBUTOR LIST

- •PREFACE

- •LIST OF ARTICLES

- •ABBREVIATIONS AND ACRONYMS

- •CONVERSION FACTORS AND UNIT SYMBOLS

- •ABLATION.

- •ABSORBABLE BIOMATERIALS.

- •ACRYLIC BONE CEMENT.

- •ACTINOTHERAPY.

- •ADOPTIVE IMMUNOTHERAPY.

- •AFFINITY CHROMATOGRAPHY.

- •ALLOYS, SHAPE MEMORY

- •AMBULATORY MONITORING

- •ANALYTICAL METHODS, AUTOMATED

- •ANALYZER, OXYGEN.

- •ANESTHESIA MACHINES

- •ANESTHESIA MONITORING.

- •ANESTHESIA, COMPUTERS IN

- •ANGER CAMERA

- •ANGIOPLASTY.

- •ANORECTAL MANOMETRY

- •ANTIBODIES, MONOCLONAL.

- •APNEA DETECTION.

- •ARRHYTHMIA, TREATMENT.

- •ARRHYTHMIA ANALYSIS, AUTOMATED

- •ARTERIAL TONOMETRY.

- •ARTIFICIAL BLOOD.

- •ARTIFICIAL HEART.

- •ARTIFICIAL HEART VALVE.

- •ARTIFICIAL HIP JOINTS.

- •ARTIFICIAL LARYNX.

- •ARTIFICIAL PANCREAS.

- •ARTERIES, ELASTIC PROPERTIES OF

- •ASSISTIVE DEVICES FOR THE DISABLED.

- •ATOMIC ABSORPTION SPECTROMETRY.

- •AUDIOMETRY

- •BACTERIAL DETECTION SYSTEMS.

- •BALLOON PUMP.

- •BANKED BLOOD.

- •BAROTRAUMA.

- •BARRIER CONTRACEPTIVE DEVICES.

- •BIOCERAMICS.

- •BIOCOMPATIBILITY OF MATERIALS

- •BIOELECTRODES

- •BIOFEEDBACK

- •BIOHEAT TRANSFER

- •BIOIMPEDANCE IN CARDIOVASCULAR MEDICINE

- •BIOINFORMATICS

- •BIOLOGIC THERAPY.

- •BIOMAGNETISM

- •BIOMATERIALS, ABSORBABLE

- •BIOMATERIALS: AN OVERVIEW

- •BIOMATERIALS: BIOCERAMICS

- •BIOMATERIALS: CARBON

- •BIOMATERIALS CORROSION AND WEAR OF

- •BIOMATERIALS FOR DENTISTRY

- •BIOMATERIALS, POLYMERS

- •BIOMATERIALS, SURFACE PROPERTIES OF

- •BIOMATERIALS, TESTING AND STRUCTURAL PROPERTIES OF

- •BIOMATERIALS: TISSUE-ENGINEERING AND SCAFFOLDS

- •BIOMECHANICS OF EXERCISE FITNESS

- •BIOMECHANICS OF JOINTS.

- •BIOMECHANICS OF SCOLIOSIS.

- •BIOMECHANICS OF SKIN.

- •BIOMECHANICS OF THE HUMAN SPINE.

- •BIOMECHANICS OF TOOTH AND JAW.

- •BIOMEDICAL ENGINEERING EDUCATION

- •BIOSURFACE ENGINEERING

- •BIOSENSORS.

- •BIOTELEMETRY

- •BIRTH CONTROL.

- •BLEEDING, GASTROINTESTINAL.

- •BLADDER DYSFUNCTION, NEUROSTIMULATION OF

- •BLIND AND VISUALLY IMPAIRED, ASSISTIVE TECHNOLOGY FOR

- •BLOOD BANKING.

- •BLOOD CELL COUNTERS.

- •BLOOD COLLECTION AND PROCESSING

- •BLOOD FLOW.

- •BLOOD GAS MEASUREMENTS

- •BLOOD PRESSURE MEASUREMENT

- •BLOOD PRESSURE, AUTOMATIC CONTROL OF

- •BLOOD RHEOLOGY

- •BLOOD, ARTIFICIAL

- •BONDING, ENAMEL.

- •BONE AND TEETH, PROPERTIES OF

- •BONE CEMENT, ACRYLIC

- •BONE DENSITY MEASUREMENT

- •BORON NEUTRON CAPTURE THERAPY

- •BRACHYTHERAPY, HIGH DOSAGE RATE

- •BRACHYTHERAPY, INTRAVASCULAR

- •BRAIN ELECTRICAL ACTIVITY.

- •BURN WOUND COVERINGS.

- •BYPASS, CORONARY.

- •BYPASS, CARDIOPULMONARY.

hydroxyapatite) as part of a circumferential fusion. Spine 2002;27:E518–E525.

107.Delecrin J, Takahashi S, Gouin F, Passuti N. A synthetic porous ceramic as a bone graft substitute in the surgical management of scoliosis: A prospective, randomized study. Spine 2000;25:563–569.

108.McAndrew MP, Gorman PW, Lange TA. Tricalcium phosphate as a bone graft substitute in trauma: Preliminary report. J Orthop Trauma 1988;2:333–339.

109.Bucholz RW, Carlton A, Holmes RE. Hydroxyapatite and tricalcium phosphate bone graft substitutes. Orthop Clin North Am 1987;18:323–334.

110.Holmes R, Mooney V, Bucholz R, Tencer A. A coralline hydroxyapatite bone graft substitute. Preliminary report. Clin Orthop 1984; 252–262.

111.Finn RA, Bell WH, Brammer JA. Interpositional ‘‘grafting’’ with autogenous bone and coralline hydroxyapatite. J Maxillofac Surg 1980;8:217–227.

112.Holmes RE. Bone regeneration within a coralline hydroxya-

patite implant. Plast Reconstr Surg 1979;63:626– 633.

113.Holmes RE, Salyer KE. Bone regeneration in a coralline hydroxyapatite implant. Surg Forum 1978;29:611–612.

114.Jamali A, Hilpert A, Debes J, Afshar P, Rahban S, Holmes R. Hydroxyapatite/calcium carbonate (HA/CC) vs. plaster of Paris: A histomorphometric and radiographic study in a rabbit tibial defect model. Calcif Tissue Int 2002;71:172– 178.

115.Kenny SM, Buggy M. Bone cements and fillers: A review. J Mater Sci Mater Med 2003;14:923–938.

116.Horstmann WG, Verheyen CC, Leemans R. An injectable calcium phosphate cement as a bone-graft substitute in the treatment of displaced lateral tibial plateau fractures. Injury 2003;34:141–144.

117.Kamano M, Honda Y, Kazuki K, Yasudab M. Palmar plating with calcium phosphate bone cement for unstable Colles’ fractures. Clin Orthop 2003; 285–290.

118.Zimmermann R, Gabl M, Lutz M, Angermann P, Gschwentner M, Pechlaner S. Injectable calcium phosphate bone cement Norian SRS for the treatment of intra-articular compression fractures of the distal radius in osteoporotic women. Arch Orthop Trauma Surg 2003;123:22–27.

119.Schildhauer TA, Bauer TW, Josten C, Muhr G. Open reduction and augmentation of internal fixation with an injectable skeletal cement for the treatment of complex calcaneal fractures. J Orthop Trauma 2000;14:309–317.

See also DRUG DELIVERY SYSTEMS; MATERIALS AND DESIGN FOR ORTHOPEDIC DEVICES; POROUS MATERIALS FOR BIOLOGICAL APPLICATIONS.

BIOMATERIALS: AN OVERVIEW

BRANDON L. SEAL

ALYSSA PANITCH

Arizona State University

Tempe, Arizona

INTRODUCTION

Biomaterials are materials that are used or that have been designed for use in medical devices or in contact with the body. Traditionally, they consist of metallic, ceramic, or synthetic polymeric materials, but more recent develop-

BIOMATERIALS: AN OVERVIEW |

267 |

ments in biomaterials design have attempted to incorporate materials derived from or inspired by biological materials (e.g., silk and collagen). Often, the use of biomaterials focuses on the augmentation, replacement, or restoration of diseased or damaged tissues and organs. The prevalence of biomaterials within society is most evident within medical and dental offices, pharmacies, and hospitals. However, the influence of biomaterials has reached into many households with examples ranging from increasingly common news media coverage of medical breakthroughs to the availability of custom color noncorrective contact lenses.

The evolving character of the discipline of biomaterials is evidenced by how the term biomaterial has been defined. In 1974, the Clemson Advisory Board, in response to a request by the World Health Organization (WHO), stated that a biomaterial is a ‘‘systemically pharmacologically inert substance designed for implantation within or incorporation with living tissue’’ (1). Dr. Jonathan Black further modified this definition to state that a biomaterial is ‘‘any pharmacologically inert material, viable or nonviable, natural product or manmade, that is part of or is capable of interacting in a beneficial way with a living organism’’ (1). An National Institute of Health (NIH) consensus definition appeared in 1983 and defined biomaterials as ‘‘any substance (other than a drug) or combination of substances, synthetic or natural in origin, which can be used for any period of time, as a whole or as a part of a system that treats, augments, or replaces any tissue, organ, or function of the body’’ (2). Thus, relatively newer definitions of the term biomaterial recognize that more modern medical and diagnostic devices will rely increasingly upon direct biological interaction between biological molecules, cells, and tissues and the materials from which these devices are manufactured.

HISTORY OF BIOMATERIALS

Compared with the much larger field of materials science, the field of biomaterials is relatively new. Although there exist recorded cases of glass eyes and metallic or wooden dental implants (some of which can be dated back to ancient Egypt), the modern age of biomaterials could not have existed without the adoption of aseptic surgical techniques pioneered by Sir Joseph Lister in the midnineteenth century and indeed, did not fully emerge as an industry or discipline until after the development of synthetic polymers just prior to, during, and following World War II. Prior to World War II, implanted biomaterials consisted primarily of metals (e.g., steel, used in pins and plates for bone fixation, joint replacements, and the covering of bone defects). In the late 1940s, Harold Ridley observed that shards of poly(methyl methacrylate) (PMMA), from airplane cockpit windshields, embedded within the eyes of World War II aviators did not provoke much of an inflammatory response (3). This observation led not only to the development of PMMA intraocular lenses, but also to greater experimentation of available materials, especially polymers, as biomaterials that could be placed in direct contact with living tissue.

268 BIOMATERIALS: AN OVERVIEW

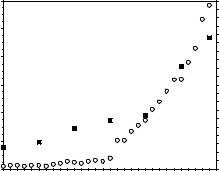

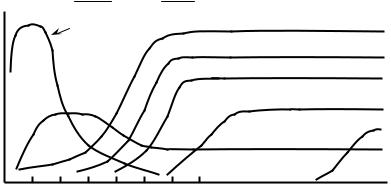

As the fields of cellular, molecular, and developmental biology began to grow during the 1970s and 1980s, new insights into the organization, function, and properties of biological systems, tissues, and interactions led to a greater understanding of how cells respond to their environment. This wealth of biological information allowed the field of biomaterials to undergo a paradigm shift. Instead of focusing primarily on replacing an organ or a tissue with a synthetic, usually nondegradable biomaterial, a new branch of biomaterials would attempt to combine biologically active molecules, therapeutics, and motifs into existing and novel biomaterial systems derived from both synthetic and natural sources (4–6). Although there exist many examples of successful, commercially available biomaterials consisting of metallic and ceramic bases, the focus of biomaterials research has shifted to the development of polymeric or composite materials with biologically sensitive or environmentally controlled properties. This change has resulted largely due to the reactivity and variety of chemical moieties that are found in or that can be engineered into natural and synthetic polymers. Indeed, by viewing biomaterials as materials designed to interact with biology rather than being inert substances, the field of biomaterials has exploded with innovative designs that promote cell attachment, encapsulation, proliferation, differentiation, migration, and apoptosis, and that allow the biomaterial to polymerize, swell, and degrade under a variety of environmental conditions and biological stimuli. Evidence of this polymer and composite revolution is the dramatic increase in the number of publications relating to biomaterials research. Figure 1 shows a plot of the number of journal articles with biomaterial or biomaterials in their title, abstract, or keyword as a function of publication year as searched in the Web of Science database. As seen in Fig. 1, publications matching the search criteria have increased exponentially starting around the early 1990s and continuing until the present. The number of scientific journals, shown in Table 1, related

PublicationsofNumber |

1200 |

|

|

|

|

|

100 |

DepartmentsBMEofNumber |

1000 |

|

|

|

|

|

80 |

||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

800 |

|

|

|

|

|

60 |

|

|

|

|

|

|

|

|

|

|

|

600 |

|

|

|

|

|

|

|

|

400 |

|

|

|

|

|

40 |

|

|

|

|

|

|

|

|

|

|

|

200 |

|

|

|

|

|

20 |

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

0 |

|

|

1975 |

1980 |

1985 |

1990 |

1995 |

2000 |

2005 |

|

Year

Figure 1. A plot of the number of publications (*) containing the word biomaterial or biomaterials in the title, abstract, or keywords, as searched in the Web of Science database, as a function of the publication year as well as a plot of the number of bioengineering or biomedical engineering departments (BME departments) within the United States as a function of time (&).

to research in the field of biomaterials has also grown. Although the number of journal articles related to biomaterials research may have resulted primarily from the large increase in the number of biomaterials-related scientific journals, the exponential growth of biomaterials is evidenced further by the growth of the number of bioengineering or biomedical engineering departments (the department in which most biomaterials programs reside) established at universities throughout the United States (Fig. 1).

MARKET SIZE AND TYPES OF APPLICATIONS

The field of biomaterials, by nature, is interdisciplinary. Successful biomaterial designs have involved talents, knowledge, and expertise provided by physicians and clinicians, materials scientists, engineers, chemists, biologists, and physicists. As a result, it is not surprising that the biomaterials industry is both relatively young and very diversified. The diversity of this industry has resulted from the types of products created and marketed, the size and location of involved companies, and the types of regulatory policies imposed by government agencies and third party reimbursement organizations. Specifically, the biomaterials industry is part of the Medical Device and Diagnostic Industry, a multibillion dollar industry comprised of organizations that design, fabricate, and/or manufacture materials that are used in the health and life science fields. The end use applications are medical and dental devices, prostheses, personal hygiene products, diagnostic devices, drug delivery vehicles, and biotechnology systems. Some examples of these applications include full and hybrid artificial organs, biosensors, vascular grafts, pacemakers, catheters, insulin pumps, cochlear implants, contact lenses, intraocular lenses, artificial joints and bones, burn dressings, and sutures. Table 2 shows a list of some common medical devices that require various biomaterials, and Table 3 displays a list of the prevalence and market potential of a few of these applications (7).

GOVERNMENT REGULATION

Within the United States, in a research only environment, biomaterials by themselves do not necessarily require government regulation. However, if any biomaterial is used within a medical or diagnostic device designed and destined for commercialization, the biomaterials used within the medical device (as well as the device itself) are subject to the jurisdiction of the U.S. Food and Drug Administration (FDA) as set forth in the Federal Food, Drug, and Cosmetic Act of 1938, the Medical Device Amendments of 1976, and the Food and Drug Administration Modernization Act of 1997. These laws have empowered the FDA to regulate conditions involving premarket controls, postmarket reporting, production involving Good Manufacturing Practices, and the registration and listing of medical devices. Any biomaterial within a marketed medical device prior to the Medical Device Amendments of 1976 were grandfathered and are considered approved materials. Modifications to these materials or

|

|

BIOMATERIALS: AN OVERVIEW |

269 |

Table 1. A List of Journals with Publications Related to the Field of Biomaterialsa |

|

|

|

Name of Journal |

Name of Journal |

Name of Journal |

|

|

|

|

|

Advanced Drug Delivery |

Biosensors and Bioelectronics (1985) |

Journal of Biomaterials Science: Polymer |

|

Reviews (1987) |

|

Edition (1990) |

|

American Journal of Drug |

Cells and Materials (1991) |

Journal of Biomedical Materials |

|

Delivery (2003) |

|

Research (1967) |

|

American Society of Artificial |

Cell Transplantation (1992) |

Journal of Controlled Release (1984) |

|

Internal Organs Journal (1955) |

|

|

|

Annals of Biomedical |

Clinical Biomechanics (1986) |

Journal of Drug Targeting (1993) |

|

Engineering (1973) |

|

|

|

Annual Review of Biomedical |

Colloids and Surfaces |

Journal of Long Term Effects of |

|

Engineering (1999) |

B: Biointerfaces (1993) |

Medical Implants (1991) |

|

Artificial Organs (1977) |

Dental Materials (1985) |

Journal of Nanobiotechnology (2003) |

|

Artificial Organs Today (1991) |

Drug Delivery (1993) |

Macromolecules (1968) |

|

Biomacromolecules (2000) |

Drug Delivery Systems and Sciences (2001) |

Materials in Medicine (1990) |

|

Biofouling (1985) |

Drug Delivery Technology (2001) |

Medical Device and Diagnostics |

|

|

|

Industry (1996) |

|

Biomedical Engineering |

e-biomed: the Journal of |

Medical Device Research Report (1995) |

|

OnLine (2002) |

Regenerative Medicine (2000) |

|

|

Bio-medical Materials and |

European Cells and Materials (2001) |

Medical Device Technology (1990) |

|

Engineering (1991) |

|

|

|

Biomaterial-Living System |

Federation of American Societies |

Medical Plastics and Biomaterials (1994) |

|

Interactions (1993) |

for Experimental Biology |

|

|

|

Journal (1987) |

|

|

Biomaterials (1980) |

Frontiers of Medical and |

Nanobiology |

|

|

Biological Engineering (1991) |

|

|

Biomaterials, Artificial Cells |

IEEE Transactions on |

Nanotechnology (1990) |

|

and Artificial Organs (1973) |

Biomedical Engineering (1954) |

|

|

Artificial Cells, Blood Substitutes, |

International Journal of |

Nature: Materials (2002) |

|

and Immobilization |

Artificial Organs (1976) |

|

|

Biotechnology (1973) |

|

|

|

Biomaterials Forum (1979) |

Journal of Bioactive and Compatible |

Tissue Engineering (1995) |

|

Biomedical Microdevices (1998) |

Polymers (2002) Journal of |

Trends in Biomaterials and Artificial |

|

|

Biomaterials Applications (2001) |

Organs (1986) |

|

aThe date of first publication is listed in parentheses following the name of each journal.

new materials are subject to controls established by the FDA. These controls consist of obtaining an Investigational Device Exemption for the medical device, including the biomaterials used within the device, prior to conducting clinical trials.

In addition, biomaterials can be considered part of a Class I, II, or III device depending on FDA classifications and depending on whether or not the biomaterial is considered to be part of a biologic, drug, or medical device. Class I devices are generally considered those devices needing the least amount of regulatory control since they do not present a great risk for a patient. Examples include tongue depressors and surgical drills. Class II devices represent a moderate risk to patients and require additional regulation (e.g., mandatory performance standards, additional labeling requirements, and postmarket surveillance). Some examples include X-ray systems and cardiac mapping catheters. Class III devices (e.g., cardiovascular stents and heart valves), represent those devices with the highest risk to patients and require extensive regulatory control. Usually, for biomaterials in direct contact with tissue within the body, devices are considered Class III devices and are subject to a Premarket Approval process before they can be sold within the United States. In general, for most biomaterials, some of the tests the FDA reviews to evaluate biomaterial safety includes tests

Table 2. Some Common Uses for Biomaterials

Organ/Procedure |

Associated Medical Devices |

|

|

Bladder |

Catheters |

Bone |

Bone plates, joint replacements |

|

(metallic and ceramic) |

Brain |

Deep brain stimulator, |

|

hydrocephalus shunt, |

|

drug eluting polymers |

Cardiovascular |

Polymer grafts, metallic stents, |

|

drug eluting grafts |

Cosmetic enhancement |

Breast implants, injectable collagen |

Eye |

Intraocular lenses, contact lenses |

Ear |

Artificial cochlea, artificial stapes |

Heart |

Artificial heart, ventricular assist |

|

devices, heart valves, pacemakers |

Kidney |

Hemodialysis instrumentation |

Knee |

Metallic knee replacements |

Lung |

Blood oxygenator |

Reproductive system |

Hormone replacement patches, |

|

contraceptives |

Skin |

Artificial skin, living skin equivalents |

Surgical |

Scalpels, retractors, drills |

Tissue repair |

Sutures, bandages |

|

|

270 BIOMATERIALS: AN OVERVIEW

Table 3. A Summary of the Prevalence and Economic Cost of Some of the Healthcare Treatments Requiring Biomaterials for the Year 2000

|

Incident |

Prevalent |

Total Therapy |

Medical |

Patient |

Patient |

Cost (Billions |

Applicationa |

Populationa |

Populationa |

of US Dollars)a |

|

|

|

|

Dialysis |

188,000 |

1,030,000 |

$67 |

Cardiovascular |

|

|

|

Bypass grafts |

733,000 |

6,000,000 |

$65 |

Valves |

245,000 |

2,400,000 |

$27 |

Pacemakers |

670,000 |

5,500,000 |

$44 |

Stents |

1,750,000 |

2,500,000 |

$48 |

Joint replacement |

1,285,000 |

7,000,000 |

$41 |

Hips |

610,000 |

|

|

Knees |

675,000 |

|

|

aAll data taken from that reported by Lysaght and O’Loughlin (7).

involving cellular toxicity (both direct and indirect), acute and chronic inflammation, debris and degradation byproducts and associated clearance events, carcinogenicity, mutagenicity, fatigue, creep, tribology, and corrosion. Further information regarding FDA approval for medical devices can be found on the FDA webpage, www.fda.gov.

Many FDA approved biomaterials continue to be monitored for efficacy and safety in an effort not only to protect patients, but also to improve biocompatibility and reduce material failure. Perhaps the best known example of an FDA regulated biomaterial is silicone. Silicone had been used since the early 1960s in breast implants. As a result, silicone breast implants were grandfathered into the Medical Device Amendments of 1976. During the 1980s, some concerns regarding the safety of silicone breast implants arose and prompted the FDA to request, in 1990, additional safety data from manufacturers of breast implants. Due to fears of connective tissue disease, multiple sclerosis, and other ailments resulting from ruptured silicone implants, the FDA banned silicone breast implants in 1992. Recently, however, manufacturers (e.g., the Mentor Corporation) have applied for and received premarket approval for the sale of silicone breast implants contingent on the compliance of various conditions (8). Thus, silicone is a good example of the complexity surrounding the testing of both efficacy and safety for biomaterials.

TYPES OF BIOMATERIALS

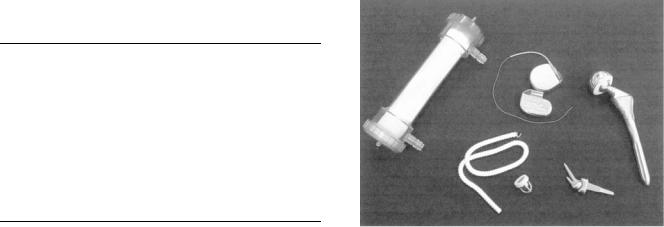

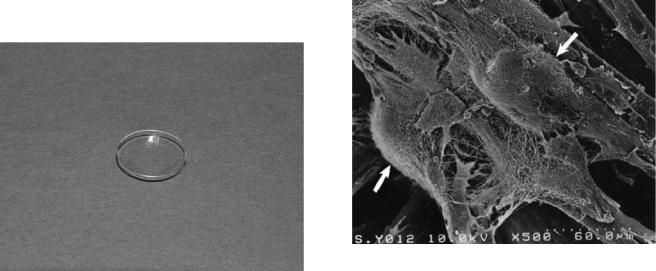

Similar to the field of materials science, the field of biomaterials focuses on four major types of materials: metals, ceramics, polymers, and composites. Examples of a few selected medical devices made from these materials are shown in Fig. 2. The materials selected for any particular application depend on the properties desired for a particular function or set of functions. In all materials applications, the structure, properties, and processing of the selected material will affect performance. As a result, physicians, scientists and engineers who design biomaterials need to understand not only mechanical and physical properties of materials, but also biological properties of materials. Mechanical and physical properties include strength, fatigue, creep resistance, flexibility, permeability

Figure 2. A representation of a few medical devices made from various biomaterials. From the upper left corner and moving clockwise, this picture shows a kidney hemodialyzer, two pacemakers, a hip replacement, an articulating wrist joint, a heart valve, and a vascular graft.

to gases and liquids, thermal and electrical properties, chemical reactivity, and degradation. Biological properties of materials largely focus on biocompatibility issues related to toxicity, immune system reactivity, thrombus formation, tribiology, inflammation, carcinogenic and teratogenic potential, integration with tissues and cells, and the ability to be sterilized. Regardless of the material, recent approaches to biomaterials research has focused on directing specific tissue interaction by using materials to introduce chemical bonds with the surrounding tissue, to act as scaffolds for tissue ingrowth, to introduce an inductive signal that will influence the behavior of surrounding cells or matrix, or to form new tissue when incubated or presented to transplanted cells.

Metals

Metals have been used as biomaterials for centuries. Although some fields (e.g., dentistry) continue to use amalgams, gold, and silver, most modern metallic biomaterials consist of iron, cobalt, titanium, or platinum bases. Since they are strong, metals are most often employed as biomaterials in orthopedic or fracture fixation medical devices; however, metals are also excellent conductors, and are therefore used for electrical stimulation of the heart, brain, nerves, muscle, and spinal cord. The most common alloys for orthopedic applications include stainless steel, cobalt, and titanium alloys. These alloys have enjoyed frequent use in medical procedures related to the function of joints and load-bearing. For example, metal alloys are commonly found in medical devices for knee replacement as well as in the femoral stem used in total hip replacements. Since all metals are subject to corrosion, especially in the salty, aqueous environment within the body, metals used as biomaterials often require an external oxide layer to protect against pitting and corrosion. These electrochemically inert oxide layers consist of Cr2O3 for stainless steel, Cr2O3 for cobalt alloys, and TiO2 for

BIOMATERIALS: AN OVERVIEW |

271 |

Figure 3. Photographs of stainless steel (a), cobalt–chromium (b), and titanium alloy (Ti6Al4V) (c) hip implants. (All three photographs are used with permission from the Department of Materials at Queen Mary University of London.)

titanium alloys. Figure 3 displays examples of three types of metallic hip replacements.

Stainless Steel Alloys. The stainless steel most commonly used as orthopedic biomaterials is classified 316L by the American Iron and Steel Institute. This particular austenitic alloy contains a very low carbon content (a maximum of 0.03%) and chromium content of 17–20%. The added chromium will react with oxygen to produce a corrosion-resistant chromium oxide layer. The 316L grade of stainless steel is a casting alloy, and its relatively high ductility makes this alloy amenable to extensive postcasting mechanical processing. Compared to cobalt and titanium alloys, stainless steel has a moderate yield and ultimate strength, but high ductility. Furthermore, it may be fabricated by virtually all machining and finishing processes and is generally the least expensive of the three major metallic alloys (4,5,9).

Cobalt Alloys. Cobalt alloys have been used since the early twentieth century as dental alloys and in heavily loaded joint applications. For use as a biomaterial, cobalt alloys are either cast (i.e., primarily formed within a mold) or wrought (i.e., worked into a final form from a large ingot). Two examples of cobalt alloys include Vitallium (designated F 75 by ASTM International), a cast alloy that consists of 27–30% chromium and >34% cobalt, and the wrought cobalt alloy MP35N (designated F 563 by ASTM International), which consists of 18–22% chromium, 15–25% nickel, and >34% cobalt. Compared to Vitallium, the MP35N alloy has demonstrated superior fatigue resistance, larger ultimate tensile strength, and a higher degree of corrosion resistance to chlorine. Consequently, this particular alloy is good for applications requiring long service life without fracture or stress fatigue. Compared to stainless steel alloys, cobalt-based alloys have slightly higher tensile moduli, but lower ductility. In addition, they are more expensive to manufacture and more difficult to machine. However, relative to stainless steel and titanium, cobalt-based alloys can offer the most useful balance of corrosion resistance, fatigue resistance, and strength (4,5,9).

Titanium Alloys. The most recent of the major orthopedic metallic alloys to be employed as biomaterials are titanium alloys. Although pure titanium is relatively weak and ductile, titanium can be stabilized by adding elements (e.g., aluminum and vanadium) to the alloy. Often, pure titanium (designated F 67 by ASTM International) is pri-

marily used as a surface coating for orthopedic medical devices. For load-bearing applications, the alloy Ti6Al4V (designated F 136 by ASTM International) is much more widely used in implant manufacturing. As in the case of stainless steel and cobalt alloys, titanium contains an outer oxide layer, composed of TiO2, that protects the implant from corrosion. In fact, of the three major orthopedic alloys, titanium shows the lowest rate of corrosion. Moreover, the density of titanium is almost half that of stainless steel and cobalt alloys. As a result, implants made from titanium are lighter and reduce patient awareness of the implant; however, titanium alloys are among the most expensive metallic biomaterials. Relative to stainless steel and cobalt alloys, titanium has a lower Young’s modulus, which can aid in reducing the stresses around the implant by flexing with the bone. Titanium has a lower ductility than the other alloys, but does demonstrate high strength. These properties allow titanium alloys to play a diverse role as a biomaterial. Titanium alloys are used in parts for total joint replacements, screws, nails, pacemaker cases, and leads for implantable electrical stimulators (4,5,9).

Despite the reduced weight and improved mechanical match of titanium alloy implants to bone relative to stainless steel and chromium alloy implants, titanium alloy implants still exhibit issues with regard to mechanical mismatch. This problem stems from the large differences in properties (e.g., elastic moduli) between bone, metals, and polymers used as acetabular cups. For example, metals have elastic moduli ranging from 100 to 200 GPa, ultrahigh molecular weight polyethylene has an elastic modulus of 1–2 GPa, and the elastic modulus of cortical bone is 12 GPa (10). In addition, it is difficult to produce a titanium implant surface that is conducive to bone ingrowth or attachment. Novel titanium foams have been investigated as a method for reducing implant weight, better matching tissue mechanics, and improving bone ingrowth. The process involves mixing titanium powder with ammonium hydrogen carbonate powder and compressing and heating the mixture to form foams with densities varying from 0.2 to 0.65 times the density of solid titanium. These densities are close to those of cancellous bone (0.2–0.3 times the density of solid titanium) and cortical bone (0.5–0.65 times the density of solid titanium) (11). While they are preliminary, studies with novel materials such as these titanium foams illustrate a trend toward the development of materials that better mimic the properties of the native tissue they are designed to replace.

272 BIOMATERIALS: AN OVERVIEW

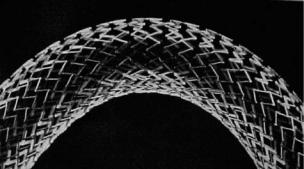

Figure 4. A photograph of the SMARTeR nitinol stent developed by the Cordis Corporation. (Reprinted from Ref. 12, with permission from Royal College of Radiologists.)

Other Metals. Besides stainless steel, cobalt alloys, and titanium alloys, there exist other examples of metals used as biomaterials. Some examples include nitinol, a singlephase nickel/titanium shape memory alloy, tantalum, a very dense, chemically inert, weak, but fatigue-resistant metal, and platinum, a very expensive metal used by itself or with iridum as a corrosion-resistant electrical conductor for electrode applications. Nitinol stents (e.g., that seen in Fig. 4) (12) and drug-eluting nitinol stents used for cardiovascular applications recently have seen enormous medical and commercial success. Indeed, metallic stents have significantly changed the way coronary blockages are treated (4,5,9).

Ceramics

Of the major types of materials used as biomaterials, ceramics have not been used as frequently as metals, polymers, or composites. However, ceramics continue to enjoy widespread use in certain bone-related applications (e.g., dentistry and joint replacement surgeries), due to their high compressive strength, high degree of hardness, excellent biocompatibility, superior tribological properties, and chemical inertness. Although they are very strong in compression, ceramics are susceptible to mechanical and thermal loading, have lower tensile strengths relative to other materials, and are very brittle in tension; this brittleness limits potential biomaterials applications.

Ceramics consist of a network of metal and nonmetal ions, with the general structure XmYn, arranged in a repeating structure. This structure depends on the relative size of the ions as well as the number of counterions needed to balance total charge. For example, if m ¼ n ¼ 1, and both ions are approximately the same size, then the structure would be of a simple cubic nature (e.g., CsCl or CsI); if the anion is much larger than the cation, then typically, a face centered cubic (fcc) structure would emerge (e.g., ZnS or CdS). If m ¼ 2 and n ¼ 3, as is the case with oxide ceramics (e.g., Al2O3), then a hexagonal closed pack structure would often result (13).

Ceramics used as biomaterials can be classified by processing–manufacturing methods, by chemical reactivity, or by ionic composition. Regarding chemical reactivity, ceramics can be bioinert, bioactive, or bioresorbable. Bio-

inert or nonresorbable ceramics are either porous or nonporous and are essentially not affected by the environment at the implant site. Bioactive or reactive ceramics are designed with specific surface properties that are intended to react with the local host environment and to elicit a desired tissue response. Bioresorbable ceramics dissolve over some prescribed period of time in vivo mediated by physiochemical processes. If one considers the application of bone replacement, then there would be about four ways for ceramics to interact with and attach to bone. First, a nonporous, inert ceramic material could be attached via glues, surface irregularities, or press-filling methods. Second, a porous, inert ceramic could be designed to have an optimal pore size, which promotes direct mechanical attachment of bone through bone ingrowth. Third, a nonporous, inert ceramic with a reactive surface could direct bone attachment via chemical bonding. Fourth, a nonporous or porous, resorbable ceramic could eventually be replaced by bone. When describing real examples of ceramics used as biomaterials, it is more useful to classify the ceramics based on ionic composition. This type of classification reveals a few major bioceramic groups: oxide ceramics, multiple oxides of calcium and phosphorus, glasses and glass ceramics, and carbon.

Oxide Ceramics. As their name implies, oxide ceramics consist of oxygen bound to a metallic species. Oxide ceramics are chemically inert, but can be nonporous or porous. One example of a nonporous oxide ceramic used as a biomaterial is aluminum oxide, Al2O3. Highly pure aluminum oxide (F 603 as designated by ASTM International), or alumina, has high corrosion resistance, good biocompatibility, high wear resistance, and good mechanical properties due to high density and small grain size. Aluminum oxide has been manufactured as an acetabular cup for total hip replacement. In comparison with metal or ultrahigh molecular weight polyethylene, Al2O3 provides better tribological properties by greatly decreasing friction within the joint and substantially increasing wear resistance. Recently, the FDA approved ceramic on ceramic hip replacements made from alumina and marketed by companies such as Wright Medical Technology and Stryker Osteonics. This ceramic on ceramic design is very resistant to wear and results in a much smaller amount of wear debris than traditional metal–polymer joints. With better wear properties and longer useful lifespan, ceramic on ceramic hip replacements likely will provide an attractive alternative to other biomaterial options, especially for younger patients that need better long-term solutions for joint replacements (4,5,9).

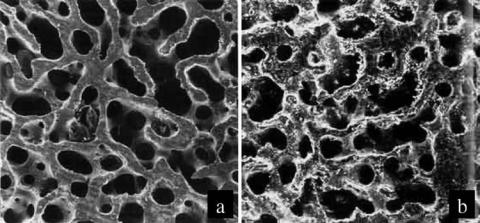

Ceramic oxides can also be porous. In bone formation, these pores are useful for allowing bone ingrowth, which will stabilize the mechanical properties of the implant without sacrificing the chemical inertness of the ceramic material. In general, there are three ways to make a porous ceramic oxide. First, a soluble metal or salt can be mixed with the ceramic and etched away. Second, a foaming agent that evolves gases during heating (e.g., calcium carbonate) can be mixed with the ceramic powder prior to firing. Third, the microstructure of corals can be used as a template to create a ceramic with a high degree

BIOMATERIALS: AN OVERVIEW |

273 |

of interconnectivity and uniform pore size. In this third approach, coral is machined into the desired shape. Then, the coral is heated up to drive off carbon dioxide. The remaining calcium oxide provides a scaffold around which the ceramic material is deposited. After firing, the calcium oxide can be dissolved using hydrochloric acid. This dissolved calcium oxide will leave behind a very uniform and highly interconnected porous structure. Interestingly, the type of coral used will affect the pore size of the resulting ceramic. For example, if the genus Porites is used, then the pore size will range from 140 to 160 mm; the genus Goniopora will result in a pore size of 200–1000 mm (5). Porous ceramics do have many advantages for bone ingrowth, especially since the porous structure more closely mimics that of cancellous bone (see Fig. 5). However, the porous structure does result in a loss of strength and a tremendous increase in surface area that interacts with an in vivo saline environment.

Multiple Oxides of Calcium and Phosphorus. Aside from many types of proteins, the extracellular environment of bone contains a large concentration of organic mineral deposits known as hydroxyapatite. Chemically, hydroxyapatite generally has the following composition: Ca10(PO4)6(OH)2. Since hydroxyapatite is a naturally occurring ceramic produced by osteoblasts, it seemed reasonable to apply hydroxyapatite as filler or as a coating to allow better integration with existing bone. Coatings of hydroxyapatite have been applied (usually by plasma spraying) to metallic implants used in applications requiring bone ingrowth to provide a tight fit between bone and the implanted device, to minimize loosening over time, and to provide some measure of isolation from the foreign body response. Although hydroxyapatite is the most commonly used bioceramic containing calcium and phosphorus, there do exist other forms of calcium and phosphorus oxides including tricalcium phosphate, Ca3(PO4)2, and octacalcium phosphate, Ca8H2PO4 5H2O (4,5,9,14).

Glasses and Glass Ceramics. Just as in the case of traditional glass, glass ceramics used as biomaterials contain large amounts of silica, SiO2. Glass ceramics are formed using controlled crystallization techniques during

Figure 5. Photographs of (a) a cross-section of human cancellous bone and (b) coral of the genus Porites. These images illustrate how biologically derived materials (e.g., coral) can be used as scaffolds to create ceramic biomaterials that mimic the structure and porosity of natural bone. (Both photographs are used with permission from Biocoral, Inc.)

which silica is cooled down at rate slow enough to allow the formation of a hexagonal crystal structure with small, crystalline grains ( 1 mm) surrounded by an amorphous phase. Bioactive glass ceramics have been studied as biomaterials because they can attach directly to tissue via chemical bonds, they have a low thermal coefficient of expansion, they have good compressive mechanical strength, the mechanical strength of the glass–tissue interface is close to that of tissue, and they resist scratching and abrasion. Unfortunately, as with all ceramics, bioactive glasses are very brittle. Two well-known examples of commercially available glass ceramics include Bioglass, which consists of SiO2, Na2O, CaO, and P2O5, and Ceravital, which contains SiO2, Na2O, CaO, P2O5, K2O, and MgO. Relative to traditional soda lime glass, bioactive glass ceramics contain lower amounts of SiO2 and higher amounts of Na2O and CaO. The high ratio of CaO to P2O5 in bioactive ceramics allows the rapid formation of a hydroxycarbonate apatite (HCA) layer at alkaline pH. For example, a 50 nm layer of HCA can form from Bioglass 45S5 after 1 h. The release of calcium, phosphorus, and sodium ions from bioactive ceramics also allows the formation of a water-rich gel near the ceramic surface. This cationic-rich environment creates a locally alkaline pH that helps to form HCA layers and provide areas of adhesion for biological molecules and cells (4,5,9).

Carbon. Processed carbon has been used in biomaterials applications as a bioceramic coating. Although carbon can exist in several forms (e.g., graphite, diamond), bioceramic carbons consist primarily of low temperature isotropic (LTI) and ultralow temperature isotropic (ULTI) carbon. This form of carbon is synthesized through the pyrolysis of hydrocarbon gases resulting in the deposition of isotropic carbon in a layer 4 mm thick. Advantages to LTI and ULTI carbon include high strength, an elastic modulus close to that of bone, resistance to fatigue compared with other materials, excellent resistance to thrombosis, superior tribological properties, and excellent bond strength with metallic substances. The LTI carbon has been used as a coating for heart valves; however, applications remain limited primarily to coatings due to processing methods (4,5,9).

274 BIOMATERIALS: AN OVERVIEW

Polymers

Since the early to mid-twentieth century, the discovery of organic polymerization schemes and the advent of new polymeric species have fueled an incredible interest in the research of biomaterials. The popularity of polymers as potential biomaterials likely stems from the fact that polymers exist in a seemingly endless variety, can be easily fabricated into many forms, can be chemically modified or synthesized with chemically reactive moieties that interact with biological molecules or living tissues and cells, and can have physical properties that resemble that of natural tissues. Some disadvantages to polymeric biomaterials include relatively low moduli, instability following certain forms of sterilization, lot-to-lot variability, a lack of well-defined standards related to manufacturing, processing, and evaluating, and, for some polymers, hydrolytic instability, the need to add potentially toxic polymerization catalysts, and tissue biocompatibility of both the polymer and potential degradation byproducts. There also exist some characteristics of polymers that can be advantageous or disadvantageous depending on the application and type of polymer. Some of these characteristics include polymer degradation, chemical reactivity, polymer crystallinity, and viscoelastic behavior. Early examples of polymeric biomaterials included nylon for sutures and cellulose for kidney dialysis membranes, but more recent developments in the design of polymeric biomaterials are leading the field of biomaterials to embrace cellular and tissue interactions in order to directly induce tissue repair or regeneration.

Polymers consist of an organic backbone from which other pendant molecules extend. As their name implies, polymers consist of repeating units of one or more ‘‘mers’’. For example, polyethylene consists of repeating units of ethylene; nylon is comprised of repeating units of a diamine and a diacid. In general, polymers used as biomaterials are made in one of two ways: condensation or addition reactions. In condensation reactions, two precursors are combined to form larger molecules by eliminating a small molecule (e.g., water). Examples of condensation polymeric biomaterials include nylon, poly(ethylene terephthalate) (Dacron), poly(lactic acid), poly(glycolic acid), and polyurethane. In addition to synthetic polymers, biological polymers (e.g., cellulose and proteins) are formed through condensation-like polymerization mechanisms. The other major polymerization mechanism used to synthesize polymers is addition polymerization. In addition polymerization, an initiator or catalyst (e.g., free radical, heat, light, or certain ions) is used to promote a rapid polymerization reaction involving unsaturated bonds. Unlike condensation reactions, addition polymerization does not result in small molecular byproducts. Furthermore, polymers can be formed using only one type of monomer or a combination of several monomers susceptible to free radical initiation and propagation. Some examples of addition reaction polymeric biomaterials include polyethylene, poly(ethylene glycol) (PEG), poly(N-isopropylacrlyamide), and poly(hydroxyethyl methacrylate) (PHEMA). The chemical structure of various synthetic and natural polymers used as biomaterials are shown in Figs. 6a and b (15).

The properties of polymers are affected greatly by chemical composition and molecular weight. In general, as polymer chains become longer, their mobility decreases, but their strength and thermal stability increases. The tacticity and size of pendant chains off the backbone will affect temperature-dependent physical properties. For example, small side groups that are regularly oriented in an isotactic or syndiotactic arrangement will allow the polymer to crystallize much more readily than a polymer containing an atactic arrangement of bulky side groups. The crystalline and glass transition temperatures of polymers will affect properties (e.g., stiffness, mechanical moduli, and thermal stability) in vivo and will consequently influence the potential application and utility of the polymer system as a biomaterial. When the functionality of a monomer exceeds two, then the polymer will become branched upon polymerization. If a sufficient number of these high functionality monomers exist within the material, then the main chains of the polymer will become chemically cross-linked. Cross-linked polymers can be much stronger and more rigid than noncross-linked polymers. However, like linear and branched polymers, crosslinked polymers can be designed such that they degrade through hydrolytic or enzymatic mechanisms.

Due to their weaker moduli compared with that of metals or ceramics, polymers are not often used in loadbearing biomaterial applications. One exception to this observation is the example of ultrahigh molecular weight polyethylene (UHMWPE), which has a molecular weight2,000,000 g mol 1 and has a higher modulus of elasticity than high or low density polyethylene. Additionally, UHMWPE is tough and ductile and demonstrates good wear properties and low friction. As a result, UHMWPE has been used extensively in the manufacturing of acetabular cups for total hip replacements. As an acetabular cup, UHMWPE is used in conjunction with metallic femoral stems to act as a load-bearing, low wear and friction interface. Some drawbacks to using UHMWPE include water absorption, cyclic fatigue, and a somewhat significant creep rate (4,5,9). Part of the problems surrounding UHMWPE involves its lower elastic modulus ( 1–2 GPa) relative to bone ( 12 GPa) and metallic implants ( 100–200 GPa)

Polymers in Sutures. One of the first widespread uses of polymers as biomaterials involved sutures. In particular, polyamides and polyesters are among the most common suture materials. Nylons, an example of a polyamide, have an increased fiber strength due to a high degree of crystallinity resulting from interchain hydrogen bonding between atoms of the amide group. Nylon can be attacked by proteolytic enzymes in vivo and can absorb water. As a result, nylon has been used more as a short-term biomaterial. Polyester sutures, such as poly(glycolic acid), poly(lactic acid), and poly(lactic-co-glycolic acid) are readily degraded through hydrolytic mechanisms in vivo. Since one side chain of lactic acid contains a bulky hydrophobic methyl group (relative to the hydrogen side group of glycolic acid), polyesters comprised principally of lactic acid degrade at a rate slower than that of polyesters consisting mostly of glycolic acid. The degradation rate of copolymers

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BIOMATERIALS: AN OVERVIEW |

275 |

|||||||||||

|

|

CH2 |

CH2 |

|

n |

|

|

|

|

|

|

|

|

|

O |

|

CH2 |

CH2 |

O |

|

|

O |

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

n |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

CF2 |

CF2 |

|

|

n |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

|

|

|

|

|

|

|

|

|

CH3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CH3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CH2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

CH |

CH2 |

|

|

|

|

|

|

|

|

|

|

|

CH2 |

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

OH |

|

|

|

|

|

|

n |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CH2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

CH3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CH |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

Si O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

3 |

|

|

n |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CH2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

CH3 |

|

|

n |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OH |

|

|

n |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CH3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

CH |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

CH2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

CH |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

|

|

CH2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

n |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

n |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

NH |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

H3C |

CH |

|

|

|

|

|

|

|

|

|

|

O |

|

CH3 |

|

|

|

|

|

O |

|

|

|

|

CH3 |

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

CH3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

n |

|

|

|

|

|

|

|

CH |

|

|