- •Features

- •Pin Configurations

- •Disclaimer

- •Overview

- •Block Diagram

- •Pin Descriptions

- •Port A (PA7..PA0)

- •Port B (PB7..PB0)

- •Port C (PC7..PC0)

- •Port D (PD7..PD0)

- •RESET

- •XTAL1

- •XTAL2

- •AVCC

- •AREF

- •AVR CPU Core

- •Introduction

- •Architectural Overview

- •Status Register

- •Stack Pointer

- •Interrupt Response Time

- •SRAM Data Memory

- •Data Memory Access Times

- •EEPROM Data Memory

- •EEPROM Read/Write Access

- •I/O Memory

- •Clock Systems and their Distribution

- •CPU Clock – clkCPU

- •I/O Clock – clkI/O

- •Flash Clock – clkFLASH

- •ADC Clock – clkADC

- •Clock Sources

- •Default Clock Source

- •Crystal Oscillator

- •External RC Oscillator

- •External Clock

- •Timer/Counter Oscillator

- •Idle Mode

- •Power-down Mode

- •Power-save Mode

- •Standby Mode

- •Extended Standby Mode

- •Analog to Digital Converter

- •Analog Comparator

- •Brown-out Detector

- •Internal Voltage Reference

- •Watchdog Timer

- •Port Pins

- •Resetting the AVR

- •Reset Sources

- •Power-on Reset

- •External Reset

- •Brown-out Detection

- •Watchdog Reset

- •Watchdog Timer

- •Interrupts

- •I/O Ports

- •Introduction

- •Configuring the Pin

- •Reading the Pin Value

- •Unconnected pins

- •Alternate Port Functions

- •Alternate Functions of Port A

- •Alternate Functions of Port B

- •Alternate Functions of Port C

- •Alternate Functions of Port D

- •Port A Data Register – PORTA

- •Port B Data Register – PORTB

- •Port C Data Register – PORTC

- •Port D Data Register – PORTD

- •External Interrupts

- •8-bit Timer/Counter0 with PWM

- •Overview

- •Registers

- •Definitions

- •Counter Unit

- •Output Compare Unit

- •Force Output Compare

- •Modes of Operation

- •Normal Mode

- •Fast PWM Mode

- •Phase Correct PWM Mode

- •Internal Clock Source

- •Prescaler Reset

- •External Clock Source

- •16-bit Timer/Counter1

- •Overview

- •Registers

- •Definitions

- •Compatibility

- •Counter Unit

- •Input Capture Unit

- •Input Capture Trigger Source

- •Noise Canceler

- •Using the Input Capture Unit

- •Output Compare Units

- •Force Output Compare

- •Modes of Operation

- •Normal Mode

- •Fast PWM Mode

- •Phase Correct PWM Mode

- •8-bit Timer/Counter2 with PWM and Asynchronous Operation

- •Overview

- •Registers

- •Definitions

- •Counter Unit

- •Output Compare Unit

- •Force Output Compare

- •Modes of Operation

- •Normal Mode

- •Fast PWM Mode

- •Phase Correct PWM Mode

- •Timer/Counter Prescaler

- •SS Pin Functionality

- •Slave Mode

- •Master Mode

- •SPI Control Register – SPCR

- •SPI Status Register – SPSR

- •SPI Data Register – SPDR

- •Data Modes

- •USART

- •Overview

- •AVR USART vs. AVR UART – Compatibility

- •Clock Generation

- •External Clock

- •Synchronous Clock Operation

- •Frame Formats

- •Parity Bit Calculation

- •USART Initialization

- •Parity Generator

- •Disabling the Transmitter

- •Receiver Error Flags

- •Parity Checker

- •Disabling the Receiver

- •Flushing the Receive Buffer

- •Asynchronous Data Recovery

- •Using MPCM

- •Write Access

- •Read Access

- •Two-wire Serial Interface

- •Features

- •TWI Terminology

- •Electrical Interconnection

- •Transferring Bits

- •START and STOP Conditions

- •Address Packet Format

- •Data Packet Format

- •Overview of the TWI Module

- •SCL and SDA Pins

- •Bit Rate Generator Unit

- •Bus Interface Unit

- •Address Match Unit

- •Control Unit

- •TWI Register Description

- •TWI Bit Rate Register – TWBR

- •TWI Control Register – TWCR

- •TWI Status Register – TWSR

- •TWI Data Register – TWDR

- •Using the TWI

- •Transmission Modes

- •Master Transmitter Mode

- •Master Receiver Mode

- •Slave Receiver Mode

- •Slave Transmitter Mode

- •Miscellaneous States

- •Analog Comparator

- •Analog Comparator Multiplexed Input

- •Features

- •Operation

- •Starting a Conversion

- •Differential Gain Channels

- •Changing Channel or Reference Selection

- •ADC Input Channels

- •ADC Voltage Reference

- •ADC Noise Canceler

- •Analog Input Circuitry

- •ADC Accuracy Definitions

- •ADC Conversion Result

- •ADLAR = 0

- •ADLAR = 1

- •Features

- •Overview

- •Test Access Port – TAP

- •TAP Controller

- •PRIVATE0; $8

- •PRIVATE1; $9

- •PRIVATE2; $A

- •PRIVATE3; $B

- •Bibliography

- •Features

- •System Overview

- •Data Registers

- •Bypass Register

- •Device Identification Register

- •Reset Register

- •Boundary-scan Chain

- •EXTEST; $0

- •IDCODE; $1

- •SAMPLE_PRELOAD; $2

- •AVR_RESET; $C

- •BYPASS; $F

- •Scanning the Digital Port Pins

- •Scanning the RESET Pin

- •Scanning the Clock Pins

- •Scanning the ADC

- •Features

- •Application Section

- •BLS – Boot Loader Section

- •Read-While-Write and no Read-While-Write Flash Sections

- •Boot Loader Lock Bits

- •Performing a Page Write

- •Using the SPM Interrupt

- •Setting the Boot Loader Lock Bits by SPM

- •Reading the Fuse and Lock Bits from Software

- •Preventing Flash Corruption

- •Fuse Bits

- •Latching of Fuses

- •Signature Bytes

- •Calibration Byte

- •Signal Names

- •Parallel Programming

- •Enter Programming Mode

- •Chip Erase

- •Programming the Flash

- •Programming the EEPROM

- •Reading the Flash

- •Reading the EEPROM

- •Programming the Lock Bits

- •Reading the Signature Bytes

- •Reading the Calibration Byte

- •SPI Serial Downloading

- •Data Polling Flash

- •Data Polling EEPROM

- •AVR_RESET ($C)

- •PROG_ENABLE ($4)

- •PROG_COMMANDS ($5)

- •PROG_PAGELOAD ($6)

- •PROG_PAGEREAD ($7)

- •Data Registers

- •Reset Register

- •Programming Enable Register

- •Virtual Flash Page Read Register

- •Programming Algorithm

- •Entering Programming Mode

- •Leaving Programming Mode

- •Performing Chip Erase

- •Programming the Flash

- •Reading the Flash

- •Programming the EEPROM

- •Reading the EEPROM

- •Programming the Fuses

- •Programming the Lock Bits

- •Reading the Signature Bytes

- •Reading the Calibration Byte

- •Electrical Characteristics

- •Absolute Maximum Ratings*

- •DC Characteristics

- •External Clock Drive Waveforms

- •External Clock Drive

- •Two-wire Serial Interface Characteristics

- •ADC Characteristics

- •Register Summary

- •Instruction Set Summary

- •Ordering Information

- •Packaging Information

- •Errata

- •ATmega32 Rev. A

- •Datasheet Change Log for ATmega32

- •Changes from Rev. 2503E-09/03 to Rev. 2503F-12/03

- •Changes from Rev. 2503D-02/03 to Rev. 2503E-09/03

- •Changes from Rev. 2503C-10/02 to Rev. 2503D-02/03

- •Changes from Rev. 2503B-10/02 to Rev. 2503C-10/02

- •Changes from Rev. 2503A-03/02 to Rev. 2503B-10/02

- •Table of Contents

Table 113. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Parallel Programming Characteristics, VCC = 5 V ± 10% (Continued) |

|

|||||||||||

Symbol |

Parameter |

Min |

Typ |

Max |

|

Units |

||||||

|

|

|

|

|

|

|

|

|||||

tBVDV |

|

BS1 Valid to DATA valid |

0 |

|

250 |

|

ns |

|||||

tOLDV |

|

|

Low to DATA Valid |

|

|

250 |

|

ns |

||||

|

OE |

|

||||||||||

tOHDZ |

|

|

High to DATA Tri-stated |

|

|

250 |

|

ns |

||||

|

OE |

|

||||||||||

Notes: 1. tWLRH is valid for the Write Flash, Write EEPROM, Write Fuse bits and Write Lock bits commands.

2.tWLRH_CE is valid for the Chip Erase command.

SPI Serial Downloading Both the Flash and EEPROM memory arrays can be programmed using the serial SPI bus while RESET is pulled to GND. The serial interface consists of pins SCK, MOSI (input), and MISO (output). After RESET is set low, the Programming Enable instruction needs to be executed first before program/erase operations can be executed. NOTE, in Table 114 on page 268, the pin mapping for SPI programming is listed. Not all parts use the SPI pins dedicated for the internal SPI interface.

SPI Serial Programming |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pin Mapping |

Table 114. Pin Mapping SPI Serial Programming |

|

|

|

||||||||||

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Symbol |

|

|

|

|

Pins |

|

|

I/O |

|

Description |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MOSI |

|

|

|

|

PB5 |

|

|

I |

|

Serial Data in |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MISO |

|

|

|

|

PB6 |

|

|

O |

|

Serial Data out |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SCK |

|

|

|

|

PB7 |

|

|

I |

|

Serial Clock |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

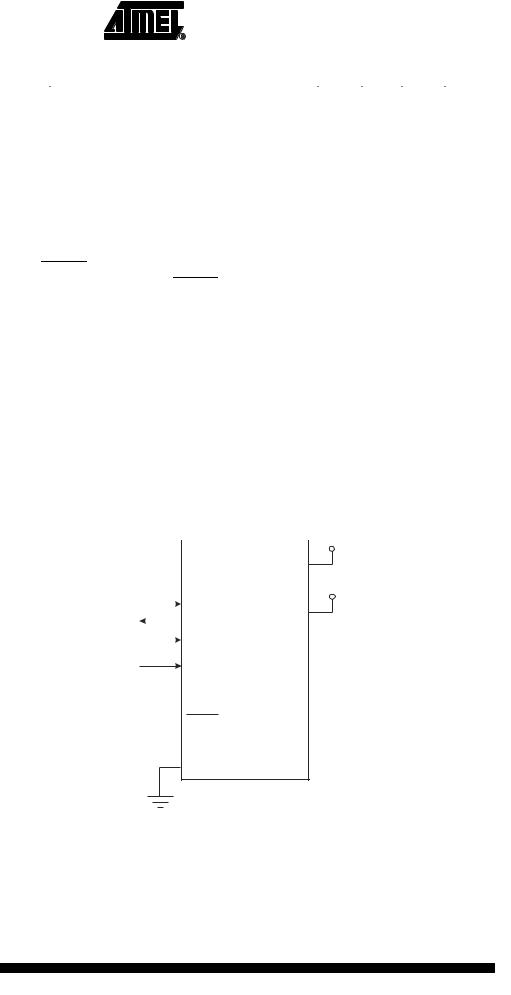

Figure 136. SPI Serial Programming and Verify(1) |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

+2.7 - 5.5V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VCC |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

+2.7 - 5.5V(2) |

|

|

MOSI |

|

|

|

|

PB5 |

AVCC |

||||||

|

|

|

|

|

||||||||||

|

|

MISO |

|

|

|

PB6 |

||||||||

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

||||||||

|

|

|

SCK |

|

|

|

|

PB7 |

|

|

|

|||

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

XTAL1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

RESET

RESET

GND

Notes: 1. If the device is clocked by the Internal Oscillator, it is no need to connect a clock source to the XTAL1 pin.

2. VCC -0.3V < AVCC < VCC +0.3V, however, AVCC should always be within 2.7 - 5.5V

When programming the EEPROM, an auto-erase cycle is built into the self-timed programming operation (in the serial mode ONLY) and there is no need to first execute the

268 ATmega32(L)

2503F–AVR–12/03

ATmega32(L)

ATmega32(L)

Chip Erase instruction. The Chip Erase operation turns the content of every memory

|

location in both the Program and EEPROM arrays into $FF. |

|

|

Depending on CKSEL Fuses, a valid clock must be present. The minimum low and high |

|

|

periods for the serial clock (SCK) input are defined as follows: |

|

|

Low:> 2 CPU clock cycles for fck < 12 MHz, 3 CPU clock cycles for fck ≥ |

12 MHz |

|

High:> 2 CPU clock cycles for fck < 12 MHz, 3 CPU clock cycles for fck ≥ |

12 MHz |

SPI Serial Programming |

When writing serial data to the ATmega32, data is clocked on the rising edge of SCK. |

|

Algorithm

When reading data from the ATmega32, data is clocked on the falling edge of SCK. See Figure 137 for timing details.

To program and verify the ATmega32 in the SPI Serial Programming mode, the following sequence is recommended (See four byte instruction formats in Table 116):

1. Power-up sequence:

Apply power between VCC and GND while RESET and SCK are set to “0”. In some systems, the programmer can not guarantee that SCK is held low during power-up. In this case, RESET must be given a positive pulse of at least two CPU clock cycles duration after SCK has been set to “0”.

2. Wait for at least 20 ms and enable SPI Serial Programming by sending the Programming Enable serial instruction to pin MOSI.

3. The SPI Serial Programming instructions will not work if the communication is out of synchronization. When in sync. the second byte ($53), will echo back when issuing the third byte of the Programming Enable instruction. Whether the echo is correct or not, all four bytes of the instruction must be transmitted. If the $53 did not echo back, give RESET a positive pulse and issue a new Programming Enable command.

4. The Flash is programmed one page at a time. The memory page is loaded one byte at a time by supplying the 6 LSB of the address and data together with the Load Program Memory Page instruction. To ensure correct loading of the page, the data low byte must be loaded before data high byte is applied for a given address. The Program Memory Page is stored by loading the Write Program Memory Page instruction with the 8 MSB of the address. If polling is not used,

the user must wait at least tWD_FLASH before issuing the next page. (See Table 115). Accessing the SPI Serial Programming interface before the Flash write

operation completes can result in incorrect programming.

5. The EEPROM array is programmed one byte at a time by supplying the address and data together with the appropriate Write instruction. An EEPROM memory location is first automatically erased before new data is written. If polling is not

used, the user must wait at least tWD_EEPROM before issuing the next byte. (See Table 115). In a chip erased device, no $FFs in the data file(s) need to be

programmed.

6. Any memory location can be verified by using the Read instruction which returns the content at the selected address at serial output MISO.

7. At the end of the programming session, RESET can be set high to commence normal operation.

8. Power-off sequence (if needed): Set RESET to “1”.

Turn VCC power off.

269

2503F–AVR–12/03

Data Polling Flash |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

When a page is being programmed into the Flash, reading an address location within |

|||||||

|

the page being programmed will give the value $FF. At the time the device is ready for a |

||||||

|

new page, the programmed value will read correctly. This is used to determine when the |

||||||

|

next page can be written. Note that the entire page is written simultaneously and any |

||||||

|

address within the page can be used for polling. Data polling of the Flash will not work |

||||||

|

for the value $FF, so when programming this value, the user will have to wait for at least |

||||||

|

tWD_FLASH before programming the next page. As a chip erased device contains $FF in |

||||||

|

all locations, programming of addresses that are meant to contain $FF, can be skipped. |

||||||

|

See Table 115 for tWD_FLASH value |

||||||

Data Polling EEPROM |

When a new byte has been written and is being programmed into EEPROM, reading the |

||||||

|

address location being programmed will give the value $FF. At the time the device is |

||||||

|

ready for a new byte, the programmed value will read correctly. This is used to deter- |

||||||

|

mine when the next byte can be written. This will not work for the value $FF, but the user |

||||||

|

should have the following in mind: As a chip erased device contains $FF in all locations, |

||||||

|

programming of addresses that are meant to contain $FF, can be skipped. This does |

||||||

|

not apply if the EEPROM is re-programmed without chip erasing the device. In this |

||||||

|

case, data polling cannot be used for the value $FF, and the user will have to wait at |

||||||

|

least tWD_EEPROM before programming the next byte. See Table 115 for tWD_EEPROM |

||||||

|

value. |

|

|

|

|

|

|

|

Table 115. Minimum Wait Delay before Writing the Next Flash or EEPROM Location |

||||||

|

|

|

|

|

|

|

|

|

Symbol |

|

|

|

|

Minimum Wait Delay |

|

|

|

|

|

|

|

|

|

|

tWD_FLASH |

|

|

|

|

4.5 ms |

|

|

tWD_EEPROM |

|

|

|

|

9.0 ms |

|

|

tWD_ERASE |

|

|

|

|

9.0 ms |

|

|

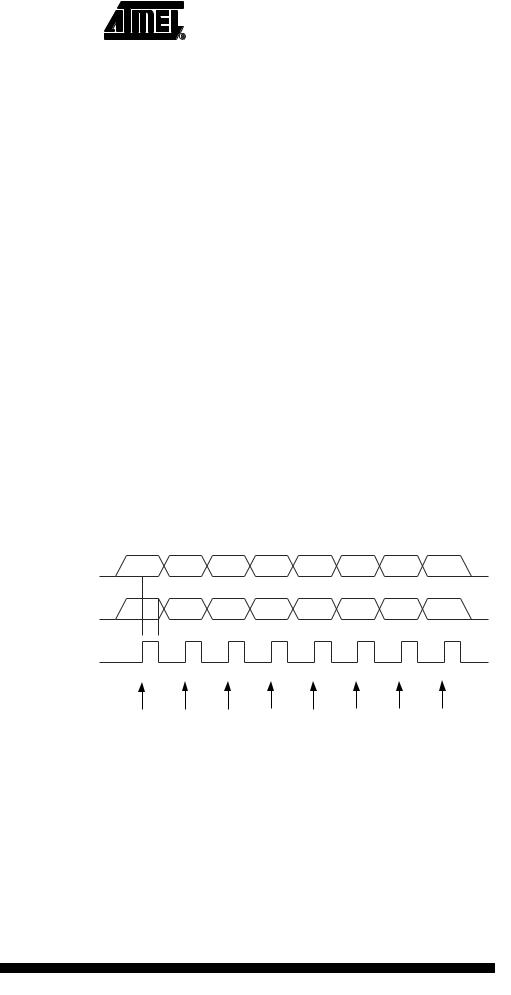

Figure 137. SPI Serial Programming Waveforms |

||||||

|

SERIAL DATA INPUT |

MSB |

|

|

|

|

LSB |

|

(MOSI) |

|

|

|

|

|

|

|

SERIAL DATA OUTPUT |

MSB |

|

|

|

|

LSB |

|

(MISO) |

|

|

|

|

|

|

SERIAL CLOCK INPUT (SCK)

SAMPLE

270 ATmega32(L)

2503F–AVR–12/03

ATmega32(L)

Table 116. SPI Serial Programming Instruction Set

|

|

|

Instruction Format |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Instruction |

Byte 1 |

Byte 2 |

Byte 3 |

Byte4 |

|

Operation |

||

|

|

|

|

|

|

|

|

|

Programming Enable |

1010 1100 |

0101 0011 |

xxxx xxxx |

xxxx xxxx |

|

Enable SPI Serial Programming after |

||

|

|

|

|

|

|

|

||

|

|

|

|

|

RESET goes low. |

|||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Chip Erase |

1010 1100 |

100x xxxx |

xxxx xxxx |

xxxx xxxx |

|

Chip Erase EEPROM and Flash. |

||

|

|

|

|

|

|

|

|

|

Read Program Memory |

0010 H000 |

00aa aaaa |

bbbb bbbb |

oooo oooo |

|

Read H (high or low) data o from |

||

|

|

|

|

|

Program memory at word address a:b. |

|||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

0100 H000 |

00xx xxxx |

xxbb bbbb |

iiii iiii |

|

Write H (high or low) data i to Program |

|

|

|

|

|

|

|

|

Memory page at word address b. Data |

|

Load Program Memory Page |

|

|

|

|

|

low byte must be loaded before Data |

||

|

|

|

|

|

|

|

high byte is applied within the same |

|

|

|

|

|

|

|

|

address. |

|

|

|

|

|

|

|

|

|

|

Write Program Memory Page |

0100 1100 |

00aa aaaa |

bbxx xxxx |

xxxx xxxx |

|

Write Program Memory Page at |

||

|

|

|

|

|

address a:b. |

|||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Read EEPROM Memory |

1010 0000 |

00xx xxaa |

bbbb bbbb |

oooo oooo |

|

Read data o from EEPROM memory at |

||

|

|

|

|

|

address a:b. |

|||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Write EEPROM Memory |

1100 0000 |

00xx xxaa |

bbbb bbbb |

iiii iiii |

|

Write data i to EEPROM memory at |

||

|

|

|

|

|

address a:b. |

|||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

0101 1000 |

0000 0000 |

xxxx xxxx |

xxoo oooo |

|

Read Lock bits. “0” = programmed, “1” |

|

Read Lock Bits |

|

|

|

|

|

= unprogrammed. See Table 103 on |

||

|

|

|

|

|

|

|

page 254 for details. |

|

|

|

|

|

|

|

|

|

|

|

|

1010 1100 |

111x xxxx |

xxxx xxxx |

11ii iiii |

|

Write Lock bits. Set bits = “0” to |

|

Write Lock Bits |

|

|

|

|

|

program Lock bits. See Table 103 on |

||

|

|

|

|

|

|

|

page 254 for details. |

|

|

|

|

|

|

|

|

||

Read Signature Byte |

0011 0000 |

00xx xxxx |

xxxx xxbb |

oooo oooo |

|

Read Signature Byte o at address b. |

||

|

|

|

|

|

|

|

|

|

|

|

1010 1100 |

1010 0000 |

xxxx xxxx |

iiii iiii |

|

Set bits = “0” to program, “1” to |

|

Write Fuse Bits |

|

|

|

|

|

unprogram. See Table 106 on page |

||

|

|

|

|

|

|

|

256 for details. |

|

|

|

|

|

|

|

|

|

|

|

|

1010 1100 |

1010 1000 |

xxxx xxxx |

iiii iiii |

|

Set bits = “0” to program, “1” to |

|

Write Fuse High Bits |

|

|

|

|

|

unprogram. See Table 105 on page |

||

|

|

|

|

|

|

|

255 for details. |

|

|

|

|

|

|

|

|

|

|

|

|

0101 0000 |

0000 0000 |

xxxx xxxx |

oooo oooo |

|

Read Fuse bits. “0” = programmed, “1” |

|

Read Fuse Bits |

|

|

|

|

|

= unprogrammed. See Table 106 on |

||

|

|

|

|

|

|

|

page 256 for details. |

|

|

|

|

|

|

|

|

|

|

|

|

0101 1000 |

0000 1000 |

xxxx xxxx |

oooo oooo |

|

Read Fuse high bits. “0” = pro- |

|

Read Fuse High Bits |

|

|

|

|

|

grammed, “1” = unprogrammed. See |

||

|

|

|

|

|

|

|

Table 105 on page 255 for details. |

|

|

|

|

|

|

|

|

||

Read Calibration Byte |

0011 1000 |

00xx xxxx |

0000 0000 |

oooo oooo |

|

Read Calibration Byte |

||

|

|

|

|

|

|

|

|

|

Note: a = address high bits b = address low bits

H = 0 – Low byte, 1 – High Byte o = data out

i = data in

x = don’t care

271

2503F–AVR–12/03

SPI Serial Programming |

|

|

|

|

|

|

|

|

|

|

|

For Characteristics of SPI module, see “SPI Timing Characteristics” on page 289. |

|||||

Characteristics |

|

|

|

|

|

Programming via the |

Programming through the JTAG interface requires control of the four JTAG specific |

||||

JTAG Interface |

pins: TCK, TMS, TDI and TDO. Control of the reset and clock pins is not required. |

||||

|

To be able to use the JTAG interface, the JTAGEN Fuse must be programmed. The |

||||

|

device is default shipped with the fuse programmed. In addition, the JTD bit in MCUCSR |

||||

|

must be cleared. Alternatively, if the JTD bit is set, the External Reset can be forced low. |

||||

|

Then, the JTD bit will be cleared after two chip clocks, and the JTAG pins are available |

||||

|

for programming. This provides a means of using the JTAG pins as normal port pins in |

||||

|

running mode while still allowing In-System Programming via the JTAG interface. Note |

||||

|

that this technique can not be used when using the JTAG pins for Boundary-scan or On- |

||||

|

chip Debug. In these cases the JTAG pins must be dedicated for this purpose. |

||||

|

As a definition in this datasheet, the LSB is shifted in and out first of all Shift Registers. |

||||

Programming Specific JTAG |

The instruction register is 4-bit wide, supporting up to 16 instructions. The JTAG instruc- |

||||

Instructions |

tions useful for Programming are listed below. |

||||

|

The OPCODE for each instruction is shown behind the instruction name in hex format. |

||||

|

The text describes which Data Register is selected as path between TDI and TDO for |

||||

|

each instruction. |

||||

|

The Run-Test/Idle state of the TAP controller is used to generate internal clocks. It can |

||||

|

also be used as an idle state between JTAG sequences. The state machine sequence |

||||

|

for changing the instruction word is shown in Figure 138. |

||||

272 ATmega32(L)

2503F–AVR–12/03