- •VOLUME 4

- •CONTRIBUTOR LIST

- •PREFACE

- •LIST OF ARTICLES

- •ABBREVIATIONS AND ACRONYMS

- •CONVERSION FACTORS AND UNIT SYMBOLS

- •HYDROCEPHALUS, TOOLS FOR DIAGNOSIS AND TREATMENT OF

- •HYPERALIMENTATION.

- •HYPERBARIC MEDICINE

- •HYPERBARIC OXYGENATION

- •HYPERTENSION.

- •HYPERTHERMIA, INTERSTITIAL

- •HYPERTHERMIA, SYSTEMIC

- •HYPERTHERMIA, ULTRASONIC

- •HYPOTHERMIA.

- •IABP.

- •IMAGE INTENSIFIERS AND FLUOROSCOPY

- •IMAGING, CELLULAR.

- •IMAGING DEVICES

- •IMMUNOLOGICALLY SENSITIVE FIELD–EFFECT TRANSISTORS

- •IMMUNOTHERAPY

- •IMPEDANCE PLETHYSMOGRAPHY

- •IMPEDANCE SPECTROSCOPY

- •IMPLANT, COCHLEAR.

- •INCUBATORS, INFANTS

- •INFANT INCUBATORS.

- •INFUSION PUMPS.

- •INTEGRATED CIRCUIT TEMPERATURE SENSOR

- •INTERFERONS.

- •INTERSTITIAL HYPERTHERMIA.

- •INTRAAORTIC BALLOON PUMP

- •INTRACRANIAL PRESSURE MONITORING.

- •INTRAOCULAR LENSES.

- •INTRAOPERATIVE RADIOTHERAPY.

- •INTRAUTERINE DEVICES (IUDS).

- •INTRAUTERINE SURGICAL TECHNIQUES

- •ION-EXCHANGE CHROMATOGRAPHY.

- •IONIZING RADIATION, BIOLOGICAL EFFECTS OF

- •ION-PAIR CHROMATOGRAPHY.

- •ION–SENSITIVE FIELD-EFFECT TRANSISTORS

- •ISFET.

- •JOINTS, BIOMECHANICS OF

- •JOINT REPLACEMENT.

- •LAPARASCOPIC SURGERY.

- •LARYNGEAL PROSTHETIC DEVICES

- •LASER SURGERY.

- •LASERS, IN MEDICINE.

- •LENSES, CONTACT.

- •LENSES, INTRAOCULAR

- •LIFE SUPPORT.

- •LIGAMENT AND TENDON, PROPERTIES OF

- •LINEAR VARIABLE DIFFERENTIAL TRANSFORMERS

- •LITERATURE, MEDICAL PHYSICS.

- •LITHOTRIPSY

- •LIVER TRANSPLANTATION

- •LONG BONE FRACTURE.

- •LUNG MECHANICS.

- •LUNG PHYSIOLOGY.

- •LUNG SOUNDS

- •LVDT.

- •MAGNETIC RESONANCE IMAGING

- •MAGNETOCARDIOGRAPHY.

- •MANOMETRY, ANORECTAL.

- •MANOMETRY, ESOPHAGEAL.

- •MAMMOGRAPHY

- •MATERIALS, BIOCOMPATIBILITY OF.

- •MATERIALS, PHANTOM, IN RADIOLOGY.

- •MATERIALS, POLYMERIC.

- •MATERIALS, POROUS.

- •MEDICAL EDUCATION, COMPUTERS IN

- •MEDICAL ENGINEERING SOCIETIES AND ORGANIZATIONS

- •MEDICAL GAS ANALYZERS

- •MEDICAL PHOTOGRAPHY.

- •MEDICAL PHYSICS LITERATURE

- •MEDICAL RECORDS, COMPUTERS IN

- •MICROARRAYS

- •MICROBIAL DETECTION SYSTEMS

- •MICROBIOREACTORS

- •MICRODIALYSIS SAMPLING

- •MICROFLUIDICS

- •MICROPOWER FOR MEDICAL APPLICATIONS

- •MICROSCOPY AND SPECTROSCOPY, NEAR-FIELD

- •MICROSCOPY, CONFOCAL

- •MICROSCOPY, ELECTRON

- •MICROSCOPY, FLUORESCENCE

- •MICROSCOPY, SCANNING FORCE

- •MICROSCOPY, SCANNING TUNNELING

- •MICROSURGERY

- •MINIMALLY INVASIVE SURGICAL TECHNOLOGY

- •MOBILITY AIDS

- •MODELS, KINETIC.

- •MONITORING IN ANESTHESIA

- •MONITORING, AMBULATORY.

- •MONITORING, FETAL.

- •MONITORING, HEMODYNAMIC

- •MONITORING, INTRACRANIAL PRESSURE

- •MONITORING, NEONATAL.

- •MONITORING, UMBILICAL ARTERY AND VEIN

- •MONOCLONAL ANTIBODIES

- •MOSFET.

- •MUSCLE ELECTRICAL ACTIVITY.

- •MUSCLE TESTING, REHABILITATION AND.

- •MUSCULOSKELETAL DISABILITIES.

drug resistance in hepatitis B virus-infected patients during antiviral therapy. J Clin Microbiol 2000;38:702–707.

9.Stuyver L, Wyseur A, Vanarnhem W, Lunel F, Laurentpuig P, Pawlotsky JMM, Kleter B, Bassit L, Nkengasong J, Vandoorn LJ, Maertens G. Hepatitis C virus genotyping by means of 50-UR/core line probe assays and molecular analysis of untypeable samples. Virus Res 1995;38:137–157.

10.Roche Diagnostics - Roche Molecular Diagnostics - Products. Automated PCR Systems. [Online]. Roche Molecular Diagnostics. http://www.rochediagnostics. com/ba_rmd/ rmd_ products_automated_pcr_systems23.html.

11.Heid CA, Stevens J, Livak KJ, Williams PM. Real time quantitative PCR. Genome Res 1996;6:986–994.

12.Cepheid – Products. (No date). GeneXpert Technology, System Overview. [Online]. Cepheid. http://www.cepheid.com/ Sites/cepheid/content.cfm?id¼164.

13.Jaffe RI, Lane JD, Bates CW. Real-time identification of Psuedomonas aeruginosa direct from clinical samples using a rapid extraction method and polymerase chain reaction (PCR). J Clin Lab Analysis 2001;15:131–137.

14.Idaho Technology - R.A.P.I.D. Successes using the R.A.P.I.D. [Online]. Idaho Technology. http://www.idahotechnology.- com/rapid/success.htm.

15.NucliSens Key Technologies. (2005). bioMe´rieux – Clinical Microbiology Products. [Online]. bioMe´rieux, Inc. http:// www.biomerieuxusa. com/clinical/nucleicacid/technology. htm.

16.NucliSens Reader. (2005). bioMe´rieux – Clinical Microbiology Products. [Online]. bioMe´rieux, Inc. http://www.biomerieuxusa.com/clinical/nucleicacid/reader.htm.

17.NucliSens EasyQ. (2005). bioMe´rieux – Clinical Microbiology Products. [Online]. bioMe´rieux, Inc. http://www.biomerieuxusa.com/clinical/nucleicacid/easyq/easyq_technology.htm.

18.DeBaar MP, Timmermans EC, Bakker M, Rooij E, van Gemen B, Goudsmit J. One-tube real-time isothermal amplification assay to identify and distinguish human immunodeficiency virus type 1 subtypes A, B, and C and circulating recombinant forms AE and AG. J Clin Microbiol 2001;39:1895–1902.

19.Lanciotti RS, Kerst AJ. Nucleic acid sequence-based amplification assays for rapid detection of West Nile and St. Louis encephalitis viruses. J Clin Microbiol 2001;39:4506–4513.

20.Walker GT, Little MC, Nadeau JG, Shank DD. Isothermal in vitro amplification of DNA by a restriction enzyme/DNA polymerase system. Proc Natl Acad Sci USA 1992;89:392– 396.

21.Little MC, Andrews J, Moore R, Bustos S, Jones L, Embres C, Durmowicz G, Harris J, Berger D, Yanson K, Rostkowski C, Yursis D, Price J, Fort T, Walters A, Collis M, Llorin O, Wood J, Failing F, O’Keefe C, Scrivens B, Pope B, Hansen T, Marino K, Williams K, Boenisch M. Strand displacement amplification and homogeneous real-time detection incorporated in a second-generation DNA probe system, BDProbeTecET. Clin Chem 1999;45:777–784.

22.Akduman D, Ehret M, Messina K, Ragsdale S, Judson FN. Evaluation of a strand displacement amplification assay

(BD ProbeTec-SDA) for detection of Neisseria gonorrhoeae in urine specimens. J Clin Microbiol 2002;40:281– 283.

23.RAPTOR. RAPTOR, Portable, Multianalyte Bioassay System. [Online]. Research International. http://www.resrchintl.com/raptor.html.

24.Bacillus anthracis. (June 2, 2003). Bacillus anthracis (anthrax). [Online]. http://microbes.historique.net/anthracis. html.

25.Donaldson KA, Kramer MF, Lim DV. A rapid detection method for Vaccinia virus, the surrogate for smallpox virus. Biosens Bioelectron 2004;20:322–327.

MICROBIOREACTORS 383

26.Franz DR, Jahrling PB, Friedlander AM, McClain DJ, Hoover DL, Bryne WR, Pavlin JA, Christopher GW, Eitzer EM, Jr.. Clinical recognition and management of patients exposed to biological warfare agents. JAMA 1997;278:399–411.

27.Nam J-M, Thaxton CS, Mirkin CA. Nanoparticle-based biobarcodes for the ultrasensitive detection of proteins. Science 2003;301:1884–1886.

28.Nam J-M, Stoeva SI, Mirkin CA. Bio-bar-code-based DNA detection with PCR-like sensitivity. J Am Chem Soc 2004;126:5932–5933.

29.Ewalt KL, Haigis RW, Rooney R, Ackley D, Krihak M. Detection of biological toxins on an active electronic microchip. Anal Biochem 2001;289:162–172.

30.Yang JM, Bell J, Huang Y, Tirado M, Thomas D, Forster AH, Haigis RW, Swanson PD, Wallace RB, Martinsons B, Krihak M. An integrated, stacked microlaboratory for biological agent detection with DNA and immunoassays. Biosens Bioelectron 2002;17:605–618.

31.Osmetech. (2005). eNose Technology. [Online]. Osmetech. http://www.osmetech.plc.uk/enose.htm.

32.Aathithan S, Plant JC, Chaudry AN, French GL. Diagnosis of bacteriuria by detection of volatile organic compounds in urine using an automated headspace analyzer with multiple conducting polymer sensors. J Clin Microbiol 2001;39:2590– 2593.

33.Bashir R. BioMEMS: State-of-the-art in detection, opportunities and prospects. Adv Drug Delivery Rev 2004;56:1565– 1586.

34.Lee SJ, Lee SY. Micro total analysis system (m-TAS) in biotechnology. Appl Microbiol Biotechnol 2004;64:289–299.

See also COLORIMETRY; COMPUTER-ASSISTED DETECTION AND DIAGNOSIS;

COMPUTERS IN THE BIOMEDICAL LABORATORY; FLUORESCENCE MEASUREMENTS; SAFETY PROGRAM, HOSPITAL.

MICROBIOREACTORS

XIAOYUE ZHU

TOMMASO BERSANO-BEGEY

YOKO KAMOTANI

SHUICHI TAKAYAMA

University of Michigan

Ann Arbor, Michigan

INTRODUCTION

This article defines microbioreactors as micrometer scale reaction vessels in which biological reactions are performed. Whereas large-scale bioreactors mainly focus on efficiently producing desired end products, microbioreactors have additional targeted applications such as studying cellular processes under simulated physiological microenvironments, and functioning as portable cellular biosensors or implantable devices inside the body to restore tissue functions. Increasing needs in developing personalized cell-based therapies and medicines together with rapid advances in microand nanotechnologies ensure that the field of microbioreactors will continue to flourish. Although most microbioreactors are still in their infancy, relatively simple compared to their macroscopic counterparts, and often not fully integrated or packaged into compact selfcontained platforms, they already have started to have an

384 MICROBIOREACTORS

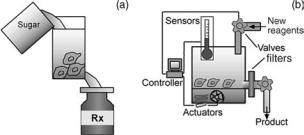

Figure 1. What are bioreactors and microbioreactors? Part

(a) shows a generalized bioreactor application, feeding cells to produce complex biomolecules for pharmaceutical applications. Part (b) shows the main components of both bioreactors and microbioreactors: a reaction chamber containing main reagents and cells, sensors (for temperature, flow rate, pH, oxygen, glucose, etc.), actuators (pumps, valves, heaters, mixers, filters), and controllers to regulate actuators based on sensor readings.

impact in pharmaceutical, medical, clinical, and biological fields (Fig. 1).

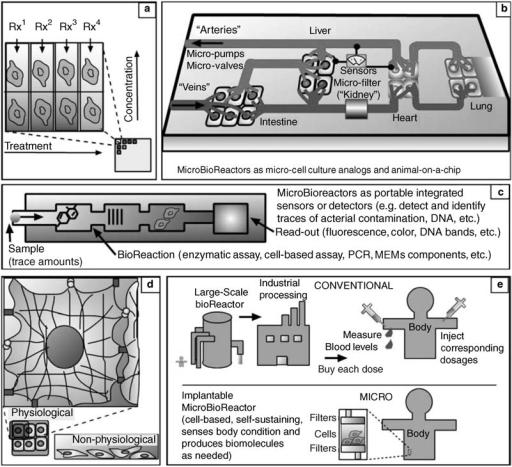

Microbioreactors enable low cost high throughput investigation of bioreactions in ways not possible with macroscopic bioreactors. For example, the development of a biopharmaceutical requires extensive optimization processes prior to scale-up for industrial manufacture: The bacterial strain or mammalian cell that produces the highest yield of a particular product is constructed or identified; cultural parameters (e.g., temperature, pH, oxygen concentration, and media composition) are systematically evaluated to maximize cell growth and product formation; the design of the reactors themselves are adjusted iteratively as the development process gradually scale-up from benchtop to production scale. With microfabrication techniques, hundreds and thousands of small reaction chambers can be produced simultaneously and operated in parallel allowing vast combinations of parameters to be screened concurrently in short periods of times (Fig. 2a). The consumption of reagents and resources are reduced dramatically because for a given reaction chamber geometry, every 10-fold reduction in linear dimension would lead to a 1000 time reduction in its volume.

To enhance the quality of information obtained from cellular studies, rather than simply increasing throughput, some microbioreactors are designed to simulate physiological cellular microenvironments. Using microbioreactors for studying cellular physiology makes intuitive sense when one considers that much of the bioreactions within living organisms occur at the microscale. For example, capillary blood vessels, lung small airways, livers sinusoids, kidney nephrons, and reproductive tracts are all networks of small sacs, ducts, and tubes. Cells in these and other similar systems are constantly perfused with nutrients and oxygen and exposed to shear stresses and gradients of chemicals (1–3). Conventional in vitro cell culture studies, such as culture dishes or 96 well plates, often fail to present many of these dynamic physiological parameters. Microbioreactors, however, can be designed to simulate many such physical and chemical conditions that cells experience inside the body. In the body, different

tissues and cell types also interact and communicate with each other. Microbioreactors can be designed to network multiple reaction chambers together to capture the complexity of living organisms and used as animal and human surrogates in pharmacokinetic and toxicology studies. Microbioreactors can also work as cell-based biosensors, where effects on cell behaviors serve as readouts for selective and sensitive detection (Fig. 2c).

Some microbioreactors aim to continuously produce and deliver small quantities of biopharmaceuticals (e.g., insulin for regulation of blood sugar) inside the body (Fig. 2e). Implantable devices that continuously produce drugs based on physiological demands would eliminate the need for repeated injections and blood tests, and allow for delivery of stable, safe, and effective doses that resemble physiological concentration profiles. Such devices contain cells that use nutrients from the body to produce and secrete drugs (4).

Besides cell-based microbioreactors, enzymatic microbioreactors are also useful for detection and analysis. Enzyme-linked immunosorbent assays (ELISA), for example, are useful in high sensitivity detection and analysis of a wide variety of proteins and chemicals related to pollution, disease, and basic biology. Microscale systems often require shorter incubation time due to the short distances that analytes and reagents have to diffuse. Microbioreactors are also more portable and thus suitable for field and point-of-care use.

The development, integration, and packaging of microbioreactors present many challenges, as well as unique opportunities. Because of scaling issues and fabrication limitations, functional microscopic devices often require totally new designs instead of simply ‘‘shrinking’’ their macroscopic counterparts. Thus microscale pumps, valves, and mixers not only look different from their macroscopic counterparts, but may also operate with different mechanisms. Microscale sensors, another crucial component of microbioreactors, is an active area of research that has yielded a variety of useful systems based on optical, electrochemical, ultrasonic, and mechanical detection schemes. Although many microscale components have been developed to date, functional microbioreactors that integrate multiple pumping, valving, mixing, sensing, and control features are still relatively uncommon. Microbioreactors generally have fewer components integrated into their systems compared to their larger counterparts.

The organization of the remainder of this article is as follows. First, the principles that govern microscale reactions and microbioreactor operation are discussed. Second, elements of microbioreactor components are described, along with a brief description of the microfabrication processes that can be used to create them. Finally, highlights of state-of-the-art microbioreactors are given with focuses on production optimization, clinical treatment, toxicology testing, development of implantable systems, and basic cell biology studies. Because of space limitations, this article is representative rather than comprehensive. We also focus mainly on cell-based bioreactors rather than enzyme-based ones. Interested readers are referred to reviews on immobilized microfluidic enzymatic reactors (5). We also exclude important bioreactor categories that are not directly

MICROBIOREACTORS 385

Figure 2. Advantages and new applications of microbioreactors over large scale bioreactors:

(a) microscale parallel cell culture and testing in a microchip configuration can be used to test and compare hundreds of conditions and parameters simultaneously, to optimize a reaction or screen potential treatments. (b) Microdevices containing interconnected chambers and microcultured cells from different tissues can be used to test drug effects on entire organisms, taking into account systemic impact of organs such as liver on drug metabolism, possibly replacing some stages of animal and human testing. (c) Microbioreactors can be used as detectors for bioactive compounds (e.g., toxins, endocrine disruptors, drugs) or biodisruptive conditions (e.g., radiation) with the advantage that all the steps of a test can be integrated in a single device that requires only trace amounts of samples and reagents. Cell-based sensors may be able to detect unknown reagents that affect living organisms. (d) Microfabrication can also provide microbioreactors with more physiologically accurate microenvironments, thus making in vitro testing more reliable and closer to in vivo conditions: for example, in actual tissues, each cell is held in its three-dimensional (3D) shape by tension through connected cytoplasmic fibers (the cytoskeletons), and cells have many surface interactions with other surface microfeatures and other cells. In contrast, in conventional cell culture that cannot microfabricate these features, cells configuration, and environment conditions, such as the amount of surface contacts, are drastically different. (e) Implantable devices containing cells such as insulin-producing pancreatic islets can be used as an improved treatment that continuously produce insulin based on the body’s minute-by-minute needs, eliminating the need for periodical blood tests and consequent injections of insulin mass-produced in conventional bioreactors.

related to medicine, such as those used for food testing, plant cell culture, and wastewater treatment.

MICROBIOREACTOR DESIGN PRINCIPLES

Basic principles of bioreactor operations, such as thermodynamics, kinetics, mass transfer, sterilization, and struc-

tural considerations, are similar for both macroand microbioreactors. The implementation of these principles into actual practice, however, can differ greatly.

Scaling Effects

At first glance, development of microbioreactors may seem to be a matter of simply shrinking macroscopic components

386 MICROBIOREACTORS

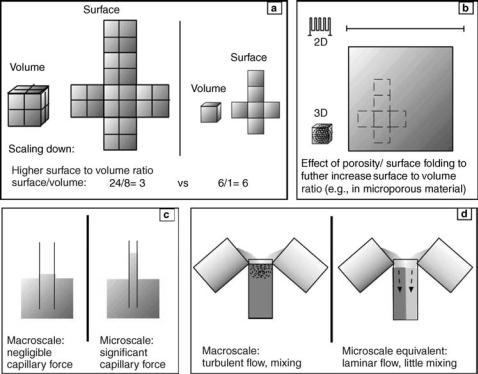

Figure 3. Microscale physics useful for microbioreactors. (a) As dimensions of devices scale down to microscopic scales, surfaces and volumes scale at different rate, so that smaller devices have a much greater surface/ volume ratio. This change affects many physical phenomena such as capillary force (c) and produces effects such as laminar flow (d), which allows two liquids to flow side by side with minimal turbulent mixing. These microscale phenomena can be useful for microbioreactor opera tion. For example, capillary force can be used to pump liquid through microchannels, and laminar flows can be used to selectively deliver different reagents to different parts of single cells. (b) Microfabrication can further increase the surface/volume ratio, in a biomimetic manner, by creating microporous structures. This is useful since many biological reactions occur on surfaces.

into smaller ones. Directly downsizing systems and components, however, compromise their functions. Operations at microscales are often altered in unexpected ways compared to those at macroscales because the relative importance of physical effects that determine the functions of the microbioreactor components is size dependent. For example, if the linear dimensions of an object are reduced equally by a factor of 100, the surface area decreases by a factor of 10,000, and the volume decreases by a factor of 1,000,000 (Fig. 3a). The resulting increase in surface/ volume ratio leads to prominence of surface effects such as surface tension and viscous drag over gravity and momentum. Thus, at the microscale, laminar flow, diffusive mixing, and capillary forces dominate over turbulence, convective mixing, and gravitational forces (Fig. 3c, d) (6). Scaling laws affect almost every aspect of microbioreactor operation. For example, it is more difficult to perform turbulent mixing at the microscale compared to at the macroscale (7–9), but more convenient to use electroosmosis flow to transport fluid samples through microchannels (10). More details of how scaling laws affect the design and operation of the microbioreactor components are noted in each section below.

Microbioreactor Operation Principles

The main challenge in bioreactor operation lies in its dynamic nature. Optimal reaction conditions must be maintained even as multiple parameters, such as concentration of molecules, activity of enzymes, quantity and quality of cells, and heat production are changing. Understanding the reaction mechanisms is helpful for

optimizing reactor designs. It is also desirable to constantly monitor and control reaction environments in real time.

Mass And Heat Balance. In bioreactor processes, it is common to assume steady state, that is, a balance of input, output flow of materials, and thermal homeostasis. As substrate input is converted into product, mass balances need to be closely monitored and controlled. In many enzymatic processes, for example, the reactions are reversible or are inhibited by products. In such cases, it is beneficial to favor the forward enzymatic reaction by keeping the upstream reagent concentrations high and constantly removing downstream products. This type of balance can be achieved to different extents by fed-batch systems or continuous flow systems that constantly replenish and remove reactor contents. Even in so-called batch reactors, where there is no flow of liquid in and out of the reaction chamber, it is often crucial to aerate and maintain sufficient levels of oxygen at all times.

As dimensions are diminished, the conductive resistance at the channel wall/fluid interface decreases, and temperature gradient increases, leading to a greater efficiency of thermal conductivity (11). Because heat flux scales with surface area while heat capacity scales with volume, thermal time constants and heat flux scale linearly with decreasing dimensions. The small thermal mass and associated fast thermal response allows for quick temperature control. On the other hand, since the microsystems can be heated and cooled quickly, it is difficult to maintain a constant temperature; external temperatures must be set at the desired temperature, or constant heating and cooling

of the microbioreactor will be required to avoid fluctuations.

A phenomenon that may not impact macroscopic bioreactors considerably, but has a significant effect on microbioreactors, is evaporation. Unless carefully monitored, evaporation will greatly affect reactant concentrations and osmolarity because of the small volume that a microbioreactor can hold.

A variety of mathematical models have been developed to analyze and control bioreactor thermodynamics and stoichiometry. Interested readers are referred to existing texts on the topic (12). For example, Roels (13,14) developed correlations to estimate some of the important thermodynamic parameters to predict yields, substrate and oxygen requirements, and heat dissipation for cellular reactions.

Reaction Kinetics. Bioreaction kinetics depends critically on temperature, pH, dissolved oxygen concentrations, and presence of inhibitors or enhancers. Oxygen fluctuation affects the metabolic and signaling pathways of cells. For bacterial bioreactors, the main concern is often to achieve a high enough oxygen transfer rate to match the oxygen uptake rate and maintain sufficiently high dissolved oxygen concentrations. For mammalian cell cultures, it is necessary to maintain an appropriate dissolved oxygen concentration. In expansion of stem cells, for example, lower oxygen concentrations that mimic physiological values gives higher yields and purity of cells (15,16). Microbioreactors present unique challenges and opportunities in terms of oxygen transfer. Microbial and eukaryotic cell cultures require constant replenishment of dissolved oxygen into the medium because of the low solubility of oxygen in aqueous solutions (8 mg/L 1 at 35 8C in distilled water) (17). For larger bioreactors, bubbling oxygen or passing ambient gas through the cell culture suspension are commonly used (18). Microscale gas formation is more challenging, but has been demonstrated elegantly using electrolysis by Maharbiz et al. (19) (see Components section for details). For microbioreactors with submilliliter volumes, bubbles are generally avoided because they can clog channels and are difficult to dislodge from microchannel walls. For such systems, it is common to use a gas-permeable membrane to oxygenate the culture medium (20,21). The large surface/volume ratio of microdevices provides an advantage for such membranebased oxygen transfer processes. Poly(dimethylsiloxane) (PDMS), a biocompatible polymer material commonly used for microdevice fabrication, is particularly advantageous in this regards due to its high permeability to oxygen.

Enzyme performance and cell growth and function are particularly sensitive to pH changes. When the reaction is not within the optimal pH range, the reaction rate declines dramatically (12). Substrates, products, or contaminants can reversibly or irreversibly affect enzyme activity. Surface interactions can also alter the kinetics of enzyme reactions, stability of enzymes (22), as well as growth and function of cells (23). Precisely dispensing nanoor picoliters of acids and bases into the tiny reaction chamber to adjust pH is technically challenging. Furthermore, because it is difficult to perform convective mixing in

MICROBIOREACTORS 387

microbioreactors, there may be local variations in the pH and in the reaction kinetics.

Mechanical Considerations. When microbioreactors are coupled with microfluidic systems, cells are subjected to shear stresses. For a given maximum flow velocity, smaller channels will give rise to larger shear stresses (1). Although excess forces can damage cells, moderate shear stresses on genetically engineered cells have actually enhanced the production yield of recombinant proteins (24). Cells in the body are also often exposed to stretching and/or compression. These forces are critical factors that regulate function of cells in muscles, hearts, blood vessels, lungs, and other tissues (25,26). For example, shear stress regulates morphology, gene expression and function of endothelial cells, the monolayers of cells lining the inside of blood vessels (27–30). Shear stress is physiologically important for maintaining vascular homeostasis (31), regenerate bone and healing fractures (32), differentiate embryonic stem cells into cardiovascular fate, leukocytes rolling and tethering to endothelial cells (33). Nuclear factor-kb (NF-kb), for example, has been identified as a shear stressresponsive transcription factor that enhances the transcription of many genes including cytokines, growth factors, adhesion molecules, and immunoreceptors in response to shear stress (34).

Some of the biochemical and structural responses of cells to stretch include enhanced expression of endothelin (35), nitric oxide (36), and integrin (37) in vascular endothelial cells, and increased extracellular matrix production in cardiac fibroblasts (38) and in smooth muscle cells (39). Mechanical loading influence cellular functions in vitro, including proliferation (40,41), differentiation (42), hypertrophy (40,43), alignment (41,44), G protein activation, second messenger activity (45), and gene expression (43,46).

Cells in the body are constantly subjected to physical forces, such as cyclic mechanical deformation involving tension, compression, shear stress, or all three. Cell proliferation, differentiation, migration, signal transduction, and gene expression are all affected by such mechanical forces (47). Although it is largely unknown how mechanical stimuli are converted into intracellular signals of gene expression (48), there are many efforts to recreate physiological mechanical signals in vitro, either in the form of shear stresses from fluid flow, hydrodynamic pressures, or mechanical stresses applied to cells through the substrates. An ideal microbioreactor would provide optimal biomechanical and biodynamic stimuli for cell and tissue growth.

Material Considerations. The material used to fabricate the reaction chambers is crucial because they directly contact cells, enzymes, and products of bioreactors. Sometimes, it is also necessary to mimic physiological cellular environments (Fig. 2d) by altering the properties of the chamber surface to resemble that of the extracellular matrix (ECM). Proteins or enzymes can be immobilized onto surfaces to manipulate cell growth. Topographical features can also be incorporated to further mimic the ECM environment.

388 MICROBIOREACTORS

Surface Chemistry. As the size of devices decreases, their surface/volume ratio increases, making surface properties increasingly important in defining the performances of smaller bioreactors because cell function is intimately linked to the properties of the surfaces to which cells attach. Depending on the application, it is necessary to promote specific adsorption of proteins that mediate cell attachment and growth onto surfaces, or to prevent adsorption of proteins and cells. Because cellular receptors that bind to surfaces are nanoscale in size, it is also important to be able to pattern adhesive surfaces with resolutions from microns to nanometers (2,49–51). Surface properties are also important for enzyme-based microbioreactors because surface properties alter enzyme activity and stability. Enzymes are commonly immobilized through physical adsorption or covalent binding onto high surface area materials, such as carbon, silica, and polymers. Use of immobilized enzymes is often favored over free enzymes because of reduction in enzyme costs, ease of recovery, stability, and ability to be incorporated into microsystems. Ratner’s recent review covers important topics including surface modification of materials to prevent nonspecific protein adsorption, immobilizing functional groups on surface, and development of synthetic materials (52).

A useful model surface for studying biomaterials interactions is a self-assembled monolayer (SAM). Often formed on gold using alkane thiols, SAMS are highly ordered arrays of linear molecules that have one end attached to the surface of gold or other bulk materials and the other end exposed to the environment. A useful feature of SAMs is that their surface properties are determined predominantly by the very terminal functional group. By altering the nature of these terminal groups, SAMs can prevent protein and cell attachment or promote binding of specific ones (53). Other types of systems that are useful for controlling protein adsorption include covalent bonding, via silanes, to silica or metal. Micropatterns of biopolymers can also be generated using photolithography, which uses patterns of light to induce region-selective chemical reactions on a surface. A more recent technique is microcontact printing, which involves transfer of small molecules or proteins onto solid substrates from an elastomeric stamp (53). Microfluidic networks have also been used for protein patterning: elastomers with embedded channel features are used to direct small volumes of protein solutions into networks of channels to create protein patterns corresponding to the path of fluid flow (54–56). Surface patterned microfluidic channels can then be used directly as microbioreactors in which micropatterned cell culture can be performed.

Topography Control. Living organisms are not flat. The endothelial lining of blood vessels, for example, exhibit an irregular wave-like topography to prevent build-up of fatty deposits (57). Endothelial monolayers have been modeled as a wavy surface by computational methods to estimate the influence of the waviness on local flow forces (58). Muscle fibers form microscale ridges and grooves onto which myoblasts can attach and proliferate (59). Microfabricated topographical features, regardless of whether they mimic physiological microtopographies or not, can be

used in microbioreactors to modulate adhesion, align or orient cells, and even affect cell growth and differentiation. Examples of topographical features that have been studied include single cliffs, grooves/ridges, spikes, hills, tunnels and tubes, fibers, cylinders, mesh, waves, and random roughness. Materials used for topographical controls include gold, silicon, carbon, inorganic compounds, such as silica, lithium niobate, silicon nitride, and polymers, such as polymethylmethacrylate, silicones, cellulose acetate, collagen, fibrin, and PDMS (51). Microtopography can also affect surface wetting and fluidic flow patterns. Even for a simple groove structure, variations of the aspect ratio and contact angle of the underlying substrate materials can dramatically alter the morphology of liquid droplets contacting the surface (60).

Sterilization. Similar to larger scale bioreactors, microbioreactors and their solutions and gases can be sterilized using heat, chemicals, radiation, or through the filtration of agents. The small reaction volumes of microbioreactors provide an advantage in terms of sterilization, because for a given concentration, the total number of cells, spores, or other contaminants depends on the volume. Then, assuming that the ‘‘death rate’’ of the contaminant is independent of reactor size or contaminant numbers, the sterilization time needed to extinct the contaminants will decrease with decreasing reactor size. In this respect, microbioreactors are more time efficient in batch sterilization than macroscopic ones. Ultraviolet (UV) sterilization is particularly convenient for transparent microbioreactors, such as those fabricated in PDMS. When pH sensors or dissolved oxygen sensors are packaged into the microbioreactor, autoclave and UV radiation may not be feasible, and alternative methods may need to be used. Flowing 70% ethanol through the chambers/channels and subsequently drying is also sufficient for many microbioreactor applications.

Other Considerations. Phototrophic microorganisms consume light energy to survive; they can grow in simple and inexpensive nutrient media. The light requirements of phototrophic microorganisms, however, impose other significant constraints on photobioreactor designs (61). These constraints are due to an exponential attenuation of the light flow passing through an optically absorbing medium. Microbioreactors, given their large surface/ volume ratios, are promising for photobioreactor applications. Cultivation of phototrophic microorganisms in optimized photobioreactors would increase the product yield several folds by maintaining the culture under appropriate conditions.

Ultrasound irradiation can change both the structure and function of biologic molecules such as proteins and deoxyribonucleic acid (DNA) (62). At mild intensity, ultrasound irradiation can increase the activity of free enzymes (63). For example, significant enhancement of reaction rate can be achieved when exposing subtilisin power to ultrasound irradiation (64). Low energy ultrasound wave irradiation can also optimize the efficiency in ethanol production by yeast from mixed office waste paper in bioreactors (65). A variety of microscale ultrasound systems have been reported. Advanced microbioreactor

systems with ultrasound components may be developed to make bioreactors more efficient.

MICROBIOREACTOR COMPONENTS

Components For Heat Transfer

External heating elements can be incorporated into microbioreactors to control temperatures. External controls of temperature include the use of standard cell culture incubators that can accommodate the whole microbioreactor (66), heating tapes, and water-to-water heat exchangers (67). Internal, embedded heaters can be comprised of materials such as thin platinum films (68) or optically transparent indium–tin oxide (ITO) (69). Temperature measurements can also be made on chip using metallic, semiconducting, or optical materials.

An important application where heaters are crucial and microbioreactors have an advantage is the polymerase chain reaction (PCR), a temperature-controlled and enzyme-mediated DNA amplification technology (70). Polymerase chain reaction requires multiple cycles of high, low, and medium temperatures to separate DNA strands, anneal the primer to the template DNA, and make complementary copies of the template DNA. Since microsystems usually have high heat conductivity and low heat capacity, the time for raising and lowering the temperature is shortened and time will be saved when cyclic temperature fluctuations during the PCR reaction is necessary. Northrup et al. (71) integrated microfabricated polysilicon heaters into a micromachined silicon reaction chamber. Schneegass et al. (68) used a thermocycler chip with integrated thin platinum film heaters and sensors for temperature. Kopp et al. (72) used external copper blocks and heating cartridges with the surface temperature monitored by a platinum thin-film resistor. Burns and co-workers (73) developed a very simple and elegant PCR device that utilizes Rayleigh–Benard convection—a steady, buoy- ancy-driven circulatory flow that occurs between two surfaces, one on top and one on the bottom, maintained at two fixed temperatures—to perform temperature cycling.

Components For Aeration

Electrolytic gas generation provides a compact, scalable approach for gas delivery to microbioreactors (19). In brief, a pair of interdigitated Ti/Pt electrodes hydrolyzes electrolyte to generate oxygen gases at the narrow end of a gradually widened hydrophilic microchannel. The oxygen bubbles move along the conical microchannels and transfer into culture medium because of the positive pressure built up during gas generation and the different surface tension forces at the front and back of the bubbles formed in the gradually widening channel. The rate of oxygen generation can be precisely controlled by pulse width modulation of the electrode potential.

The smaller the bioreactor, the more crucial it is to avoid bubble formation to prevent blockage of microchannels. For such systems, it is advantageous to use gas permeable membranes that allow diffusion of gases through it without introduction of bubbles. Because the surface/volume ratio

MICROBIOREACTORS 389

is large in microsystems, oxygen transfer through gaspermeable membranes is often sufficient to ensure adequate oxygenation for biomass production. A straightforward method to fabricate gas-permeable membranes is to spincoat PDMS prepolymer onto silanized silicon wafers, cure and harden to generate a thin membrane, then peel it off (20,21).

Components For Fluid Control

Valves. Valves can be categorized into active and passive valves. A passive valve is a flow-dependent obstruction that functions without any external actuation. Passive valves are mostly unidirectional. In an active valve, fluid flow is directed by active actuation (74). The advantage that active valves have over passive valves is the degree of control one has over the timing, rate, and direction of fluid flow. This type of control is necessary to make real-time adjustments and for feedback control of microbioreactors. Although a large variety of valves have been reported, it is still a challenge to integrate multiple valves into a functional bioreactor system. Difficulties arise because many valves are incompatible with other components to be integrated, or because the valves require large external systems for actuation.

Passive valves have been used for restricting flow to one direction, removing air from liquid, or making flows stop at select channel regions. Although the level of control is lower compared to active valves, passive valves have the advantages of having few or no moving parts, less complexity, easy fabrication, and less chance to break due to fatigue (75). Recent approaches for passive control valves involve the use of hydrophobic materials, surface patterning, and changing channel fluid resistance (by changing channel geometry) (11). Passively moving micropiston valves have also been fabricated in situ inside microchannels using laser polymerization of a nonstick polymer (76).

Most conventional active microvalves couple a flexible diaphragm (77,78) to, thermopneumatic (79), piezoelectric (80), electrostatic, electromagnetic (81), bimetallic, or other types of actuators. The scaling of these actuation forces to the microscale, however, is often unfavorable and requires macroscale external actuators for operation. An interesting alternative to active valves is the use of autonomously regulated valves made of hydrogels that swell in response to pH or other specific chemical or thermal environment (11,82). The volume changes of the hydrogel can valve or obstruct fluid flow directly, or indirectly, through deformation of a thin PDMS membrane. The PDMS, when deformed, partially occludes an orifice to regulate the feedback stream of compensating buffer solution (17). By altering their chemistry, hydrogels can also valve in response to the changes of temperature, light, electric fields, carbohydrates, or antigens. Ehrick et al. (83) incorporated genetically engineered proteins within hydrogels that swell in response to various ligands as potential valves for microfluidic channels. Other types of valves include the use of commercially available Braille displays (84) or a pneumatic valve system to deform flexible microchannels (85).

390 MICROBIOREACTORS

Pumps. A micropump should ideally be able to pump a wide range of fluids and gases, be self-priming, and be programmable. Ideal micropumps are still lacking; thus, many microfluidic applications use macroscopic pumps, such as syringe pumps. Micropumps can be classified into two main types: mechanical pumps and nonmechanical pumps (71). Mechanical pumps use electromagnetic, piezoelectric, pneumatic, shape memory, electrostatic, thermopneumatic, or thermomechanic components to deliver fluid. Mechanical pumps provide higher control over average flow rates, but the flow is often pulsed and the fabrication relatively complex (53,85). Many types of nonmechanical micropumps have also been successfully developed. The flow from nonmechanical pumps is usually pulse-free with a wide range of flow rates at low pressures and the fabrication is often less complex compared to mechanical pumps. An electrokinetic pump that utilizes an electric field for pumping conductive fluids by electrophoresis or electroosmotic flow (EOF) is the most common method to control flow in microfluidic systems (71). Electrokinetic pumps have the advantages of direct control, fast response, and simplicity. However, the substrate material, joule heating effect, and microchannel charge have to be considered. Other types of nonmechanical pumps include electrohydrodynamic pumps that use electrostatic forces acting on dielectric fluids, phase-transfer pumps that use pressure gradient between gas and liquid phases, electrowetting fluid actuation systems that use interfacial forces, electrochemical pumps that use the pressure of gas bubbles generated by electrolysis of water (71), magnetohydrodynamic pumps (86), capillary force, gravity-driven pumps (87), pneumatic pumps (85), and pumps that use action of piezoelectric pin arrays in refreshable Braille displays (84).

Multiple Laminar Streams. For most flows in small channels, viscous forces dominate; thus flow is laminar and lacks turbulence. When two or more streams pass through microchannels, they flow in parallel as if they are separated by physical boundaries. Laminar flow is a challenge for mixing, but a useful phenomenon for microscale fluid patterning (Fig. 3d) (55,88). By taking advantage of diffusive mixing (but not turbulent mixing) and laminar flows, spatiotemporally defined gradients can be generated and have been used to study chemotaxis (89,90). Multiple laminar flows have also been used for developing microfluidic assay systems [i.e., T-sensor (91)], and studying subcellular processes when the interfaces of the laminar streams are positioned over a single cell (92).

Mixers. Mixing is challenging in microfluidic systems because laminar flows preclude turbulent mixing (Fig. 3d). Microscale mixers, therefore, generally use elongational flows or laminar shears to increase interfacial areas between different fluids and mixing by diffusion. Distributive mixing physically splits the fluid streams into smaller segments and redistributes them to reduce the striation thickness. Passive and active mixers have been developed for microfluidic systems, including laminating mixers (93), rotary mixers (94), mixing based on out of phase forward and backward pumping of different liquids (84), plume

mixers (nozzle arrays), chaotic advection mixers (9,95), movement of liquid plugs (96), and an electroosmotically driven micromixer that uses multiple intersecting channels to enhance lateral transport (97). Thorough reviews on micromixers have been given by Hessel et al. (98) and Nguyen and Wu (99).

Components For Mechanical Stimulation

Shear. Methods commonly used to impart shear stress on cells include cone viscometers, parallel plates, and capillary tube flow chambers (100,101). Gradients of shear stress can also be generated in a curved D-shape microchannel (102). Flow-induced cytoskeleton rearrangements were shown to depend on the geometry of the channel (D-shape channel versus flat surfaces, representing experience in microcirculation and large veins, respectively) and the presence of inflammatory drugs (103).

Stretch. When subjecting cultured cells to mechanical stretch, proper design and application of a strain device are required to provide a well-defined and reproducible strain field to study mechanotransduction. Information from such in vitro models, which facilitate systematic variations in mechanical conditions and allow rapid analyses, would yield tremendous insights into mechanical parameters that may be important in vivo (104). Biaxial cell strain devices have been used to strain lung cells (105,106) by repeated mechanical deformations of a membrane on which cells are attached. Strain could also be applied using a magnetic force (107), or via uniaxial cyclical stretch (108).

Components For Separation And Purification

Lysing. Cell contents are separated from their surrounding environment by a cell membrane. The membrane and an underlying cytoskeletal network provide mechanical strength to the cell and preserve its integrity. The first step in many analyses or isolation of cell contents is to disrupt the cell membrane. There are a variety of mechanical (homogenization, milling, ultrasonic disruption, and blenders) and nonmechanical (detergent, organic solvent, osmotic shock, enzymatic permeabilization, electrical discharge, heating, and pressure cycling) methods for disrupting cell membranes on the macroscopic scale. Demonstration of cell lysis on the microscopic scale inside microfluidic devices, however, has mostly been with nonmechanical methods that use detergents (96,109), electrical discharges, or lasers (110). Miniaturized cell electrolysis devices can work with small amounts of cells and reduce the amount of purification compared to other protocols (111,112). For example, Waters et al. (113) developed a microchip that is capable of performing Escherichia coli lysis, PCR amplification, and eletrophoretic analysis on a single device.

Separation. Cell separation techniques are fundamental to clinical diagnosis, therapy, and biotechnological production (114). For example, it is crucial to have purified cells before proliferation and production of cellular products. Current approaches include optical tweezers (115), centrifugation (116,117), filtration

(109,116,118), fluorescence-based cell sorting (FACS) (119,120) or magnetically activated cell sorting (MACS) (121), electric field-based manipulations and separations (114,122–124), and cell-motility based sorting (125,126). Microtechnology opens new opportunities in cell and biomolecule sorting that take advantage of laminar flow behaviors (125), electrical field properties (127), or other microscale phenomena. It also provides the opportunity to combine multiple modes of separation into an integrated system. Researchers have used physiological fluid mechanical phenomenon observed in blood microcirculation (plasma skimming and leukocyte margination) to filter leukocytes from whole blood (128). Petersson et al. (129) combined acoustic wave forces and laminar flow to continuously sort erythrocytes from lipid particles in the whole blood. Because these two components were different in density and responsiveness to pressure, erythrocytes were enriched at the pressure node (along the center of the channel) and lipid particles were gathered at the pressure antinodes (along the side walls). Finally, the erythrocytes and lipid microemboli separated into different branches at the end of the main channel. Because of the variety of different properties by which cells of interest need to be sorted, it is important to develop multiple modes of cell sorting. Reviews about microfluidic cell analysis and sorting devices can be found elsewhere (130,131).

Filtration. Microfabrication techniques have been developed to integrate filters and membranes inside microbioreactors. Zhao et al. (132) and Hisamoto et al. (133) successfully produced semipermeable nylon membranes inside microfluidic channels, by taking advantage of laminar flow so that a polymerization reaction would occur at the liquid interface of the two flows and produce a thin membrane in predetermined areas of a microfluidic device.

Components For Monitoring And Control

A key requirement for microbioreactors is the ability to measure parameters, such as temperature, dissolved oxygen, pH, and flow rate. For systems involving cells, mass balances are even more complex than with enzyme bioreactors because of the larger number of products and byproducts produced and the complex responses of cells to the changes in material concentrations. In small volumes, it is difficult or impossible to use standard, macroscopic, industrial probes. Miniaturized sensors must be developed (17). Sensors that do not consume the analytes are also preferred to avoid depletion and also because sample extraction is hard to achieve in closed and compact microsystems without disrupting the devices.

Optical, electrochemical, and thin-film solid-state conductivity are the three main categories of microsensing schemes. Many of the most useful microdetection schemes are based on optical measurements such as fluorescence intensity (134), fluorescence lifetime, chemiluminescence (135), and bioluminescence (136). Optical sensing is convenient because molecular or nanoscale ‘‘sensors’’ are simple to introduce inside microchannels and readout can be detected from a distance without direct external contacts. In addition, many optical probes can sense without con-

MICROBIOREACTORS 391

suming oxygen or perturbing pH. Nonperturbing sensors are important for maintaining a constant microenvironment because the quantities of chemicals are small in microbioreactors. Bioluminescence and chemiluminescence are sensitive with the detection limits down to 10 18–10 21 mol, which offers great advantage over other spectroscopic-based detection mechanisms. Laser-induced fluorescence detections in microsystems have been reviewed by Johnson and Landers (137). Other optical detection methods for microfluidic systems have been reviewed by Mogensen et al. (138).

Sol–gel-based probes encapsulated by biologically localized embedding (PEBBLEs) allow real-time measurement of molecular oxygen, pH, and ions inside and around living cells (139). Kostov et al. (17) used an optical sensing system integrated with semiconductor light sources and detectors to perform continuous measurements of pH, optical density, and dissolved oxygen in miniature bioreactors. A drawback of optical sensing is the need for light sources, lenses for focusing, and detectors, which are more challenging to miniaturize compared to the sensor probes themselves. A useful solution is to use optical fiber-based systems, which allows decoupling of the probes from the light sources and detectors, and enables detection at sites inaccessible by conventional spectroscopic sensors (140). Compared with silicon micromachining techniques, the fabrication and integration of polymeric optical elements (waveguides, lenses and fiber-to-waveguide couplers) with microfluidic channels are fast and simple (141). An oxygensensitive fluorescent dye has been developed to monitor dissolved oxygen levels in a system. This provides advantages over electrochemically based sensors [for a review, see Ref. 142] due to their size, ease of fabrication, and sensitivity (141).

Electronic microsensor is another category that contains a large number of useful biochemical detectors (143). Electronic microsensors usually require direct hard wiring of sensors to a readout system but can be easier to multiplex and are often smaller overall compared to optical systems. For example, Walther et al. (144) integrated a pHISFET (ion-sensitive field-effect transistor), a tempera- ture-sensitive diode, and a thin-film platinum redox electrode on a single chip. The chip is mounted on a carrier and inserted into the chamber to monitor various biological parameters such as pH and redox potential. Brown and coworkers developed polymer membrane-based solid-state sensors to measure pH, and ions (145).

Microfabricated ultrasensitive nanocalorimeters can measure heat generation to monitor cell metabolic activity in response to agonist and antagonist using as few as 10 cells and without prior knowledge of the mode of action of these drugs. This measurement is noninvasive and quantitative and is envisioned to be useful for pharmaceutical companies to find drug candidate (146).

Li et al. (147) developed a microfabricated acoustic wave sensor to measure the stiffness of a single cell. This sensor is promising for drug screening and toxicology studies. For example, the acoustic wave sensor is envisioned to measure the rigidity of a heart cell to distinguish the effect of positive and negative ionotropic drugs. Positive ionotropic drugs are useful for treating congestive heart failure and

392 MICROBIOREACTORS

negative ionotrpic drugs for hypertension. The acoustic wave sensor is also interesting for single cell muscle physiology.

Cells themselves can be used to sense and amplify biological signals. Several groups have developed histamine sensors by integrating cells on microfluidic devices (148,149). This chip-based detector caters to the need for a simple, rapid, and safe method for allergy identification. Cells can be engineered to have a variety of biological recognition events coupled to reporter genes to specifically sense analytes of interest (150).

Some new exciting prospects for future biosensors are in the area of nanotechnology. For example, quantum dots (151) and nanoscale PEBBLES (139) are extending the limits of sensitivity, stability, biocompatibility, and flexibility in optical sensing. Quantum dots are small semiconductor nanocrystals (on the order of nanometers to a few micrometers). Fluorescent quantum dots are able to detect biological species by fluorescing only when coming in contact with viable cells, making them useful probes for many types of labeling studies. These quantum dots are photobleached very slowly and can be manufactured to emit a wide range of wavelengths. They can be used in cell biology for the labeling of cellular structures, tracking the fate of individual cells, or as contrast agents (152). Nano- wire-based sensors with their small size and higher sensitivity would also be ideal for integration into microbioreactors (153). Many microsensors have been developed and are ready for integration into microbioreactors.

Fabrication

A variety of methods and types of substrates are available for microfabrication. The most traditional and widely used method of microfabrication is photolithography. Originally developed for the microelectronics industry, photolithography is precise, highly reproducible, and capable of mass production. Photolithography uses patterns of UV light coming through a photomask to area-selectively induce chemical reactions in a polymeric, light-sensitive photoresist coated onto a semiconductor substrate. During development, the light exposed regions of the photoresist are selectively removed or selectively left behind generating micropatterned photoresist structure. The exposed areas of the substrate are then chemically etched to provide features of various depths and shapes.

Due to the high equipment costs involved in photolithography and because silicon and glass substrates used in electronic and mechanical devices are not necessarily the best materials for biological applications, alternative types of microfabrication have been developed. A cost-effective and experimentally straightforward method called soft lithography has been particularly useful for biological applications (2,53). Soft lithography uses elastomeric materials, such as PDMS to create microstructures, and to pattern and manipulate surfaces. The process involves casting PDMS against a photolithographically defined master mold to yield a polymeric replica. The PDMS replica is then sealed against another material to form channels and reservoirs. Alternatively, the replica can be used in a

technique called microcontact printing, where the PDMS mold is used as a stamp to transfer protein or molecular ink to a substrate. The PDMS has several properties, which make it useful for biological applications: (1) biocompatibility allows cell culture on and inside PDMS structures,

(2) optical transparency allows optical inspection and sensing, (3) gas permeability allows long-term growth of cells without depletion of oxygen, (4) flexibility allows cell cultured on PDMS to be mechanically stretched (2,50,53).

Other polymer based microfabrication techniques include hot embossing, injection molding, and laser ablation. A hot embossing technique called nano-imprint lithography developed by Chou et al. (154) has the ability to fabricate sub-10 nm nanometer features. This process creates nanostructures in a resist by deforming the resist shape with embossing (155). Moriguchi et al. (156) developed a unique photothermal microfabrication technique, where agar microchamber arrays with living cells inside them can be remolded in situ during cell cultivation.

Integration

The development of a microbioreactor requires assembling multiple functional units (for electronic, mechanical, biological, and chemical processing) into a compact device. Integration and packaging poses a whole new challenge on top of the challenges to develop individual components. With macroscopic bioreactors, it is relatively straightforward to connect different components together with little or no worries of space organization. As one scales down, the placement of components must be performed strategically as the room around the reactor chamber decreases dramatically (because volume scales as length cubed, a 10 time reduction in linear dimensions, e.g., will lead to a 1000 time reduction in the available space). There are also technical challenges to fabricate microscale fittings and connectors, or to join two components via connectors even if they could be fabricated. A variety of processes used to build integrated circuits and microelectromechanical systems have played a major role in fabricating integrated microfluidic systems and microbioreactors. These technologies, known collectively as micromachinging, selectively etch away or deposit structural layers on silicone wafers.

Recent efforts to reduce costs, enhance material biocompatibility, and needs for diverse chemical and mechanical properties have also led to the use of a wide variety of polymeric materials in microfabricated devices. Integration, unless planned carefully, can lead to material incompatibilities in fabrication or operation. Notable accomplishments of integrated microfluidic systems include DNA analysis chips (78,157), pneumatically driven microfluidic cell sorters and protein recrystallization chips (77,119,158,159), portable cell-based biosensor systems (160), microfermentors with integrated sensors (17,20,21), and a computerized microfluidic cell culture system actuated using the pins of a refreshable Braille display (84). Integrating fluid control components for cell-culture microbioreactors is rapidly progressing, but still underdeveloped. Interested readers are referred to recent review articles on integrated microfluidic devices (161).

SPECIFIC EXAMPLES OF MICROBIOREACTORS

This section presents select examples of microbioreactors. The examples are not exhaustive, but are meant to show representative examples in each of the following four categories: (1) microbioreactors that are used to optimize bioproduction, (2) microbioreactors that provide cells with physiological microenvironments to more accurately predict physiological drug kinetics and toxicity, (3) microbioreactors that are used to develop cell-based therapies, and

(4) microbioreactors for mechanistic studies. Because the field is still young, the devices are relatively simple and many are still prototypes rather than refined products ready for real world applications. The rapid advances, however, promise an increasing role of microbioreactors in the clinic, laboratory, and at home or other points of need.

Microbioreactors For Optimizing Production Conditions

With the development of microtechnologies, more and more bioprocess optimization is performed in small volume bioreactors with integrated detection systems. For example, Rao and co-workers (17) have demonstrated parallel fermentations of E. coli. in a milliliter-size microbioreactor. A smaller, microliter-size fermentor has been developed recently by the Jensen’s group (20). The performances of these microbioreactors are comparable to traditional liter-size fermentors: Measurements of pH, dissolved oxygen (DO) and optical density (OD) of biomass in these microbioreactors have similar profiles as those in benchtop fermentors. Similarities in cellular metabolism and growth show the potential of using microbioreactors for bioprocess optimization. Arrays of microfermentors with integrated sensors and actuators are envisioned to drastically reduce the cost and time for developing new bioprocesses.

Microbioreactors For Toxicological And Drug Testing

Drugs need to be tested for toxicity and efficacy before administration to humans. Accurate prediction, however, is a challenge because most current drug tests are performed only on human cells or animals. Animal tests are expensive and time consuming, and efficacy of a drug obtained from an animal surrogate study can still be difficult to extrapolate to humans (162). Even when one uses human cells for analysis, the result may be totally different from what occurs physiologically because cells cultured in flasks or dishes experience a totally different microenvironment. Therefore, a microscale human surrogate with microcirculatory systems, threedimensional (3D) tissue organizations, and appropriate cell–cell and tissue–tissue interactions would be beneficial in predicting human responses to drug treatment more precisely. Below are two notable examples of such efforts.

Bioartificial Livers. There are two major applications for which artificial livers are developed: one is to replace organ functions in patients with liver failure, and the other is to perform toxicology testing of drug candidates. Organ repla-

MICROBIOREACTORS 393

cement functions require large bioartificial livers (BALs), whereas the toxicology studies would benefit from microscale BALs capable of conducting high throughput analyses. Microscale BALs are promising as convenient and low cost in vitro models for screening drug toxicities particularly in light of the fact that approximately one-half of all drug toxicities involve the liver.

Liver failure is the seventh leading cause of death by disease in the United States. About 26, 000 people died each year because of liver failure. Transplantation is limited by the supply of donor organs and the cost of the surgery (163). Extracorporeal BAL devices have been proposed as substitutes for transplantation. Macroscopic BALs have been tested in clinical trials (164). In an attempt to maximize the efficacy of the BALs, and to develop in vitro liver systems for biological and toxicological studies, several groups have microfabricated liver cell culture systems (165).

Microbioreactors for liver cell cultures have several configurations, ranging from flat-plate (163) or matrixsandwiched monolayer designs (166) to 3D perfusion cultures (165). A flat-plate microbioreactor with an oxygen permeable membrane was shown to support viability and synthetic functions of hepatocytes cocultured with 3T3-J2 fibroblasts (163). This microchannel bioreactor was also functional when connected extracorporeally to a rat (162). The results indicate that this device can potentially be used as a liver support device and for the eventual scale-up to clinical devices. Compared with other configurations, monolayer designs excel in mass transfer, easy fabrication, and easy optical analysis of cells (165), although cells might be damaged by exposure to shear stress (167). Griffith and co-workers (165) developed an array of microbioreactors (with each channel 300 300 230 mm, L W H in dimension) that support 3D culture of liver cells by perfusion. Liver cells cultured in this device showed viable tissue structures and tight junctions, glycogen storage, and bile canaliculi. Membrane-based 3D perfusion hepatocyte culture systems have also been developed (66).

Micro CCA. It is important to integrate cells from different tissues together to simulate physiological drug metabolism. Shuler and co-workers developed Cell Culture Analogs (CCAs) that combine mathematical pharmacokinetics models with cell culture-based experimental studies to mimic human responses. The CCAs have compartmentalized cell cultures representing different tissues. Interconnections between these compartments allow circulation of media and metabolites. Since the CCAs mimic the time-dependent exposure and the metabolic interaction between multiple types of tissues and cells, predictions from the CCAs may be more accurate compared to existing in vitro models. Shuler and coworkers proved the concept of CCA with a macroscopic three-compartment (liver, lung, and other tissues) system and showed the feasibility and potential usefulness of such devices in testing naphthalene toxicity (168,169). MicroCCAs with three (liver, lung, and other tissues) and four (liver, lung, fat, and other tissues) compartments have also been reported (170,171).

394 MICROBIOREACTORS

Microbioreactors For Therapeutical Applications

Microfluidic Systems As Assisted Reproductive Technologies. Microdevices provide unique platforms for artificial reproduction and may ultimately increase the efficiency, safety, and cost-effectiveness of in vitro fertilization procedures. Currently, many embryo experiments are performed in macroscopic culture dishes, where human or animal oocytes (eggs) and embryos are manipulated manually. Use of pipettes for cellular manipulations is labor intensive and low in accuracy, reproducibility, and efficiency. In addition, the practice of transferring embryos from one type of media into another is abrupt and may shock the embryo due to the sudden change of environment (172–174); inside the female tract, the supply of nutrients, growth factors, and hormones changes gradually as the embryo development progresses. An alternative to manual pipetting is the use of microfluidic channels. Microfluidics is ideal for use in artificial reproduction, because it is a procedure that occurs physiologically inside small tubes and ducts, the size and numbers of cells (oocytes, sperms) required match well with dimensions of microsystems.

Beebe et al. (175) demonstrated manipulations of embryos and oocytes within microfluidic channels. The microfluidic systems can transport single mouse embryos through a channel network (176), remove the zona pellucida by chemical treatment (177), remove cumulus cells from oocytes via mechanical suction (178), and culture embryos in static or dynamic fluid environments (179). In some cases, embryos cultured in microfluidic channels develop faster compared to embryo grown in culture dishes and with growth kinetics that are closer to what is observed in vivo.

Cho et al. (125) developed a Microscale Integrated Sperm Sorter (MISS) that isolates motile sperms based on the ability of the motile sperms, but not the nonmotile ones, to cross-laminar flow streamlines. The device allows small volume samples that are difficult to handle with conventional sperm-sorting techniques to be sorted efficiently using a mild biomimetic sorting mechanism. The MISS integrates power source, sample injection ports, and sorting channel into one disposable polymer device making the device potentially useful not only clinically, but also as an at-home male infertility test (180).

Implantable Microcapsules. Microbioreactors that produce and release natural or recombinant bioagents are useful for delivering therapeutic agents in vivo to enhance metabolic function (181) or treat neurological disorders (182) and cancers (183,184). Mammalian cells, plant cells, microorganisms, enzymes, and biochemical compounds have been encapsulated in a variety of semipermeable containers mainly made of synthetic and natural hydrogels (e.g., poly(vinyl alchohol), poly(hydroxyl ethyl methacrylate), calcium alginate k-carrageenan, chitosan, collagen, and gelatin). Here we focus on the application of microencapsulated mammalian cells. The outer membranes of the microspheres encapsulating the cells serve as selective barriers that allow exchange of nutrients, wastes, and therapeutic agents but block the passage of encapsulated cells as well as macromolecular components of the immune

system. This approach has been effective in delivering genetically engineered cells that secrete growth hormone to partially correct growth retardation (185), recombinant human bone morphogenetic protein-2 (rhBMP-2) to induce bone formation and regeneration (186), interleukin-2 to delay tumor progression and prolong survival (187), coagulation factor IX for treatment of hemophilia B (188), dopamine to treat Parkinson’s disease (182), insulin to maintain blood glucose level (189), and analgesic substances to relief pain (190). Most of these works are aided by using murine and canine models. Some of the most advanced systems are in early clinical trials. Biocompatibility (191,192) mechanical stability of the capsule material (193–195), efficacy (196), safety (197), and cost are still under evaluation and optimization. Reviews of therapeutic uses of microencapsulated genetically engineered cells can be found elsewhere (198).

Microbioreactors For Understanding Biological Responses

Use Of Multiple Laminar Streams To Study Subcellular Biology And Chemotaxis. Physiological cell environments are heterogeneous with local production and consumption of key growth factors, nutrients, and signaling molecules. Microfluidic systems are useful for mimicking such micropatterns of chemicals around cells. A particularly simple and useful method is to take advantage of small channel dimensions to generate multiple laminar streams that flow in parallel and adjacent to each other inside the same microchannel with minimum mixing (Fig. 3d). Such techniques can be even used to treat different parts of single living cells with different small molecular drugs, proteins, and small particles such as low density lipoprotein (LDL) (88).

Cancer and normal cells receive similar local stimuli inside the body, but behave totally differently. A critical question is why these differences arise. Taking advantage of multiple laminar flows to perform subcellular epidermal growth factor (EGF) stimulation, Sawano et al. (92) revealed differences in signal propagation between carcinoma and normal cells in response to local EGF stimulation.

Many cells direct their motion in response to chemical gradients. This phenomenon, called chemotaxis, protects microorganisms by allowing them to move toward more favorable conditions. In mammals, chemotaxis is important for guiding cell migration during development, embryogenesis, cancer metastasis, and inflammation. A challenge for analyzing chemotaxis is the lack of methods to generate well-defined chemical gradients that are stable and do not change with time. This difficulty arises due to the diffusivity of molecules and resulting changes of concentration profiles over time. Jeon et al. (90) demonstrated the use of microfluidic systems with branched networks of channels to generate stable gradients of interleukin-8 (IL-8) with linear, parabolic, and periodic concentration profiles. The position and shape of the concentration gradients were controlled by adjusting the flow rates and the positions to which reagent of interest were added into the channel network (89,199). The well-defined gradients allowed straightforward quantification of chemotaxis

coefficients as well as to observe complex migration behaviors of leukocytes in response to different concentration gradient profiles.

Studies Of Vascular Diseases In Microfluidic Channels.

The mechanical forces that accompany blood flow and pressure fluctuation influence vascular cellular biology and pathology in many ways. As the blood flow along a vessel, the viscous drag forces constantly expose endothelial cells (ECs) to shear stress. The pulsatility of the blood flow also induces a periodic change of circumferential strain on ECs and their underlying smooth muscle cells (SMCs). These mechanical forces have been found to cause important biological changes in endothelial cell morphology and function, such as alignment and elongation (30,200), low density lipoprotein uptake (201), tissue plasminogen activator synthesis and secretion (202), and proliferation (67). There has also been studies about the combined effect of shear stress and cyclic strain on ECs (203–205) and SMCs (206–208). While much has been revealed about the alterations in EC function induced by mechanical stresses, relatively little is known about the mechanism mechanical signaling.

Capillary-size microfluidic channels were used to model malaria, a potentially vital disease caused by loss of deformability of red blood cells due to P. falciparum parasites infection. Erythrocytes exhibited increased rigidity and decreased deformability with the progression of the disease, as demonstrated by their increased difficulties to transverse through 2 to 8 mm wide PDMS channels. This type of microfluidic system may potentially be useful to screen antimalaria drugs (209).

CONCLUSION AND FUTURE PROSPECTS

The convergence of bioreactors with advances in microtechnology is starting an exciting revolution in medicine. With microfabrication technologies, many copies of a device can be generated and operated with quick procedures and reduced cost. The ability to perform parallel assays allows high throughput optimization of bioprocess conditions, opening the way for cost-efficient biopharmaceuticals production.

Humans and other living organisms are inherently microscopic in their essence, being comprised of networks of microscopic reactors (i.e., the cells), and interconnected by microfluidic vasculatures. Efforts to miniaturize bioreactors would lead to not only the development of smaller pharmaceutical production and screening systems, but also the construction of more physiological in vitro cell culture systems where the ultimate goal is to develop microbioreactors as animal or human surrogates. Even for cullture of single cell types, the ability of microfluidic systems to simulate physiological microenvironments is useful for revealing disease mechanisms, drug testing, use as biosensors, and single-cell-based clinical procedures such as in vitro fertilization. More complex microbioreactor systems with multiple cell types are being developed for toxicology studies. So-called animals-on-a-chip or minihumans provides exciting prospects for efficient drug discovery and personalized medicine.

MICROBIOREACTORS 395

Current state-of-the-art microbioreactors are still relatively simple with few components and limited sensing and control. Many are highly specialized and nonroutine in their use. The overall footprints of the systems are also often still macroscopic. Current advances in microand nanotechnologies as well as in medicine, however, promise rapid improvements in performance, accessibility, and sophistication of microbioreactors. Current trends point to a future where the gap between manmade devices and living organisms will narrow and applications of microbioreactors to medicine will grow.

ACKNOWLEDGMENTS

We thank the Whitaker Foundation, National Science Foundation (BES-0238625, DMI-0403603), National Institutes of Health (EB00379-01, HD049607-01), NASA (NNC04AA21A), and the U.S. Army Research Laboratory and the U.S. Army Research Office under contract/grant number DAAD19-03-1-0168 for financial support. We thank G. D. Smith, S. C. Chang, H. Chen, P.Y. Choi, B. H. Chueh, T. Kable, E. O. Kass, K. Ke, J.H. Kim, S. M. K. Lau, E.C. Lee, W.H. Lee, S.R. Mandal, J.A. Miller, Y. Murgha, S.O. Charoen, A.B. Ozel, S.J. Segvich, P.D. Settimi, D. Sud, B. Teply, M. Zhang, C. Zhong for assistance.

BIBLIOGRAPHY

1.Walker GM, Zeringue HC, Beebe DJ. Microenvironment design considerations for cellular scale studies. Lab Chip 2004;4:91–97.

2.Shim J, et al. Microand nanotechnologies for studying cellular function. Curr Top Med Chem 2003;3:687–703.

3.Bhadriraju K, Chen CS. Engineering cellular microenvironments to cell-based drug testing improve. Drug Discov Today 2002;7:612–620.

4.Desai TA, et al. Microfabricated immunoisolating biocapsules. Biotechnol Bioeng 1998;57:118–120.

5.Krenkova J, Foret F. Immobilized microfluidic enzymatic reactors. Electrophoresis 2004;25:3550–3563.

6.Madou MJ. Fundamentals of Microfabrication. Boca Raton (FL): CRC Press; 2002.

7.Tabeling P, et al. Chaotic mixing in cross-channel micromixers. Philos Trans R Soc London Ser A-Math Phys Eng Sci 2004;362:987–1000.

8.Stremler MA, Haselton FR, Aref H. Designing for chaos: Applications of chaotic advection at the microscale. Philos. Trans R Soc Lond Ser A-Math Phys Eng Sci 2004;362:1019–1036.