mls94-complete[1]

.pdf

Figure 1.2: The Cincinnati Milacron T 3 (The Tomorrow Tool) robot. (Courtesy of Cincinnati Milacron)

opment of Computer Numerically Controlled (CNC) machine tools for accurate milling of low-volume, high-performance aircraft parts. The first robots, developed by George Devol in 1954, replaced the master manipulator of the teleoperator with the programmability of the CNC machine tool controller. He called the device a “programmed articulated transfer device.” The patent rights were bought by a Columbia University student, Joseph Engelberger, who later founded a company called Unimation in Connecticut in 1956. Unimation installed its first robot in a General Motors plant in 1961. The key innovation here was the “programmability” of the machine: it could be retooled and reprogrammed at relatively low cost so as to enable it to perform a wide variety of tasks. The mechanical construction of the Unimation robot arm represented a departure from conventional machine design in that it used an open kinematic chain: that is to say, it had a cantilevered beam structure with many degrees of freedom. This enabled the robot to access a large workspace relative to the space occupied by the robot itself, but it created a number of problems for the design since it is di cult to accurately control the end point of a cantilevered arm and also to regulate its sti - ness. Moreover, errors at the base of the kinematic chain tended to get amplified further out in the chain. To alleviate this problem, hydraulic actuators capable of both high power and generally high precision were

3

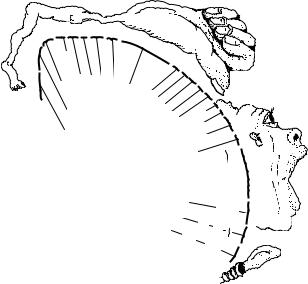

Figure 1.3: The Unimation PUMA (Programmable Universal Manipulator for Assembly). (Courtesy of St¨aubli Unimation, Inc.)

used for the joint actuators.

The flexibility of the newly introduced robots was quickly seen to be enhanced through sensory feedback. To this end, Ernst in 1962 developed a robot with force sensing which enabled it to stack blocks. To our knowledge, this system was the first that involved a robot interacting with an unstructured environment and led to the creation of the Project MAC (Man And Computer) at MIT. Tomovic and Boni developed a pressure sensor for the robot which enabled it to squeeze on a grasped object and then develop one of two di erent grasp patterns. At about the same time, a binary robot vision system which enabled the robot to respond to obstacles in its environment was developed by McCarthy and colleagues in 1963. Many other kinematic models for robot arms, such as the Stanford manipulator, the Boston arm, the AMF (American Machine and Foundry) arm, and the Edinburgh arm, were also introduced around this time. Another novel robot of the period was a walking robot developed by General Electric for the Army in 1969. Robots that responded to voice commands and stacked randomly scattered blocks were developed at Stanford and other places. Robots made their appearance in Japan through Kawasaki’s acquisition of a license from Unimation in 1968.

4

Figure 1.4: The AdeptOne robot. (Courtesy of Adept Technology, Inc.)

Figure 1.5: The CMU DD Arm I. (Courtesy of M.J. Dowling)

5

Figure 1.6: The Odex I six-legged walking robot. (Photo courtesy of Odetics, Inc.)

In 1973, the first language for programming robot motion, called WAVE, was developed at Stanford to enable commanding a robot with high-level commands. About the same time, in 1974, the machine tool manufacturer Cincinnati Milacron, Inc. introduced its first computercontrolled manipulator, called The Tomorrow Tool (T 3), which could lift a 100 pound load as well as track moving objects on an assembly line. Later in the seventies, Paul and Bolles showed how a Stanford arm could assemble water pumps, and Will and Grossman endowed a robot with touch and force sensors to assemble a twenty part typewriter. At roughly the same time, a group at the Draper Laboratories put together a Remote Center Compliance (RCC) device for part insertion in assembly.

In 1978, Unimation introduced a robot named the Programmable Universal Machine for Assembly (PUMA), based on a General Motors study. Bejczy at Jet Propulsion Laboratory began a program of teleoperation for space-based manipulators in the mid-seventies. In 1979, the SCARA (Selective Compliant Articulated Robot for Assembly) was introduced in Japan and then in the United States.

As applications of industrial robots grew, di erent kinds of robots with attendant di erences in their actuation methods were developed.

6

For light-duty applications, electrically powered robots were used both for reasons of relative inexpensiveness and cleanliness. The di culty with electric motors is that they produce their maximum power at relatively high speeds. Consequently, the motors need to be geared down for use. This gear reduction introduces friction, backlash, and expense to the design of the motors. Consequently, the search was on to find a way of driving the robot’s joints directly without the need to gear down its electric motors. In response to this need, a direct drive robot was developed at Carnegie Mellon by Asada in 1981.

In the 1980s, many e orts were made to improve the performance of industrial robots in fine manipulation tasks: active methods using feedback control to improve positioning accuracy and program compliance, and passive methods involving a mechanical redesign of the arm. It is fair to say, however, that the eighties were not a period of great innovation in terms of building new types of robots. The major part of the research was dedicated to an understanding of algorithms for control, trajectory planning, and sensor aggregation of robots. Among the first active control methods developed were e cient recursive Lagrangian and computational schemes for computing the gravity and Coriolis force terms in the dynamics of robots. In parallel with this, there was an e ort in exactly linearizing the dynamics of a multi-joint robot by state feedback, using a technique referred to as computed torque. This approach, while computationally demanding, had the advantage of giving precise bounds on the transient performance of the manipulator. It involved exact cancellation, which in practice had to be done either approximately or adaptively. There were may other projects on developing position/force control strategies for robots in contact with the environment, referred to as hybrid or compliant control. In the search for more accurately controllable robot manipulators, robot links were getting to be lighter and to have harmonic drives, rather than gear trains in their joints. This made for flexible joints and arms, which in turn necessitated the development of new control algorithms for flexible link and flexible joint robots.

The trend in the nineties has been towards robots that are modifiable for di erent assembly operations. One such robot is called Robotworld, manufactured by Automatix, which features several four degree of freedom modules suspended on air bearings from the stator of a Sawyer e ect motor. By attaching di erent end-e ectors to the ends of the modules, the modules can be modified for the assembly task at hand. In the context of robots working in hazardous environments, great strides have been made in the development of mobile robots for planetary exploration, hazardous waste disposal, and agriculture. In addition to the extensive programs in reconfigurable robots and robots for hazardous environments, we feel that the field of robotics is primed today for some large technological advances incorporating developments in sensor and

7

actuator technology at the milliand micro-scales as well as advances in computing and control. We defer a discussion of these prospects for robotics to Chapter 9.

2Multifingered Hands and Dextrous Manipulation

The vast majority of robots in operation today consist of six joints which are either rotary (articulated) or sliding (prismatic), with a simple “end- e ector” for interacting with the workpieces. The applications range from pick and place operations, to moving cameras and other inspection equipment, to performing delicate assembly tasks involving mating parts. This is certainly nowhere near as fancy as the stu of early science fiction, but is useful in such diverse arenas such as welding, painting, transportation of materials, assembly of printed circuit boards, and repair and inspection in hazardous environments.

The term hand or end-e ector is used to describe the interface between the manipulator (arm) and the environment, out of anthropomorphic intent. The vast majority of hands are simple: grippers (either twoor three-jaw), pincers, tongs, or in some cases remote compliance devices. Most of these end-e ectors are designed on an ad hoc basis to perform specific tasks with specific parts. For example, they may have suction cups for lifting glass which are not suitable for machined parts, or jaws operated by compressed air for holding metallic parts but not suitable for handling fragile plastic parts. Further, a di culty that is commonly encountered in applications is the clumsiness of a six degree of freedom robot equipped only with these simple hands. The clumsiness manifests itself in:

1.A lack of dexterity. Simple grippers enable the robot to hold parts securely but they cannot manipulate the grasped object.

2.A limited number of possible grasps resulting in the need to change end-e ectors frequently for di erent tasks.

3.Large motions of the arm are sometimes needed for even small motions of the end-e ector. Since the motors of the robot arm are progressively larger away from the end-e ector, the motion of the earliest motors is slow and ine cient.

4.A lack of fine force control which limits assembly tasks to the most rudimentary ones.

A multifingered or articulated hand o ers some solutions to the problem of endowing a robot with dexterity and versatility. The ability of a

8

Hip |

|

Knee |

Trunk |

Ankle |

|

Toes |

|

Shoulder

Elbow

Wrist |

Hand |

Little |

|

|

|

|

Ring |

|

|

|

|

Middle |

Neck |

|

|

|

Index |

|

|

|

|

|

|

|

|

|

Thumb |

|

|

Fingers |

|

Brow |

|

|

and |

eyeball |

] |

||

|

|

|

||

|

|

Face |

|

|

|

Eyelid |

n |

||

|

|

|||

|

|

|

Lips |

o |

|

|

|

i |

|

|

|

|

|

t |

|

|

|

|

a |

|

|

|

|

z |

|

|

Jaw |

i |

|

|

|

n a |

||

|

|

|

|

]l |

Tongue |

|

|

|

] |

|

t |

|

|

Swallowing |

|

|

|

|

|

|

o c |

|

|

|

|

n |

|

|

i |

o |

|

|

|

|

|

|

|

a |

||

|

|

|

io |

|

|

V |

||

|

|

|

|

|

|

v |

|

|

|

|

t |

|

|

i |

|

||

|

|

a |

|

|

|

l |

|

|

|

|

ic |

|

|

|

S |

a |

[ |

a |

t |

|

|

|

|

|||

|

|

|

|

|

||||

[M |

s |

|

|

[ |

|

|

||

|

|

|

|

|

|

|||

Medial |

Lateral |

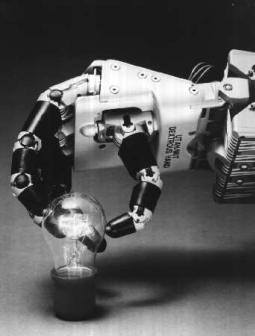

Figure 1.7: Homunculus diagram of the motor cortex. (Reprinted, by permission, from Kandel, Schwartz, and Jessel, Principles of Neural Science, Third Edition [Appleton and Lange, Norwalk, CT, 1991]. Adapted from Penfield and Rasmussen, The Cerebral Cortex of Man: A Clinical Study of Localization of Function [Macmillan, 1950])

multifingered hand to reconfigure itself for performing a variety of di erent grasps reduces the need for changing end-e ectors. The large number of lightweight actuators associated with the degrees of freedom of the hand allows for fast, precise, and energy-e cient motions of the object held in the hand. Fine motion force-control at a high bandwidth is also facilitated for similar reasons. Indeed, multifingered hands are a truly anthropomorphically motivated concept for dextrous manipulation: we use our arms to position our hands in a given region of space and then use our wrists and fingers to interact in a detailed and intricate way with the environment. We preform our fingers into grasps which pinch, encircle, or immobilize objects, changing grasps as a consequence of these actions. One measure of the intelligence of a member of the mammalian family is the fraction of its motor cortex dedicated to the control of its hands. This fraction is discerned by painstaking mapping of the body on the motor cortex by neurophysiologists, yielding a homunculus of the kind shown in Figure 1.7. For humans, the largest fraction (30–40%) of

9

Figure 1.8: The Utah/MIT hand. (Photo courtesy of Sarcos, Inc.)

the motor cortex is dedicated to the control of the hands, as compared with 20–30% for most monkeys and under 10% for dogs and cats.

From a historical point of view, the first uses of multifingered hands were in prosthetic devices to replace lost limbs. Childress [18] refers to a device from 1509 made for a knight, von Berlichingen, who had lost his hand in battle at an early age. This spring-loaded device was useful in battle but was unfortunately not handy enough for everyday functions. After the Berlichingen hand, numerous other hand designs have been made from 1509 to the current time. Several of these hands are still available today; some are passive (using springs), others are bodypowered (using arm flexion control or shrug control). Some of the hands had the facility for voluntary closure and others involuntary closure. Childress classifies the hands into the following four types:

1.Cosmetic. These hands have no real movement and cannot be activated, but they can be used for pushing or as an opposition element for the other hand.

2.Passive. These hands need the manual manipulation of the other (non-prosthetic) hand to adjust the grasping of the hand. These were the earliest hands, including the Berlichingen hand.

10

Figure 1.9: The Salisbury Hand, designed by Kenneth Salisbury. (Photo courtesy of David Lampe, MIT)

3.Body powered. These hands use motions of the body to activate the hand. Two of the most common schemes involve pulling a cable when the arm is moved forward (arm-flexion control) or pulling the cable when the shoulders are rounded (shrug control). Indeed, one frequently observes these hands operated by an amputee using shrugs and other such motions of her upper arm joints.

4.Externally powered. These hands obtain their energy from a storage source such as a battery or compressed gas. These are yet to displace the body-powered hands in prostheses.

Powered hand mechanisms came into vogue after 1920, but the greatest usage of these devices has been only since the 1960s. The Belgrade hand, developed by Tomovi´c and Boni [113], was originally developed for Yugoslav veterans who had lost their arms to typhus. Other hands were invented as limb replacements for “thalidomide babies.” There has been a succession of myoelectrically controlled devices for prostheses culminating in some advanced devices at the University of Utah [44], developed mainly for grasping objects. While these devices are quite remarkable mechanisms, it is fair to say that their dexterity arises from the visionguided feedback training of the wearer, rather than any feedback mechanisms inherent in the device per se.

As in the historical evolution of robots, teleoperation in hazardous or hard to access environments—such as nuclear, underwater, space, mining,

11

Figure 1.10: Styx, a two-fingered planar hand built at UC Berkeley in 1988.

and, recently, surgical environments—has provided a large impetus for the development of dextrous multifingered hands. These devices enable the operator to perform simple manipulations with her hands in a remote environment and have the commands be relayed to a remote multifingered manipulator. In the instance of surgery, the remote manipulator is a surgical device located inside the body of the patient.

There have been many attempts to devise multifingered hands for research use which are somewhere between teleoperation, prosthesis, and dextrous end-e ectors. These hands truly represent our dual point of view in terms of jumping back and forth from an anthropomorphic point of view (mimicking our own hands) to the point of view of intelligent end-e ectors (for endowing our robots with greater dexterity). Some examples of research on multifingered hands can be found in the work of Skinner [106], Okada [84], and Hanafusa and Asada [39]. The Okada hand was a three-fingered cable-driven hand which accomplished tasks such as attaching a nut to a bolt. Hanafusa and Asada’s hand has three elastic fingers driven by a single motor with three claws for stably grasping several oddly shaped objects.

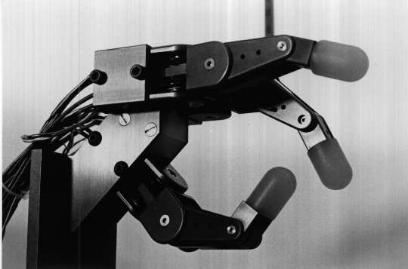

Later multifingered hands include the Salisbury Hand (also known as the Stanford/JPL hand) [69], the Utah/MIT hand [44], the NYU hand [24], and the research hand Styx [76]. The Salisbury hand is a three-fingered hand; each finger has three degrees of freedom and the joints are all cable driven. The placement of the fingers consists of one

12