- •HOW TO USE THIS MANUAL

- •TO LOCATE WHAT YOU ARE LOOKING FOR:

- •COMPONENT PARTS AND WORK TO BE DONE

- •SYMBOL

- •ABBREVIATIONS USED IN THIS MANUAL

- •01 GENERAL INFORMATION

- •COUNTRY AND AREA CODES

- •WARNING/CAUTION/NOTE

- •GENERAL PRECAUTIONS

- •SUZUKI GSX-R600K6 (’06-MODEL)

- •SERIAL NUMBER LOCATION

- •FUEL, OIL AND ENGINE COOLANT RECOMMENDATION

- •BREAK-IN PROCEDURES

- •CYLINDER IDENTIFICATION

- •INFORMATION LABELS

- •SPECIFICATIONS

- •02 PERIODIC MAINTENANCE

- •PERIODIC MAINTENANCE SCHEDULE

- •MAINTENANCE AND TUNE-UP PROCEDURES

- •COMPRESSION PRESSURE CHECK

- •SDS CHECK

- •03 ENGINE

- •ENGINE COMPONENTS REMOVABLE WITH ENGINE IN PLACE

- •ENGINE REMOVAL AND INSTALLATION

- •ENGINE DISASSEMBLY

- •ENGINE REASSEMBLY

- •04 FI SYSTEM DIAGNOSIS

- •PRECAUTIONS IN SERVICING

- •FI SYSTEM TECHNICAL FEATURES

- •ECM TERMINAL

- •SELF-DIAGNOSIS FUNCTION

- •FAIL-SAFE FUNCTION

- •FI SYSTEM TROUBLESHOOTING

- •SENSORS

- •05 FUEL SYSTEM AND THROTTLE BODY

- •FUEL DELIVERY SYSTEM

- •FUEL SYSTEM

- •THROTTLE BODY

- •06 EXHAUST SYSTEM

- •EXHAUST SYSTEM

- •EXCVA (EXHAUST CONTROL VALVE ACTUATOR) AND EXCV (EXHAUST CONTROL VALVE)

- •07 COOLING AND LUBRICATION SYSTEM

- •ENGINE COOLANT

- •COOLING CIRCUIT

- •COOLING FAN

- •ECT SENSOR

- •THERMOSTAT

- •WATER PUMP

- •LUBRICATION SYSTEM

- •08 CHASSIS

- •EXTERIOR PARTS

- •FRONT WHEEL

- •FRONT FORK

- •STEERING DAMPER

- •STEERING

- •HANDLEBARS

- •REAR WHEEL

- •REAR SHOCK ABSORBER

- •REAR SUSPENSION

- •FRONT BRAKE

- •REAR BRAKE

- •TIRE AND WHEEL

- •DRIVE CHAIN

- •09 ELECTRICAL SYSTEM

- •CAUTIONS IN SERVICING

- •LOCATION OF ELECTRICAL COMPONENTS

- •CHARGING SYSTEM

- •STARTER SYSTEM AND SIDE-STAND/IGNITION INTERLOCK SYSTEM

- •IGNITION SYSTEM

- •COMBINATION METER

- •LAMPS

- •RELAYS

- •BATTERY

- •10 SERVICING INFORMATION

- •TROUBLESHOOTING

- •WIRING HARNESS, CABLE AND HOSE ROUTING

- •TIGHTENING TORQUE

- •SERVICE DATA

- •11 EMISSION CONTROL INFORMATION

- •EMISSION CONTROL SYSTEMS

- •PAIR (AIR SUPPLY) SYSTEM AND EMISSION CONTROL SYSTEM INSPECTION

- •PAIR (AIR SUPPLY) SYSTEM HOSE ROUTING

- •HO2 SENSOR INSPECTION (For E-02, 19)

- •12 WIRING DIAGRAM

COOLING AND LUBRICATION SYSTEM 7-1

COOLING AND LUBRICATION SYSTEM

CONTENTS

ENGINE COOLANT |

..................................................................................... |

|

|

|

|

|

COOLING CIRCUIT ..................................................................................... |

|

|

|

|

|

|

COOLING CIRCUIT ........................................................INSPECTION |

|

|

|

|||

RADIATOR AND WATER ..............................................................HOSES |

|

|

|

|||

RADIATOR REMOVAL ......................................................................... |

|

|

|

|

||

RADIATOR CAP .............................................................INSPECTION |

|

|

|

|||

RADIATOR INSPECTION .........................................AND CLEANING |

|

|||||

RADIATOR INSTALLATION................................................................. |

|

|

|

|||

WATER HOSE INSPECTION................................................................ |

|

|

|

|||

COOLING FAN............................................................................................. |

|

|

|

|

|

|

REMOVAL ............................................................................................. |

|

|

|

|

|

|

INSPECTION ......................................................................................... |

|

|

|

|

E |

|

INSTALLATION |

|

|

|

|

||

|

|

|

L |

|||

COOLING FAN RELAY INSPECTION |

||||||

|

|

|||||

ECT SENSOR .............................................................................................. |

|

|

P |

|

||

REMOVAL |

|

|

|

|||

|

|

|

|

|

||

INSPECTION ......................................................................................... |

|

M |

|

|

||

INSTALLATION |

|

|

|

|||

A |

|

|

|

|||

THERMOSTAT |

|

|

|

|||

|

|

|

|

|

||

REMOVAL ............................................................................................. |

|

|

|

|

|

|

S |

|

|

|

|

||

INSPECTION .........................................................................................

INSTALLATION.....................................................................................

WATER PUMP .............................................................................................

REMOVAL AND DISASSEMBLY .........................................................

INSPECTION .........................................................................................

REASSEMBLY AND INSTALLATION ..................................................

LUBRICATION SYSTEM .............................................................................

OIL COOLER.........................................................................................

OIL PRESSURE ....................................................................................

OIL FILTER............................................................................................

OIL PRESSURE REGULATOR.............................................................

OIL STRAINER......................................................................................

OIL JET..................................................................................................

OIL PUMP..............................................................................................

OIL PRESSURE SWITCH .....................................................................

ENGINE LUBRICATION SYSTEM CHART ..........................................

ENGINE LUBRICATION SYSTEM........................................................

7- |

2 |

|

|

7- |

3 |

|

|

7- |

3 |

|

|

7- |

4 |

|

|

7- |

4 |

|

|

7- |

4 |

|

|

7- |

4 |

|

|

7- |

5 |

|

|

7- |

5 |

|

|

7- |

6 |

|

|

7- |

6 |

|

|

7- |

6 |

|

|

7- |

6 |

|

|

7- |

7 |

|

|

7- |

7 |

|

|

7- |

7 |

|

|

7- |

7 |

|

7 |

7- |

8 |

|

|

7- |

9 |

|

|

|

|||

7- |

9 |

|

|

7- |

9 |

|

|

7-10 |

|

|

|

7-11 |

|

|

|

7-11 |

|

|

|

7-13 |

|

|

|

7-14 |

|

|

|

7-17 |

|

|

|

7-17 |

|

|

|

7-18 |

|

|

|

7-18 |

|

|

|

7-18 |

|

|

|

7-18 |

|

|

|

7-18 |

|

|

|

7-18 |

|

|

|

7-18 |

|

|

|

7-19 |

|

|

|

7-20 |

|

|

|

|

|

|

|

7-2 COOLING AND LUBRICATION SYSTEM

ENGINE COOLANT

At the time of manufacture, the cooling system is filled with a 50:50 mixture of distilled water and ethylene glycol anti-freeze. This 50:50 mixture will provide the optimum corrosion protection and excellent heat protection, and will protect the cooling system from freezing at temperatures above –31 °C (–24 °F).

If the motorcycle is to be exposed to temperatures below –31 °C (–24 °F), this mixing ratio should be increased up to 55% or 60% according to the figure.

Anti-freeze density |

Freezing point |

|

|

50% |

–30 °C (–24 °F) |

|

|

55% |

–40 °C (–44 °F) |

|

|

60% |

–55 °C (–67 °F) |

|

|

|

|

*Use a high quality ethylene glycol base anti-freeze, mixed with distilled water. Do not mix an alcohol base anti-freeze and different brands of anti-freeze.

*Do not put in 60% and more anti-freeze or 50% and less. (Refer to below figure.)

*Do not use a radiator anti-leak additive.

50% Engine coolant including reserve tank capacity |

|

|

|

|

E |

||||||||||

Anti-freeze |

|

|

1 350 ml (2.9/2.4 US/lmp.pt) |

|

L |

||||||||||

|

|

|

|

|

|

|

|

|

|

||||||

Water |

|

|

|

1 350 ml (2.9/2.4 US/lmp.pt) |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

P |

|

|

|

|

|

|||

|

(˚F) |

(˚C) |

|

|

M |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

32 |

0 |

|

|

|

|

|

(˚F) (˚C) |

|

|

|

(kgf/cm²) |

|||

|

|

|

|

|

|

|

|

|

|||||||

|

14 |

–10 |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

302 150 |

|

|

|

|

|||||

|

–4 |

–20 |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

A |

|

|

284 140 |

|

|

|

|

|

|

|||

|

–22 |

–30 |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|||||

pointFreezing |

|

S |

|

|

pointBoiling |

266 130 |

|

|

|

|

|

|

|||

–40 |

–40 |

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|||||

|

–58 |

–50 |

|

|

|

|

|

248 120 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|||||

|

–76 |

–60 |

|

|

|

|

|

230 110 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

–94 |

–70 |

|

|

|

|

|

212 100 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.5 |

pressure |

|

0.9 |

||

|

||

0.5 |

Gauge |

|

0 |

||

|

20 |

40 |

60 |

80 |

100 |

0 |

10 |

20 |

30 |

40 |

50 |

60 |

|

Density (%) |

|

|

|

Density (%) |

|

|

||||

Fig. 1 Engine coolant density-freezing point curve

Fig. 2 Engine coolant density-boiling point curve

*You can be injured by scalding fluid or steam if you open the radiator cap when the engine is hot. After the engine cools, wrap a thick cloth around cap and carefully remove the cap by turning it a quarter turn to allow pressure to escape and then turn the cap all the way off.

*The engine must be cool before servicing the cooling system.

*Coolant is harmful;

•If it comes in contact with skin or eyes, flush with water.

•If swallowed accidentally, induce vomiting and call physician immediately.

•Keep it away from children.

COOLING AND LUBRICATION SYSTEM 7-3

COOLING CIRCUIT

RESERVOIR |

THERMOSTAT |

CYLINDER HEAD |

ECT SENSOR |

|

TANK |

||||

|

||||

|

|

CYLINDER |

|

|

RADIATOR |

|

|

|

|

|

|

WATER |

|

|

|

|

PUMP |

|

|

|

|

Oil cooler |

|

COOLING CIRCUIT INSPECTION

Before removing the radiator and draining the engine coolant, |

E |

|||||

inspect the cooling circuit for tightness. |

|

|

||||

L |

||||||

• Remove the right under cowling. ( 8-5) |

||||||

|

|

|

|

|||

• Remove the radiator cap 1 and connect the tester 2 to the |

|

|

||||

filler. |

|

P |

|

|

||

M |

|

|

||||

|

|

|

||||

Do not remove the radiator cap when the engine is |

|

|

|

|||

hot. |

A |

|

|

|

|

|

S |

|

|

|

|

||

|

|

|

|

|

||

|

|

|

|

|

|

|

•Give a pressure of about 120 kPa (1.2 kgf/cm², 17 psi) and see if the system holds this pressure for 10 seconds.

•If the pressure should fall during this 10-second interval, it means that there is a leaking point in the system. In such a case, inspect the entire system and replace the leaking component or part.

When removing the radiator cap tester, put a rag on the filler to prevent spouting of engine coolant.

Do not allow the pressure to exceed the radiator cap release pressure, or the radiator can be damaged.

• Remove the under cowlings. ( 8-5)

• Drain the engine coolant. ( 2-17)

• Remove the radiator assembly. ( 3-4)

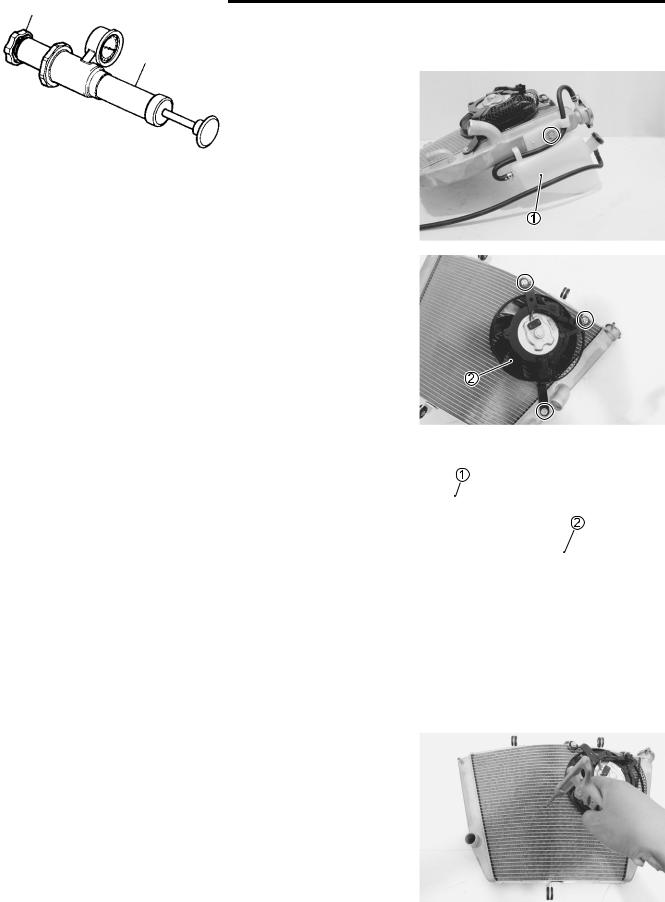

• Remove the reservoir tank 1, cooling fan 2 from the radiator.

|

|

|

E |

|

|

L |

|

RADIATOR CAP INSPECTION |

P |

|

|

• Fit the cap 1 to the radiator cap tester 2. |

|

||

• Build up pressure slowly by operating the tester. ake sure |

|

||

that the pressure build-up stops at 93 – 123MkPa (0.93 – 1.23 |

|

||

kgf/cm2, 13.2 – 17.5 psi) and that, with the tester held stand- |

|

||

|

A |

|

|

still, the cap is capable of holding that pressure for at least 10 |

|

||

seconds. |

S |

|

|

|

|

|

|

• Replace the cap if it is found not to satisfy either of these two |

|

||

requirements. |

|

|

|

Radiator cap valve opening pressure Standard: 108 – 137 kPa

(1.1 – 1.4 kgf/cm2, 15.4 – 19.5 psi)

RADIATOR INSPECTION AND CLEANING

Road dirt or trash stuck on the fins must be removed.

Use of compressed air is recommended for this cleaning.

COOLING AND LUBRICATION SYSTEM 7-5

Fins bent down or dented can be repaired by straightening them with the blade of a small screwdriver.

RADIATOR INSTALLATION

• Install the cooling fan.

Cooling fan mounting bolt: 8 N·m (0.8 kgf-m, 6.0 lb-ft)

•Install the radiator.

•Route the radiator hoses properly. ( 10-24)

•Pour engine coolant. ( 2-17)

•Bleed air from the cooling circuit. ( 2-18)

•Install the under cowlings. ( 8-5)

|

|

E |

|

WATER HOSE INSPECTION |

L |

||

P |

|||

• Remove the under cowlings. ( 8-5) |

|||

• Lift and support the fuel tank. ( 5-3) |

|||

|

|||

Any water hose found in a cracked condition or flattened must |

|||

be replaced. |

M |

||

Any leakage from the connectingAsection should be corrected by |

|||

proper tightening. |

S |

|

|

|

|

||