- •Contents

- •Vocabulary

- •Elements and compounds

- •1.6. Read the following text and say if it is true that interatomic distance is fixed in all states of a metal. Read again to answer the questions after it.

- •Vocabulary

- •Three states of matter

- •1.10. Learn to read the following measurements.

- •1.11. Read out the numbers.

- •1.12. A) Compare the spanners. Make sentences.

- •At the Descriptive Geometry Class

- •Vocabulary

- •Characteristic Features of Some Elements

- •Vocabulary Test

- •Grammar Test

- •Vocabulary

- •Materials science in the past and present

- •2.9. Form nouns from the following words:

- •Vocabulary

- •Engineering materials and their properties (Part I)

- •2.12. Reread the text and rewrite the following according to the model, replacing the words in italics with an expression from the text which has a similar meaning.

- •2.16. Read and translate the following text. Talk about the properties of engineering materials in your own words.

- •Vocabulary

- •Engineering materials and their properties (Part II)

- •Vocabulary Test

- •Grammar Test

- •Unit 3. Metals: properties, classification and crystal structure

- •Read the list of words below and choose the ones related to science of materials:

- •Vocabulary

- •Metals, alloys and their uses

- •3.4. Reading comprehension. Read the text Availability, Properties and Classification of Metals and for questions 1–5 (after the text) choose the best answers from a–d.

- •Vocabulary

- •Availability, properties and classification of metals

- •3.5. Use the questions and talk giving the main ideas of the text above.

- •Vocabulary

- •Metallic crystal structure

- •Vocabulary Test

- •Grammar Test

- •Unit 4. Engineering materials. Iron and ferrous metals

- •4.2. Read the text Iron and Its Properties. Answer the following questions. What new have you learnt from the text?

- •Vocabulary

- •Iron and its properties

- •Vocabulary

- •4.4. Connect the two matching parts of the sentences related to the blast furnace operation.

- •Vocabulary

- •Ferrous metals

- •From the history of steelmaking

- •Alloy steels

- •Grammar and Vocabulary Questionnaire

- •Structural steels for shipbuilding

- •Vocabulary Test

- •Grammar Test

- •4.17. Just for fun.

- •4.18. Read the text and agree and disagree with the statements after it.

- •4.19. In the above text, find the English equivalents for the following words and word combinations:

- •4.20. Read the text and write a list of titanium and its alloys qualities that make titanium different from other metals. A wonder metal

- •Long-term corrosion protection for hulls and water jets

- •Nonmetallic materials

- •4.24. What kinds of non-metal things do people use at home and at work in the office? Entitle the text below. Compare metals and non-metals as structural materials.

- •Unit 5. Materials technology

- •Vocabulary

- •Processing and heat treatment of metals

- •Visit to a Plant

- •Hardening plain carbon steel

- •Vocabulary

- •Welding processes

- •Gas welding

- •Hard to define

- •Nanotechnology

- •Larger to smaller: materials perspective

- •References

- •Appendix Summary tips Аннотирование и реферирование

- •Аннотация и реферат

- •Структура реферата

- •Этапы реферирования и аннотирования

- •Некоторые рекомендации по составлению аннотации и реферата

Hardening plain carbon steel

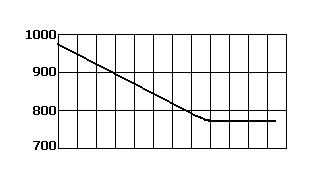

The hardening of plain carbon steel consists of two stages: first heating to a specific temperature and then cooling rapidly. The cooling process is known as quenching. The correct temperature to which steel must be heated varies with its carbon content (see Fig. 1). Overheating can cause grain growth resulting in weak components.

Temperature (ºC)

-

0.1

0.3

0.5

0.7

0.9

1.1

% carbon content

Fig. 1. …………………….

The hardness of the heat-treated steel depends on two factors:

1. Type of quenching bath.

This contains either water or quenching oil, depending on the speed of cooling required. The more rapidly a plain carbon steel is cooled, the harder it is. However, overrapid cooling can result in faults, e.g. cracking and distortion. Therefore, the correct quenching bath should be chosen to treat the workpiece as required (see Table 2).

2. The carbon content (see Table 1).

Note

workpiece n – обрабатываемое изделие

Table 1. ……… |

|

Table 2. ……. |

|||

% Carbon Content of Steel |

Effect of Hardening |

|

% Carbon Content |

Quenching Bath |

Required Treatment |

0.0 – 0.25 |

No effect |

|

0.3 – 0.5 |

oil |

toughening |

0.3 – 0.5 |

Some effect: becomes tougher |

|

0.5 – 0.9 |

oil |

toughening |

0.5 – 0.9 |

Good effect: becomes hard |

|

0.5 – 0.9 |

water |

hardening |

0.9 – 1.3 |

Very good effect: becomes very hard |

|

0.9 – 1.3 |

oil |

hardening |

Table 3. Requirements for Hardening Plain Carbon Steel

Rеquirements |

% Carbon Content |

Maximum Temperature, C |

Quenching Bath |

1. Very hard plain carbon steel component |

|

|

|

2. Hard plain carbon steel component |

|

|

|

3. Tough plain carbon steel component |

|

|

|

5.7. a) Read the text Welding Processes and find a key sentence in each paragraph. Sum up the key sentences and give the main ideas of the text. b) Write out phrases with -ing forms and translate them.

Vocabulary

intimate proximity |

— |

непосредственная близость |

fusion n |

— |

плавление |

interpenetration n |

— |

взаимопроникновение |

weld n |

— |

сварной шов |

riveting n |

— |

клепка |

fusion welding |

— |

сварка плавлением |

filler metal |

— |

присадочный металл |

filler metal feed |

— |

подача присадочной проволоки |

manual welding |

— |

ручная сварка |

semiautomatic welding |

— |

полуавтоматическая сварка |

pressure welding |

— |

сварка давлением |

thermal conductivity |

— |

теплопроводность |

deposited layer |

— |

наплавленный слой, наплавка |

parent metal |

— |

основной металл, перешедший в шов |

fusion line |

— |

линия сплавления |

sound weld |

— |

качественный сварной шов |

heat-affected zone (HAZ) |

— |

зона термического влияния (ЗТВ) |

welded structure |

— |

сварная конструкция |

butt joint |

— |

стыковое соединение |

lap joint |

— |

соединение внахлестку |

T joint |

— |

Т-образное соединение |

corner joint |

— |

угловое соединение |