- •HOW TO USE THIS MANUAL

- •TO LOCATE WHAT YOU ARE LOOKING FOR:

- •COMPONENT PARTS AND WORK TO BE DONE

- •SYMBOL

- •ABBREVIATIONS USED IN THIS MANUAL

- •01 GENERAL INFORMATION

- •COUNTRY AND AREA CODES

- •WARNING/CAUTION/NOTE

- •GENERAL PRECAUTIONS

- •SUZUKI GSX-R600K6 (’06-MODEL)

- •SERIAL NUMBER LOCATION

- •FUEL, OIL AND ENGINE COOLANT RECOMMENDATION

- •BREAK-IN PROCEDURES

- •CYLINDER IDENTIFICATION

- •INFORMATION LABELS

- •SPECIFICATIONS

- •02 PERIODIC MAINTENANCE

- •PERIODIC MAINTENANCE SCHEDULE

- •MAINTENANCE AND TUNE-UP PROCEDURES

- •COMPRESSION PRESSURE CHECK

- •SDS CHECK

- •03 ENGINE

- •ENGINE COMPONENTS REMOVABLE WITH ENGINE IN PLACE

- •ENGINE REMOVAL AND INSTALLATION

- •ENGINE DISASSEMBLY

- •ENGINE REASSEMBLY

- •04 FI SYSTEM DIAGNOSIS

- •PRECAUTIONS IN SERVICING

- •FI SYSTEM TECHNICAL FEATURES

- •ECM TERMINAL

- •SELF-DIAGNOSIS FUNCTION

- •FAIL-SAFE FUNCTION

- •FI SYSTEM TROUBLESHOOTING

- •SENSORS

- •05 FUEL SYSTEM AND THROTTLE BODY

- •FUEL DELIVERY SYSTEM

- •FUEL SYSTEM

- •THROTTLE BODY

- •06 EXHAUST SYSTEM

- •EXHAUST SYSTEM

- •EXCVA (EXHAUST CONTROL VALVE ACTUATOR) AND EXCV (EXHAUST CONTROL VALVE)

- •07 COOLING AND LUBRICATION SYSTEM

- •ENGINE COOLANT

- •COOLING CIRCUIT

- •COOLING FAN

- •ECT SENSOR

- •THERMOSTAT

- •WATER PUMP

- •LUBRICATION SYSTEM

- •08 CHASSIS

- •EXTERIOR PARTS

- •FRONT WHEEL

- •FRONT FORK

- •STEERING DAMPER

- •STEERING

- •HANDLEBARS

- •REAR WHEEL

- •REAR SHOCK ABSORBER

- •REAR SUSPENSION

- •FRONT BRAKE

- •REAR BRAKE

- •TIRE AND WHEEL

- •DRIVE CHAIN

- •09 ELECTRICAL SYSTEM

- •CAUTIONS IN SERVICING

- •LOCATION OF ELECTRICAL COMPONENTS

- •CHARGING SYSTEM

- •STARTER SYSTEM AND SIDE-STAND/IGNITION INTERLOCK SYSTEM

- •IGNITION SYSTEM

- •COMBINATION METER

- •LAMPS

- •RELAYS

- •BATTERY

- •10 SERVICING INFORMATION

- •TROUBLESHOOTING

- •WIRING HARNESS, CABLE AND HOSE ROUTING

- •TIGHTENING TORQUE

- •SERVICE DATA

- •11 EMISSION CONTROL INFORMATION

- •EMISSION CONTROL SYSTEMS

- •PAIR (AIR SUPPLY) SYSTEM AND EMISSION CONTROL SYSTEM INSPECTION

- •PAIR (AIR SUPPLY) SYSTEM HOSE ROUTING

- •HO2 SENSOR INSPECTION (For E-02, 19)

- •12 WIRING DIAGRAM

FI SYSTEM DIAGNOSIS 4-105

SENSORS

CMP SENSOR INSPECTION

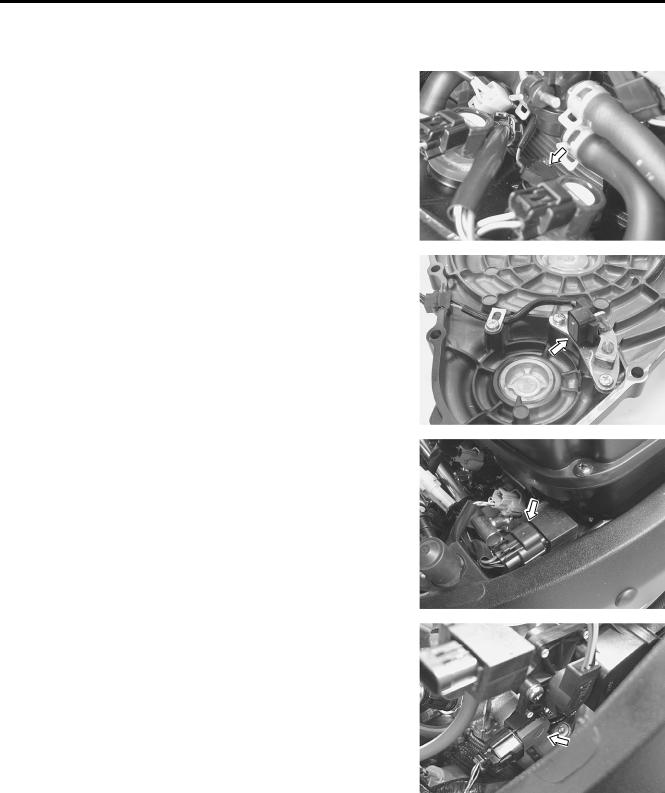

The camshaft position sensor is installed on the cylinder head cover. ( 4-33)

CMP SENSOR REMOVAL AND INSTALLATION

•Remove the CMP sensor. ( 3-26)

•Install the CMP sensor in the reverse order of removal.

CMP sensor: 10 N·m (1.0 kgf-m, 7.0 lb-ft)

•Remove the clutch cover. ( 3-16)

•Install the clutch cover in the reverse order of removal.

|

|

|

E |

IAP SENSOR INSPECTION |

|

L |

|

|

|

|

|

The intake air pressure sensor is installed at the rear side of the |

|||

air cleaner box. ( 4-38) |

|

P |

|

IAP SENSOR REMOV |

M |

|

|

L ND INSTALLATION |

|||

• Lift and support the fuel tank. ( 5-3) |

|

|

|

• Remove the IAP sensor. |

A |

|

|

|

|

|

|

• Install the IAP sensor in the reverse order of removal. |

|

||

S |

|

|

|

TP SENSOR INSPECTION

The throttle position sensor is installed at the right side of the

No. 4 throttle body. ( 4-44)

TP SENSOR REMOVAL AND INSTALLATION

•Remove the aircleaner box and lift up the throttle body. ( 5-14)

•Remove the TP sensor. ( 5-17)

•Install the TP sensor in the reverse order of removal.

TPS ADJUSTMENT

• Adjust the TP sensor. ( 4-20)

4-106 FI SYSTEM DIAGNOSIS

ECT SENSOR INSPECTION

The engine coolant temperature sensor is installed at the cylinder head. ( 4-49)

ECT SENSOR REMOVAL AND INSTALLATION

•Remove the ECT sensor. ( 7-7)

•Install the ECT sensor in the reverse order of removal.

ECT sensor: 18 N·m (1.8 kgf-m, 13.0 lb-ft)

IAT SENSOR INSPECTION

The intake air temperature sensor is installed to the air cleaner box. ( 4-53)

IAT SENSOR REMOVAL AND INSTALLATION

• Lift and support the fuel tank. ( 5-3)

• Remove the IAT sensor from the air cleaner box.

• Install the IAT sensor in the reverse order of removal.

AP SENSOR INSPECTION |

L |

E |

|

The AP sensor is located under the front seat. ( 4-57) |

|

AP SENSOR REMOVAL AND INSTALLATIONP |

|

• Remove the AP sensor from the frame. |

|

A |

|

• Install the AP sensor in the reverse order ofMremoval. |

|

S |

|

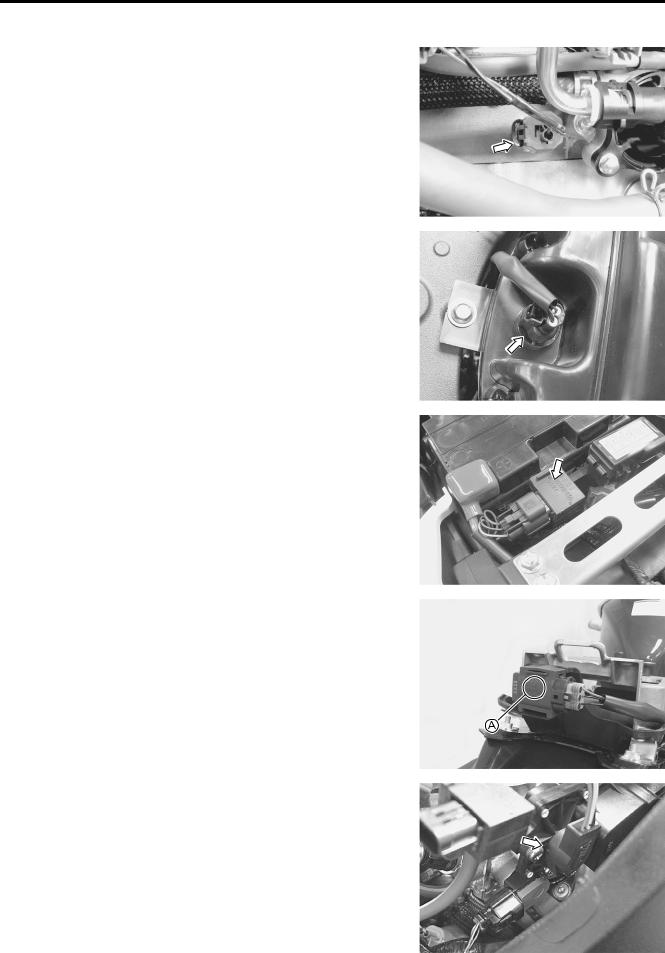

TO SENSOR INSPECTION

TO SENSOR REMOVAL AND INSTALLATION

The tip-over sensor is located at the rear of seat tail rail. ( 4-63)

•Remove the TO sensor.

•Install the TO sensor in the reverse order of removal.

NOTE:

When installing the TO sensor, the arrow mark A must be pointed upward.

STP SENSOR INSPECTION

STP SENSOR REMOVAL AND INSTALLATION

The secondary throttle position sensor is installed at the right side of the No. 4 throttle body.

•Remove the aircleaner box and lift up the throttle body. ( 5-14)

•Remove the STP sensor. ( 5-17)

•Install the STP sensor in the reverse order of removal.

FI SYSTEM DIAGNOSIS 4-107

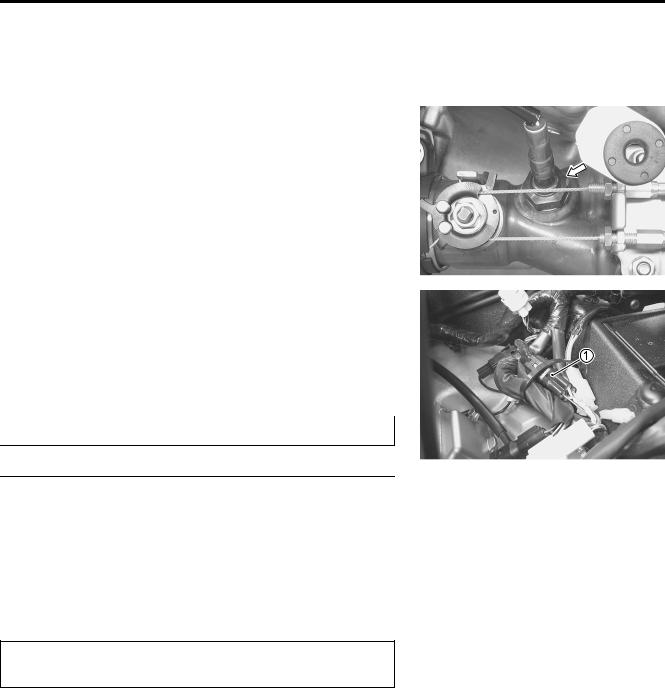

• Remove the right under cowling. ( 8-5)

• Lift and support the fuel tank. ( 5-3)

• Disconnect the coupler 1 and remove the HO2 sensor.

|

|

|

|

|

E |

Do not remove the HO2 sensor while it is hot. |

|

|

|||

|

|

|

L |

||

|

|

|

|||

|

P |

|

|

||

|

|

|

|

||

|

|

|

|

||

Be careful not to expose it to excessive shock. |

|

|

|

||

Do not use an impact wrench while removing or |

|

|

|||

installing the HO2 sensor. |

M |

|

|

|

|

|

|

|

|

||

Be careful not to twist or damage the sensor lead |

|

|

|||

wires. |

A |

|

|

|

|

S |

|

|

|

|

|

|

|

|

|

|

|

• Installation is in the reverse order of removal.

Do not apply oil or other materials to the sensor air hole.

• Tighten the sensor unit to the specified torque.

HO2 sensor: 48 N·m (4.8 kgf-m, 34.5 lb-ft)

• Route the HO2 sensor lead wire properly.( 10-20)