- •Кафедра иностранных языков

- •Contents

- •Conventional Power Generation in Russia ………………………………… 35

- •Modes of Heat Transfer

- •Famous People

- •Hydroelectric Power Plants

- •Famous People

- •Vladimir Grigorievich Shukhov ( 1853 - 1939)

- •Nuclear Power Plants

- •Famous People

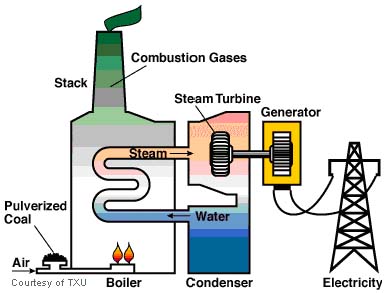

- •Fossil-fuel Power Plants

- •Famous People

- •Steam Turbine

- •Famous People

- •Furnace

- •Famous People r obert Boyle (1627-1691)

- •Hydroelectric power

- •Famous People

- •Steam Nozzles

- •Famous people

- •Gas Burners

- •Famous People

- •Old and Modern Theories of Heat

- •Famous People

- •Supplementary texts Part I What do the words ‘Hot’, ‘Cold’ , and ‘Temperature’ mean?

- •Generators

- •Engines

- •Protection Against Environmental Pollution

- •What Is Heat?

- •Evaporation

- •How Can We Use Steam?

- •Electric Current Generation

- •Conventional Power Generation in Russia

- •Amount of Heat Depends on Current and Resistance

- •The Turbine Nozzle

- •Electric Power Plants

- •Chernobyl Accident

- •Part II Renewable energy

- •Steam Generation

- •The Steam-Generating Units

- •Heat Exchangers

- •Direct-Contact Feed-Water Heaters

- •Closed Feed Water Heaters

- •Condensers

- •How a Condenser Works

- •Steam turbine

- •Gas turbine

- •Electricity generation

- •Primary energy sources used in electrical power generation

- •Advantages and Disadvantages of Hydro Systems

- •Automatic Production and Technology Processes

- •Краткий грамматический справочник Страдательный залог

- •Причастие (The Participle)

- •Независимый причастный оборот (The Absolute Participle Construction)

- •Герундий (The Gerund)

- •Сложный герундиальный оборот

- •Инфинитив (The Infinitive)

- •Функции инфинитива

- •Объектный инфинитивный оборот (The Complex Object)

- •Субъектный инфинитивный оборот (The Complex Subject)

- •Инфинитивный оборот с предлогом "for" (Infinitive Construction Introduced by the Preposition "for")

- •Grammar exercises

- •Irregular Verbs Неправильные глаголы

- •Idioms, Prepositional and Conjunctional Phrases

- •Англо-русский словарь

- •Библиографический список

Steam turbine

A steam turbine extracts the energy of dry pressurized superheated

steam as mechanical movement.

In

a Parsons-Westinghouse steam turbine nozzles apply supersonic steam

to a curved

blade. The blade whips the steam back in the opposite direction,

simultaneously allowing the steam to expand a bit. A stationary blade

then redirects

the steam towards the next blade. The process repeats until the steam

is completely

expanded. The moving blades are mounted radially on the rotor. The

stationary

blades are mounted to the case of the turbine.

steam turbine extracts the energy of dry pressurized superheated

steam as mechanical movement.

In

a Parsons-Westinghouse steam turbine nozzles apply supersonic steam

to a curved

blade. The blade whips the steam back in the opposite direction,

simultaneously allowing the steam to expand a bit. A stationary blade

then redirects

the steam towards the next blade. The process repeats until the steam

is completely

expanded. The moving blades are mounted radially on the rotor. The

stationary

blades are mounted to the case of the turbine.

Turbines usually consist of a number of stages, with each stage being specifically optimized for the pressure and volume of steam that it will operate with.

Steam turbines of this type have some weak spots. First, some steam leaks through the annulus where the journal of the shaft penetrates the casing. Usually this is limited by some sort of rotating labyrinth seal, but it can be a problem, especially on the high-pressure end of the turbine. Also, most steam turbines are very particular about what they expect in their feed. Water droplets can quickly damage a steam turbine if the turbine blades have not been designed to withstand the presence of water droplets.

The turbine described above was invented by Charles A. Parsons, and improved by George Westinghouse.

A number of other types of turbines have been developed that work effectively with steam. The de Laval turbine (invented by Gustaf de Laval) accelerated the steam to full speed before running it against a turbine blade. This was good, because the turbine is simpler, less expensive and does not need to be pressure-proof. It can operate with any pressure of steam. It is also, however, less efficient.

Problems with turbines are quite rare but any imbalance of the rotor blades can lead to vibration, which in extreme cases can lead to a blade letting go and punching straight through the casing. If water gets into the gas and is blasted onto the blades rapid erosion of the blades can occur, possibly leading to imbalance and failure. The control of a turbine with a governor is essential, as turbines need to be run up slowly, to prevent damage. Uncontrolled acceleration of the turbine rotor can lead to the over-speed trip being activated to shut off the activating gas supply to the turbine. If this fails then the turbine may continue accelerating until it breaks apart, often spectacularly, probably extremely dangerously. The high pressures inside the casing lead to problems in sealing the output shaft. Turbines are expensive to make, requiring precision manufacture and special quality materials. This purchase cost is offset by much lower maintenance requirements and the small size of a turbine when compared to its shaft power output.

Electrical power stations around the world use large steam turbines driving turbo-generators to produce vast amounts of electricity. Other uses of steam turbines are in ships, pumps and motors at land based plant where steam is often available as a production by-product. Steam turbines were tested on railways, without success, although gas turbines

are now commonly used. (From Wikipedia, the free encyclopedia)

http://en.wikipedia.org/wiki/Steam_turbine