- •Chapter I introduction

- •1. The subject of hydraulics

- •2. Historical background

- •3. Forces acting on a fluid. Pressure

- •4. Properties of liquids

- •Chapter II hydrostatics.

- •5. Hydrostatic pressure

- •6. The basic hydrostatic equation

- •7. Pressure head. Vacuum. Pressure measurement

- •8. Fluid pressure on a plane surface

- •Fig. 12. Pressure distribution on a rectangular wall

- •9. Fluid pressure on cylindrical and spherical surfaces. Buoyancy and floatation

- •Fig. 18. Automatic relief valve.

- •Relative rest of a liquid

- •10. Basic concepts

- •11. Liquid in a vessel moving with uniform acceleration in a straight line

- •12. Liquid in a uniformly rotating vessel

- •The basic equations of hydraulics

- •13. Fundamental concepts

- •14. Rate of discharge. Equation of continuity

- •15. Bernoulli's equation for a stream tube of an ideal liquid

- •16. Bernoulli's equation for real flow

- •17. Mead losses (general considerations)

- •18. Examples of application of bernoulli's equation to engineering problems

- •Chapter V flow through pipes. Hydrodynamic similarity

- •19. Flow through pipes

- •20. Hydrodynamic similarity

- •21. Cavitati0n

- •Chapter VI laminar flow

- •22.Laminar flow in circular pipes

- •23. Entrance conditions in laminar flow. The α coefficient

- •24. Laminar flow between parallel boundaries

- •Chapter VII turbulent flow

- •25. Turbulent flow in smooth pipes

- •26. Turbulent flow in rough pipes

- •27. Turbulent flow in noncircular pipes

- •Chapter VIII local features and minor losses

- •28. General considerations concerning local features in pipes

- •29. Abrupt expansion

- •30. Gradual expansion

- •31. Pipe contraction

- •32. Pipe bends

- •33. Local disturbances in laminar flow

- •34. Local features in aircraft hydraulic systems

- •Chapter IX flow through orifices, tubes and nozzles

- •35. Sharp-edged orifice in thin wall

- •36. Suppressed contraction. Submerged jet

- •37. Flow through tubes and nozzles

- •38. Discharge with varying head (emptying of vessels)

- •39. Injectors

- •Relative motion and unsteady pipe flow

- •40. Bernoulli's equation for relative motion

- •41. Unsteady flow through pipes

- •42. Water hammer in pipes

- •Chapter XI calculation of pipelines

- •43. Plain pipeline

- •44. Siphon

- •45. Compound pipes in series and in parallel

- •46. Calculation of branching and composite pipelines

- •47. Pipeline with pump

- •Chapter XII centrifugal pumps

- •48. General concepts

- •49. The basic equation for centrifugal pumps

- •50. Characteristics of ideal pump. Degree of reaction

- •51. Impeller with finite number of vanes

- •52. Hydraulic losses in pump. Plotting rated characteristic curve

- •53. Pump efficiency

- •54. Similarity formulas

- •55. Specific speed and its relation to impeller geometry

- •56. Relation between specific speed and efficiency

- •57. Cavitation conditions for centrifugal pumps (according to s.S. Rudnev)

- •58. Calculation of volute casing

- •59. Selection of pump type. Special features of centrifugal pumps used in aeronautical and rocket engineering

7. Pressure head. Vacuum. Pressure measurement

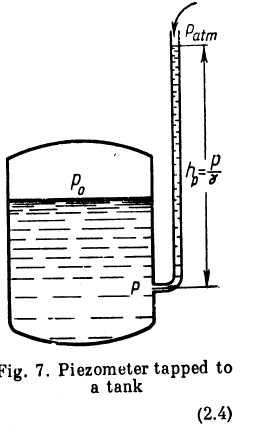

The pressure head — represents the height of a column of a given liquid referred to a given absolute or gauge pressure p. The pressure head referred to gauge pressure can be measured with a so-called piezometer, which is the simplest device for measuring pressure. A piezometer is a vertical glass tube the upper end, of which is open . to the atmosphere while the lower end is connected to a small hole in the wall of a liquid container (Fig. 7).

Applying Eq. (2.2) to the liquid in the piezometer, we obtain

![]()

where pab — absolute pressure of the liquid at the level of the attached end of the piezometer;

![]() atmospheric

pressure.

atmospheric

pressure.

From this, the height of the liquid in the piezometer is

![]()

where pg = gauge pressure at the same level.

Obviously, if the free surface of a still liquid is subjected to atmospheric pressure, the pressure head at any point of the liquid is equal to the depth of that point.

Pressure in fluids is often expressed numerically in terms of head according to Eq. (2.4). One atmosphere, for example, corresponds to:

![]() m

of water

m

of water

![]() m

of mercury.

m

of mercury.

If the absolute pressure in a fluid is less than atmospheric, we have a partial or complete vacuum. The magnitude of a vacuum is measured as the difference between the atmospheric and absolute pressures:

![]()

![]()

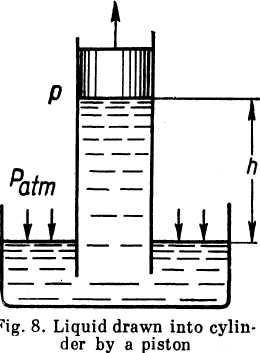

Take,

for example, a tube with a tightly fitting piston, lower one end of

it into a container with a liquid and then draw the piston up (Fig.

8). The liquid will follow the piston and rise together with it to

some height h

above

the free surface, which is subject to atmospheric

pressure. For the points immediately under the piston the deptb  with

respect to the free surface is negative. Hence, from Eq. (2.2), the

absolute pressure in the liquid below the piston is

with

respect to the free surface is negative. Hence, from Eq. (2.2), the

absolute pressure in the liquid below the piston is

![]() .

.

and the vacuum is

![]()

![]()

As the piston rises the absolute pressure in the liquid decreases. The lower limit for the absolute pressure is zero; the maximum value of vacuum is numerically equal to atmospheric pressure. Hence, the maximum elevation of the liquid in our example, i. e., the maximum height of suction, can be found from Eq. (2.5), assuming p = 0 (or, more precisely, p = pt).

Thus, neglecting the vapour pressure pt, we have

![]()

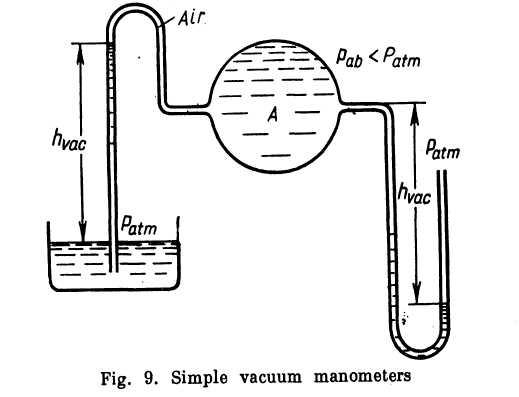

At normal atmospheric pressure (1.033 kg/cm2) the height hmax is 10.33 m for water, 13.8 m for gasoline (γ = 750 kg/m') and 0.76 m or mercury.The simplest device for measuring vacuum, or negative pressure, is a glass U-tube arranged either with one end open, like the right-hand tube in Fig. 9, or inverted with the free end submerged in a liquid, like the left-hand tube.

In laboratories, besides piezometers, various manometers and mechanical gauges are used to measure the pressure of liquids and gases.

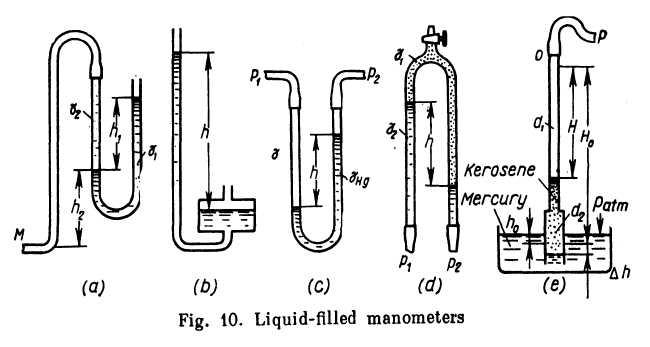

The U-tube manometer (Fig. 10a) has the bend of a transparent tube filled with mercury or, if the pressures are small, alcohol, water or tetrabromo-ethane (δ = 2.95). If the pressure of a liquid is measured at a point M and the connecting tube is filled with the same liquid, the elevation of the manometer above M must be taken into account. Thus, the gauge pressure at point M is

![]()

A modification of the U-tube manometer in which one limb is widened (Fig. 10?>) is more convenient as only one level of the working liquid has to be read. When the diameter of the wider limb is appreciably greater than that of the tube, the level in the former can be regarded as constant. For very small pressures of gas and greater

accuracy the manometer tube is inclined to the horizontal. The length of the column of liquid is inversefy proportional to the sine of the angle of inclination, the accuracy of reading improving accordincrly.

Differences of pressure at two points are measured with differential manometers, the simplest of which is the U-tube (Fig. 10c). When such a manometer, with mercury in the bend, is used to measure the difference between pressures px and p2 in a liquid of specific weight y which completely fills the connecting limbs, we have

![]()

For measuring small pressure differentials of water an inverted U-tube is used with oil or kerosene filling the upturned bend(Fig. 10d). For this case we have

![]()

The well-type manometer in Fig. lOe is designed for measuring air pressures or vacuums from about 0.1 to 0.5 atm. An alcohol or water manometer would require a very high column, making it unwieldy, while a mercury-filled manometer would be inaccurate due to the low column of mercury. This type of manometer is used in high-speed wind tunnel tests.

The well is filled with mercury and the tube with alcohol, kerosene or some other liquid. Kerosene is especially convenient due to its low rate of evaporation. A judicious selection of the diameters of the upper and lower portions of the tube (dx and d2) enables any effective specific weight yef to be obtained from the equation

![]()

where p = measured pressure or vacuum;

H = manometer reading.

The expression for yef is obtained from the following equations (see Fig. 10e):

![]()

which is the equilibrium equation for the mercury and kerosene columns at p = patm;

![]()

which is the equilibrium equation at p > patm ;and

![]()

which is the equation of volumes (the volume of the kerosene moving from the upper tube d, to the lower tube d2 is equal to the volume of the displaced mercury). Substituting and transposing, we obtain

![]()

At

d2

=

2d1,

for example,

![]()

Pressures higher than two or three atmospheres are measured with mechanical gauges of the Bourdon-tube or diaphragm type. Their action is based on the deflection of a hollow tube, diaphragm or bellows caused by the applied pressure. The deflection is transmitted through a suitable mechanism to a needle which indicates the pressure on a dial.

In aircraft systems manometers are used to measure the pressure of fuel supplied to the injectors of a gas turbine engine or to the carburettor of a reciprocating engine, the pressure of oil in the lubricating system, etc.

The most widely used in aircraft systems is the electrical manometer, as well as different types of mechanical gauges. The sensor element of an electrical manometer is a diaphragm which deflects under the applied pressure and actuates the slide of a potentiometer.