- •Chapter I introduction

- •1. The subject of hydraulics

- •2. Historical background

- •3. Forces acting on a fluid. Pressure

- •4. Properties of liquids

- •Chapter II hydrostatics.

- •5. Hydrostatic pressure

- •6. The basic hydrostatic equation

- •7. Pressure head. Vacuum. Pressure measurement

- •8. Fluid pressure on a plane surface

- •Fig. 12. Pressure distribution on a rectangular wall

- •9. Fluid pressure on cylindrical and spherical surfaces. Buoyancy and floatation

- •Fig. 18. Automatic relief valve.

- •Relative rest of a liquid

- •10. Basic concepts

- •11. Liquid in a vessel moving with uniform acceleration in a straight line

- •12. Liquid in a uniformly rotating vessel

- •The basic equations of hydraulics

- •13. Fundamental concepts

- •14. Rate of discharge. Equation of continuity

- •15. Bernoulli's equation for a stream tube of an ideal liquid

- •16. Bernoulli's equation for real flow

- •17. Mead losses (general considerations)

- •18. Examples of application of bernoulli's equation to engineering problems

- •Chapter V flow through pipes. Hydrodynamic similarity

- •19. Flow through pipes

- •20. Hydrodynamic similarity

- •21. Cavitati0n

- •Chapter VI laminar flow

- •22.Laminar flow in circular pipes

- •23. Entrance conditions in laminar flow. The α coefficient

- •24. Laminar flow between parallel boundaries

- •Chapter VII turbulent flow

- •25. Turbulent flow in smooth pipes

- •26. Turbulent flow in rough pipes

- •27. Turbulent flow in noncircular pipes

- •Chapter VIII local features and minor losses

- •28. General considerations concerning local features in pipes

- •29. Abrupt expansion

- •30. Gradual expansion

- •31. Pipe contraction

- •32. Pipe bends

- •33. Local disturbances in laminar flow

- •34. Local features in aircraft hydraulic systems

- •Chapter IX flow through orifices, tubes and nozzles

- •35. Sharp-edged orifice in thin wall

- •36. Suppressed contraction. Submerged jet

- •37. Flow through tubes and nozzles

- •38. Discharge with varying head (emptying of vessels)

- •39. Injectors

- •Relative motion and unsteady pipe flow

- •40. Bernoulli's equation for relative motion

- •41. Unsteady flow through pipes

- •42. Water hammer in pipes

- •Chapter XI calculation of pipelines

- •43. Plain pipeline

- •44. Siphon

- •45. Compound pipes in series and in parallel

- •46. Calculation of branching and composite pipelines

- •47. Pipeline with pump

- •Chapter XII centrifugal pumps

- •48. General concepts

- •49. The basic equation for centrifugal pumps

- •50. Characteristics of ideal pump. Degree of reaction

- •51. Impeller with finite number of vanes

- •52. Hydraulic losses in pump. Plotting rated characteristic curve

- •53. Pump efficiency

- •54. Similarity formulas

- •55. Specific speed and its relation to impeller geometry

- •56. Relation between specific speed and efficiency

- •57. Cavitation conditions for centrifugal pumps (according to s.S. Rudnev)

- •58. Calculation of volute casing

- •59. Selection of pump type. Special features of centrifugal pumps used in aeronautical and rocket engineering

30. Gradual expansion

A gradually expanding pipe is commonly called a diffuser. In a diffuser the velocity decreases and the pressure increases. The kinetic energy of the particles of the liquid enables them to move against the growing pressure. The degradation of kinetic energy is along the diffuser and from the centre line to the boundary. The energy of layers at the boundary is so small that the increased pressure may stop the flow there or even reverse it. As a result, eddies form and the flow separates from the wall (Fig. 62). The greater the angle of divergence of a diffuser the more pronounced these phenomena and the greater the turbulence loss. Besides, there exist ordinary friction losses like those in pipes of uniform cross-section.

The total loss of head in a diffuser hdtf thus comprises two components:

![]() (8.2)

(8.2)

where hf = loss of head due to friction;

hexp = loss of head due to expansion (turbulence loss). The friction loss can be computed approximate-ly in the following manner. Consider a conical diffuser with a divergence angle α; the radius of the diffuser

intake is rx and of the outlet base, r2 (Fig. 63). As the cross-sectional radius and velocity of flow are variable along the diffuser, we should take a differential length dl along the wall and express the differential loss of head due to friction by the basic equation (4.18). We have:

![]()

where v = mean velocity across an arbitrary section of radius r. From the elementary triangle,

From the continuity equation,

where vx = velocity at the diffuser entrance.

Substituting these expressions into the equation for dhf and in-legrating from r, to r2, i. e., over the whole of the diffuser, and assuming the friction factor Xt constant,

whence

and finally

where is

the so-called rate of divergence of the diffuser.

the so-called rate of divergence of the diffuser.

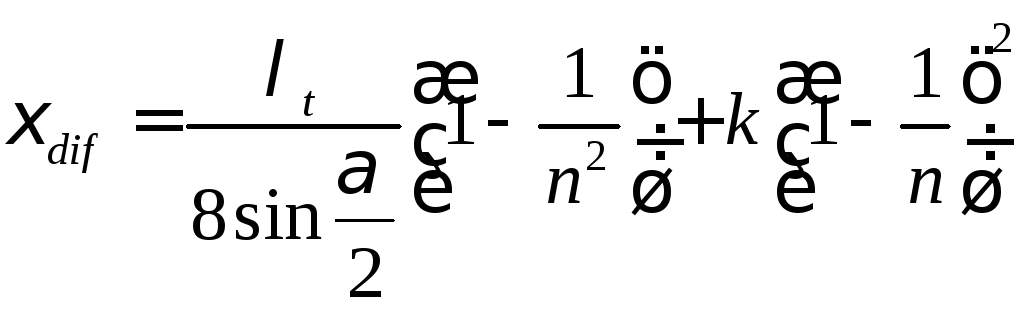

The second component in Eq. (8.2)—the expansion, or turbulence, loss—is of essentially the same nature in a diffuser as in an abrupt expansion (though its value is smaller) and it is commonly expressed by the same equation (8.1) or (8.1') with a correction factor к less than unity:

(8.4)

(8.4)

As the shock produced by a liquid flowing through a diffuser is less than in an abrupt expansion, the factor к is sometimes called the shock reduction factor. The value of к for divergence angles of the order 5-20° can be computed from the following empirical formula developed by the Soviet scientist I.E. Idelchik:

![]() (8.5)

(8.5)

or according to Fligner's approximate formula

к = sin α. (8.6)

Taking Eqs (8.3) and (8.4) into account, the initial equation (8.2) can be rewritten as follows:

(8.7)

(8.7)

and the loss coefficient of a diffuser can be expressed finally by the formula

(8.8)

(8.8)

It

will be observed that

![]() depends

on the angle a, the frictionfactor

Xt

and

the rate of divergence n.

depends

on the angle a, the frictionfactor

Xt

and

the rate of divergence n.

It

is important to establish how

![]() dependent

on a. With anglea

increasing for a given λt

and

n,

the

first term in Eq. (8.8), which is

due to friction, decreases, as the cone is shorter, and the second,

which

is due to turbulence and separation, increases.

dependent

on a. With anglea

increasing for a given λt

and

n,

the

first term in Eq. (8.8), which is

due to friction, decreases, as the cone is shorter, and the second,

which

is due to turbulence and separation, increases.

When angle a decreases eddy formation is less, but friction is greater, as for a given rate of divergence n the diffuser is longer and the friction surface increases accordingly.

The

function

![]() is

minimum at some optimum value ofa

(Fig. 64).

is

minimum at some optimum value ofa

(Fig. 64).

The

values of the cone angle can be found approximately from Eq.(8.8),

replacing

![]() by

1/2 sin a, as follows: differentiate Eq. (8.8)with

respect to a taking into account Eq. (8.6), equate it

to

by

1/2 sin a, as follows: differentiate Eq. (8.8)with

respect to a taking into account Eq. (8.6), equate it

to

z ero

and solve for a:

ero

and solve for a:

![]()

Substituting into this formula friction factors of the order Xt = 0.015-0.025 and a rate of divergence of the order n = 2-4, we obtain a mean optimum cone angle of about 6°, which is confirmed by experimental data.

In real solutions, in order to reduce the diffuser length for a given value of n, the cone angle is made somewhat larger, viz., α = 7-9°. The value of a for square diffusers is commonly taken the same.

For rectangular diffusers diverging in one plane (flat diffusers) the optimum divergence angle is greater than for conical or square diffusers, amounting to 10-12°.

If

space limitations make it impossible to use divergence angles in

the optimum range, at α > 15-25°, specially designed diffusers

If

space limitations make it impossible to use divergence angles in

the optimum range, at α > 15-25°, specially designed diffusers

should be used which ensure a constant pressure gradient along the centre line (dp/dx = const). Such a curved diffuser is shown schematically in Fig. 65.

The reduction in energy loss in such diffuses, as compared with straight cones, is the greater the larger the соде angle a, reaching 40 per cent at a of the order of 40-60°. Furthermore, in a curved diffuser the flow is more stable.

Good results are also obtained by using stepped diffusers, consisting of an ordinary optimum-angle diffuser followed by an abrupt expansion (Fig. 66). The latter does not cause high energy losses as the velocity drops considerably by the time the flow reaches the enlargement. The total resistance of such a diffuser is much less than that of an ordinary diffuser of the same length and rate of divergence.