- •Chapter I introduction

- •1. The subject of hydraulics

- •2. Historical background

- •3. Forces acting on a fluid. Pressure

- •4. Properties of liquids

- •Chapter II hydrostatics.

- •5. Hydrostatic pressure

- •6. The basic hydrostatic equation

- •7. Pressure head. Vacuum. Pressure measurement

- •8. Fluid pressure on a plane surface

- •Fig. 12. Pressure distribution on a rectangular wall

- •9. Fluid pressure on cylindrical and spherical surfaces. Buoyancy and floatation

- •Fig. 18. Automatic relief valve.

- •Relative rest of a liquid

- •10. Basic concepts

- •11. Liquid in a vessel moving with uniform acceleration in a straight line

- •12. Liquid in a uniformly rotating vessel

- •The basic equations of hydraulics

- •13. Fundamental concepts

- •14. Rate of discharge. Equation of continuity

- •15. Bernoulli's equation for a stream tube of an ideal liquid

- •16. Bernoulli's equation for real flow

- •17. Mead losses (general considerations)

- •18. Examples of application of bernoulli's equation to engineering problems

- •Chapter V flow through pipes. Hydrodynamic similarity

- •19. Flow through pipes

- •20. Hydrodynamic similarity

- •21. Cavitati0n

- •Chapter VI laminar flow

- •22.Laminar flow in circular pipes

- •23. Entrance conditions in laminar flow. The α coefficient

- •24. Laminar flow between parallel boundaries

- •Chapter VII turbulent flow

- •25. Turbulent flow in smooth pipes

- •26. Turbulent flow in rough pipes

- •27. Turbulent flow in noncircular pipes

- •Chapter VIII local features and minor losses

- •28. General considerations concerning local features in pipes

- •29. Abrupt expansion

- •30. Gradual expansion

- •31. Pipe contraction

- •32. Pipe bends

- •33. Local disturbances in laminar flow

- •34. Local features in aircraft hydraulic systems

- •Chapter IX flow through orifices, tubes and nozzles

- •35. Sharp-edged orifice in thin wall

- •36. Suppressed contraction. Submerged jet

- •37. Flow through tubes and nozzles

- •38. Discharge with varying head (emptying of vessels)

- •39. Injectors

- •Relative motion and unsteady pipe flow

- •40. Bernoulli's equation for relative motion

- •41. Unsteady flow through pipes

- •42. Water hammer in pipes

- •Chapter XI calculation of pipelines

- •43. Plain pipeline

- •44. Siphon

- •45. Compound pipes in series and in parallel

- •46. Calculation of branching and composite pipelines

- •47. Pipeline with pump

- •Chapter XII centrifugal pumps

- •48. General concepts

- •49. The basic equation for centrifugal pumps

- •50. Characteristics of ideal pump. Degree of reaction

- •51. Impeller with finite number of vanes

- •52. Hydraulic losses in pump. Plotting rated characteristic curve

- •53. Pump efficiency

- •54. Similarity formulas

- •55. Specific speed and its relation to impeller geometry

- •56. Relation between specific speed and efficiency

- •57. Cavitation conditions for centrifugal pumps (according to s.S. Rudnev)

- •58. Calculation of volute casing

- •59. Selection of pump type. Special features of centrifugal pumps used in aeronautical and rocket engineering

37. Flow through tubes and nozzles

A tube is a short unrounded pipe whose length is only several diameters [l = (2-6)d] (Fig. 88a). An orifice in a thick wall is actually a tube (Fig. 88b).

Two flow regimes are observed in efflux of a liquid through tubes with unrounded edges into a gas. The first regime is shown schematically in Fig. 88a and b. On entering the tube the jet converges and forms a vena contracta in about the same way, and for the same reason, as in the case of a free jet through an orifice in a thin wall. Then

the jet expands and issues from the tube in a stream of the same diameter as the pipe. Between the vena contracta and tube walls a zone of violently eddying liquid is formed. As the jet has the same diameter as the aperture, ε = 1 and, consequently, μ = φ. For low-viscous liquids the mean values of the coefficients are

![]()

![]()

The rate of discharge through a circular tube running full (first regime) is greater than through an orifice in a thin wall; the velocity, on the other hand, is less owing to greater friction.

Consider a jet of liquid issuing under pressure p0 into a gas having pressure p2 (say, into the combustion chamber of a liquid-propel-lant rocket motor). The rated head for unsuppressed contraction is

![]()

As the pressure in the jet at the tube outlet is p2, at the vena contracta inside the tube, where the velocity is greater, the pressure px is lower than p2. Furthermore, the higher the head under which the jet is issuing, and consequently the greater the rate of discharge, the less the absolute pressure in the vena contracta. The difference p2 — p1 varies as the head H. This is demonstrated by Bernoulli's equation written between sections 1-1 and 2-2 (Fig. 88a) in the form

![]()

The last term is the loss of head due to jet expansion. This is completely analogous to an abrupt expansion, hence the loss of head due to expansion is given by Eq. (8.1). The vena contracta is determined by the same coefficient of contraction as in flow through an orifice. Therefore, from the continuity equation,

![]()

Using

this formula to eliminate vx

from

the foregoing Bernoulli equation

and writing the velocity v2

in

terms of the velocity coefficient

of the tube,

![]() we

obtain the pressure drop insidethe

tube:

we

obtain the pressure drop insidethe

tube:

(9.13)

(9.13)

Substitution of the values cp = 0.82 and e = 0.64 into this expression yields

![]() (9.13`)

(9.13`)

At some critical head Hcr the absolute pressure at section 1-1 in the tube becomes zero and

![]()

But

at H

>

Hcr

this

would mean a negative pressure px

which

is

practically impossible in liquids; it follows then that at H

>

Hcr

the

first flow regime (tube running full) is impossible. This is

confirmed

experimentally, and at

![]() the

flow regime changes suddenly.

The jet springs clear of the walls of the tube and issues from

it as shown in Fig. 88c.

the

flow regime changes suddenly.

The jet springs clear of the walls of the tube and issues from

it as shown in Fig. 88c.

This regime is identical to efflux through an orifice in a thin wall and it is characterised by the same jet coefficients. Thus, in a changeover from the first flow regime to the second the velocity increases and the rate of discharge, owing to jet contraction, decreases.

For the case of a jet of water into the atmosphere running clear

![]()

A submerged jet through a tube cannot run clear and the first regime persists at H>Hcr. With the head H increasing, however, the discharge coefficient drops and as a result of cavitation inside the tube the loss coefficient increases.

It follows, thus, that circular tubes possess some appreciable shortcomings: in the first regime (running full) resistance is great and the coefficient of discharge is small; in the second regime (running clear) the coefficient of discharge is even less. Furthermore, the flow regime through cylindrical tubes is unstable.

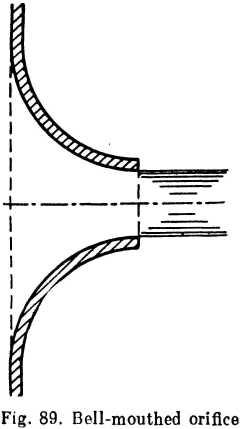

For these reasons cylindrical tubes are not favoured and, in fact, they are almost never specially provided for (with the exception of some liquid-propellant rocket motors). In engineering practice, however, tubes are frequent as bores in thick walls. Their performance can be improved substantially by rounding the inlet edge (broken lines in Fig. 88b). The greater the curve the higher the coefficient of discharge and the lower the loss coefficient. In the limit, when the radius of curvature equals the thickness of the wall, the circular tube becomes a bell-mouthed orifice (Fig. 89).

A bell-mouthed orifice is a widely used type of mouthpiece with a coefficient of discharge approaching unity, low losses, no vena con-tracta, a stable flow regime and a firm jet.

The loss coefficient is about the same as for a gradual contraction

![]()

the lower values of ζ corresponding to high Reynolds numbers and vice versa.

Correspondingly,

μ =φ = 0.99-0.96.

A diffuser mouthpiece (Fig. 90) is a diverging taper pipe affixed to a bell-mouthed orifice. Addition of a tail-pipe leads to lower pressure at the throat of the tube and, consequently, higher velocity and rate of discharge. The discharge of a bell-mouthed orifice can be increased by as much as 2.5 times by the addition of a diverging mouthpiece.

Such mouthpieces are used when the discharge for a given head must be as high as possible through a small orifice. Application, however, is limited to low heads (H = 1-4 m) as otherwise cavitation

develops in the throat, with a resulting increase in resistance and reduction of rate of discharge.

The diagram in Fig. 91 shows how the coefficient of discharge of a diverging mouthpiece is affected by the head increasing due to cavitation at the throat. The discharge coefficient is referred to the cross-sectional area of the throat, i. e.,

![]()

The curve was obtained in tests with a cone having an optimum angle and rate of divergence ensuring the highest coefficient of discharge.

Example. In some liquid-propellant rocket motors the fuel components are supplied into the combustion chambers through so-called spray injectors which are simple boreholes. Determine the required number of oxidiser injectors for the motor of a Schmetterling rocket if G = 1.6 kg/sec, pressure drop in injector Δр = 6 kg/cm2, pressure in the chamber p2 = 25 kg/cm2, orifice diameter d0 =. 1.5 mm, ratio of wall thickness to orifice diameter d/d0 = 0.5. The oxidiser is nitric acid, specific weight y = 1,510 kg/m8, kinematic viscosity v = 0.02 cm2/sec.

How many injectors would be required if 6/d0 = 2.5?

Solution, (i) Theoretical velocity of efflux:

![]()

Reynolds number:

![]()

The graph in Fig. 84 gives the coefficient of discharge as a function of Ret: μ= 0.62.

Total area of all injector mouths:

![]() sq cm

sq cm

Number of injectors:

![]()

If the bore ratio were6/do= 2.5, the efflux would be as from an external cylindrical tube. To determine the flow regime find /±pcr Eq. (9.13 ) gives

![]() kg/cm²

kg/cm²

As bpcr > AP, the first flow regime (running full) will obtain and the coefficient of discharge is \i = 0.82. Consequently,

![]()