- •Chapter I introduction

- •1. The subject of hydraulics

- •2. Historical background

- •3. Forces acting on a fluid. Pressure

- •4. Properties of liquids

- •Chapter II hydrostatics.

- •5. Hydrostatic pressure

- •6. The basic hydrostatic equation

- •7. Pressure head. Vacuum. Pressure measurement

- •8. Fluid pressure on a plane surface

- •Fig. 12. Pressure distribution on a rectangular wall

- •9. Fluid pressure on cylindrical and spherical surfaces. Buoyancy and floatation

- •Fig. 18. Automatic relief valve.

- •Relative rest of a liquid

- •10. Basic concepts

- •11. Liquid in a vessel moving with uniform acceleration in a straight line

- •12. Liquid in a uniformly rotating vessel

- •The basic equations of hydraulics

- •13. Fundamental concepts

- •14. Rate of discharge. Equation of continuity

- •15. Bernoulli's equation for a stream tube of an ideal liquid

- •16. Bernoulli's equation for real flow

- •17. Mead losses (general considerations)

- •18. Examples of application of bernoulli's equation to engineering problems

- •Chapter V flow through pipes. Hydrodynamic similarity

- •19. Flow through pipes

- •20. Hydrodynamic similarity

- •21. Cavitati0n

- •Chapter VI laminar flow

- •22.Laminar flow in circular pipes

- •23. Entrance conditions in laminar flow. The α coefficient

- •24. Laminar flow between parallel boundaries

- •Chapter VII turbulent flow

- •25. Turbulent flow in smooth pipes

- •26. Turbulent flow in rough pipes

- •27. Turbulent flow in noncircular pipes

- •Chapter VIII local features and minor losses

- •28. General considerations concerning local features in pipes

- •29. Abrupt expansion

- •30. Gradual expansion

- •31. Pipe contraction

- •32. Pipe bends

- •33. Local disturbances in laminar flow

- •34. Local features in aircraft hydraulic systems

- •Chapter IX flow through orifices, tubes and nozzles

- •35. Sharp-edged orifice in thin wall

- •36. Suppressed contraction. Submerged jet

- •37. Flow through tubes and nozzles

- •38. Discharge with varying head (emptying of vessels)

- •39. Injectors

- •Relative motion and unsteady pipe flow

- •40. Bernoulli's equation for relative motion

- •41. Unsteady flow through pipes

- •42. Water hammer in pipes

- •Chapter XI calculation of pipelines

- •43. Plain pipeline

- •44. Siphon

- •45. Compound pipes in series and in parallel

- •46. Calculation of branching and composite pipelines

- •47. Pipeline with pump

- •Chapter XII centrifugal pumps

- •48. General concepts

- •49. The basic equation for centrifugal pumps

- •50. Characteristics of ideal pump. Degree of reaction

- •51. Impeller with finite number of vanes

- •52. Hydraulic losses in pump. Plotting rated characteristic curve

- •53. Pump efficiency

- •54. Similarity formulas

- •55. Specific speed and its relation to impeller geometry

- •56. Relation between specific speed and efficiency

- •57. Cavitation conditions for centrifugal pumps (according to s.S. Rudnev)

- •58. Calculation of volute casing

- •59. Selection of pump type. Special features of centrifugal pumps used in aeronautical and rocket engineering

16. Bernoulli's equation for real flow

In going over from adifferential streain tube of an ideal liquid to real flow, i. e., a stream of visctius fluid having finite dimensions and constrained by walls, it is necessary to take into account: first, nonuniform velocity distribution across the sections and, second, energy (head) losses, both of whicb are due to viscosity.

When a viscous liquid moves along a solid surface, say in a pipe, the flow is retarded due to viscosity and molecular adhesion between the liquid and the walls. The velocity therefore, is greatest along the centre line of the stream. The closer to the walls the less the speed, down to zero. The result is a velocity profile like the one shown in Fig. 28.

The velocity variations mean that layers of the liquid are slipping relative to one another as a result of which tangential shearing strains, or friction stresses, appear. Furthermore, in a viscous liquid the particles often move erratically in swirls and eddies. This results in loss of energy, therefore the total energy, or total head, of a viscous stream is not constant as in the case of an ideal liquid. It is gradually dissipated in overcoming the resistances and drops along the stream.

Owing to nonuniform velocity distribution the notions of mean velocity vm across a section (see Sec. 14) and mean specific energy at that section must be introduced.

Before investigating Bernoulli's equation for a real liquid we shall assume that the basic hydrostatic law holds good for the cross-sections considered in the form of Eq. (2.3), i. e., that the piezometric head is constant for a given section:

![]() (across the section).

(across the section).

Thereby we assume that stream tubes in a moving liquid exert the same transverse pressure on each other as in a motionless liquid. This is actually the case, and it can be proved theoretically for the case of parallel streamlines across a given section, which is the kind of cross-sections we shall consider.

Let us introduce the concept of power of a flow. Power is defined as the total energy of a flow transferred through a given section per unit time. As the energy of the fluid particles varies across a section, let us first express the elementary power, i. e., the power of a differential stream tube, in terms of the total specific energy of the fluid at a given point and the differential weight rate of discharge.

We have

The power of the whole stream is found by integrating the foregoing expression over the whole of area S:

or, taking into account the assumption made,

![]()

The mean total specific energy of the fluid across the section is found by dividing the total power of the stream by the weight rate of discharge. Using the expression (4.4), we have

*

It should be borne in mind that the only real pressure in this

equation is

the static pressure p.

The

other two terms, zγ and

![]() ,

however, can easily be expressed in terms of pressure p, which is

why they are also called "pressures”.

,

however, can easily be expressed in terms of pressure p, which is

why they are also called "pressures”.

Multiplying

and dividing the last term by

![]() we obtain

we obtain

(4.14)

(4.14)

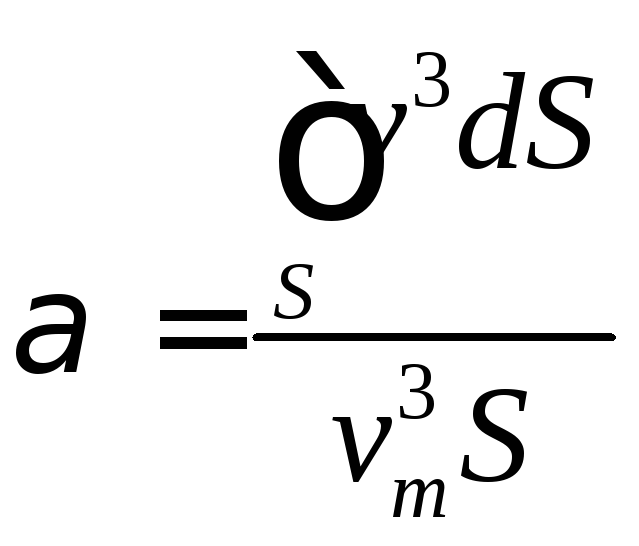

where a is a dimensionless coefficient introduced to take account of nonuniform velocity distribution and equal to

(4.15)

(4.15)

Multiplying

the numerator and denominator of this expression by

![]() ,

we find that the coefficient a represents the ratio of the actual

kinetic energy of the stream at a given section to its kinetic

energy if the

velocity distribution was uniform across the section. For the

commonly observed velocity distribution (Fig.28), a is always

greater

than unity*, being unity when the velocity profile is a straight

line.

,

we find that the coefficient a represents the ratio of the actual

kinetic energy of the stream at a given section to its kinetic

energy if the

velocity distribution was uniform across the section. For the

commonly observed velocity distribution (Fig.28), a is always

greater

than unity*, being unity when the velocity profile is a straight

line.

Consider

two cross-sections of a real stream, denoting the mean total

head at those sections by

![]() and

and

![]() respectively.

Then,

respectively.

Then,

![]() (4.16)

(4.16)

where 2/г = total loss of energy (or head) along the stream between the two sections.

Applying Eq. (4.14), the foregoing equation can be rewritten as follows:

![]() (4.16')

(4.16')

This is Bernoulli's equation for real flow. It differs from the equation for a differential stream tube in an ideal liquid by the term representing the loss of energy (head) and the coefficient which takes into account the nonuniform velocity distribution. Furthermore, the equation contains the mean velocities across the respective sections.

Graphically this equation can be represented by a diagram like the one drawn for an ideal fluid, but taking into account the head losses. The latter increase steadily along the flow (Fig. 29).

Whereas Bernoulli's equation for an ideal fluid stream tube is an expression of the law of conservation of mechanical energy, for real flow it represents an energy-balance equation taking losses into account. The energy dissipated by the flow does not vanish, of course. It changes into.another, form of energy, heat, which raises the temperature of the liquid.

*

This can be proved by expressing the velocity v

in

Eq. (4.15) as a sum

![]() ,

dividing the integral into four integrals and analysing the

numerical

value of each.

,

dividing the integral into four integrals and analysing the

numerical

value of each.

The drop in the mean value of the total energy between any two points of a stream referred to unit length is called the energy gradient. The change in,the potential energy of a fluid referred to unit length is called the hydraulic gradient. In a pipe of uniform diameter with a constant velocity profile the two gradients are apparently the same.