- •Introduction to the Anchor Handling Course

- •Technical Specifications:

- •Winch Layout:

- •Power Settings / Bollard Pull

- •All operations on board must be performed in accordance with Company Procedures.

- •Risk Assessment

- •Planning

- •Planning:

- •Goal, example:

- •What to do:

- •Electrical winches

- •Winch operation

- •General Arrangement

- •A/H-Drum at full Capacity

- •Over speed

- •Water brake

- •Band brake

- •QUICK & Full Release

- •Hydraulic Winches

- •Lay out (B-type)

- •Hydraulic winch, “B-type”

- •TOWCON

- •Instruction for use of Wire Drums

- •Changing of Chain Wheels (Wildcats / Chain Lifter)

- •TRIPLEX - SHARK JAW SYSTEM.

- •Operation

- •Maintenance and inspections

- •Safety

- •2. OPERATION:

- •QUICK RELEASE:

- •EMERGENCY RELEASE:

- •CONTROL PANEL

- •Marks for Locked on Hinge Link

- •2.2- OPERATION OF THE "JAW IN POSITION ACCEPT" LEVER:

- •2.3 OPERATION OF THE CONTROL PANEL AT EMERGENCY POWER.

- •3. ELECTRIC AND HYDRAULIC POWER SYSTEM.

- •3. 1. ARRANGEMENT OF SYSTEM.

- •3.2. FUNCTIONING OF QUICK RELEASE - JAWS ONLY.

- •3.3. FUNCTIONING OF EMERGENCY RELEASE

- •4.2 Test without Load.

- •4.3 Test with Load.

- •5. General Maintenance

- •5.1 Accumulators Depressurising

- •5.2 Shark Jaw Unit

- •5.3 Guide Pins Units

- •5.4 Hydraulic System

- •5.5 Electric System

- •6. Control Measurements / Adjustments.

- •6.2 Adjustment of inductive proximity switches on lock cylinders.

- •6.3 Adjustment of Pressure Switches for Lock Pressure.

- •7. Test Program – Periodical Control

- •7.2 Checking List – Periodic Control Mechanical / Hydraulic.

- •7.3 Checking List – Periodic Control Electrical

- •7.4 Testing without Load – Yearly Testing.

- •7.5 Load Test – Emergency Release – 5 Year Control.

- •“Mark on line !”

- •“Double set of Jaws, Pins and Wire lifter”

- •View from the bridge.

- •“JAW READY FOR OPERATION”

- •“JAW LOCK POSITION ACCEPTED”

- •KARM FORK – SHARK JAW SYSTEM.

- •Wire and chain Stopper

- •Inserts for KARM FORK

- •Martensite:

- •Recommendations:

- •1. THE BASIC ELEMENTS OF STEEL WIRE ROPE

- •2. STEEL WIRE ROPE CONSTRUCTIONS

- •3. SPECIAL STEEL WIRE ROPES

- •4. USE OF STEEL WIRE ROPE

- •5. SELECTING THE RIGHT STEEL WIRE ROPE

- •6. ORDERING STEEL WIRE ROPE

- •7. STEEL WIRE ROPE TOLERANCES

- •8. HANDLING, INSPECTION AND INSTALLATION

- •9. INSPECTION AND MAINTENANCE

- •10. ELONGATION AND PRE-STRETCHING

- •11. OPERATING TEMPERATURES

- •12. MARTENSITE FORMATION

- •13. END TERMINATIONS

- •14. SOCKETING (WIRELOCK)

- •15. DRUM CAPACITY

- •16. CLASSIFICATION AND USE OF STEEL WIRE ROPE

- •17. ROPES

- •18. CHAINS AND LIFTING COMPONENTS

- •19. TECHNICAL CONVERSION TABLES

- •SWIVEL

- •MoorLink Swivel

- •Pin Extractor

- •Socket Bench

- •Chains and Fittings

- •STUD LINK MOORING CHAIN

- •OPEN LINK MOORING CHAIN

- •KENTER JOINING LINKS

- •PEAR SHAPE ANCHOR CONNECTING LINK

- •DETACHABLE CONNECTING LINK

- •D’ TYPE JOINING SHACKLES

- •‘D’ TYPE ANCHOR SHACKLES

- •SHACKLES

- •JAW & JAW SWIVELS

- •BOW & EYE SWIVELS

- •MOORING RINGS

- •FISH PLATES

- •PELICAN HOOKS

- •SLIP HOOKS

- •‘J’ CHASERS

- •PERMANENT CHASERS

- •DETACHABLE PERMANENT CHAIN CHASERS

- •PERMANENT WIRE CHASERS

- •‘J’ LOCK CHAIN CHASERS

- •The way to break the anchor loose of the bottom is therefore:

- •Table of contents

- •Introduction

- •General

- •Mooring systems

- •Mooring components

- •History of drag embedment anchors

- •Characteristics of anchor types

- •History of vryhof anchor designs

- •Criteria for anchor holding capacity

- •Theory

- •Criteria for good anchor design

- •Aspects of soil mechanics in anchor design

- •Soil classification

- •Fluke/shank angle

- •Fluke area

- •Strength of an anchor design

- •Anchor loads and safety factors

- •Anchor behaviour in the soil

- •Proof loads for high holding power anchors

- •Anchor tests

- •Soil table

- •Practice

- •Introduction

- •Soil survey

- •Pile or anchor

- •Setting the fluke/shank angle

- •Connecting a swivel to the Stevpris anchor

- •Chasers

- •Chaser types

- •Stevpris installation

- •Laying anchors

- •Retrieving anchors

- •Anchor orientation

- •Decking the Stevpris anchor

- •What not to do!

- •Racking the Stevpris

- •Deploying Stevpris from the anchor rack

- •Boarding the anchor in deep water

- •Ballast In fluke

- •Chaser equilibrium

- •Deployment for permanent moorings

- •Piggy-backing

- •Piggy-back methods

- •Stevmanta VLA installation

- •Installation procedure

- •Stevmanta retrieval

- •Double line installation procedure

- •Stevmanta retrieval

- •Double line installation with Stevtensioner

- •The Stevtensioner

- •The working principle of the tensioner

- •Measurement of the tensions applied

- •Umbilical cable and measuring pin

- •Break - link

- •Duration of pretensioning anchors and piles

- •Handling the Stevtensioner

- •General tensioning procedures

- •Hook-up

- •Lowering

- •Tensioning mode

- •Retrieving

- •Supply vessels/anchor handling vessels

- •Product data

- •Introduction

- •Dimensions of vryhof anchor types

- •Proof load test for HHP anchors (US units)

- •Dimensions of vryhof tensioners

- •Proof load/break load of chains (in US units)

- •Chain components and forerunners

- •Connecting links

- •Conversion table

- •Mooring line catenary

- •Mooring line holding capacity

- •Shackles

- •Wire Rope

- •Wire rope sockets

- •Thimbles

- •Synthetic ropes

- •Mooring hawsers

- •Main dimensions chasers

- •Stevin Mk3 UHC chart

- •Stevin Mk3 drag and penetration chart

- •Stevpris Mk5 UHC chart

- •Stevpris Mk5 drag and penetration chart

- •Stevmanta VLA UPC chart

- •Introduction

- •Propulsion system

- •Propellers

- •Thrusters

- •Rudders

- •Manoeuvring

- •Current

- •Wind

- •Other forces

- •Turning point (Pivot point)

- •Ship handling

- •General layout Jack-Up drilling unit:

- •General information about a Semi Submersible drilling unit:

CHASERS & GRAPNELS

PERMANENT CHASERS

BEL 102 - 106 - 110

G

Hø

A

|

C |

|

D |

F |

|

E |

||

B |

Type |

S.W.L. |

Proof |

|

|

|

|

|

|

|

|

|

Test |

|

A |

B |

C |

D |

E |

F |

G |

H |

||

BEL |

100 |

250 |

in |

65.25 |

45.00 |

39.00 |

30.00 |

12.00 |

7.50 |

4.88 |

3.38 |

102 |

Tonnes |

Tonnes |

mm |

1657 |

1143 |

991 |

762 |

305 |

191 |

124 |

86 |

BEL |

130 |

250 |

in |

67.00 |

46.00 |

39.00 |

30.00 |

15.00 |

8.00 |

5.13 |

3.88 |

106 |

Tonnes |

Tonnes |

mm |

1702 |

1168 |

991 |

762 |

381 |

203 |

130 |

99 |

BEL |

130 |

250 |

in |

73.50 |

49.00 |

44.50 |

33.00 |

13.00 |

8.00 |

5.13 |

3.88 |

110 |

Tonnes |

Tonnes |

mm |

1867 |

1245 |

1130 |

838 |

330 |

203 |

130 |

99 |

Weight: BEL 102 1088 Kg

BEL 106 1451 Kg

BEL 110 1433 Kg

Lifting eye dimensions shown are standard for each type. Specials can be made to suit customer requirements.

3.5

CHASERS & GRAPNELS

DETACHABLE PERMANENT CHAIN CHASERS

BEL 107 - 108 - 111

G

Hø

A

|

C |

|

F |

D |

E |

B |

Type |

S.W.L. |

Proof |

|

|

|

|

|

|

|

|

|

Test |

|

A |

B |

C |

D |

E |

F |

G |

H |

||

BEL |

100 |

250 |

in |

74.25 |

45.00 |

42.50 |

30.00 |

12.00 |

7.50 |

4.88 |

3.38 |

107 |

Tonnes |

Tonnes |

mm |

1886 |

1143 |

1080 |

762 |

305 |

191 |

124 |

86 |

BEL |

130 |

250 |

in |

76.00 |

46.00 |

42.00 |

30.00 |

15.00 |

8.00 |

5.13 |

3.88 |

108 |

Tonnes |

Tonnes |

mm |

1931 |

1168 |

1067 |

762 |

381 |

203 |

130 |

99 |

BEL |

130 |

250 |

in |

78.50 |

49.00 |

44.50 |

33.00 |

13.00 |

8.00 |

5.13 |

3.88 |

111 |

Tonnes |

Tonnes |

mm |

1994 |

1245 |

1130 |

838 |

330 |

203 |

130 |

99 |

Weight: BEL 107 1238 Kg

BEL 108 1656 Kg

BEL 111 1742 Kg

Lifting eye dimensions shown are standard for each type. Specials can be made to suit customer requirements.

3.6

CHASERS & GRAPNELS

PERMANENT WIRE CHASERS

BEL 210 - 213 - 214 - 215

G E

A

D F

B

Hø

C

|

|

Proof |

|

|

|

|

|

|

|

|

|

|

S.W.L. |

Test |

|

|

|

|

|

|

|

|

|

Type |

Tonnes |

Tonnes |

|

A |

B |

C |

D |

E |

F |

G |

H |

BEL 210 |

130 |

250 |

mm |

2073 |

1245 |

1203 |

838 |

330 |

432 |

130 |

99 |

BEL 213 |

130 |

250 |

mm |

1962 |

1099 |

1086 |

692 |

330 |

445 |

130 |

99 |

BEL 214 |

130 |

250 |

mm |

2318 |

1308 |

1397 |

902 |

330 |

508 |

130 |

99 |

BEL 215 |

250 |

400 |

mm |

2051 |

1168 |

1060 |

711 |

356 |

445 |

178 |

127 |

Weight: BEL 210 1959 kg

BEL 213 1846 kg

BEL 214 2530 kg

BEL 215 2495 kg

Lifting eye dimensions shown are standard for each type. Specials can be made to suit customer requirements.

3.7

CHASERS & GRAPNELS

‘J’ LOCK CHAIN CHASERS

BEL 115

82.00 |

2083 |

12.00 |

4.88 |

|||

305 |

124 |

|||

|

|

|

|

|

3.38 |

86 |

|

||

ø28.00 711

21.00 |

58.50 |

533 |

1486 |

BEL 115/35 for chain 21/2 inch to 31/2 inch.

BEL 115/45 for chain 33/4 inch to 41/2 inch.

Safe Working Load: |

100 Tonnes |

Proof Test Load: |

250 Tonnes |

Weight: |

1778 Kg |

3.8

MTC

MTC

Anchor Handling Course

Breaking the anchor off the bottom:

Breaking out anchors takes its time mainly because:

Breaking out forces is caused by the volume of the soil on the fluke and the sucking or under pressure below it. Pulling up the anchor increases the soil resistance due to the dilatant behaviour of the soil. This resistance decreases with time, reducing the negative pressure and thus easing the break out.

For most anchors the following guide is useful:

1.In sandy soil the break out force will be between 12 and 17% of the anchor's test load.

2.In clay soil the break out force will be about 60% of the anchor’s test load.

3.In sticky soft soil the break out force can exceed 100% of the anchor’s test load.

As the typical test tension of the anchor is around 1/3 break strain of the chain or wire in use, the following table is a summary of the forces:

Chain type |

1/3 Break load |

Sandy 17% |

Clay 60% Soft Soil 100% |

|

76 mm U3 |

143 |

24 |

86 |

143+ |

76 mm ORQ |

154 |

26 |

93 |

154+ |

76 mm K4 |

200 |

34 |

120 |

200+ |

Breaking the anchor off the bottom is very likely the operation where there has been most loss of time and equipment.

It is a very time-consuming and hard job to get the anchor up, when the connection between the anchor and the vessel is broken.

Wrong use of equipment and wrong technique gives many possibilities of damaging the work and or the pennant wire, other anchor handling equipment i.e. the swivel and especially maybe also the winch.

One of these possibilities must here be mentioned:

The mentioned possibility of damaging the wire is overload on the wire during the work with breaking the anchor loose from the bottom.

A very common but inappropriate method is to shorten up on the work wire - heave in on the winch – and keep on going until the stern roller is above the anchor position and the anchor will break loose or the wire / equipment will break. See fig 1, page 2, chapter 11.

Shorten up on the work wire might help breaking loose the anchor in many situations, but on the other hand there is a high risk for overloading your equipment.

The tension, which during the above mentioned method is used on the wire, is depended on following circumstances:

1.Winch pull force

2.Vessel’s displacement

3.Nature of the sea / sea state

M:\ANCHOR HANDLING\Course Material\Training Manual New\Chapter 11\Breaking the anchor off the bottom.doc

Chapter 11 |

Page 1 |

MTC

MTC

Anchor Handling Course

Pt. 1 is depending on the size of the winch and which layer you are working on. If you are using one of the bigger winch sizes you are able to exceed the breaking load of the wire.

Pt. 2 and pt. 3 can easily by many times exceed the breaking load of the wire regardless the size of winch – small or large.

|

|

D |

|

B |

B |

|

|

|

|

|

A |

C |

|

A |

Fig 1

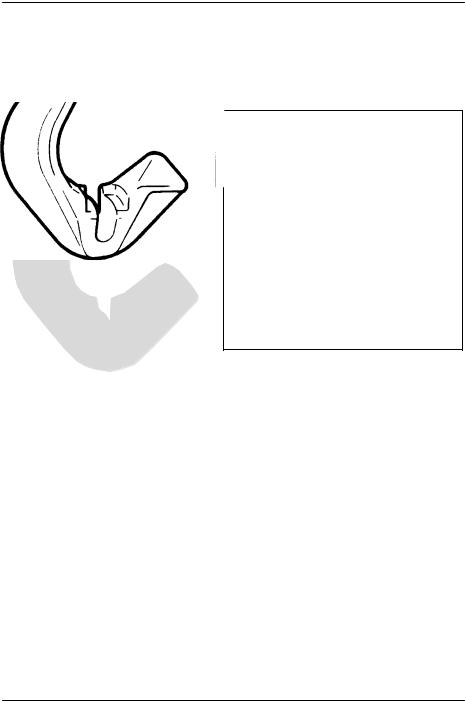

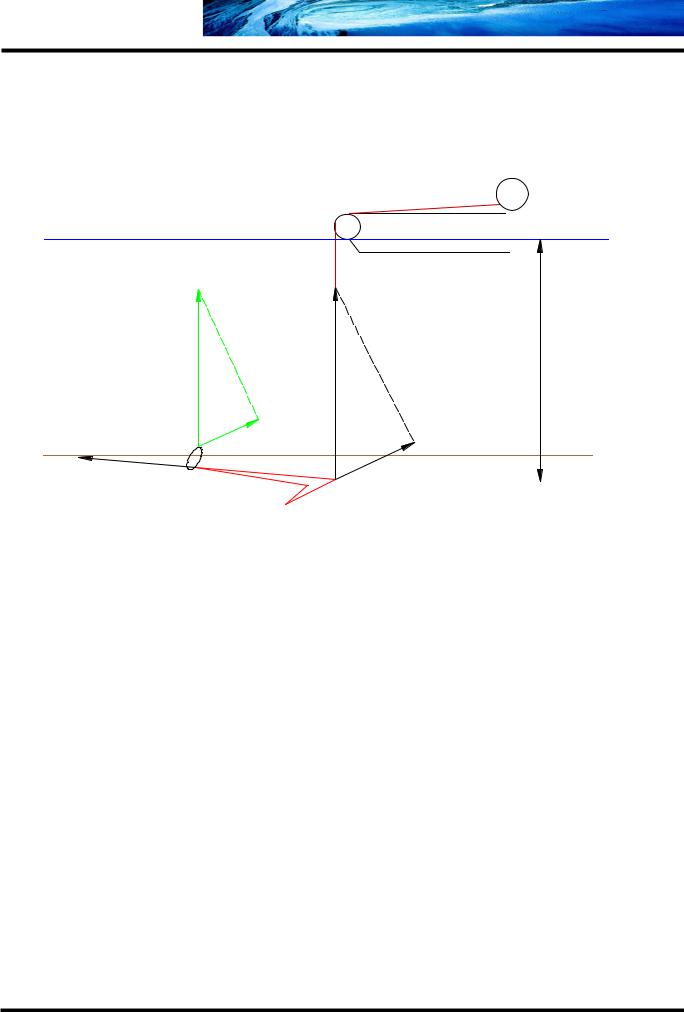

•“A” is the break loose force, indicating the best direction and size of tension to be used for breaking loose the anchor.

•“B” will be the tension you will get in your work wire in order to obtain the required force “A”, if position of the stern roller is above the anchor,

•“D” is water depth plus penetration of anchor.

Anchors in very soft clay can be buried very deep. A penetration of 60 meters is mentioned.

Another fact is that the soil aft of the anchor is disturbed due to the penetration of the anchor.

While the soil above the anchor might be intact and has probably been it for several thousand years.

The forces illustrated on fig 1 are the same if position of chaser collar is on top of the anchor shank as e.g. on a Stevpris. (Illustrated with green arrows on fig 1)

M:\ANCHOR HANDLING\Course Material\Training Manual New\Chapter 11\Breaking the anchor off the bottom.doc

Chapter 11 |

Page 2 |