- •Introduction to the Anchor Handling Course

- •Technical Specifications:

- •Winch Layout:

- •Power Settings / Bollard Pull

- •All operations on board must be performed in accordance with Company Procedures.

- •Risk Assessment

- •Planning

- •Planning:

- •Goal, example:

- •What to do:

- •Electrical winches

- •Winch operation

- •General Arrangement

- •A/H-Drum at full Capacity

- •Over speed

- •Water brake

- •Band brake

- •QUICK & Full Release

- •Hydraulic Winches

- •Lay out (B-type)

- •Hydraulic winch, “B-type”

- •TOWCON

- •Instruction for use of Wire Drums

- •Changing of Chain Wheels (Wildcats / Chain Lifter)

- •TRIPLEX - SHARK JAW SYSTEM.

- •Operation

- •Maintenance and inspections

- •Safety

- •2. OPERATION:

- •QUICK RELEASE:

- •EMERGENCY RELEASE:

- •CONTROL PANEL

- •Marks for Locked on Hinge Link

- •2.2- OPERATION OF THE "JAW IN POSITION ACCEPT" LEVER:

- •2.3 OPERATION OF THE CONTROL PANEL AT EMERGENCY POWER.

- •3. ELECTRIC AND HYDRAULIC POWER SYSTEM.

- •3. 1. ARRANGEMENT OF SYSTEM.

- •3.2. FUNCTIONING OF QUICK RELEASE - JAWS ONLY.

- •3.3. FUNCTIONING OF EMERGENCY RELEASE

- •4.2 Test without Load.

- •4.3 Test with Load.

- •5. General Maintenance

- •5.1 Accumulators Depressurising

- •5.2 Shark Jaw Unit

- •5.3 Guide Pins Units

- •5.4 Hydraulic System

- •5.5 Electric System

- •6. Control Measurements / Adjustments.

- •6.2 Adjustment of inductive proximity switches on lock cylinders.

- •6.3 Adjustment of Pressure Switches for Lock Pressure.

- •7. Test Program – Periodical Control

- •7.2 Checking List – Periodic Control Mechanical / Hydraulic.

- •7.3 Checking List – Periodic Control Electrical

- •7.4 Testing without Load – Yearly Testing.

- •7.5 Load Test – Emergency Release – 5 Year Control.

- •“Mark on line !”

- •“Double set of Jaws, Pins and Wire lifter”

- •View from the bridge.

- •“JAW READY FOR OPERATION”

- •“JAW LOCK POSITION ACCEPTED”

- •KARM FORK – SHARK JAW SYSTEM.

- •Wire and chain Stopper

- •Inserts for KARM FORK

- •Martensite:

- •Recommendations:

- •1. THE BASIC ELEMENTS OF STEEL WIRE ROPE

- •2. STEEL WIRE ROPE CONSTRUCTIONS

- •3. SPECIAL STEEL WIRE ROPES

- •4. USE OF STEEL WIRE ROPE

- •5. SELECTING THE RIGHT STEEL WIRE ROPE

- •6. ORDERING STEEL WIRE ROPE

- •7. STEEL WIRE ROPE TOLERANCES

- •8. HANDLING, INSPECTION AND INSTALLATION

- •9. INSPECTION AND MAINTENANCE

- •10. ELONGATION AND PRE-STRETCHING

- •11. OPERATING TEMPERATURES

- •12. MARTENSITE FORMATION

- •13. END TERMINATIONS

- •14. SOCKETING (WIRELOCK)

- •15. DRUM CAPACITY

- •16. CLASSIFICATION AND USE OF STEEL WIRE ROPE

- •17. ROPES

- •18. CHAINS AND LIFTING COMPONENTS

- •19. TECHNICAL CONVERSION TABLES

- •SWIVEL

- •MoorLink Swivel

- •Pin Extractor

- •Socket Bench

- •Chains and Fittings

- •STUD LINK MOORING CHAIN

- •OPEN LINK MOORING CHAIN

- •KENTER JOINING LINKS

- •PEAR SHAPE ANCHOR CONNECTING LINK

- •DETACHABLE CONNECTING LINK

- •D’ TYPE JOINING SHACKLES

- •‘D’ TYPE ANCHOR SHACKLES

- •SHACKLES

- •JAW & JAW SWIVELS

- •BOW & EYE SWIVELS

- •MOORING RINGS

- •FISH PLATES

- •PELICAN HOOKS

- •SLIP HOOKS

- •‘J’ CHASERS

- •PERMANENT CHASERS

- •DETACHABLE PERMANENT CHAIN CHASERS

- •PERMANENT WIRE CHASERS

- •‘J’ LOCK CHAIN CHASERS

- •The way to break the anchor loose of the bottom is therefore:

- •Table of contents

- •Introduction

- •General

- •Mooring systems

- •Mooring components

- •History of drag embedment anchors

- •Characteristics of anchor types

- •History of vryhof anchor designs

- •Criteria for anchor holding capacity

- •Theory

- •Criteria for good anchor design

- •Aspects of soil mechanics in anchor design

- •Soil classification

- •Fluke/shank angle

- •Fluke area

- •Strength of an anchor design

- •Anchor loads and safety factors

- •Anchor behaviour in the soil

- •Proof loads for high holding power anchors

- •Anchor tests

- •Soil table

- •Practice

- •Introduction

- •Soil survey

- •Pile or anchor

- •Setting the fluke/shank angle

- •Connecting a swivel to the Stevpris anchor

- •Chasers

- •Chaser types

- •Stevpris installation

- •Laying anchors

- •Retrieving anchors

- •Anchor orientation

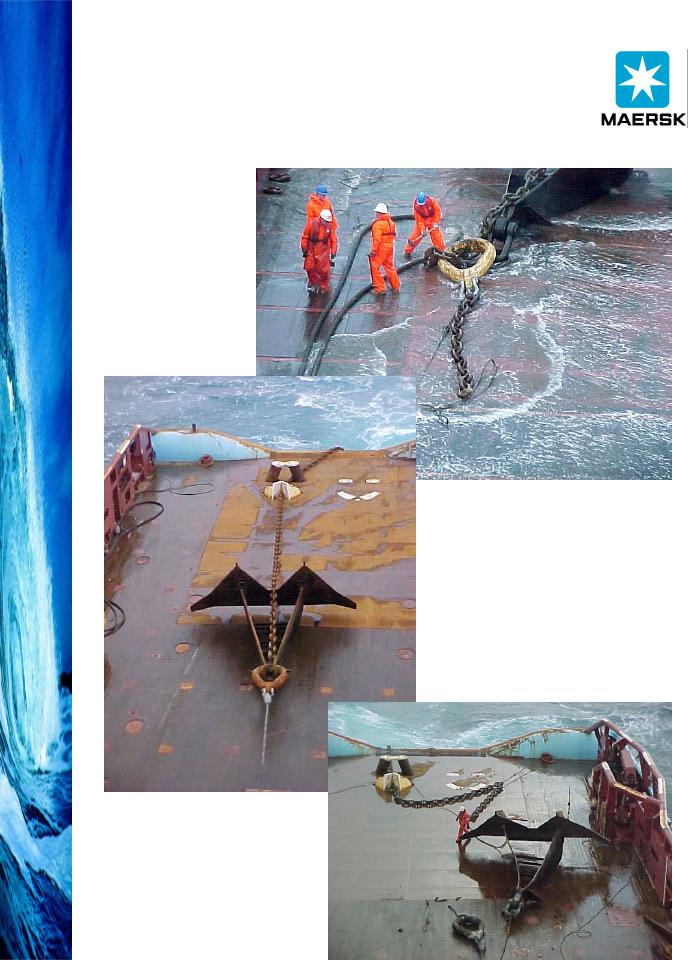

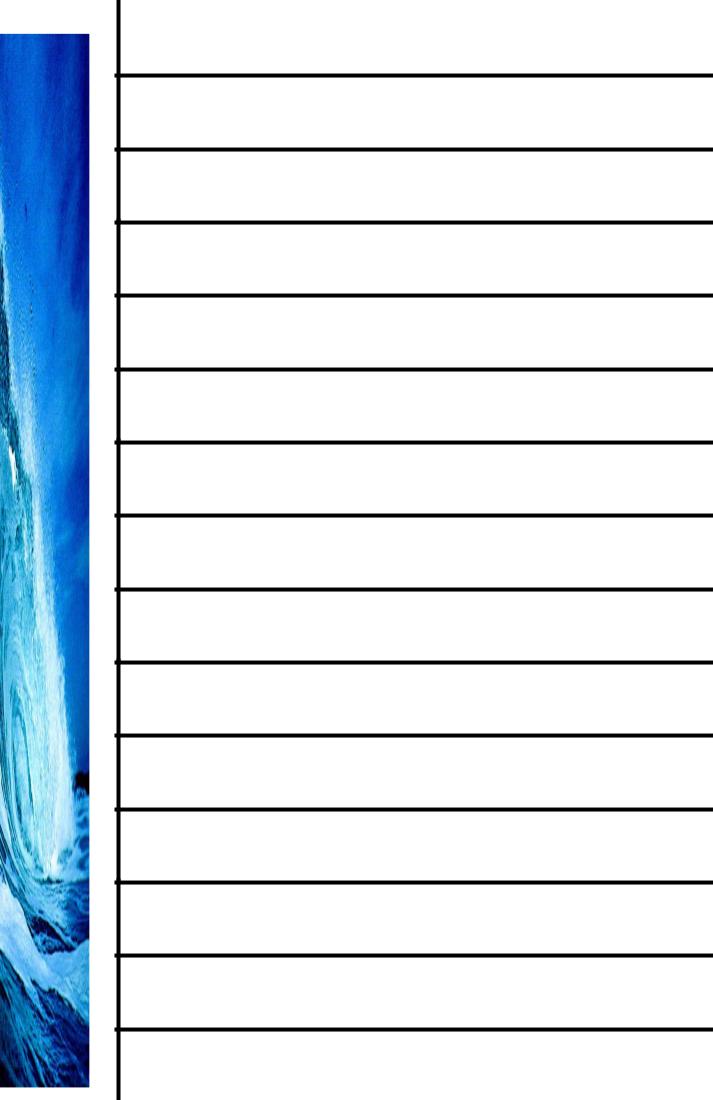

- •Decking the Stevpris anchor

- •What not to do!

- •Racking the Stevpris

- •Deploying Stevpris from the anchor rack

- •Boarding the anchor in deep water

- •Ballast In fluke

- •Chaser equilibrium

- •Deployment for permanent moorings

- •Piggy-backing

- •Piggy-back methods

- •Stevmanta VLA installation

- •Installation procedure

- •Stevmanta retrieval

- •Double line installation procedure

- •Stevmanta retrieval

- •Double line installation with Stevtensioner

- •The Stevtensioner

- •The working principle of the tensioner

- •Measurement of the tensions applied

- •Umbilical cable and measuring pin

- •Break - link

- •Duration of pretensioning anchors and piles

- •Handling the Stevtensioner

- •General tensioning procedures

- •Hook-up

- •Lowering

- •Tensioning mode

- •Retrieving

- •Supply vessels/anchor handling vessels

- •Product data

- •Introduction

- •Dimensions of vryhof anchor types

- •Proof load test for HHP anchors (US units)

- •Dimensions of vryhof tensioners

- •Proof load/break load of chains (in US units)

- •Chain components and forerunners

- •Connecting links

- •Conversion table

- •Mooring line catenary

- •Mooring line holding capacity

- •Shackles

- •Wire Rope

- •Wire rope sockets

- •Thimbles

- •Synthetic ropes

- •Mooring hawsers

- •Main dimensions chasers

- •Stevin Mk3 UHC chart

- •Stevin Mk3 drag and penetration chart

- •Stevpris Mk5 UHC chart

- •Stevpris Mk5 drag and penetration chart

- •Stevmanta VLA UPC chart

- •Introduction

- •Propulsion system

- •Propellers

- •Thrusters

- •Rudders

- •Manoeuvring

- •Current

- •Wind

- •Other forces

- •Turning point (Pivot point)

- •Ship handling

- •General layout Jack-Up drilling unit:

- •General information about a Semi Submersible drilling unit:

Maersk Training Centre A/S

Anchor Handling

Simulator Course

“Best Practise in

Anchor Handling”

Maersk Training Centre A/S

1.Program. Abbreviations

Introduction to Anchor Handling Course

2.“MAERSK TRAINER” Technical Specifications

3.Company Policy. Procedures

4.Risk Assessment. Planning

5.Anchor Handling Winches. Chain Wheels

6.Shark Jaws, Triplex

7.Shark Jaws, Karm Fork

8.Wire Rope, Guidelines, Maintenance

9.Anchor Handling Equipment

Swivel – Pin Extractor – Socket Bench

10.Chains and Fittings Chasers and Grapnels

11.Anchor Handling Breaking the anchor…..

12.Anchor Deployment – PCP

13.Vryhof Anchor Manual 2000

14.Ship Handling. Manoeuvring

15.Drilling Units / - Operations

MTC

MTC

COURSE NAME

Manual standard clause

This manual is the property of Maersk Training Centre A/S (hereinafter “MTC A/S) and is only for the use of Course participants conducting courses at MTC A/S.

This manual shall not affect the legal relationship or liability of MTC A/S with or to any third party and neither shall such third party be entitled to reply upon it.

MTC A/S shall have no liability for technical or editorial errors or omissions in this manual; nor any damage, including but not limited to direct, punitive, incidental, or consequential damages resulting from or arising out of its use.

No part of this manual may be reproduced in any shape or form or by any means electronically, mechanically, by photocopying, recording or otherwise, without the prior permission of MTC A/S.

Copyright MTC 2002-09-10

Prepared by: PFR

Modified & printed: 2003-01-07

Modified by:

Internal reference: M:\ANCHOR HANDLING\Course Material\Training Manual New\Chapter 00\2.0 Index.doc

Contact MTC

Maersk Training Centre A/S

Dyrekredsen 4

Rantzausminde

5700 Svendborg

Denmark

Phone: |

+45 63 21 99 99 |

Telefax: |

+45 63 21 99 49 |

Telex: |

SVBMTC |

E-mail: |

MTC@MAERSKTRAININGCENTRE.COM |

Homepage: WWW.MAERSKTRAININGCENTRE.COM

Managing Director: Claus Bihl

2.0 Index.doc |

Chapter 00 |

Page 2 |

MTC

MTC

Anchor Handling Course

Introduction to the Anchor Handling Course

Background

A.P.Møller owns and operates a modern fleet of anchor handling vessels.

The vessels are chartered to oil companies, and rig operators; the jobs are anchor handling, tow and construction jobs.

The technical development of these ships has been fast to meet the increased demands.

The demands to the performance of the ships have been increased too.

A few hours off service can mean large economic losses for the different parties involved.

In the last years an increased focus have been on avoiding accidents, and the frequency of these accidents are low. To get the frequency even lower, actions to avoid accidents are needed. “Learning by doing”, on board an anchor handling vessels as the only mean of education, will not be accepted in the future. Part of this training process needs to be moved ashore, where crew, ship and equipment can be tested without risk in all situations.

Here we will use the anchor-handling simulator.

A study of accidents and incidents occurred on anchor handling vessels (AHV) during anchor handling operations reveals that some of the most common causes leading to incidents and/or accidents are lack of or inadequate:

•Experience

•Knowledge

•Planning

•Risk assessment

•Communication

•Teamwork

•Awareness

The keywords for addressing these causes are: “training, training and more training”

The value of on-board, hands-on training is well known and beyond any doubt but the knowledge and experience gained is sometimes paid with loss of human life or limbs, environmental pollution and/or costly damage to property.

This simulator course was developed in order to give new officers on AHV’s the possibility of acquiring the basic knowledge and skills in a “as close to the real thing as possible” environment, the only thing, however, that might get damaged is “ones own pride”.

The aims of the anchor handling course are:

•To promote safe and efficient anchor handling operations by enhancing the bridge teams knowledge of, and skills in anchor handling operations.

M:\ANCHOR HANDLING\Course Material\Training Manual New\Chapter 01\2.Introduction & Abbreviations.doc

Chapter 01 |

Page 1 |

MTC

MTC

Anchor Handling Course

The objectives of the anchor handling course are:

By planning of and, in the simulator, carrying out anchor handling operations under normal conditions, the participant shall demonstrate a thorough knowledge of and basic skills in:

•Planning and risk assessment of anchor handling operations adhering to procedures and safety rules

•As conning officer carry out exercises in anchor handling operations

•As winch operator carry out exercises in anchor handling operations

•On user level, the design, general maintenance and correct safe use of anchor handling equipment

•The use of correct phraseology

The simulator course

The course consists of theoretical lessons alternating with simulator exercises.

The theoretical lessons

The theoretical lessons addresses:

•AHV deck lay-out and equipment

•AH winch (electrical and hydraulic) lay-out and function

•Anchor types, chain, wires, grapnels, etc. maintenance and use

•Planning of AH operations

•Risk assessment

•Procedures

•Safety aspects and rules

The simulator exercises

The simulator exercises consist of one familiarisation exercise and 3 to 4 AH operations. The weather condition during the exercises will be favourable and other conditions normal.

The tasks in the AH exercises are:

•Preparing the AHV for anchor handling

•Running out an anchor on a water depth of 100 to 700 meters

•Retrieving an anchor from a water depth of 100 to 700 meters

•Operating an anchor system with insert wire

During the simulator exercises the participants will man the bridge. They will be forming a bridge team, one acting as the conning officer the other as the winch operator. A captain/chief engineer will act as a consultant.

Before commencing the exercise, the participants are expected to make a thorough planning of the AH operation. They will present the plan to the instructor in the pre-operation briefing for verification.

M:\ANCHOR HANDLING\Course Material\Training Manual New\Chapter 01\2.Introduction & Abbreviations.doc

Chapter 01 |

Page 2 |

MTC

MTC

Anchor Handling Course

During the exercises, the simulator operator will act and communicate as all relevant personnel e.g.:

•Deckhands – engine room

•Rig crew – crane driver – tow master

•Etc.

The instructor will monitor the progress of the exercises and evaluate the performance of the team and each individual.

Debriefing

Each exercise will be followed by a debriefing session during which the instructor and the team will discuss the progress and the outcome of the exercise.

M:\ANCHOR HANDLING\Course Material\Training Manual New\Chapter 01\2.Introduction & Abbreviations.doc

Chapter 01 |

Page 3 |

MTC

MTC

Anchor Handling Course

Commonly used abbreviations:

AHTS: |

Anchor Handling tug supply |

PSV: |

Platform supply vessel |

DVS: |

Diving support vessel |

SV: |

Survey vessel |

MODU: |

Mobil offshore drilling unit |

FPU: |

Floating production unit |

FPDSO: |

Floating production, drilling, storage and offloading |

FPSO: |

Floating production, storage and offloading |

FPS: |

Floating production system |

TLP: |

Tension leg platform |

SBM: |

Single buoy mooring |

SPM: |

Single point mooring |

CALM: |

Catenary anchored leg mooring |

SALM: |

Single anchor leg mooring |

SSCV: |

Semi submersible crane vessel |

HLV: |

Heavy lift vessel |

RTV: |

Rock dumping/trenching vessel |

PLV: |

Pipe laying vessel |

SSAV: |

Semi submersible accommodation vessel |

ROV: |

Remotely operated vehicle |

ROT: |

Remotely operated tool |

AUV: |

Autonomous underwater vehicle |

DP: |

Dynamic positioning |

DPO: |

Dynamic positioning officer |

HPR: |

Hydroaccoustic positioning reference |

TW: |

Towing winch |

AHW: |

Anchor Handling winch |

DMW: |

Dead Man Wire |

PCP: |

Permanent chaser pennant |

HHP: |

High holding power anchors |

VLA: |

Vertical load anchors |

SCA: |

Suction caisson anchor |

DEA: |

Drag embedded anchor |

Sepla: |

Suction embedded plate anchor. |

QMS: |

Quality management system |

HSE: |

Health, safety and environment |

ISM: |

International ships management |

WW:Work Wire

VSP: |

Vertical seismic survey |

Weight in water: Weight x 0,85

M:\ANCHOR HANDLING\Course Material\Training Manual New\Chapter 01\2.Introduction & Abbreviations.doc

Chapter 01 |

Page 4 |