- •Introduction to the Anchor Handling Course

- •Technical Specifications:

- •Winch Layout:

- •Power Settings / Bollard Pull

- •All operations on board must be performed in accordance with Company Procedures.

- •Risk Assessment

- •Planning

- •Planning:

- •Goal, example:

- •What to do:

- •Electrical winches

- •Winch operation

- •General Arrangement

- •A/H-Drum at full Capacity

- •Over speed

- •Water brake

- •Band brake

- •QUICK & Full Release

- •Hydraulic Winches

- •Lay out (B-type)

- •Hydraulic winch, “B-type”

- •TOWCON

- •Instruction for use of Wire Drums

- •Changing of Chain Wheels (Wildcats / Chain Lifter)

- •TRIPLEX - SHARK JAW SYSTEM.

- •Operation

- •Maintenance and inspections

- •Safety

- •2. OPERATION:

- •QUICK RELEASE:

- •EMERGENCY RELEASE:

- •CONTROL PANEL

- •Marks for Locked on Hinge Link

- •2.2- OPERATION OF THE "JAW IN POSITION ACCEPT" LEVER:

- •2.3 OPERATION OF THE CONTROL PANEL AT EMERGENCY POWER.

- •3. ELECTRIC AND HYDRAULIC POWER SYSTEM.

- •3. 1. ARRANGEMENT OF SYSTEM.

- •3.2. FUNCTIONING OF QUICK RELEASE - JAWS ONLY.

- •3.3. FUNCTIONING OF EMERGENCY RELEASE

- •4.2 Test without Load.

- •4.3 Test with Load.

- •5. General Maintenance

- •5.1 Accumulators Depressurising

- •5.2 Shark Jaw Unit

- •5.3 Guide Pins Units

- •5.4 Hydraulic System

- •5.5 Electric System

- •6. Control Measurements / Adjustments.

- •6.2 Adjustment of inductive proximity switches on lock cylinders.

- •6.3 Adjustment of Pressure Switches for Lock Pressure.

- •7. Test Program – Periodical Control

- •7.2 Checking List – Periodic Control Mechanical / Hydraulic.

- •7.3 Checking List – Periodic Control Electrical

- •7.4 Testing without Load – Yearly Testing.

- •7.5 Load Test – Emergency Release – 5 Year Control.

- •“Mark on line !”

- •“Double set of Jaws, Pins and Wire lifter”

- •View from the bridge.

- •“JAW READY FOR OPERATION”

- •“JAW LOCK POSITION ACCEPTED”

- •KARM FORK – SHARK JAW SYSTEM.

- •Wire and chain Stopper

- •Inserts for KARM FORK

- •Martensite:

- •Recommendations:

- •1. THE BASIC ELEMENTS OF STEEL WIRE ROPE

- •2. STEEL WIRE ROPE CONSTRUCTIONS

- •3. SPECIAL STEEL WIRE ROPES

- •4. USE OF STEEL WIRE ROPE

- •5. SELECTING THE RIGHT STEEL WIRE ROPE

- •6. ORDERING STEEL WIRE ROPE

- •7. STEEL WIRE ROPE TOLERANCES

- •8. HANDLING, INSPECTION AND INSTALLATION

- •9. INSPECTION AND MAINTENANCE

- •10. ELONGATION AND PRE-STRETCHING

- •11. OPERATING TEMPERATURES

- •12. MARTENSITE FORMATION

- •13. END TERMINATIONS

- •14. SOCKETING (WIRELOCK)

- •15. DRUM CAPACITY

- •16. CLASSIFICATION AND USE OF STEEL WIRE ROPE

- •17. ROPES

- •18. CHAINS AND LIFTING COMPONENTS

- •19. TECHNICAL CONVERSION TABLES

- •SWIVEL

- •MoorLink Swivel

- •Pin Extractor

- •Socket Bench

- •Chains and Fittings

- •STUD LINK MOORING CHAIN

- •OPEN LINK MOORING CHAIN

- •KENTER JOINING LINKS

- •PEAR SHAPE ANCHOR CONNECTING LINK

- •DETACHABLE CONNECTING LINK

- •D’ TYPE JOINING SHACKLES

- •‘D’ TYPE ANCHOR SHACKLES

- •SHACKLES

- •JAW & JAW SWIVELS

- •BOW & EYE SWIVELS

- •MOORING RINGS

- •FISH PLATES

- •PELICAN HOOKS

- •SLIP HOOKS

- •‘J’ CHASERS

- •PERMANENT CHASERS

- •DETACHABLE PERMANENT CHAIN CHASERS

- •PERMANENT WIRE CHASERS

- •‘J’ LOCK CHAIN CHASERS

- •The way to break the anchor loose of the bottom is therefore:

- •Table of contents

- •Introduction

- •General

- •Mooring systems

- •Mooring components

- •History of drag embedment anchors

- •Characteristics of anchor types

- •History of vryhof anchor designs

- •Criteria for anchor holding capacity

- •Theory

- •Criteria for good anchor design

- •Aspects of soil mechanics in anchor design

- •Soil classification

- •Fluke/shank angle

- •Fluke area

- •Strength of an anchor design

- •Anchor loads and safety factors

- •Anchor behaviour in the soil

- •Proof loads for high holding power anchors

- •Anchor tests

- •Soil table

- •Practice

- •Introduction

- •Soil survey

- •Pile or anchor

- •Setting the fluke/shank angle

- •Connecting a swivel to the Stevpris anchor

- •Chasers

- •Chaser types

- •Stevpris installation

- •Laying anchors

- •Retrieving anchors

- •Anchor orientation

- •Decking the Stevpris anchor

- •What not to do!

- •Racking the Stevpris

- •Deploying Stevpris from the anchor rack

- •Boarding the anchor in deep water

- •Ballast In fluke

- •Chaser equilibrium

- •Deployment for permanent moorings

- •Piggy-backing

- •Piggy-back methods

- •Stevmanta VLA installation

- •Installation procedure

- •Stevmanta retrieval

- •Double line installation procedure

- •Stevmanta retrieval

- •Double line installation with Stevtensioner

- •The Stevtensioner

- •The working principle of the tensioner

- •Measurement of the tensions applied

- •Umbilical cable and measuring pin

- •Break - link

- •Duration of pretensioning anchors and piles

- •Handling the Stevtensioner

- •General tensioning procedures

- •Hook-up

- •Lowering

- •Tensioning mode

- •Retrieving

- •Supply vessels/anchor handling vessels

- •Product data

- •Introduction

- •Dimensions of vryhof anchor types

- •Proof load test for HHP anchors (US units)

- •Dimensions of vryhof tensioners

- •Proof load/break load of chains (in US units)

- •Chain components and forerunners

- •Connecting links

- •Conversion table

- •Mooring line catenary

- •Mooring line holding capacity

- •Shackles

- •Wire Rope

- •Wire rope sockets

- •Thimbles

- •Synthetic ropes

- •Mooring hawsers

- •Main dimensions chasers

- •Stevin Mk3 UHC chart

- •Stevin Mk3 drag and penetration chart

- •Stevpris Mk5 UHC chart

- •Stevpris Mk5 drag and penetration chart

- •Stevmanta VLA UPC chart

- •Introduction

- •Propulsion system

- •Propellers

- •Thrusters

- •Rudders

- •Manoeuvring

- •Current

- •Wind

- •Other forces

- •Turning point (Pivot point)

- •Ship handling

- •General layout Jack-Up drilling unit:

- •General information about a Semi Submersible drilling unit:

TEKNISK INFORMATION |

10-31 |

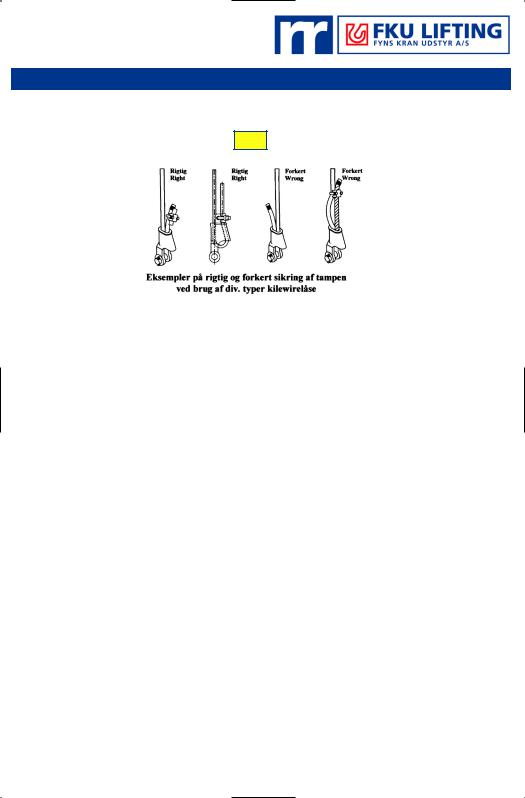

Fig. 50 |

|

14. ISTØBNING MED WIRELOCK

Istøbning (Wirelock)

Hvis intet andet er aftalt mellem kunde og Fyns Kran Udstyr, så udfører Fyns Kran Udstyr istøbning af tovpære med Wirelock - er en speciel stærk 2-komponent støbemasse. Wirelock anvendes i større og større grad i stedet for zink bl.a. p.g.a. :

·at varmeudviklingen er væsentlig lavere i forhold til zinkstøbning. Herved elimineres risikoen for hærdning af ståltrådene med udmattelsesbrud til følge. Desuden undgår man at fedtet forsvinder (bortsmelter) i overgangszonen ved tovpærehalsen.

·Wirelock kræver ikke opvarmning af tovpære forudsat, at denne ikke har en temperatur på under 10 °C.

·Wirelock tillader fuld belastning 1 - 2 time efter støbningen.

·Wirelock kræver ingen specielle hjælpemidler i.f.m. istøbningen.

·Wirelock er modstandsdygtig overfor syre, saltvand, olie og fedt.

·Wirelock tåler chokbelastning og stød.

·Wirelock kan anvendes til alle former for istøbning.

·Wirelock trænger bedre ind mellem trådene end zink.

·Wirelock kan anvendes op til 115 °C

Wirelock er bl.a. godkendt af Arbejdstilsynet, Det Norske Veritas og Lloyd's Register of Shipping.

14. SOCKETING (WIRELOCK)

Unless otherwise agreed between the customer and Fyns Kran Udstyr, Fyns Kran Udstyr will undertake socketing with Wirelock. Wirelock is an especially strong twin-component moulding material. Wirelock is increasingly being used instead of zinc, e.g. because:

·Heat generation is much lower than with a zinc seal. The risk of hardening of the steel wires, causing stress fractures, is thus eliminated. The disappearance (melting away) of grease is also avoided at the junction by the base of socket.

·Wirelock does not require heating of the rope socket, as long as its temperature is not below 10 °C.

·Wirelock permits full loading 1-2 hours after the sealing process.

·Wirelock does not require any special ancillary tools in connection with the sealing process.

·Wirelock is resistant to acid, salt water, oil and grease.

·Wirelock tolerates shock loading and impact.

·Wirelock can be used for all types of seal.

·Wirelock penetrates further in between the wires than zinc.

·Wirelock can be used in temperatures of up to 115 °C.

Wirelock has been approved by such bodies as the Danish Directorate of Labour Inspection, Det Norske Veritas and Lloyd's Register of Shipping.

FKU LIFTING A/S |

Randers |

Odense |

København |

10 |

|

89 11 12 89 |

63 96 53 00 |

43 73 35 66 |

Jan 2002

TEKNISK INFORMATION |

10-32 |

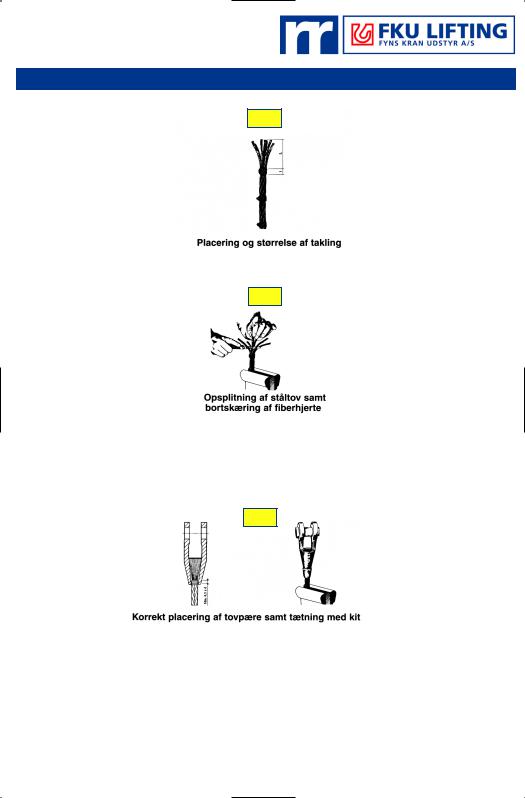

Vejledning for istøbning af ståltove

1.Ståltovsenden indføre i tovpæren, hvoref ter ståltovet takles. Afstanden fra tovenden til den øverste kant af taklingen (L) skal svare til længden på den koniske del af tovpæren minus ståltovsdiameter (d). Længden på taklingen (l) skal være minimum 1,5 x d.

2.Opsplitning af de enkelte tråde i dugterne kan herefter ske. Hvis ståltovet indeholder et stålhjerte skal dette også splittes op. Eventuelle fiberhjerter kappes over taklingen. Opsplitningen skal være ensartet og gå helt ned til taklingen.

Hvis ståltovet kun består af 19 tråde eller mindre, skal trådene i toppen ombukkes. HUSK at tillægge længden af ombukket til længden af det opsplittede stykke.

1)Den opsplittede del af ståltovet (kosten) rengøres/affedtes f.eks. i en sodaopløsning. Ved afrensningen og en efterfølgende skylning skal ståltovet vende nedad således, at væsken ikke trænger ned ståltovet.

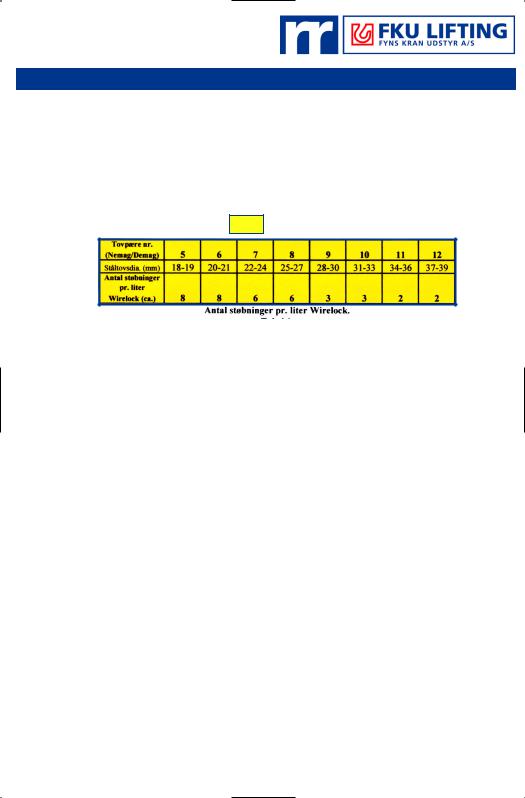

2)Træk tovpæren op over kosten indtil trå dene er i niveau med overkanten af tovpæren. Kontroller, at et stykke (ca. 0,5 x d) af den øverste del af taklingen befinder sig i den koniske del af tovpæren.

Ståltovet fastgøres, så det står lodret samtidig med, at et stykke (ca. 25 x d) af ståltovet hænger lodret. Herefter tætnes tovpærehalsen med f.eks. kit for at forhindre udtrængning af Wirelock under istøbingen.

Fig. 1

Placing and size of rope sockets

Fig. 2

Splitting the steel wire rope and removing the fibre core

Fig. 3

Correct location of the rope socket and packing with putty

Guidelines for Socketing with Wirelock

1.Insert the end of the steel wire rope into the rope socket, and fasten the steel wire rope. The distance from the end of the rope to the uppermost part of the rigging

(L) must correspond to the length of the conical part of the rope socket minus the diameter of the steel wire rope (d). The length of the rigging (l) must be at least 1.5 x d.

2.The individual wires in the strands can be split after this. If the steel wire rope contains a steel core, this must also be split open. If there are any fibre cores, they may be cut above the rigging. The split must be clean and go as far down as the rigging.

If the steel wire rope only consists of 19 wires or less, the wires at the top must be doubled up. Remember to add the length of the doubled section to the length of the split section.

1)Clean/de-grease the split section of the steel wire rope (the brush), e.g. in a soda solution. When being cleaned and then rinsed off, the steel wire rope must be facing downwards so that the solution does not penetrate the rope.

2)Pull the rope socket over the brush until the wires level with the upper edge of the rope socket. Check that a part (min. 0.5 x d) of the upper section of the rigging is in the conical part of the rope socket.

Fasten the steel wire rope so that it is vertical, while a piece (approx. 25 x d) of the steel wire rope is hanging vertically. Pack the base of socket with e.g. putty to prevent any Wirelock escaping during the sealing process.

3) Bland de to komponenter

sammen i en plasticspand eller lignende

(komponenterne skal have en temperatur på mellem 10 °C og max. 25 °C). Blandingen omrøres grundigt i ca. 2 minutter. Ved en lufttemperaturer under 10 °C bør een pose "booster" (accelerator) tilsættes før omrøring.

3)Mix the two components together in e.g. a plastic bucket. The components must have a temperature of 10-25 °C. Stir the mixture thoroughly for around two minutes. If the air temperature (sealing temperature) is below 10 °C, a bag of "booster" (accelerator) should be added before stirring.

FKU LIFTING A/S |

Randers |

Odense |

København |

10 |

|

89 11 12 89 |

63 96 53 00 |

43 73 35 66 |

Jan 2002

TEKNISK INFORMATION |

10-33 |

På posen er angivet, til hvilken mængde Wirelock den skal anvendes. Under 3 °C bør to poser booster tilsættes. Istøbingen kan godt foretages i frostgrader, blot man sørger for, at Wirelock massen ikke kommer under 10 °C under hele istøbningsprocessen.

BEMÆRK : Blandingsforholdet mellem de enkelte komponenter er nøje afstemt og må ikke deles.

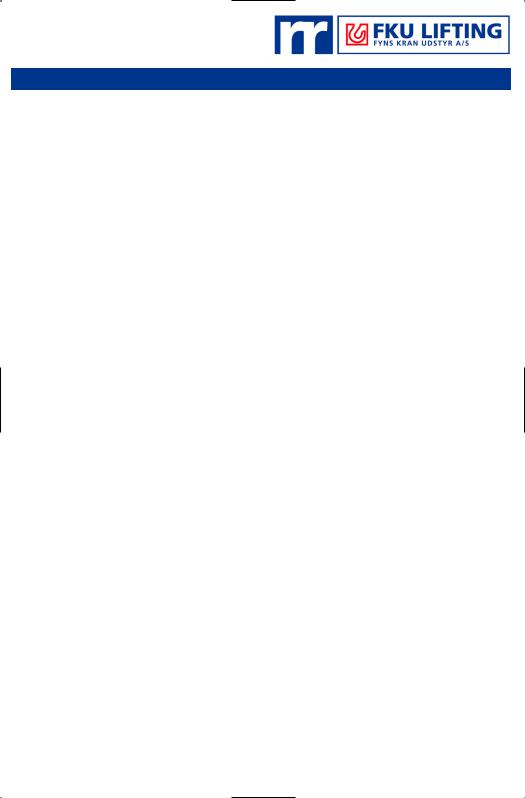

Forbruget af Wirelock ses af tabel 1.

Tabel 1

The bag provides instructions about how much Wirelock must be used. Below 3 °C two bags should be added. The sealing process can be undertaken at temperatures below 0 °C, as long as measures are taken to ensure that the Wirelock putty itself does not come under 10 °C at any time during the process.

NB: The mix ratio between the individual components is precisely calculated and should not be divided.

The following table shows how Wirelock should be applied.

Number of seals per litre Wirelock

4) Blandingen hældes i tovpæren, indtil tovpæren er fyldt helt op. For at forhindre dannelsen af luftbobler skal en let "piskning" med et stykke ståltråd foretages nede mellem ståltovets tråde. Flere istøbninger kan godt foretages forudsat, at ihældning sker lige efter hinanden.Evt. overskydende Wirelock kan ikke gemmes, men skal kasseres.

BEMÆRK : Blandingsmassen starter med at være tykflydende. Herefter bliver massen tyndere og tyndere indtil et vist punkt, hvorefter selve hærdeprocessen går igang. Wirelock skal ihældes, inden massen når sit tyndeste punkt.

5)Wirelock er fremstillet således, at hærdetiden er 10 minutter i tem peraturområdet 18 °C til 24 °C. Det bør dog bemærkes, at produktets hærdetid er meget følsom overfor temperaturen på Wirelock, f.eks. er hærdetiden kun ca. 5 minutter ved 30 °C og ca. 20 minutter ved 10 °C. Hærdetiden har ingen indflydelse på kvaliteten af hærdningen.

Tovpæren må belastes 1 time efter, at Wirelock er hård i overfladen (se også afsnit 9.8.2).

6)Kit fjernes. Specielt når tovpærehalsen hænger opad under brugen, anbefaler Fyns Kran Udstyr, at tovpærehalsen fyldes op med vandfortrængende olie/fedt for at minimere risikoen for rustdannelse på dette kritiske sted (hulrummet fyldes med vand).

Kontrol af istøbning

a)Hvis man ridser med en skruetrækker i støbemassen i tovpæreåb ningen, og der fremkommer en hvid stribe, er hærdningen foregået, som den skal.

4)Pour the mixture into the rope socket until the rope socket is full. To prevent air bubbles forming, a piece of steel wire should be used to "whip" gently between the wires in the steel wire rope. Several applications may be made at a time, provided that they are done in quick succession. Any surplus Wirelock must be disposed of.

NB: At the outset the mixture has a thick, liquid consistency. It then becomes thinner until a certain point at which the hardening process begins. The Wirelock must be poured before the mixture reaches its thinnest state.

5)Wirelock is produced in such a way that its hardening time is 10 minutes in the 18-24 °C temperature range. It should, however, be noted that the product's hardening time is very sensitive to the temperature of the Wirelock, e.g. it is only approx. 5 minutes at 30 °C and approx. 20 minutes at 10 °C. The hardening time has no effect on the quality of the hardening.

Loads can be applied to the rope socket one hour after the Wirelock is hard on the surface.

6)Putty must be removed. Particularly in cases where the unit is to be used with the base of socket upwards, Fyns Kran Udstyr recommends that the base of socket be filled up with water-repel- lent oil/grease in order to minimise the risk of rust at this critical point due to penetration of water.

Seal Inspection

a)If a screwdriver is used to scratch the Wirelock at the opening of the rope socket and a white stripe appears, the hardening process has been completed correctly.

FKU LIFTING A/S |

Randers |

Odense |

København |

10 |

|

89 11 12 89 |

63 96 53 00 |

43 73 35 66 |

Jan 2002

TEKNISK INFORMATION |

10-34 |

b)Desto mørkere Wirelock er, desto højere temperatur har hærde processen opnået. Den mørke farve opnås p.g.a korrekte temperaturforhold. Hvis farven er blågrøn, er dette ensbetydende med en "kold" støbning/hærdning. Istøbningen kan kun godkendes, hvis skruetrækkerprøven er O.K. (se punkt a).

Genbrug af tovpærer

Fjernelse af Wirelock i brugte tovpærer kan ske ved opvarmning til 250 °C i ovn, hvorefter støbemassen krakelerer ved slag og kan fjernes med dorn. For at undgå opvarmning af tovpæren er det bedre blot at presse materialet ud med specialværktøj.

BEMÆRK: Tovpæren må under ingen omstændigheder opvarmes til mere end 250 °C forudsat, at leverandøren af tovpærerne ikke har angivet andet.

BEMÆRKNINGER:

a)Tovpære og tov skal jævnligt kontrolleres for brud/beskadigelse, specielt i og ved tovpærehalsen.

b)Undgå brug af åben ild under blandingen og istøbning med Wirelock. Hærderen indeholder styren, hvis flammepunkt er ca. 30 °C.

c)Der skal anvendes beskyttelsesbriller og hansker ved istøbning. Hvis det foregår indendørs, skal der være lokal udsugning.

d)Wirelock må ikke komme i forbindelse med stærke alkaliske opløsninger som acetone og lignende, da disse stoffer kan nedbryde Wirelock.

e)Hvis tovpæren har en temperatur på under 10 °C, bør denne opvarmes f.eks. ved at lægge den i en spand varmt vand.

f)En forudsætning for at sidste anvendelsesdato gælder er, at Wirelock opbevares mellem 10 °C og max. 25 °C.

Ved hver leverance medsendes "Leverandør Brugsanvisning" på Wirelock.

Fyns Kran Udstyr foretager gerne istøbningen med Wirelock enten hos dig eller i vort splejseri. Fyns Kran Udstyr er også leveringsdygtig i såvel tovpærer samt andre typer fittings.

b)The darker the Wirelock, the higher the temperature during the hardening process. The dark colour is achieved due to correct hardening conditions. If the colour is bluish-green, it indicates a "cold" sealing/hardening process. The sealing process may only be approved if the screwdriver test has been passed.

Re-use of sockets

Dismantling of Wirelock in used rope sockets can be undertaken by means of heating in a furnace to a temperature of 250 °C, after which the seal cracks when struck and can be removed with a mandrel. To avoid heating up the rope socket, it is recommended that the material be pressed out using special equipment.

Note:

a)Rope and rope socket must be inspected regularly for fractures, especially in and around the base of socket.

b)Avoid using an open flame during the mixing and sealing process with Wirelock. The hardening agent contains an acid that is flammable at approx. 30 °C.

c)Protective glasses and gloves must be worn during the sealing process. If undertaken indoors, air extraction equipment must be used.

d)Wirelock must not come into contact with strong alkaline solutions such as acetone, as these substances can cause the Wirelock to disintegrate.

e)If the rope socket has a temperature of below 10 °C, it should be warmed up, e.g. by placing it in a bucket of warm water.

f)The "use before" date presupposes that the Wirelock is stored

at 10-25 °C.

g)Every consignment is accompanied by "Supplier's Directions for Use" of Wirelock.

Fyns Kran Udstyr will be pleased to carry out the sealing process with Wirelock either on your premises or in our own splicing shop. Fyns Kran Udstyr is also a supplier of rope sockets and other types of fittings.

FKU LIFTING A/S |

Randers |

Odense |

København |

10 |

|

89 11 12 89 |

63 96 53 00 |

43 73 35 66 |

Jan 2002