- •Introduction

- •Table of Contents

- •1. Main Data and Outputs

- •1.1 Maximum continuous output

- •1.2 Reference conditions

- •1.3 Operation in inclined position

- •1.4 Dimensions and weights

- •2. Operating ranges

- •2.1 Engine operating range

- •2.2 Loading capacity

- •2.3 Low air temperature

- •2.4 Operation at low load and idling

- •3. Technical Data

- •3.1 Wärtsilä 4L20

- •3.2 Wärtsilä 6L20

- •3.3 Wärtsilä 8L20

- •3.4 Wärtsilä 9L20

- •4. Description of the Engine

- •4.1 Definitions

- •4.2 Main components and systems

- •4.3 Cross sections of the engine

- •4.4 Overhaul intervals and expected lifetimes

- •5. Piping Design, Treatment and Installation

- •5.1 Pipe dimensions

- •5.2 Trace heating

- •5.3 Operating and design pressure

- •5.4 Pipe class

- •5.5 Insulation

- •5.6 Local gauges

- •5.7 Cleaning procedures

- •5.8 Flexible pipe connections

- •5.9 Clamping of pipes

- •6. Fuel Oil System

- •6.1 Acceptable fuel characteristics

- •6.2 Internal fuel oil system

- •6.3 External fuel oil system

- •7. Lubricating Oil System

- •7.1 Lubricating oil requirements

- •7.2 Internal lubricating oil system

- •7.3 External lubricating oil system

- •7.4 Crankcase ventilation system

- •7.5 Flushing instructions

- •8. Compressed Air System

- •8.1 Internal compressed air system

- •8.2 External compressed air system

- •9. Cooling Water System

- •9.1 Water quality

- •9.2 Internal cooling water system

- •9.3 External cooling water system

- •10. Combustion Air System

- •10.1 Engine room ventilation

- •10.2 Combustion air system design

- •11. Exhaust Gas System

- •11.1 Internal exhaust gas system

- •11.2 Exhaust gas outlet

- •11.3 External exhaust gas system

- •12. Turbocharger Cleaning

- •12.1 Turbine cleaning system

- •12.2 Compressor cleaning system

- •13. Exhaust Emissions

- •13.1 Diesel engine exhaust components

- •13.2 Marine exhaust emissions legislation

- •13.3 Methods to reduce exhaust emissions

- •14. Automation System

- •14.1 UNIC C1

- •14.2 UNIC C2

- •14.3 Functions

- •14.4 Alarm and monitoring signals

- •14.5 Electrical consumers

- •15. Foundation

- •15.1 Steel structure design

- •15.2 Mounting of main engines

- •15.3 Mounting of generating sets

- •15.4 Flexible pipe connections

- •16. Vibration and Noise

- •16.1 External forces and couples

- •16.2 Mass moments of inertia

- •16.3 Structure borne noise

- •16.4 Air borne noise

- •17. Power Transmission

- •17.1 Flexible coupling

- •17.2 Clutch

- •17.3 Shaft locking device

- •17.4 Power-take-off from the free end

- •17.5 Input data for torsional vibration calculations

- •17.6 Turning gear

- •18. Engine Room Layout

- •18.1 Crankshaft distances

- •18.2 Space requirements for maintenance

- •18.3 Transportation and storage of spare parts and tools

- •18.4 Required deck area for service work

- •19. Transport Dimensions and Weights

- •19.1 Lifting of engines

- •19.2 Engine components

- •20. Product Guide Attachments

- •21. ANNEX

- •21.1 Unit conversion tables

- •21.2 Collection of drawing symbols used in drawings

Product Guide

17. Power Transmission

17. Power Transmission

17.1 Flexible coupling

The power transmission of propulsion engines is accomplished through a flexible coupling or a combined flexible coupling and clutch mounted on the flywheel. The crankshaft is equipped with an additional shield bearing at the flywheel end. Therefore also a rather heavy coupling can be mounted on the flywheel without intermediate bearings.

The type of flexible coupling to be used has to be decided separately in each case on the basis of the torsional vibration calculations.

In case of two bearing type generator installations a flexible coupling between the engine and the generator is required.

17.1.1 Connection to generator

Figure 17.1 Connection engine/single bearing generator (2V64L0071)

124 |

Product Guide Wärtsilä 20 - 3/2009 |

Product Guide

17. Power Transmission

Figure 17.2 Connection engine/two-bearing generator (4V64F0001a)

Engine |

|

Dimensions [mm] |

|

||

D1 |

L |

K |

min D |

||

|

|||||

W 4L20 |

120 |

150 |

140 |

130 |

|

W 6L20 |

150 |

190 |

180 |

160 |

|

W 8L20 |

150 |

190 |

180 |

160 |

|

W 9L20 |

150 |

190 |

180 |

160 |

|

17.2 Clutch

In many installations the propeller shaft can be separated from the diesel engine using a clutch. The use of multiple plate hydraulically actuated clutches built into the reduction gear is recommended.

A clutch is required when two or more engines are connected to the same driven machinery such as a reduction gear.

To permit maintenance of a stopped engine clutches must be installed in twin screw vessels which can operate on one shaft line only.

17.3 Shaft locking device

To permit maintenance of a stopped engine clutches must be installed in twin screw vessels which can operate on one shaft line only. A shaft locking device should also be fitted to be able to secure the propeller shaft in position so that wind milling is avoided. This is necessary because even an open hydraulic clutch can transmit some torque. Wind milling at a low propeller speed (<10 rpm) can due to poor lubrication cause excessive wear of the bearings

The shaft locking device can be either a bracket and key or an easier to use brake disc with calipers. In both cases a stiff and strong support to the ship’s construction must be provided.

Product Guide Wärtsilä 20 - 3/2009 |

125 |

Product Guide

17. Power Transmission

Figure 17.3 Shaft locking device and brake disc with calipers

17.4 Power-take-off from the free end

At the free end a shaft connection as a power take off can be provided. If required full output can be taken from the PTO shaft.

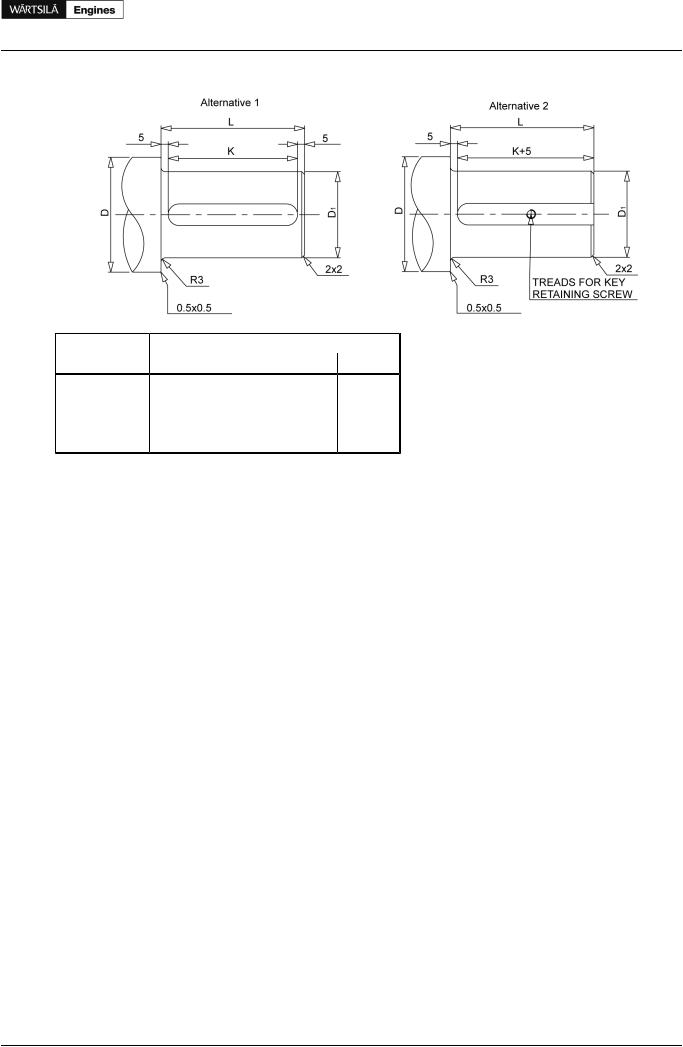

Figure 17.4 PTO alternative 1 (DAAE079074) |

Figure 17.5 PTO alternative 2 (DAAE079045) |

Rating [kW] 1) |

Dimensions [mm] |

Rating [kW] 1) |

|

|

Dimensions [mm] |

|

|

|||

|

D1 |

A |

|

D1 |

D2 |

A |

B |

C |

E |

F |

700 |

80 |

105 |

1700 |

100 |

170 |

610 |

860 |

970 |

280 |

108 |

2300 |

120 |

150 |

2200 |

110 |

185 |

630 |

880 |

990 |

300 |

118 |

Rating is dependent on coupling hub. Max. output may also be restricted due to max coupling weight 135 kg. 1320 kW always accepted.

External support bearing is not possible for resiliently mounted engines.

1) PTO shaft design rating, engine output may be lower

126 |

Product Guide Wärtsilä 20 - 3/2009 |

Product Guide

17. Power Transmission

17.5 Input data for torsional vibration calculations

A torsional vibration calculation is made for each installation. For this purpose exact data of all components included in the shaft system are required. See list below.

Installation

•Classification

•Ice class

•Operating modes

Reduction gear

A mass elastic diagram showing:

•All clutching possibilities

•Sense of rotation of all shafts

•Dimensions of all shafts

•Mass moment of inertia of all rotating parts including shafts and flanges

•Torsional stiffness of shafts between rotating masses

•Material of shafts including tensile strength and modulus of rigidity

•Gear ratios

•Drawing number of the diagram

Propeller and shafting

A mass-elastic diagram or propeller shaft drawing showing:

•Mass moment of inertia of all rotating parts including the rotating part of the OD-box, SKF couplings and rotating parts of the bearings

•Mass moment of inertia of the propeller at full/zero pitch in water

•Torsional stiffness or dimensions of the shaft

•Material of the shaft including tensile strength and modulus of rigidity

•Drawing number of the diagram or drawing

Main generator or shaft generator

A mass-elastic diagram or an generator shaft drawing showing:

•Generator output, speed and sense of rotation

•Mass moment of inertia of all rotating parts or a total inertia value of the rotor, including the shaft

•Torsional stiffness or dimensions of the shaft

•Material of the shaft including tensile strength and modulus of rigidity

•Drawing number of the diagram or drawing

Flexible coupling/clutch

If a certain make of flexible coupling has to be used, the following data of it must be informed:

•Mass moment of inertia of all parts of the coupling

•Number of flexible elements

•Linear, progressive or degressive torsional stiffness per element

•Dynamic magnification or relative damping

•Nominal torque, permissible vibratory torque and permissible power loss

•Drawing of the coupling showing make, type and drawing number

Operational data

•Operational profile (load distribution over time)

Product Guide Wärtsilä 20 - 3/2009 |

127 |