Крючков Фундаменталс оф Нуцлеар Материалс Пхысицал Протецтион 2011

.pdfcompositions of plutonium in the spent fuel of some reactors are given in Table 5.1.

|

|

|

|

|

|

|

Table 5.1 |

|

Isotopic composition of plutonium in power reactor fuels |

|

|

||||||

|

|

|

|

|

|

|

|

|

Reactor |

Fuel burnup, |

|

Isotopic composition, % |

|

|

|||

(GW×day/t) |

239Pu |

|

240Pu |

241Pu |

|

242Pu |

|

|

AGR |

18.0 |

53.7 |

|

30.8 |

9.9 |

|

5.0 |

|

RBMK |

20.0 |

50.2 |

|

33.7 |

10.2 |

|

5.4 |

|

BWR |

27.5 |

59.8 |

|

23.7 |

10.6 |

|

3.3 |

|

PWR |

33.0 |

56.0 |

|

24.1 |

12.8 |

|

5.4 |

|

The isotopic composition of NM is known to determine the properties thereof. The following depends on isotopic composition:

∙critical mass;

∙generation of spontaneous-fission neutrons which influence the

design and power of explosives. For plutonium, the number of these depends directly on the concentrations of 240Pu and 242Pu;

∙generation of heat (for plutonium, this depends directly on the concentration of 238Pu);

∙radiation.

The NM chemical form is what defines to a great extent the choice of measurement techniques and the measurements results. The mass fraction of nuclear material varies in a sample depending on the oxidation level, this to be taken into account when analyzing the weighing result.

Nuclear material is subject to categorization. The category of nuclear material is a quantitative characteristic thereof in the context of NM accounting and control. The category of the onsite nuclear material defines the requirements to the accuracy of test measurements for the NM balance closing (relative standard percent deviations from the inventories) (see Table 5.2).

Errors of NM test measurement results are of a fundamental importance. For example, no loss or theft of less then 150 g of plutonium can be detected when the mass of a 10-kg plutonium sample is determined with an accuracy of 0.5% in the confidence interval of 68% (or 1.5% in the confidence interval of 99%).

221

|

|

Table 5.2 |

|

|

Requirements to the accuracy of NM measurements |

||

|

|

|

|

No. |

Facility type |

Relative standard |

|

|

deviation, % |

|

|

|

|

|

|

1 |

Uranium enrichment |

0.2 |

|

|

|

|

|

2 |

Chemical transformations: uranium |

0.3 |

|

|

conversion and fuel fabrication |

|

|

|

|

|

|

3 |

Plutonium conversion and fuel fabrication |

0.5 |

|

|

|

|

|

4 |

Chemical treatment of uranium |

0.8 |

|

|

|

|

|

5 |

Chemical treatment of plutonium |

1.0 |

|

|

|

|

|

6 |

Isolated scrap* storage |

4.0 |

|

|

|

|

|

7 |

Isolated waste storage |

25 |

|

|

|

|

|

* Scrap – NM reject removed from process for treatme nt.

The nuclear material balance is the result of comparing the book inventory of nuclear material against its inventory in the material balance area (MBA).

The quantity of nuclear material in each MBA shall be determined by measuring the quantity and composition of nuclear material, controlled through accounting and checkouts of nuclear material and verified by physical inventory takings. The final step in a physical inventory taking is balance closing for each nuclear material over the period between the previous and the given physical inventory taking, and determination of the inventory difference and the error thereof.

Physical inventories for each MBA are taken on a periodic basis with the material balance periods (BP) established depending on the category of the nuclear material in the MBA, as well as on the process and other sitespecific features.

An anomaly in accounting and control of nuclear material is as a shortage (a surplus) of nuclear material, errors in accounting records and reports, damage or failures of NM access controls, and breaches in NM fabrication, utilization and transfer procedures.

The measurement program shall be developed for each MBA, this to include the list of measurement techniques, samplers and sampling procedures, measurement frequency data, the required measurement accuracy and the measurement data submission dates and forms.

222

Measurement procedures are subject to metrological certification as required by effective state or industry standards.

Standard samples (standards) used to calibrate instrumentation and check the measurement data accuracy are subject to metrological certification under requirements of effective state or industry standards and shall have the respective certificate.

Each enterprise shall develop and put into operation a measurement quality control program to be part of the NM measurement system. The objective of the program is to ensure the quality of measurements.

The technique to control NM is chosen given the properties of the material and the measurement conditions: physical state, purity, desired accuracy of determination, time required to perform an analysis, number of analyses (1 per month, 100 per week), volume of the analyzed sample, available equipment and standards, qualification of personnel and the funding allocated.

A note should be made that NM test measurements are not direct: the mass of material or its isotopic composition is found from results of measuring the electrical pulse count rate, current variations, spring deformation and so on. The measured effect (N) and the quantity sought for (F) relate through the coefficient k, which is obtained via calibration by measuring standards (NM samples with the known characteristics Fst) on a test measurement bench: k = Fst / Nst, where Nst is the measured effect for the standard.

The accuracy of NM mass determination depends on the test measurement error and the uncertainty of the calibration factor k, the second component prevailing in many cases. In turn, the test measurement data normally needs to be corrected to account for a number of influencing factors caused by specific features of the NM sample, information distortions in the electronic measuring channel and so on.

The NM balance equation has the following form: ID=BI+R– S–EI, where ID is the inventory difference; BI is the book inventory; R is the NM received for storage over the period between the inventory takings; S is the NM shipped over the same period, and EI is the ending inventory of NM. EI = k×N, where N is the number of counts and k is the calibration factor that relates the quantity to be determined to the measurement result.

The judgments on the inventory taking result are made by comparing ID and 3 ID.

Different stages of a nuclear fuel cycle (Fig. 5.1) deal with different physical and chemical forms of NM and involve loss of NM. Different

223

physical and chemical forms of NM require various measurement technologies for accounting of material. In addition to control of the NM presence and integrity, NM measurement data serves to control processes, as well as to ensure nuclear and radiation safety standards. Measurement procedures and devices are selected so that to provide a comprehensive solution to all of the tasks listed herein.

Therefore, subject to measurement is nuclear material in different states and forms, combined diversely with other material and having different activity levels. Accordingly, these tasks require different techniques and equipment to be accomplished.

Supervision with respect to accounting for and control of NM involves two measurement types:

∙accounting measurements – quantitative characterization of NM and products the results whereof are entered on accounting records;

∙verifying measurements – measurements the results whereof are used to verify the quantitative characteristics or attributes of NM or items.

Test measurements have the purpose of determining the numerical value of the NM quantity. These seek to ensure the best accuracy of the result. There is however a number of control tasks that require only quality data of samples. These include:

∙characterization of unlabeled or erroneously labeled samples;

∙determination of the NM presence in samples on a “y es or no”

basis;

∙rapid inventory taking;

∙verification of the shipper data by the reeiver, etc.

224

Ore mining |

|

|

|

|

Ore processing |

|

|

|

Treatment |

|

|

|

into UF6 |

|

|

|

|

|

|

|

Uranium |

|

Gas-diffusion, |

enrichment |

|

centrifugal, laser |

|

|

|

|

|

|

Pelletfabrication |

|

FA |

|

fabrication |

|

|

|

|

|

|

|

Fresh FA

storage

Power |

NPP |

|

generation |

||

|

Spent FA starage

|

|

|

|

Spent fuel treatment |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Radwaste |

|

Waste |

||

|

processing |

|

storage |

||

|

|

|

|

|

|

Fig. 5.1. Flowchrt of NM transformations in a fuel cycle

225

5.2. Nondestructive NM assay techniques. Calibration and standards

Nuclear material is checked by counting of items, identification of items (barcodes), weighing, measurement of volume, sample taking for chemical analyses and nondestructive assays.

Nondestructive assay (NDA) is determination of the NM type and/or quantity in a sample without changing the characteristics of the sample or penetrating into it.

Nondestructive assay is commonly used in the following cases:

∙when there is a need for rapid testing;

∙monitoring of processes;

∙where no representative sample taking is feasible (e.g. in control of production waste, scrap and so on);

∙where no destructive testing is practicable.

Destructive analysis is not appropriate in cases:

∙where a great deal of measurements is involved (e.g. during an inventory taking);

∙where data is required forthwith (e.g. in an unscheduled inspection);

∙where no sampling of the item tested is permitted (e.g. a nuclear explosive);

∙where material is not accessible for sampling (e.g. deposits in pipelines);

∙where analysis is too expensive.

NDA can be both passive and active.

Active analysis includes irradiation of the items to be tested by an external radiation source (neutrons, X-rays, gamma radiation) to induce secondary irradiation of NM. The radiations emitted (neutrons, X-ray quanta) are interpreted as “signatures” to determin e the quantity and composition of the fissile material present.

Passive analysis relies on spontaneous radiation (gamma, X-ray, neutron) measurement for the material which is the “signature” thereof.

There is an extensive choice of currently available instruments and techniques to detect, identify, analyze and test NM in different physical and chemical forms. NDA equipment differs both in dimensions and sophistication, ranging from portable devices used by inspectors to check NM to large-sized factory systems used routinely by operators.

NDA is normally conducted by measuring NM gamma and neutron radiation. NDA equipment is calibrated and assay results are verified by standard destructive methods (radiochemistry, mass spectrometry). The

226

material involved in processes is analyzed in NDA laboratories using automated instrumentation. Deposits in process equipment are evaluated by portable devices.

The important advantages offered by NDA are as follows:

∙assays do not normally take much time;

∙assays are not expensive (with no the instrument cost taken into account);

∙there is no waste and no reagents are required.

The shortcomings of NDA are as follows:

∙relatively greater errors of results (normally 3 to 10% or even more); these are higher than in destructive analysis;

∙complexities involved in obtaining standards (large-size NM standards are either costly or do not exist).

The following measurement control procedures ensure the quality of measurements in NDA:

∙equipment calibration: required to secure accuracy (avoid biases in results) and estimate standard deviations of calibration results. Calibrations relate the measurement results to the national (international) system of units;

∙frequent checks using working standards;

∙independent multiple measurements to estimate random assay errors;

∙a periodic comparative analysis of samples using proven standard destructive techniques;

∙interlaboratory exchange of samples for secured agreement of measurement data with the data from other laboratories.

Calibration of instruments and techniques used for NDA requires standards. Standards are made depending on the measurement method chosen. The quality of any analysis result depends on the quality of calibration, this, in turn, defined by the quality of standards.

Standard-based calibration measurements are used to determine the dependence between the instrument output and the NM mass in the sample. Standards are also used to test, check or normalize instrument and system output.

“True” values of a standard’s parameters are normal ly found by destructive analysis (DA). Standards are expensive and long to make. Properly understanding the principles on which NDA is based helps minimize the number of standards needed.

Some standards are hard to make and store. Over time, the properties of a standard may change so that it will no longer fall into the same category

227

as the NM under control. This will also require a new standard to be made to replace the old one.

There are two categories of standards:

∙Certified Reference Materials (CRM): these are made of highly pure NM. CRM standards are certified by the most accurate measurement methods and in more than one laboratory. Such standards require certificates;

∙Working Reference Materials (WRM) – these have less accurate characteristics than CRMs. WRM standards are normally used to calibrate specific NDA instruments at enterprises where they are required.

CRM standards for specific site uses are not altogether available, so laboratories or factories need to make their own working standards.

Russian regulations respecting calibrations, certifications of procedures and requirements to reference samples are documented in respective state standards: GOST 8.315–97 “Standard Samples of Mater ial Composition and Properties”, and GOST 8.563–96 “Measurement Pro cedures” and others.

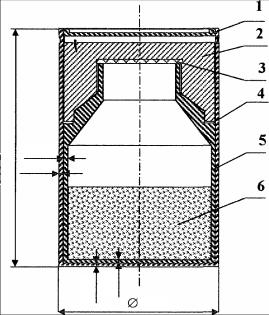

Russian state standard samples (SSS) for the plutonium isotopic composition and mass were released in 2000 (Fig. 5.2). A complete SSS set

consists of 10 samples. The isotopic compositions in various sets of 238Pu:239Pu:240Pu:241Pu:242Pu are equal to 1.82:60.47:22.20:10.59:4.84 and

0.12:97.20:2.27:0.061:0.10. The relative uncertainty in determination of the plutonium mass fraction in an SSS is ±0.30% with the confidence

probability of 95%. The plutonium mass varies between SSSs in a range of 1 g to 2.5 kg.

Mathematical Monte-Carlo modeling makes standards much less required. By determining so the shape of the calibration curve, one can normalize it with the aid of physical standards.

One can also lessen the required number of standards through cross calibration. This principally consists in having one instrument out of a number of similar instruments thoroughly calibrated with a broad range of measurements for the controlled parameter covered (e.g., mass of the NM in samples). The characteristics of this “reference ” instrument obtained by the calibration are recorded and used to interpret the results of measurements with other similar instruments. It is assumed in this that the shape of the calibration curve K = f (m) reflects the properties of the whole range of similar instruments.

228

169.7

1.52

1.50

2.01 |

2.01 |

110.3

Fig. 5.2. A diagram of a Russian plutonium SSS package with a plutonium mass of 502.26 g: 1 –holder lid; 2 – vial cap; 3 – gasket; 4 – holder body; 5 – vial body; 6 – РuO2 of the density 3.1 g/cm3

The IAEA-employed NDA equipment is largely based on measurements of γ-radiations and neutrons emitted by different NM (Table 5.3 and Fig. 5.3).

Gamma ray measurements offer a number of advantages:

∙they require small personnel to perform;

∙no calibration is needed to interpret assay results in many cases;

∙the result is obtained right after the measurement is done;

∙errors in results are relatively small.

Gamma ray spectrometry is used to determine the uranium enrichment and the isotopic composition of plutonium, as well as for K-edge densitometry of plutonium nitrate solutions and for checks of the LWR SFA burnup, etc.

229

|

|

|

|

|

|

Table 5.3 |

|

Most intensive NM γ-radiations used for nondestructive assays |

|||||||

|

|

|

|

|

|

|

|

Isotop |

Energy, |

Activity, |

|

Mean free path, mm |

|

||

e |

keV |

g/g×s |

|

|

High Z, r |

Low Z, r |

|

234U |

120.9 |

9.35×104 |

|

0.23 |

69 |

|

|

235U |

143.8 |

8.40×10 |

3 |

|

0.36 |

73 |

|

|

|

|

|||||

|

185.7 |

4.32×104 |

|

0.69 |

80 |

|

|

238U |

766.4 |

2.57×10 |

1 |

|

10.0 |

139 |

|

|

|

|

|||||

1001.1 |

|

|

13.3 |

159 |

|

||

|

7.34×101 |

|

|

||||

238Pu |

152.7 |

5.90×10 |

6 |

|

0.40 |

75 |

|

|

|

|

|||||

|

766.4 |

1.387×105 |

9.5 |

139 |

|

||

239Pu |

129.3 |

1.436×10 |

5 |

0.27 |

71 |

|

|

|

|

||||||

|

413.7 |

3.416×104 |

3.7 |

106 |

|

||

240Pu |

45.2 |

3.80×106 |

|

0.07 |

25 |

|

|

160.3 |

3.37×104 |

|

0.45 |

76 |

|

||

|

642.5 |

1.044×103 |

7.4 |

127 |

|

||

241Pu |

148.6 |

7.15×10 |

6 |

|

0.37 |

74 |

|

|

|

|

|||||

|

208.0 |

2.041×107 |

0.86 |

83 |

|

||

241Am |

59.5 |

4.54×10 |

10 |

0.14 |

38 |

|

|

|

|

|

|||||

125.3 |

|

|

0.26 |

70 |

|

||

|

5.16×106 |

|

|

||||

Nondestructive γ-analysis has the following stages:

∙measurement of the pulse count rate in complete γ-quanta absorption peaks in the detector;

∙making the allowance for the electronic path distortions;

∙making the allowance for the γ-quanta absorption in the sample and en route to the detector;

∙calculation of the corrected count rate.

Where required, calibration may be used to determine the coefficient of proportionality between the measurement results and the NM quantity under determination.

230