Крючков Фундаменталс оф Нуцлеар Материалс Пхысицал Протецтион 2011

.pdfPIT planning

Onsite physical inventory taking is an extremely responsible procedure which requires stringent work planning. “Failing to plan is planning to fail” is the best adage to describe the significance of the PIT planning.

The PIT commission shall estimate the volume of the PIT work and develop the PIT plan. The PIT plan shall describe in full the sequence of all operations with NM to be done, the facilities to be employed and the respective deliverables. The PIT plan shall include the following important parts:

∙breakdown of NM by types;

∙selection of NM for accounting and verifying measurements;

∙grouping of passive NM by strata and calculation of the random sampling volume for each stratum;

∙sequence of measurements and required instrumentation;

∙operation of working materials to record measurement results and preparation of reports;

∙a complete time profile of the work performance;

∙persons in charge of work stages.

The PIT plan constitutes a voluminous package of documents. Early experiments in the field made by the Kurchatov Institute proved PIT planning to be a responsible and time-taking procedure. Thus, the documents that described all procedures of the initial physical inventory taking for one bulk (HEU) handling facility formed a volume of several hundreds pages. Each facility unfortunately requires generation of its own procedural documentation based on generic regulations. One important note in this connection is that a model document has been issued by Rostekhandzor of Russia to provide a general guidance for the PIT preparation and implementation (Methodical Recommendations on Implementing Nuclear Material PIT at Nuclear Facilities and Nuclear Material Storage Points (RB-026-04, Moscow, 2004)). This general guide serves as the basis for each facility to generate procedural documentation of its own.

Enterprise preparation for physical inventory taking

After the order to implement the physical inventory taking in the MBA is received (before the PIT starts), the required arrangements shall be undertaken. These shall include preparation of documentation, nuclear material, process components and instrumentation for the PIT.

291

All NM in operation is given the form to be convenient for the inventory taking. For example, packages with NM shall be positioned so that the inspection of seal prints, the reading of seals’ factory numbers and batch numbers and so on would not be hampered.

NM that requires accounting measurements of the quantities and compositions thereof shall be placed separately from the other. Labels shall be prepared to designate the material that has been inventoried.

The equipments and service lines shall be cleaned.

Preparation of documentation shall include the making of the inventory listing (IL) as of the PIT time and checkout of same against the rest of documentation. When this is checked out, the custodian shall compare the data on the items shown in the IL against the physical inventory listing (PIL) data from the previous PIT, the inventory change report (ICR) and the initial information on the items (certificates, invoices, measurement records, etc.).

Metrologists shall check the availability of all the instruments to be used for measurements during the physical inventory taking.

Sequence of physical inventory takings

Site PIT techniques and procedures depend on the type of the process and the quantity and the type of NM in the MBA and are specified in the PIT plan. However, there are a number of general conditions to be noted. These are namely as follows:

∙For the period of the PIT, the MBA to be inspected shall have NM shipment, receipt and write-off operations and formation of new items suspended.

∙Measurements should be done during the inventory taking based on the developed time profile and subject to the specified sequence of measurements.

∙The nuclear material inventory taking work in the MBA shall be carried out by not less than two persons simultaneously.

∙The inventory taking shall involve the custodian’s control of nuclear material.

The physical inventory work requires the reconciled IL for NM within the MBA to start. Using this listing, the WITC shall check the conformity of the physical inventory to accounting data:

a) Checkout of the attributes of the items within the MBA (presence of the IL items and the integrity thereof):

∙items with NM in the MBA are checked for being actually present;

292

∙location;

∙items are examined for external defects and TIDs are inspected for the absence of breaks;

∙IDs of the TIDs and the items are reconciled (using a scanner if there are barcode labels);

Measurements of the attributes are assumed to confirm the declared data

if:

∙the items with NM are at such locations as indicated in accounting records;

∙the items do not have external defects;

∙the TIDs are not broken;

∙the barcode information matches that in the accounting records.

Measurements of NM attributes are normally done for all items in the MBA.

b)Verifying and accounting measurements. Measurements shall be performed at key measurement points using instruments intended for verifying and accounting measurements.

c)The quantity and accuracy of discard, if any, shall be estimated.

Verifying measurements (audits) shall be performed to check the

availability and conformity to accounting data within the item material measurement error limits. Verifying measurements shall be performed for passive nuclear material, as well as for active NM that was subjected to accounting measurements prior to the current inventory taking and have been under access controls since. Verifying measurements shall seek to identify defective items. Defective items are understood as items with characteristics other than conforming to accounting data.

Verifying measurements shall include checks of the following NM parameters:

∙net weight;

∙product volume;

∙element and isotope concentrations;

∙NM mass in the product.

The parameters for the last two positions are normally checked by nondestructive assays.

Where checks find the difference of the measured value and the accounted quantity being other than falling beyond the 99% confidence interval, the accounted value of the said characteristic is assumed to be confirmed. Otherwise, the item that contains this NM shall be considered defective. In this case, the anomalous discrepancy obtained shall be

293

analyzed and investigated and accounting measurements of the NM shall be performed.

Where access controls have been applied to NM, verifying measurements of the material shall be performed on a sampling basis using sample size statistical calculation techniques. The volume and type of verifying measurements shall be specified in the PIT program.

Accounting measurements. The inventory taking includes accounting measurements for the characteristics of active NM that have not been performed prior to the inventory taking.

Based on the work results, the WITC shall prepare the nuclear material physical inventory listing (NM PIL), the material balance report (MBR) and the inventory taking statement. The WITC shall report all discrepancies (deficiencies, surplus, wrong writes-off or registrations of material used in processes, etc.), as detected in the course of the work, to the enterprise administration.

The inventory taking shall be finished with the material balance closing, and the inventory difference (ID) and ID determination error estimations for each NM type. If no anomaly in the nuclear material accounting and control is established by the PIT, the documented inventory of nuclear material in the MBA shall be taken as the inventory of nuclear material in the MBA as of the beginning of the next material balance period.

Finalization of physical inventory taking results

NM PILs, inventory taking statements with the WIC findings and recommendations, as well as material balance reports (MBR) shall be prepared as the result of the PITs.

1)The items measurement results shall be entered on the PIL. This lists data for each item in the MBA as obtained by accounting measurements (given errors). Similarly to the IL-list, the PIL-list shall have the items entered thereon grouped by types, strata and batches.

2)Preparation of the material balance report (MBR). Each NM in the MBA shall have a separate MBR prepared for it, this to represent the NM balance with a breakdown by facilities. The MBR shall be prepared based on the PIL from the previous and the current inventory takings and the ICR over the current MBP. Separate columns in the MBR shall show the booked NM inventory, the NM quantity increase and decrease for the MBP reported on and the final physical inventory of NM.

294

The data in the MBR shall be given for each item (stratum) in such sequence as would match the PIL and the ICR. The NM quantities in each item (stratum) and errors shall be entered by lines so that the MBR columns had the material balance components aligned in the MBR columns.

The ID value shall be determined as the algebraic sum of all items in the MBR. The MBR shall give the calculated error σID. The MBR shall be signed by the chairman and the members of the WITC.

3) The inventory taking statement shall contain the conclusion with respect to the conformity or nonconformity of the NM physical inventory to the IL data. The ID quantity and the estimated range of its permissible values shall be presented. Entries on the detected anomalies (if any have been found by the inventory taking) shall be made, the inventory taking commission to formulate recommendations for these to be removed. The anomaly established by the WITC shall be described in details in the memorandum enclosed with the PIT document package. The statement shall be signed by the chairman and all the commission members who took part in the inventory taking. The statement shall be made available to the custodian for examination.

PIT cost. Initial PIT problem

Physical inventory takings are an extremely costly process. For example, the US Department of Energy that has in control six national laboratories and some three dozens more nuclear industry facilities, including assembly and disassembly plants at Pantex, a commercial nuclear production facility in Hanford and others, spends millions of US dollars annually on physical inventory takings. This takes place in the conditions when US nuclear industry has large quantities of material held currently in containers which are sealed and inspected periodically or continuously. This spending is allocated when not all material is subject to measurement and the initial inventory takings date back to a long time ago.

Russian spending on PITs, with the initial physical inventory takings being required and NM inventories being no less immense than in the USA, can hardly be overestimated.

An initial PIT requires all nuclear material to be measured. There are many organizations in Russia that need initial physical inventories to be taken. The experiments made by the Kurchatov Institute [2] have proved that initial inventory takings for only two of its facilities are expected to take nearly one year of work. This brings to life a great deal of problems with the total labor expenditures the initial physical inventory taking at

295

Kurchatov’s may entail estimated at a level of 60 to 70 man-years. The initial physical inventory to be taken at Kurchatov’s is expected to last for several years.

It needs to be said that the labor consumption in physical inventory takings can be decisively curtailed to a great extent by means of access controls (containment and surveillance), provided these are employed as extensively as they can be. Estimates show that access controls, if applied to the nuclear material of the Kurchatov’s facilities, are expected to make the volume of routine physical inventory takings (not of initial ones) several times smaller. Thus, a five times reduction in this value means that all this work can be done by a team of 6 or 7 persons in approximately 2 years.

Manning problem

Manning problems are faced by many operators within the Russian nuclear fuel cycle. It needs to be acknowledged so that lack of sufficient personnel to have NM physical inventories taken in Russia in near future is rather a concern. Later on, however, things with this can be somewhat settled thanks to a reduction in the overall labor expenditures after the initial PITs are completed given access controls are employed.

Early physical inventories takings led to the understanding that even expert staff who were or are involved in building the existing economical and safe nuclear facilities have proved to be unable to elaborate and use the physical inventory taking procedures without being given a prior special training. The explanation is that a physical inventory taking is actually a sort of a global physical experiment, so the absolute must for Russia now is a well-established framework for training and retraining personnel to operate the NM accounting, control and physical protection system.

Nuclear material balances

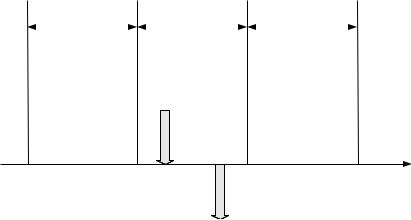

We shall assume that the site under consideration has periodic NM physical inventories taken thereat (Fig. 6.1). The period of time Т between the two successive physical inventory takings is called the material balance period.

Let we know the physical inventory PI of the material in the given material balance area as of the time t0 of the previous physical inventory taking and that IN of material was received in the given MBA over the material balance period Т. This is exactly the quantity of the material the receipt whereof has been booked in records.

296

Similarly, DE is the quantity of the material shipped from the given balance material area over the period (t0, t1) between the physical inventory takings.

T |

|

T |

|

T |

|

|

|

|

|

MPB

|

PI |

EI |

EI |

t0 |

t1 |

|

DE |

Fig. 6.1. NM balance closing cycle in an MBA

The book inventory of the nuclear material is the quantity of the nuclear material to be present in the MBA as shown in the documents as of a particular date. The final book inventory BI of the material in the given material balance area as of the current physical inventory taking time is evidently:

BI = PI + IN – DE |

(6.1) |

The physical inventory EI of the nuclear material is the quantity of the material as determined in the course of the current physical inventory taking by measurements and computations.

The difference between the book inventory BI of the material as of the current PIT time and the physical inventory EI is called the inventory difference (ID). The objective of the nuclear material balance closing is to find the ID.

The following equation gives a formal determination of the inventory difference ID:

ID = BI – EI = (BI + IN) – (EI + DE) |

(6.2) |

297

The equation (6.2) is the basic balance relation. This equation should be solved on a periodic basis for each material balance area. It is solved for separate types of the NM held within the MBA concerned. Let us remind that the NM type is the nuclear material the isotopic composition whereof is in the given interval limits (e.g., uranium, uranium-235, plutonium, etc.).

Statistical interpretation of the nuclear material balance

The inventory difference cannot be avoided because of unavoidable measurement system errors. It may both positive and negative.

In a general case, the values I, EI, IN and DE in equation (6.2) are found experimentally and contain systematic and random measurement errors. The measured values I, EI, IN and DE are not negative random values having certain probability density distributions. The total value ID is also a random quantity, either negative or equal to zero, having a certain probability density distribution as generated by the superposition of the probability density distributions of the quantities I, EI, IN and DE.

Equation (6.2) has three important sequences.

1)The quantity ID is the superposition of multiple random quantities and so, according to the central limit theorem, its distribution is close to normal (Gaussian distribution). In this case, the bounds of the 95% and 99% confidence intervals are determined easily depending on σID.

2)The inventory difference (ID) is linear relative to the components thereof. This circumstance will be further used to plot calculation models

for σID.

3) If the terms of equation (6.2) are independent variables, then the statistical straggling of the ID is described by the quantity

Var (ID) = σ2PI + σ2EI + σ2IN + σ2DE |

(6.3) |

To determine the quantity of the ID’s mean-square error, the “measurement error carry” technique shall be prefer ably employed. This consists in that the inventory difference errors are computed from the measurement errors for the quantities in the NM balance equation. Also taken into account are random and systematic components of errors and potential correlations of the NM characteristic measurement errors.

It should be noted that where a great deal of measurements is involved in the components of equation (6.3), Var (ID) may amount to an intolerably great quantity. The approach with the division of measurements into accounting and verifying ones, as taken in the measured material balance

298

system, enables the problem of great ID variances to be removed to a certain extent. To this end, the material balance equation (6.2) is considered by components. The NM available for the MBP under consideration may be classified as follows.

Passive NM is the material that has not been changed in any way (and has been under access controls) over the MBP preceding the given PIT. It is subject to verifying measurements during the PIT.

Active NM is the NM that has had its state changed and have undergone or is subject to accounting measurements (processing, change of accounting data, etc.).

Examples of passive and active NM determination

1)A storage facility for unirradiated NM. All material is under TIDs. Over the MBP, material was received at and shipped from the storage facility. How shall the material left as of the time of the next PIT be classified?

2)A process department for uranium dioxide production out of uranium hexafluoride is considered. There was no nuclear material in the MBA as of the previous PIT time. Over the MBP, cylinders with UF6 were received from which UO2 was produced, containerized and shipped to another department. As of the time of the current PIT, the MBA had cylinders with UF6 remainder and containerized UO2 left therein. Shall all NM be classified as active?

Anomalies in accounting of NM are revealed in the course of physical inventory takings and material balance closing. For the above NM classes, the following criteria for detection of anomalies in accounting and control of NM are considered.

Passive NM balance closing

The anomaly for passive NM is the discrepancy in accounting and verifying data to above the permissible limits. In this case, a new accounting measurement of NM is performed. Where the accounting data is verified, this NM changes neither ID nor the ID uncertainty. Therefore, with anomalies absent in the verifying measurements:

ID = IDACT; Var(ID) = Var(IDACT).

Active nuclear material balance closing and inventory difference determination

For active NM, in a general case, the conclusion on the balance arrived at, based on the coincidence of the IL and the PIL for each item, cannot be

299

made due to active NM being subject to change during the MBP. So in the event of active NM, an integral criterion for the conformity of the accounted for and physical NM remainder in the MBA as of the current PIT time is considered. The inventory difference quantity acts as this criterion.

The active NM balance closing suggests that the IL and PIL conformity should be established both in the number of products and in attributes. Apart from this, the inventory difference and its limiting values should be determined for active nuclear material. A correct evaluation of the inventory quantity requires waste, loss, discard and NM deposition in process equipment to be taken into account.

For active NM, the anomaly is the IL/PIL discrepancies in the number of items or attributes thereof. The integral criterion of the anomaly detection is the modulus in excess of the inventory difference or its threefold mean-square error, or the values of any of the following quantities, the confidence probability being 0.95:

∙2% of the total book inventory of the given nuclear material and all quantity increases thereof over the MBP for commercial nuclear facilities;

∙3% of the same quantity for nuclear research facilities;

∙3 kg of plutonium or uranium–233 in the MBAs that c ontain category 1 and 2 nuclear material;

∙8 kg of uranium–235 in the MBAs that contain catego ry 1, 2 and 3 nuclear material;

∙70 kg of uranium–235 for uranium enriched to below 20%.

Limits of allowable ID deviations based on accounting of NM measurement errors

Let us assume that the ID is characterized by normal distribution. We shall designate

S = σID = (Var(ID)) |

1/2 |

2 |

2 |

2 |

2 |

1/2 |

. (6.3) |

|

= (σ I + |

σ EI + σ IN + σ DE) |

|

||||

Two intervals are considered to analyze the allowable ID values. The

interval (–2 σ , +2σ ) is a 95% confidence interval. The interval (–3 σ ,

ID ID ID

+3σ ) is a 99% confidence interval:

ID

a)95% confidence interval. The probability of this interval being exceeded is small (0.05). It defines the bounds (warning limit) of the statistically insignificant ID straggling range.

b)99% confidence interval. The bounds of this interval define the permissible ID values. The frequency of false signals for such interval is

300