Крючков Фундаменталс оф Нуцлеар Материалс Пхысицал Протецтион 2011

.pdf

Gamma ray spectrometry and neutron coincidence count are complementary techniques a combination of which enables determination of plutonium content in NM. Another example is when standards are made by titrimetry to calibrate nondestructive measurement systems by densitometry and XFA.

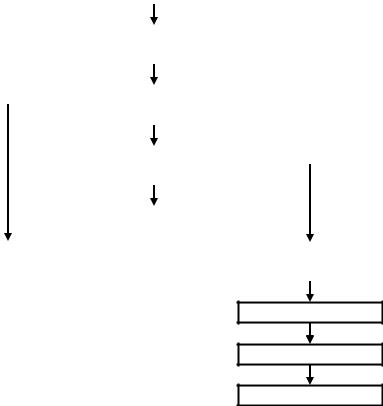

Simultaneous use of more than one technique to measure any NM parameter makes it possible to improve the confidence of the overall result thanks to mutual compensation of potential methodological errors (see Fig. 5.28 for the flowchart of a coupled plutonium analysis at a Sellafield facility).

Simultaneous use of more than one technique leads to the integration of their respective equipment in one facility and the creation of measuring systems in the form of stations.

|

|

Portion of PuO2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Gamma neutron |

|

|

|

|

|

counter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dissolution |

|

|

|

|

|

( 50 mg of Pu/g) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dilution |

|

|

|

|

|

( 10 µg of Pu/g) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Titration |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

KED/gamma- |

|

|

Dilution |

||

counter |

|

|

( 10 µg of Pu/g) |

||

Chemical treatment

Alpha spectrometry

Mass spectrometry

Fig. 5.28. Flowchart of a coupled plutonium analysis

281

|

|

|

|

|

Table 5.16 |

|

Basic NM analysis technique used at analytical laboratories |

||||||

|

|

|

|

|

|

|

Analysis technique |

Analyzed |

Material type |

|

Error, % |

|

|

element or |

|

random |

systematic |

|

||

|

isotope |

|

|

|

|

|

|

Element analysis |

|

|

|

|

|

Titration by Davis- |

U |

U, U–Pu, |

0.05 |

0.05 |

|

|

Grey method |

U–Th |

|

||||

|

|

|

|

|

||

Titration by |

|

|

|

|

|

|

McDonald-Savage |

Pu |

Pu material |

0.1 |

0.1 |

|

|

method |

|

|

|

|

|

|

Coulometry |

Pu |

Pure Pu material |

0.05 |

0.05 |

|

|

Gravimetry with |

U, Pu |

U oxides, Pu |

0.05 |

0.05 |

|

|

combustion |

oxides |

|

||||

|

|

|

|

|

||

K-edge densitometry |

U, Th, Pu |

U, Pu, U–Pu, |

0.2 |

0.2 |

|

|

U–Th |

|

|||||

|

|

|

|

|

|

|

XFA |

Pu |

Pu material |

0.2 |

0.2 |

|

|

XFA with photon |

|

Pure U and Pu |

|

|

|

|

wavelength |

Pu, U |

oxides, МОХ- |

0.3 |

0.3 |

|

|

separation |

|

fuel |

|

|

|

|

|

Isotopic analysis |

|

|

|

|

|

Isotope dilution |

|

Spent fuel |

|

|

|

|

U, Pu |

solutions, Pu and |

|

0.1 |

0.1 |

|

|

mass spectrometry |

|

|

||||

|

U–Pu material |

|

|

|

|

|

|

|

|

|

|

|

|

Thermal ionization |

U and Pu |

All Pu and U |

|

|

|

|

material, spent |

|

0.05 |

0.05 |

|

||

mass spectrometry |

isotopes |

|

|

|||

fuel solutions |

|

|

|

|

||

|

|

|

|

|

|

|

Gamma ray |

|

|

|

|

|

|

spectrometry with |

Am, Np, Pu |

Pure U and Pu |

|

|

|

|

high-resolution |

|

0.5–2.0 |

0.5–2.0 |

|

||

isotopes |

material |

|

|

|||

detectors (Ge- |

|

|

|

|

||

|

|

|

|

|

|

|

detectors) |

|

|

|

|

|

|

Gamma ray |

235U |

Low-enriched U |

|

|

|

|

spectrometry (NaI- |

|

0.2–0.5 |

0.2–0.5 |

|

||

detectors) |

|

material |

|

|

|

|

|

|

|

|

|

|

|

Alpha spectrometry |

238Pu |

Pu material |

|

0.2 |

0.3 |

|

Laser fluorometry |

Np |

Pu material |

|

2.0 |

2.0 |

|

Pu |

Pu |

Pu, U–Pu |

|

0.2 |

0.2 |

|

spectrophotometry |

|

|

||||

|

|

|

|

|

|

|

282

CHAPTER 6

MAIN ACCOUNTANCY PROCEDURES

6.1. NM transfer procedures

Shipper/receiver difference

A classic problem exists: let there be a 28-kg bar of butter. It is required to divide this butter into 280 pieces of 100 g each using scales measuring 100-g weights with an accuracy of plus or minus 5 g. The question is: can it be done? That is, can 28 kg of butter be cut into 280 pieces of 100 g each with the aid of such scales.

Many higher schools of commerce in the world use this problem to demonstrate the existing difference in the shipper’s and the receiver’s data.

Solutions to the problem were searched for experimentally involving both skilled salespersons and beginners. The answer to the question is that, provided both of them use the scales with a division of 5 g, the beginner normally cuts the butter into 274-278 pieces, which is slightly less than it ought to be. Contrary to this, the one with professional skills cuts a bit more than required, that is, from 282 to 286 pieces.

The explanation to this discrepancy is that the people involved are inclined to behave differently when addressing the problem. A skilled salesperson knows that weighing is sure to involve errors, systematic errors included, because measuring equipment tends to have their characteristics changed over time. Scales are prone to aging, rusting (e.g. through oxidation) and so on. Understanding this leads to skilled persons getting 280 pieces of butter exactly by putting into each piece a bit less than 100 g, which is, still, within the acceptable tolerance of 5 g.

A beginner tries to get pieces of exactly one hundred grams each by making them initially a bit heavier because making them weighing less than 100 g is subject to penalty. So this results in the above statistics.

The experiments of the kind serve to confirm that an uncertainty in data (say, a scale division of 5 g), if any, makes the measurement result dependent on secondary factors, including the mentality of the person doing measurements. The mentality of a skilled salesperson is not to sell at a loss.

This problem (with respective experiments) is exactly the one concerned with the concept of the shipper/receiver difference. An accurate shipper normally ships more than an accurate receiver receives. They have different mentality.

283

In the given context, things stand like this. No bookkeeping system takes account of the existing shipper/receiver difference. Yet, this difference is taken into account by any measured material balance system. The material concerned is not, quite naturally, stolen or has anything done with it en route. This simply shows to what extent our knowledge about what is really going on is uncertain. We should remember that our knowledge is far from being absolute, the difference being a random quantity and depending on how perfect the shipper’s and the receiver’s measurement systems are. It should be also noted that multiple transfers of large NM quantities may lead to the uncertainty of data on the total material accumulating and reaching significant values.

Tolerable shipper/receiver differences

So what shipper/receiver difference is allowed in Russia?

The shipper/receiver difference in the mass of the nuclear material being transferred is determined as the difference between the values of the masses shown by the shipper (certificate data) and those obtained in verifying measurements.

Let S and R be respectively the shipped and the received NM quantities. S and R are random quantities as measured by the shipper and the receiver and have respective errors of σS and σR.

For the shipper/receiver difference (S–R) , the mean-square deviation from its mathematical expectation is

σS–R = (σ 2S + σ 2R)1/2,

if the measurements of S and R are assumed to be independent.

It should be remembered that the confidence interval is the one that covers the parameter of interest (random quantity) with a given probability. The following confidence intervals are used in accounting for and control of NM:

∙0.95 – insignificant statistical straggling interva l;

∙0.99 – permissible statistical straggling interval.

If S–R is a normally distributed random quantity and М(S– R) is its mathematical expectation, then the interval М(S–R )±2.58·σS–R makes a 99% confidence interval.

The General Rules specify that where the difference (S–R ) is other than zero within its 99% confidence interval, this may be believed to be the sequence of the shipper and receiver NM measurement errors. The NM

284

concerned is booked by the receiver subject to the shipper data. This is normally explained by the shipper data having been obtained by accounting NM measurements and the receiver data by verifying NM measurements.

Where the difference (S–R ) is beyond the 99% confidence interval, respective measures should be taken either to have this data agreed or, if the shipper/receiver discrepancy has been confirmed to be great, to identify the causes for the NM loss or surplus. In this case, the receiver shall send special reports to the state atomic energy management authorities and the nuclear safety regulator.

How nuclear material is transferred

NM transfers involve the following as the General Rules define.

1.A transfer of NM shall be authorized only if the shipper and the receiver have been licensed to handle NM and have contracted with Rosatom for transfers of NM for use (for federally owned NM).

2.The shipper shall give the receiver a prior notification of NM to be shipped (this is the binding requirement because any NM dispositions entail nuclear and radiation safety/security issues).

3.The shipper shall condition and measure the material and prepare respective account and cover documents. Cover documents give NM container data (seal types and identifiers, gross weights of containers, etc.). These attributes are used for the initial acceptance of cargo. Data on NM characteristics (certificate data) shall be dispatched by special mail or together with cargo.

4.NM shall be transferred in the presence of the shipper and receiver representatives. The receiver representative shall check the attributes of NM, including:

∙external examination and quantity check of the NM containers;

∙integrity check of the tamper indicating devices applied to the vehicle and the NM containers;

∙conformity of the container identifiers and the tamper indicating devices to respective invoices.

∙verifying measurements of the NM container gross weight.

5.Where required, the receiver shall implement verifying measurements for other NM parameters.

The receiver shall define the necessity, form and volume of verifying measurements given that, after these are done, NM should be booked within the NM A&C system of the receiving organization which shall take over, from that time onwards, the entirety of the legal responsibility for the

285

safety of NM in such quantity as shown in the shipper’s cover documentation. Verifying measurements shall take into account the form of transfer (between MBAs within one site, between sites, export/import), the category of the NM transferred, the type of the containers and tamper indicating devices, and the shipper’s measurement quality.

6.If no verifying measurements have been done in full, the NM is subject to initial acceptance and booking.

The NM shall be finally accepted and booked no later than 10 days after it is received, which is the deadline for all required verifying NM measurements to be completed with the measurement results compared against the shipper data and the significance of the (S– R) difference estimated.

7.Where major discrepancies are detected, the NM received from the shipper shall be accepted for the time being based on the receiver documentation with a statement to be made out as to the nonconformity of the data. The NM received shall not go into process until the discrepancy with the shipper data is settled.

Example of the allowable shipper/receiver measurement difference calculation

A transfer of containerized NM is considered. The shipper and the receiver measure the gross weight of the NM container using scales with normally distributed measurement errors.

The shipper’s cover documents show the container gross weight to be 25.05 kg. The receiver’s incoming test measurement gives the container gross weight of 24.96 kg, which is recorded.

The relative errors of both the shipper’s and the receiver’s scales are indicated in the scales specifications and constitute δ = 0.4% for the scales concerned, these having being reduced to a 95% confidence interval.

a)May the receiver book this NM in its corporate records?

b)May the receiver accept this NM if the shipper has failed to show the measurement error data in its documents?

6.2. Physical inventory taking and balance of NM

The knowledge about nuclear material suggests that we have data on the NM inventories in an MBA and on the incoming and outgoing NM flows over a special period called the material balance period (MBP). NM transfers and physical inventory takings are the main accountancy procedures that give such knowledge about NM. These procedures suggest

286

that all incoming and outgoing NM flows are measured with all NM inventories measured at the end of the material balance period.

NM transfer procedures have been discussed hereinabove in this chapter. Hereinafter, NM physical inventory taking (PIT) procedures and the structuring of the NM balances in MBAs will be considered [1].

Many in the expert community believe a physical inventory taking to be a large-scale physical experiment, so a detailed examination of PIT procedures is to be complemented with practical training to model individual PIT stages. PIT modeling needs not necessarily involve use of nuclear material (thus, river sand can be weighed instead of NM). Here, we shall try to describe this procedure as the whole.

Grouping of physically inventoried items

1)Type of nuclear material means nuclear material having its isotopic composition within the given interval. NM types are defined by regulatory documents (uranium, uranium-235, uranium-233, plutonium and so on). NM balance is closed for each NM type.

2)For convenience of PIT data adjustment, any material that was received in or shipped from the MBA, or was generated or being available at the beginning or left at the end of the material balance period, is classified as active or passive material.

Active NM includes products that were subjected to accounting measurements over the most recent material balance period or during the physical inventory taking. Specifically, active NM includes products processed in the given material balance period, fabricated products, waste generated in the given material balance period, products which came to require accounting measurements to generate a new certificate, etc. Where active NM was undergoing accounting measurements prior to the current PIT, these are subject to verifying measurements during the inventory taking.

Passive NM includes products that have not changed by the inventory taking time, since the previous inventory taking, products for which no accounting measurements have been done, and products being under access controls or having such coatings as may be viewed, as such, as access controls with the absence of access confirmed by means of access controls. Passive material also includes the material received in the MBA in the material balance period, booked based on the shipper data and having been, as of the inventory taking time, under access controls since the receipt time.

287

Passive material is subject to verifying measurements during the inventory taking.

3) Stratification is grouping of items with similar characteristics. Stratum is a group of batches or separate items having similar physical and chemical characteristics and isotopic compositions. Grouping by strata makes it easier to analyze large quantities of identical items (sampling measurements).

Objectives of physical inventory takings

The new accounting (measured material balance) system requires mandatory physical inventories to be periodically taken in each MBA.

Physical inventory taking is determination of the NM physical inventories in MBAs by measurements. So the object of physical inventory takings is formulated in the definition thereof. Additionally, physical inventory takings:

∙Determine if the physical parameters of the item conform to the existing accounting data. The conformity confirms the integrity of NM and the confidence of NM data;

∙Detect, as the result of the total check, drawbacks and infringements in accounting and control of NM (that is, efficiency of the NM A&C system is evaluated).

Types of NM physical inventory takings

Physical inventories may be taken both on a scheduled (at regular intervals) and an unscheduled basis. A scheduled PIT determines the inventory of all NM types in the MBA (including the NM received for use on an interim basis).

An unscheduled PIT may determine the physical inventory of some NM types or determine the physical inventory of NM in a portion of the MBA (for all or any NM types). Unscheduled physical inventories are taken in the MBA:

∙when the custodian is substituted;

∙when, in the event of a team custodian, the team head (leader) is substituted, more than 50% of the team members retire or at least one team member so requests;

∙by a decision of the enterprise administration;

∙if anomalies are detected in accounting and control of NM;

288

∙in the event of an off-normal occurrence (lack of an item, unauthorized access to the MBA, an accident and other emergencies);

∙when the enterprise is reorganized involving change of custodians.

Frequency of inventory takings

The approach to determining the PIT frequency is based on the concept of NM attractiveness and overall quantities, that is, the category of NM.

Thus, the frequency of physical inventory takings will be different for different nuclear material, say, plutonium metal in significant quantities and low-enriched dioxide uranium quantities (or nuclear material in irradiated fuel). In particular, as recommended by the US Department of Energy, physical inventories for top-graded nuclear material in respective process departments should be taken not less than once in two months. That is, 100% control of the NM physical inventories should be carried out every two months.

As applied to the material balance area as may be determined in spent fuel stores of nuclear power plants, the requirements are naturally less stringent. The reason is that spent fuel as such is intrinsically safe due to being rather highly active.

The following frequency of inventory takings is accepted in Russia, depending on the category of nuclear material in the MBA (NP-030-05):

∙1 calendar month for MBAs with material of category 1;

∙3 calendar months for MBAs with material of category 2 and/or 3;

∙6 calendar months for MBAs with material of category 3 to 6;

∙12 calendar months for MBAs with material of category 4 to 12;

∙12 calendar months for all onsite nuclear material.

The frequency of physical inventory takings for MBAs with nuclear material inventorying which involves major personnel exposures may be reduced as agreed with Rostekhnadzor and Rosatom of Russia subject to the justification provided. This normally involves extra technical arrangements to control access to nuclear material (for example, BFS–1,2 at State Research Center “Institute of Physics and Power Engineering”).

Organization of onsite physical inventory takings

As a large-scale physical experiment, a PIT procedure requires the whole series of prior measures to be successfully implemented. We shall consider these in brief.

289

Prior to each PIT, the order for this to be held is issued by the chief executive officer. The order specifies the basic organizational arrangements required for the site physical inventory to be taken. Among other things, the following is determined:

∙the MBAs in which the PIT will be implemented;

∙the names of the PIT commission members;

∙the dates for preparing accounting data, equipment and instrumentation required for the inventory taking;

∙the dates for preparing the items to be inventoried for checking;

∙the inventory taking dates and the submission date of the PIT reports.

To prepare, hold and analyze the results of the NM physical inventory taking, the following PIT commissions are formed at the enterprise: a central inventory-taking commission (CITC) and, within the site divisions, working inventory-taking commissions (WITC).

The WITCs plan the PIT, prepare the MBAs and implement the PIT within the specified dates. During the inventory talking the WITC members:

∙detect and record the shortcomings in accounting, storage and utilization of NM, and make proposals on eliminating these;

∙bring to the notice of executive staff the detected shortcomings in accounting and storage of NM.

The CITC shall provide procedural guidance for the inventory taking to be organized and implemented within the enterprise’s material balance areas (coordination of works and counseling). Essential to the PIT implementation are safety and radiation safety precautions. These should be therefore defined in the respective inventory-taking instruction and approved by the organization’s nuclear and radiation safety services.

A division’s WITC shall be made up of skilled personnel having access to operations with NM, as well as to accounting and technical records. Normally, a WITC comprises:

∙the chairman (head of division);

∙representatives of the nuclear safety and radiation monitoring services;

∙representatives of the A&C system computerized accounting service;

∙physical measurement and statistical experts;

∙a representative of the CITC;

∙representatives of the security service and other members.

The custodian shall take part in preparing the MBA for the PIT and shall be present during the commission’s work. However, he/she shall not be a member of the PIT commission.

290