Крючков Фундаменталс оф Нуцлеар Материалс Пхысицал Протецтион 2011

.pdfCategorization of nuclear material in Russia (NP–03 0–05 [1])

Categories of nuclear material are defined depending on the NM mass, the form of the NM-containing product and the NM type (Tables 2.3 – 2.6). Depending on the quantity of nuclear material, the MBA facility may fall into category I, II, III or IV. The next parameter is the form of the NMcontaining product. As evidenced by Tables 2.3-2.6, this demonstrates the attractiveness of nuclear material. Attractiveness is assessed by how rapidly a nuclear material can be converted to a form fit to produce nuclear weapon.

Noteworthy is that irradiated fuel is the least attractive. The reason is simple. Such fuel is inherently safe which makes it an essentially unlikely target for theft or misuse. Same is true for low-enrichment uranium that needs to be highly enriched to be used directly in nuclear weapons production.

Cases are possible when the area of interest contains different products and diverse NM. To categorize the existing NM in these conditions, one is expected to proceed from the total mass of NM in each product and the quantitative mass limits, as specified in Tables 2.3 – 2.6, for the nuclear material in products falling under a higher category.

Russia defines NM physical protection, accounting and control requirements subject to the following categorization of nuclear material.

131

|

|

|

|

|

Table 2.3 |

|

|

|

Nuclear material of category I |

|

|

||

|

|

|

|

|

|

|

Products |

|

|

Nuclear material |

|

Mass of nuclear |

|

|

|

|

|

|

material, kg, not less |

|

|

|

|

|

|

than |

|

Metal products: |

|

|

|

2 |

|

|

metal articles, billets; |

Pu, U–233 |

|

by total mass of Pu |

|

||

ingots, grit, alloys and |

|

|

and U–233 |

|

||

mixtures; |

|

|

|

|

|

|

fuel elements and assemblies |

HEU |

|

5 |

|

||

with a content of metallic and |

|

|

by U–235 isotope |

|

||

intermetallic fuel; |

|

Mixture or |

|

2 |

|

|

reject articles and waste |

combination of |

|

by total mass of Pu, |

|

||

processed by remelting without |

Pu, U–233, HEU |

|

U–233, U–235, |

|

||

dissolution |

|

and other nuclear |

|

Np–237, Am and Cf |

|

|

|

|

|

material |

|

|

|

Products |

|

|

Nuclear material |

|

Mass of nuclear |

|

|

|

|

|

|

material, kg, not less |

|

|

|

|

|

|

than |

|

Products with high content of |

|

|

6 |

|

||

nuclear material: |

|

Pu , U–233 |

|

by total mass of Pu |

|

|

carbides, |

oxides, |

chlorides, |

|

|

and U–233 |

|

nitrides, |

fluorides, |

alloys and |

|

|

20 |

|

mixtures thereof; fuel elements |

HEU |

|

by U–235 isotope |

|

||

and assemblies containing fuel |

|

|

|

|

||

out of above compounds, as |

|

|

|

|

||

well as other products with NM |

|

|

|

|

||

concentration (content) of not |

|

|

|

|

||

less than 25 g/l (25 g/kg) |

|

|

|

|

||

132

|

|

|

|

|

Table 2.4 |

|

|

|

|

Nuclear material of category II |

|

|

|

|

|

|

|

|

|

|

|

Products |

|

Nuclear material |

Mass of nuclear |

|

|

|

|

|

|

|

material, kg |

|

Metal products: |

|

Pu, U–233 |

³ 0.5 but < 2 |

|

||

metal |

articles, |

billets, ingots, |

|

by total mass of Pu |

|

|

grit, |

alloys |

and |

mixtures |

|

and U–233 |

|

thereof; |

and |

assemblies |

HEU |

³ 1 but < 5 |

|

|

fuel elements |

|

by U–235 isotope |

|

|||

with a content of metallic and |

|

|

||||

Mixture or |

³ 0.5 but < 2 |

|

||||

intermetallic fuel; |

|

|

||||

|

combination of Pu, |

by total mass of Pu, |

|

|||

reject articles and waste |

|

|||||

U–233, HEU and |

U–233, U–235, |

|

||||

processed by remelting without |

|

|||||

other nuclear |

Np–237, Am and Cf |

|

||||

dissolution |

|

|

|

|||

|

|

material |

|

|

||

|

|

|

|

|

|

|

Products with high content of |

|

³ 2 but < 6 |

|

|||

nuclear material: |

|

Pu, U–233 |

by total mass of Pu |

|

||

carbides, oxides, chlorides, |

|

and U–233 |

|

|||

nitrides, fluorides, alloys and |

|

|

|

|||

HEU |

³ 6 but < 20 |

|

||||

mixtures thereof; fuel elements |

|

|||||

|

by U–235 isotope |

|

||||

and assemblies containing |

|

|

||||

Mixture or |

³ 2 but < 6 |

|

||||

fuel out of above compounds, |

|

|||||

combination of Pu, |

by total mass of Pu, |

|

||||

as well as products with NM |

|

|||||

U–233, HEU and |

U–233, U–235, |

|

||||

concentration (content) of not |

|

|||||

other nuclear |

Np–237, Am, Cf |

|

||||

less than 25 g/l (25 g/kg) |

|

|||||

material |

|

|

||||

|

|

|

|

|

|

|

Products with low content of |

Pu, U–233 |

³ 16 |

|

|||

nuclear material: |

|

|

by total mass of |

|

||

products requiring complex |

|

Pu and U–233 |

|

|||

treatment; products with NM |

HEU |

³ 50 |

|

|||

concentration (content) of 1 to |

|

by U–235 isotope |

|

|||

25 g/l (1 to 25 g/kg) |

|

|

|

|||

|

Mixture or |

³16 |

|

|||

|

|

|

|

|

||

|

|

|

|

combination of Pu, |

by total mass of Pu, |

|

|

|

|

|

U–233, HEU and |

U–233, U–235, |

|

|

|

|

|

other nuclear |

Np–237, Am and Cf |

|

|

|

|

|

material |

|

|

133

|

|

|

Table 2.5 |

|

Nuclear material of category III |

|

|

||

|

|

|

|

|

Products |

Nuclear material |

|

Mass of nuclear |

|

|

|

|

material, kg |

|

Metal products: |

Pu, U–233 |

|

³ 0.2 but < 0.5 |

|

metal articles, billets, ingots, |

|

|

by total mass of Pu |

|

grit, alloys and mixtures |

|

|

and U–233 |

|

thereof; |

HEU |

|

³ 0.5 but < 1 |

|

fuel elements and assemblies |

|

|

by U–235 isotope |

|

with a content of metallic and |

|

|

|

|

Mixture or |

|

³ 0.2 but < 0.5 |

|

|

intermetallic fuel; |

|

|

||

combination of Pu, |

|

by total mass of Pu, |

|

|

reject articles and waste |

|

|

||

U–233, HEU and |

|

U–233, U–235, |

|

|

processed by remelting |

|

|

||

other nuclear |

|

Np–237, Am and Cf |

|

|

without dissolution |

|

|

||

material |

|

|

|

|

|

|

|

|

|

Products with high content |

Pu, U–233 |

|

³ 0.5 but < 2 |

|

of nuclear material: |

|

|

by total mass of |

|

carbides, oxides, chlorides, |

|

|

Pu and U–233 |

|

nitrides, fluorides, alloys and |

HEU |

|

³ 2 but £ 6 |

|

mixtures thereof; fuel |

|

|

by U–235 isotope |

|

elements and assemblies |

|

|

|

|

Mixture or |

|

³ 0.5 but < 2 |

|

|

containing fuel out of above |

|

|

||

combination of Pu, |

|

by total mass of Pu, |

|

|

compounds, as well as |

|

|

||

U–233, HEU |

|

U–233, U–235, |

|

|

products with NM |

|

|

||

and other nuclear |

|

Np–237, Am and Cf |

|

|

concentration (content) of not |

|

|

||

material |

|

|

|

|

less than 25 g/l (25 g/kg) |

|

|

|

|

|

|

|

|

|

Products with low content |

Pu, U–233 |

|

³ 3 but < 16 |

|

of nuclear material: |

|

|

by total mass of |

|

products requiring complex |

|

|

Pu and U–233 |

|

treatment; |

HEU |

|

³ 8 but < 50 |

|

products with NM |

|

|

by U–235 isotope |

|

concentration (content) of 1 to |

|

|

|

|

Mixture or |

|

³ 3 but < 16 |

|

|

25 g/l (1 to 25 g/kg) |

|

|

||

combination of Pu, |

|

by total mass of Pu, |

|

|

|

|

|

||

|

U–233, HEU |

|

U–233, U–235, |

|

|

and other nuclear |

|

Np–237, Am and Cf |

|

|

material |

|

|

|

134

|

|

Table 2.6 |

|

Nuclear material of category IV |

|||

|

|

|

|

Products |

Nuclear material |

NM mass, kg, not more |

|

|

|

than |

|

Metal products: metal articles, |

Pu, U–233 |

0.2 by total mass of Pu |

|

billets, ingots, grit, alloys and |

|

and U–233 |

|

mixtures thereof; fuel elements |

HEU |

0.5 by U–235 isotope |

|

and assemblies with a content of |

Mixture or |

0.2 by total mass of Pu, |

|

metallic and intermetallic fuel; |

combination of Pu, |

U–233, U–235, |

|

reject articles and wastes |

|

||

U–233, HEU and |

Np–237, Am and Cf |

|

|

processed by remelting without |

|

||

other nuclear |

|

|

|

dissolution |

|

|

|

materials |

|

|

|

|

|

|

|

Products with high content of |

Pu, U–233 |

0.5 by total mass of Pu |

|

NM: carbides, oxides, chlorides, |

|

and U–233 |

|

nitrides, fluorides, alloys and |

HEU |

2 by U–235 isotope |

|

mixtures thereof; fuel elements |

Mixture or |

0.5 by total mass of Pu, |

|

and assemblies containing fuel |

|

||

combination of Pu, |

U–233, U–235, |

|

|

out of above compounds, as well |

|

||

U–233, HEU and |

Np–237, Am and Cf |

|

|

as other products with NM |

other nuclear |

|

|

concentration (content) of not |

|

|

|

material |

|

|

|

less than 25 g/l (25 g/kg) |

|

|

|

|

|

|

|

Products with low content of |

Pu, U–233 |

3 by total mass of Pu |

|

NM: products requiring complex |

|

and U–233 |

|

treatment; products with NM |

HEU |

8 by U–235 isotope |

|

concentration (content) in a range |

Mixture or |

3 by total mass of Pu, |

|

of 1 to 25 g/l(1 to 25 g/kg) |

combination of Pu, |

U–233, U–235, |

|

|

|

||

|

U–233, HEU and |

Np–237, Am and Cf |

|

|

other nuclear |

|

|

|

material |

|

|

All other products including: |

|

Total mass of all |

|

a) products containing Pu, U–233 and HEU with a |

nuclear material is not |

|

|

concentration (content) of below 1 g/l (1 g/kg); |

less than the minimum |

|

|

b) any uranium compounds with a U–235 content in |

quantities |

|

|

uranium of below 20%; |

|

|

|

c) any products with an absorbed dose rate of not less |

|

|

|

than 1 Gy/h = 109 rad/h at a distance of 1 m; |

|

|

|

d) any compounds of: plutonium with a plutonium-238 |

|

|

|

isotope content of over 80%; thorium, neptunium–237 , |

|

|

|

americium–241, americium–243 and californium–252; |

|

|

|

e) special non-nuclear material and any compounds |

|

|

|

thereof |

|

|

|

135

NM categorization practice

The existing material should be categorized if the core contains:

∙fresh FAs of a research reactor core (the reactor grid is composed of 16 FAs, each FA containing 90% of uranium in the form of a uranium and aluminum alloy. One FA contains 300 g of uranium-235);

∙one fresh FA of a research reactor;

∙fresh FAs of a light-water power reactor numbering a third of the overall reactor load (a 4.4%-enriched UO2 fuel is used, one FA contains 19 g of uranium–235. There are 160 FAs in the reactor. The overall reactor load is 80 t of UO2);

∙one spent FA;

∙metal waste with 250 g of plutonium and a container with PuO2 of the net weight 6.5 kg;

∙450 kg of natural uranium.

2.2. Forms of nuclear material. Batch of nuclear material

Forms of nuclear material

All nuclear material may have one of the following two forms.

Item NM in the form of canned material. This has a unique identification number of its own. Examples of item NM are fuel elements and fuel assemblies.

Bulk-form NM is any NM other than canned NM, i.e. having an unclad form (gases, liquids, powders, pellets). This material cannot be permanently identified as its quantity and composition in containers can be changed.

Depending on the existing NM form, various instruments and identifiers are used to account for this NM. So, bulk nuclear material can be tested destructively with sampling and subsequent sample analysis. These methods are not applicable to item NM. On the other hand, this NM is often measured nondestructively.

Batch of nuclear material

An exclusively important concept used in the new system (as, though, in the old system as well) is nuclear material batch. This concept is used to record item and bulk NM.

A batch of NM is a collection of uniform items that contain NM the parameters whereof are determined in a single series of measurements.

136

Uniformity means that, e.g., one batch cannot contain items of different enrichments.

Each NM batch has five data elements:

∙name of NM batch. Batch name is the identifier composed of a number of symbols. The identifier shows the manufacturer code, the batch serial number and so on. Therefore, name is used as the unique identifier of NM batch;

∙number of uniform items in batch. The number of items is often equal to 1. “Item” is the term often used to denote an NM batch. Examples of batches: fuel element (the number of items in batch is 1), container with UF6 (the number of items in batch is 1), five containers with UO2 powder (a batch is understood as the given set of containers of which each is viewed as an item);

∙NM ligature mass (Мlig) which is the mass of a material that contains a chemical or physical NM composition with some inert substance. For example, the mass of the U-Al alloy is understood as the ligature mass of NM in the U–Al alloy used as fuel in some research reactors (of the IRT type). The ligature mass of NM in the form of a chemical compound of uranium dioxide (fuel of light-water power reactors) is understood to be the mass of the UO2 compound;

∙element mass (Мel). For example, for the UO2 compound we have the element masses of Мel = МU, Мel = МO;

∙isotope mass (Мis). Accounting deals primarily with fissile isotopes: U–

235 isotope for uranium and Pu–239, 241 isotopes fo r plutonium. Enrichment, a similar parameter, is considered occasionally instead of the U–235 mass.

The five noted NM batch parameters are central to NM accounting and balancing closing. These parameters are applicable both to item and bulk NM. For material in the form of items, however, all data that accompanies unirradiated material is the manufacturer data, while data for bulk material normally change over time.

2.3. Material balance area (MBA). Organization of accounting and control of NM in MBAs

Material balance area

Material balance area (MBA) is the central concept to the new NM accounting and control system. MBA is an elementary structural unit of the state NM accounting and control system.

137

There is no such notion in bookkeeping where NM balances are operated for the whole of the enterprise. As a concept, MBA was introduced in 1959 by US experts and “legalized” by the IAEA in the Guidelines for States’ Systems of Accounting for and Control of Nuclear Materials (1980 [2]) going later into the Concept of the State Nuclear Material Accounting and Control System as approved by the Russian Federation Government in October 1996 [3].

Definition of MBA: A territorially and administratively area established within a nuclear facility or an NM storage point to account for and control nuclear material, the quantity of nuclear material therein determined by measurements each time it is transferred into or out of the given area with the nuclear material balance closed for the respective time period.

Therefore, controlled inputs and outputs are defined clearly in an MBA, and the NM inventory is periodically subject to determination by NM physical inventory takings (PIT).

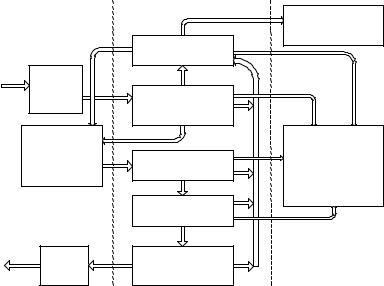

Construction of MBA. Proper selection of the NM balance area structure is essential to ensuring sound operations of the corporate NM accounting and control system. However, MBAs are often hard to size and set boundaries for. For example, Figure 2.1 shows a simplified flowchart of a power reactor fuel fabrication plant.

Store

Feed sup

UF

UO2

STO

Finish prod

shipme FA STO

Processes |

|

|

|

wast |

|

|

LIQUID AND |

|

|

WASTE |

|

SCRAP |

|

samp |

|

|

|

||

GAS-PLASMA |

|

samp |

|

CONVER |

scrap |

|

|

|

sampl |

ANALYTICA |

|

|

|

||

PELLETIZING |

|

|

LABORATO |

|

|

MASS– |

|

|

|

|

|

|

|

|

CHEMICAL |

FUEL PIN |

|

|

ANALYSIS |

|

|

|

|

|

scrap |

samp |

|

|

|

|

|

FA |

|

|

|

Fig. 2.1. NPP fuel fabrication. Flowchart of major processes 138

It includes many processes. MBAs, however, should be such that to make it easy to measure incoming and outgoing NM flows and take physical inventories with no great economic loss due to suspension of production.

Sizing of MBAs is so a matter of optimization since the decision is made based on a number of contradictory requirements. Examples:

a)if an MBA is large, there is less corporate documentation and it is easier to report. Physical inventories are however harder and more expensive to take in the MBA as this requires the production process to be stopped;

b)if an MBA is small, physical inventories are easier to take. Still, a great deal of reporting is required for the whole of the enterprise.

To choose the MBA structure, each enterprise proceeds from this kind of contradictory conditions and follows a number of generic MBA selection guidelines. Here are some of such guidelines:

∙the number of MBAs at the enterprise is chosen such that they be enough to ensure accounting and control of all NM. Each MBA is documented and subject to approval from a superior organization. Ultimately, the number and boundaries of MBAs are approved by Rosatom that implements federal-level accounting and control of NM;

∙each MBA shall form a single indivisible area (a simply connected region);

∙MBA structuring requires MBAs to have their boundaries welldefined and matching (other than crossing) those of guarded areas. MBAs and guarded areas may have coinciding boundaries;

∙if an MBA has boundaries failing to make material in different MBAs less likely to be intentionally or unintentionally mixed, this renders control of this area senseless;

∙determination of the MBA boundaries shall take into account the existing physical barriers. Physical barriers are structural elements (walls, ceilings, gates, doors) and dedicated structures (fencing, anti-ram facilities, meshes, reinforced doors, containers);

∙operational divisions, such as plant laboratories, warehouses, as well as departments requiring special protection of information, form separate MBAs.

The IAEA and some organizations in Russia have developed and use dedicated techniques to structure MBAs based on design data. Data on how every facility is designed is arranged as a questionnaire. Answers to the

139

questions in this enable one to get a set of data required to define the MBA boundaries.

Determination of NM flows and inventories in MBAs

Incoming and outgoing NM flows, as well as NM inventories in MBAs are determined at key measurement points (KMP).

Key measurement point (KMP) is where nuclear material can be measured to have NM flows and inventories determined.

Inventory determination methods for canned articles (FAs, individual fuel elements (FE) and others) are accounting of items (identification of items plus counting thereof) and nondestructive NM measurements.

For bulk material these are a set of measuring procedures used to determine the inventory with potential sampling taken into account. Chemical and isotopic compositions are measured on the samples taken. This gives significance to making so that NM samples to be representative.

Figure 2.2 demonstrates measurements for different NM forms (bulk and items) at key measurement points for the fuel element loading department in an NPP fuel fabrication cycle. It can be seen that both destructive (for incoming NM flow) and nondestructive NM analyses are used to account for NM.

Attributes are the data that determines unambiguously if NM has any feature.

Examples of attributes:

∙Is there NM in the given item or not?

∙Does the tamper indication device verify to the absence of unauthorized access to NM or not?

∙Is NM of the type shown in certificate data or not?

∙Does the NM gross weight differ from certificate data in the measurement error limits or not?

∙Does the number of items in the container coincide with documented data or not?

∙Is the item with the given identifier at its specified location or not?

Attributes are particularly useful with basic accounting procedures. This is the case, say, when an NM transfer requires incoming material to be rapidly received. Incoming tests of material are based predominantly on attributes.

140