water quality and system

.pdf

< previous page |

page_154 |

next page > |

Page 154

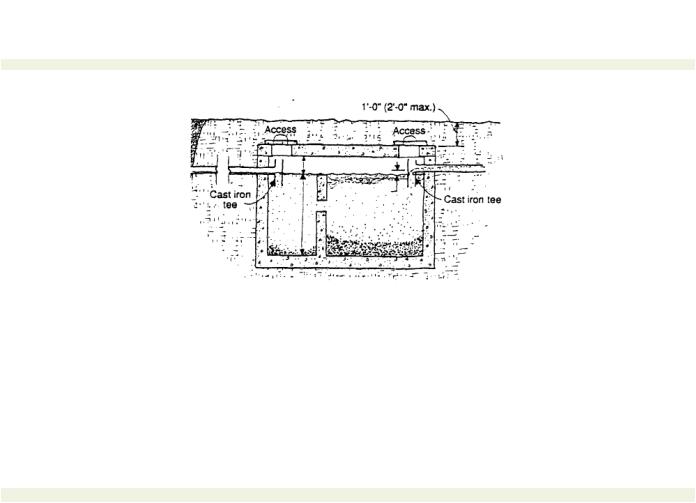

Figure 9-2.

Typical septic tank. Courtesy: Stein and Reynolds, Mechanical And Electrical Equipment for Buildings, 8th Edition. ©1992 John Wiley & Sons, reprinted with permission.

Septic tanks work well for single-family dwellings and small remote businesses but are easily overloaded, and the process can be interrupted by oil, strong bleach or chemical cleaning compounds, or other chemicals that are toxic to the microbes. In addition, large amounts of sand, grease or garbage can overload the primary chamber and in these instances an interceptor is required.

Periodically, every few years, septic tanks must be pumped out to remove debris and solids that have filled up the primary vessel.

Storage Tanks

One short-term facility solution to sewerage disposal problems is to provide an underground storage tank where waste waters can flow. Then, periodically, the facility hires a septic tank pumping company to come and pump the sewage and haul it in trucks to a treatment disposal location. As regulations increase relative to the disposal of sanitary wastes, this option will become more and more attractive. It is often used as a temporary measure during construction of a large facility while the sanitary sewer system is still under construction. Underground sewer tanks are regulated by the County Health Department and are leak-tested and inspected.

< previous page |

page_154 |

next page > |

< previous page page_155

Table 9-2. Location of sewage disposal system. Courtesy of the International Association of Plumbing And Mechanical

Officials, ANSI 40-1996 (pending) Safety Requirements for Plumbing, Uniform Plumbing Code. |

|

|||||||

Minimum Horizontal |

Building Sewer |

Septic Tank |

Disposal Field |

Seepage Pit or Cesspool |

||||

Distance In Clear |

|

|

||||||

Required From: |

2 feet |

(0.6 m) |

5 feet |

(1.5 m) |

8 feet |

(2.4 m) |

8 feet |

(2.4 m) |

Buildings or |

||||||||

structures1 |

|

|

6 feet |

(1.5 m) |

5 feet |

(1.5 m) |

8 feet |

(2.4 m) |

Property line adjoining Clear2 |

|

|||||||

private property |

50 feet3 |

(15.2 m} |

50 feet |

(15.2 m) |

100 feet |

(30.5 m) |

150 feet |

(45.7 m) |

Water supply wells |

||||||||

Streams |

50 feet |

(15.2 m) |

50 feet |

(15.2 m) |

50 feet7 |

(15.2 m) |

100 feet7 |

(30.5 m)7 |

Trees |

- |

|

10 feet |

(3.0 m) |

- |

(1.5 m) |

10 feet |

(3.0 m) |

Seepage pits or |

- |

|

5 feet |

(1.5 m) |

5 feet |

12 feet |

(3 7 m) |

|

cesspools |

- |

|

5 feet |

(1.5 m) |

4 feet' |

(1 2 m) |

5 feet |

(1.5 m) |

Disposal field |

(0.3 m) |

|||||||

On site domestic water 1 foot6 |

5 feet |

(1.5 m) |

5 feet |

(1.5 m) |

5 feet |

(I 5 m) |

||

service line |

- |

|

- |

|

5 feet |

(1.5 m) |

5 feet |

(1 5 m) |

Distribution box |

(3.0 m) |

(3.0 m) |

||||||

Pressure public water |

10 feet8 |

10 feet |

10 feet |

(3.0 m) |

10 feet |

(3.0 m) |

||

main Note:

When disposal fields and/or seepage pits are installed in sloping ground, the minimum horizontal distance between any part of the leaching system and ground surface shall be fifteen (1.5) feet (4 6 m).

1. |

Including porches and steps, whether covered or uncovered, breezeways, roofed porte-cocheres, |

|

roofed patios, carports. covered walks, covered driveways and similar structures or |

2. |

appurtenances. |

See also Section 313.3 of the Uniform Plumbing Coda. |

|

3 |

All drainage piping shall clear domestic water supply wells by at least fifty (50) feet (15.2 m) |

|

This distance may be reduced to not less than twenty-five (25) feet (7.6 m) when the drainage |

4. |

piping is constructed of materials approved for use within a building. |

Plus two (2) feet (0.6 m) for each additional foot (0.3 m) of depth in excess of one (1) foot (0 3 |

|

5. |

m) below the bottom of the dram line. (See a/so Section K 6.) |

See Section 720.0 of the Uniform Plumbing Code. |

|

6. |

For parallel construction - For crossings, approval by the Health Department shall be required. |

7. |

These minimum clear horizontal distances shall also apply between disposal field, seepage pits, |

|

and the ocean mean higher high tide line. |

next page >

Page 155

< previous page |

page_155 |

next page > |

< previous page |

page_156 |

next page > |

Page 156

In addition, concrete blocks are placed on the tank's sides and straps placed over it to hold it should a large rainstorm or tidewater run into the soil around the tank, making it try to float out of the ground. The lifting force can be several tons for a 5,000 gallon-tank.

Other Types/Packaged Units

Several vendors make packaged units available that are combinations of the sewage disposal types discussed here. A method of evaluating them would be a combination of cost, BOD removal, size and utility requirements.

Oxygenated Ditch

A small effective sewer treatment facility is known as the oxygenated ditch, which uses a oval or circular pattern where the raw sewage flows after primary treatment. In this system, a paddle-wheel moves the water in the ditch. The paddles inject air. The movement agitates the flow to allow mixing and aeration of organic matter. Baffles along the bottom stop the sludge and augers move the sludge into the center where it is pumped into drying beds. If necessary, the clear effluent can be drawn off, but usually the water is allowed to evaporate. The oxygenated ditch takes more room than trickling filters, but less than lagoons. Its advantage is that it requires few operators and is fairly forgiving if injected with chemicals.

Soil Conditions

The design of sewage lagoons, septic tank leach fields, and to some extent buried pipe are dependent upon the soil conditions in the area. A detailed discussion of soil types and parameters is beyond the scope of this text, but a few brief items are mentioned here for the facility manager.

Rock - Rock is ideal subgrade materialhowever, removing it is expensive. If there is a choice, do not use rock for this purpose.

Sand And Gravel - Sand and gravel is excellent material and it is highly porous. Most codes do not allow constructing sewage lagoons on sand or gravel because the high porosity will allow the sewer discharges to leach to groundwater.

Clay - There are two kinds of clays, called fat clays and lean clays. Fat clays form a gummy sticky material when a clay is wet.

< previous page |

page_156 |

next page > |

< previous page |

page_157 |

next page > |

Page 157

These clays are excellent barriers for drainage when thick enough. Most ponds are lined with some form of a fat clay. Lean clays are easier to work with because they are also impervious but do not ball up as much. Lean clays bind to themselves better than fat clays. A fat clay will often dry up and blow away while a lean clay will not.

By rolling a ball of wet soil between the palms, a quick judgment can be made between lean and fat clays. If the material rolls out very thin, smaller than a No. 2 pencil lead, then it is a fat clay. If it will not roll much smaller than a pencil before breaking, then it is a lean clay. Often, soil is a combination of these.

Cobble Rock - Occasionally, a lean clay will have cobble rock in it. Cobble rock are stones between 4 and 9 inches. Large stones are not a problem for a pond liner but they provide a path of water along the rockas a result the liner would need to be thicker.

Cobble rock is not good bedding material for pipes in the ground because the soil will collapse leaving only the stones. With the weight of material over the pipe, the stone can puncture or crack the pipe. Table 9-3 shows septic and leaching rates for five types of soils.

Groundwater - Soil types are affected by groundwater and leaching sewage into the groundwater table is allowed only by permission. Note: Some areas of high groundwater will cause septic and storage type tanks to float if they are water-tight and there is less water in the water tank than in the adjacent ground.

Table 9-3. Design criteria for the five soils typically used in the design of sewage lagoons, septic tank leach fields and similar facilities. Source: The International Association of Plumbing And Mechanical Officials, ANSI 40-1996 (pending) Safety Requirements for Plumbing, Uniform Plumbing Code.

|

Required sq.ft. of |

Maximum absorption |

||

Type of soil |

leaching area/ |

capacity in gals./sq.ft. for |

||

100 gals. (m2/L) |

a 24-hr. period (I/M2) |

|||

Coarse sand or gravel |

20 |

(0.005) |

5.0 |

(203.7) |

Fine sand |

25 |

(0.006) |

4.0 |

(162.9) |

Sandy loam or sandy clay |

40 |

(0.01 o) |

2.5 |

(101.8) |

Clay with considerable sand or gravel 90 |

(0.022) |

1.1 |

(44.8) |

|

Clay with small amount of sand or |

120 |

(0.030) |

0.8 |

(32.6) |

gravel |

|

|

|

|

< previous page page_157 next page >

< previous page |

page_159 |

next page > |

Page 159

Chapter 10

Water Quality Enhancement

Now that we understand the need for water purity and how supply and wastewater systems work, we can decide the best method of treating our facility's water supply. A variety of equipment is available to do the jobwith many choices of systems that can improve our water's quality for occupant use.

Water System Improvements

To improve a facility's water supply, a number of equipment options are available. Water can be softened if it is hard, as well as filtered, distilled, cooled and so on. Each system is usually installed near where the water comes into a building or onto a complex. Some require an enclosure to protect the various pipes, vessels, valves, and instruments from the elements of harsh winters, however.

Water Softeners

Of all the water treatment systems, perhaps the water softener is the one that is most often encountered in facility management problems.

Hard Water - Calcium or magnesium will deposit on fittings and fixtures and on the insides of pipes. Water with these minerals in it makes it hard to get soap to form suds. Hence, the water is called hard water. These minerals leave a white scale residue when

< previous page |

page_159 |

next page > |

< previous page |

page_160 |

next page > |

Page 160

it dries or when water boils away in a pot. In addition to deposits, washing with hard water leads to stiff clothes and frizzled hair.

Depending upon the amount of hardness, which varies 6-120 grains per gallon, the economics of investing in a water softener can be paid back by savings in soap costs used in laundering and bathing.

As water hardness was explained in Chapter 8, here we will focus on equipment and methods used for water softening. The hardness is a dissolved salttherefore, the method of softening is a chemical process where the undesired salt is exchanged with a salt that dissolves in water. In effect, the hard calcium carbonate is exchanged with sodium and becomes sodium bicarbonate; expressed as a chemical formula, this is:

Softeners - Water softeners (see Figure 10-1) are comprised of two or more vessels. The first vessel contains brine and the second vessel contains resin. The resin vessel contains beds of thousands of tiny beads called zeolite. The beads are sold in bulk form to the many water softener manufacturing companies throughout the world. Inside the water softener, the zeolite beads are coated with sodium chloride salts by rinsing the resin bed with brine made from sodium chloride salt solution. As soft water is drawn out of the water softener, the fresh hard water flows through the resin beds of zeolite where the sodium salts caked on the tiny beads exchange with the calcium salts in the water. The water coming out of the water softener is now ''softened" because the calcium carbonate salts have been exchanged for sodium bicarbonate salts.

Periodically, the resin beads are regenerated with fresh sodium chloride brine, so a second tank called a brine tank is used to store brines before being drawn into the resin bed. During regeneration, the zeolite beads are flushed and rinsed with brine. The calcium, actually calcium chloride, is rinsed away in a drain cycle and the sodium salts in the brine recharge the resins for the next cycle.

People sensitive to the presence of sodium in their diet are sometimes cautioned to refrain from drinking water softened by this method. Hard water poses few health effects below 25 grains per gallonhowever, in some areas of the country, the hardness can exceed 160 grains per gallon. When the level of dissolved salts in a water supply reaches these levels, it is necessary to remove them. Water softening will exchange sodium salts for calcium and

< previous page |

page_160 |

next page > |

< previous page |

page_161 |

next page > |

Page 161

Figure 10-1.

Typical water softener. Courtesy: Water And Power

Technologies Systems, Inc., Salt Lake City, UT.

magnesium salts, but the total volume of dissolved solids remains the same. To completely remove the salts, another process such as reverse osmosis is required.

Water softener manufacturers, using hardness sampling kits, can calculate the amount of "hardness" or the presence of calcium carbonates in the incoming water supplies. Then, by estimating the amount of water used by the facility per day, it is possible to calculate the number of cubic feet of resin that will be needed to soften that amount of water.

System Variables - Some of the variables that are faced by the water softener manufacturer are hardness of the incoming supply, volume used by the facility per day, peak flow of water at any one time in the day, and pressure of water. With these parameters specified by a facility manager, the facility can be confident the water softener meets the needs without being oversized.

In addition, the facility manager may want to inquire:

1. How much does the hardness vary over the the year and has the equipment taken the variations into account?

< previous page |

page_161 |

next page > |

< previous page |

page_162 |

next page > |

Page 162

2. How much does the pressure vary over the year, and has the equipment taken the variations into account? It is up to the facility to decide what water is to be softened. A survey sheet (see Figure 10-2) will aid the facility manager in overseeing the specification of water softeners for his facility.

In addition to the zeolite resin beds, the brine tank requires the periodic addition of salts to recharge the brines. There is no easy way to add salts. Most facility staffs haul the salt in to where the brine tank is on a fork lift or a pallet jack, and spend a few minutes or an hour or two cutting open the salt bags and dumping raw sodium chloride salts into the brine tank.

A number of maintenance problems occur when pieces of the paper bags fall into the brine tank and the facility staff does not remove it. The paper eventually plugs up the brine tank drain line and softening stops.

Options - Modern water softeners come with a variety of options designed to enhance the quality of water and reduce operating costs. Industrial water softeners have double resin beds. In this way, one resin bed supplies soft water to the building while the other one regenerates. Regeneration time depends upon the size of the bed but most are able to regenerate in less than three hours. Some facilities set timers on the water softeners to regenerate at night when water use in the facility is low.

Instrumentation - A water softener requires a control system to change the positions of valves for regeneration. The control system can work off a meter that measures the flow, a mechanical clock timer or electronic controls. As is always the case with electronics, either a battery backup should be supplied or the electronics will reset themselves after a power failure. This type of problem is common in many facilities and a facility manager can expect to find electronic controls on the water softener if he continues to receive a water problem call right after a power bump in his facility. Some softeners have only mechanical control that uses turbine meters and water pressure to control the cycles of the systems. These mechanical-only softeners do not require any electrical power with the inherent cost advantage of zero electric costs. However, most water softeners are located inside, and with the lights, it is a simple matter to provide power for the water softener control system.

Newer softeners use a hardness-monitoring probe inserted into

< previous page |

page_162 |

next page > |

< previous page |

page_163 |

next page > |

|

|

Page 163 |

1.Is the water hard? |

|

|

2.How hard is the water? |

grains per gallon |

|

3.What are the advantages of softening it that are desired?

Cost savings in soap reduction

Soft clothing and other washed items

Cosmetic enhancement of clean skin and hair

4.What size of a unit do I need based on flows and use?

5.Is there room for it in the present facility?

6.Does the room have the necessary drains, power and water supplies for this project?

Figure 10-2.

Questions for determining the feasibility of water softening.

the water pipe just downstream from the softener. The probe constantly reads the hardness and, when the resin bed is exhausted and needs regeneration, the probe signals the start of a regeneration cycle. The probe can be sequenced with a clock that trips a switch that will not start the regeneration cycle until late the next night when the plant is not operating.

Maintenance Considerations - Facility management of water softeners consists of performing routine service on the equipment. Logs or records should indicate the staff is checking the softener daily and using a test kit to verify the readings of the hardness of both the incoming water and the softened water. The logs should also indicate when raw salt was added to the brine tank. Knowing the volume of water used and the volume from the brine tank for a regeneration cycle, it should be fairly easy to predict the time when salts are required to be added.

A facility manager should also be careful about scheduling maintenance of water softeners during certain high operating hours. The wrong settings and valve positions can lead to brine contamination in the building's water piping. This problem requires flushing of all

< previous page |

page_163 |

next page > |

< previous page |

page_164 |

next page > |

Page 164

the lines in the building by the staff and the embarrassment of having to tell the staff not to drink the water until the lines have been flushed. Fortunately, the brine, while it may have an unpleasant taste, is not a serious health risk to most individuals.

Water softeners loose about three percent of the resin bed per year of operation. Old water softeners can have the resins checked by a water softener vendor to confirm the adequacy of the resins.

Support Utilities - For facility managers contemplating the addition of a water softener system, planning needs to take into account whether the softener must be enclosed within a building, which is a requirement in cold weather climates as the lines, valves and beds will freeze during winter. Warm weather facilities can locate the softeners outside provided the brine tank is kept covered to prevent contamination by dust and wind blown debris. Outside installations should have lighting for maintenance and power outlets that are electrically ground-fault-protected since much of the maintenance around water softeners is "wet"-type work.

Recent modifications to OSHA 1910 (Worker Safety Rules) will require confined space entry procedures be established for entering into tanks or vaults for maintenance. Chapter 14 provides a description of confined space entry procedures. Alternatives to sodium water softeners include use of other resins that exchange the calcium with non-sodium type materials or high pressure reverse osmosis units to filter out the calcium particles. Since reverse osmosis units do more than remove calcium ions, they are discussed separately later in this chapter.

Filters

Several types of filters are used to remove unwanted turbidity and particles. All filters use a media to capture the particles. Media types include sand, diatomaceous earth and fiber cartridge. Usually filtration is used in recirculating loops to remove unwanted items such as hair, sand, sticks, small stones and other particle matter.

Filters can be used as stand-alone items for particle removal only, or as a preliminary treatment step prior to more refined treatment. Filters are often used as a pretreatment step in chlorination or other water sterilization steps. In some utilities for small cities or towns, filtration and chlorination are all of the treatment provided for drinking water.

< previous page |

page_164 |

next page > |