water quality and system

.pdf

< previous page |

page_93 |

1.How old is the water heating system in the facility? |

Years |

2. Any complaints from occupants? |

|

Too hot |

No. of calls |

Too cold |

No. of calls |

3.An inspection of the water heater tanks and equipment reveals ... (check all that apply.)

Loose, fallen tank insulation

Red stains on pipe, insulation or floor

Wet and humid conditions in the room

Musty odors or conditions

Dry conditions |

|

4.Are the gauges and thermometers working properly? |

|

Yes |

No |

Pressure |

|

Temperature |

|

5.Are there any records or logbooks for the system? |

|

Yes |

No |

Last preventive maintenance inspection? |

|

Last check of the fuel burner or system by utility? |

|

6. Any previous studies? |

|

Yes |

No |

If ''yes," was there any action taken, and what were the results? |

|

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

Figure 6-1.

Hot water system assessment.

< previous page page_93

next page >

Page 93

next page >

< previous page |

page_94 |

next page > |

Page 94

that with a large tank heating slowly, there is plenty of hot water, but the tank and the room for the tank are expensive. If the water is not used, energy is wasted while keeping the water warm while waiting for demands.

The other problem with a tank system is keeping the water warm in a long run of pipe between the user and the tank. The user turns on the tap and hot water does not come out for several seconds while the water between the tank and the tap slowly recharges with hot water again. Here, hot water is wasted when it sits idle and cools. In addition, allowing the water to run wastes it as well.

At the other extreme, a device called a "tankless" heater is put at the end of the pipe. With this heater, the water is not heated until it is ready to be usedbut now, the fuel to heat the water has to be run to the heater. If the facility is large and spread out, multiple fuel lines and heaters have to be placed throughout the complex.

The decisions for hot water system tradeoffs requires professional judgment. The judgment is made initially when the facility is designed by somebody who uses codes and standards to determine which options will work best for the facility. In most areas of the United States, designers use the ASHRAE Handbook, which is published by the 100+-year-old American Society of Heating, Refrigerating and Air-Conditioning Engineers of Atlanta, GA.

Data from research and other published sources is used to determine how much hot water is needed for the items that require hot water use. A dishwasher, a shower, a hot meal, etc. are all typical examples of where hot water is used. Table 6-1 provides a guide for how much hot water is needed in various types of facilities, and Table 6-2 provides an estimate of domestic use for various hot water items like dishwashers. Since the temperature for use varies with device, typical temperatures are also recommended by ASHRAE. The temperatures presented in Table 6-3 provide the facility manager with guidance for design temperatures.

Another area of tradeoffs that require judgment is in the choice of fuels for heating the water. As with the choice of large or small storage, decisions are made whether fuel or electricity will be used for heat. If fuel is used, which fuel? Natural gas, LPG and fuel oil are common. Finally, solar energy can also be used.

Choice of fuels is an energy question. Facility managers should be aware that hot water systems use little fuel relative to other energy uses in a facility. As little as 6-7 percent of the facility manager's budget for energy consumption could be expended for hot water heating for domestic use.

< previous page |

page_94 |

next page > |

< previous page |

page_95 |

Table 6-1. Probable hot water demand for various facilities. Source: American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), ASHRAE Handbook, 1991.

On an hourly and daily basis, normal use

Type of building |

Maximum hour |

Maximum day |

Average day |

Men's dormitories |

3.8 gal |

22.0 gal |

13.1 gal |

|

(14.4L)/student |

(83.4L)/student |

(49.7L)/student |

Women's dormitories |

5.0 gal |

26.5 gal |

12.3 gal |

|

(19L)/student |

(100.4L)/student |

(46.6L)/student |

Office buildings |

0.4 gal |

2.0 gal |

1.0 gal |

|

(1.5L)/person |

(7.6L)/person |

(3.8L)/person |

Food service establishments: |

|

|

|

Type Afull-meal restaurants |

1.5 gal (5.7 L)/max.11.0 gal |

2.4 gal (9.1 L)/avg. |

|

and cafeterias |

meals/h |

(41.7L)/max. meals/hmeals/day* |

|

Type Bdrive-ins, grilles, |

0.7 gal (2.6 L)/max.6.0 gal (22.7L)/max. |

0.7 gal (2.6 L)/avg. |

|

luncheonettes, sandwich and |

meals/h |

meals/h |

meals/day* |

snack shops |

|

|

|

Apartment houses: no. of |

|

|

|

apartments |

|

|

|

20 or less |

12.0 gal |

80.0 gal |

42.0 gal |

|

(45.5L)/apt. |

(303,2L)/apt. |

(159.2L)/apt. |

50 |

10.0 gal |

73.0 gal |

40.0 gal |

|

(37.9L)/apt. |

(276.7L)/apt. |

(151.6L)/apt. |

75 |

8.5 gal (32.2 L)/apt.66.0 gal (250 L)/apt. |

38.0 gal (144 L)/apt. |

|

100 |

7.0 gal (26.5 L)/apt.60.0 gal |

37.0 gal |

|

|

|

(227.4L)/apt. |

(140.2L)/apt. |

200 or more |

5.0 gal (19 L)/apt. |

50.0 gal (195 L)/apt. |

35.0 gal |

|

|

|

(132.7L)/apt. |

Elementary schools |

0.6 gal |

1.5 gal (5.7L)/student0.6 gal |

|

|

(2.3L)/student |

|

(2.3L)/student* |

Junior and senior high schools 1.0 gal |

3.6 gal |

1.8 gal |

|

|

(3.8L)/student |

(13.6L)/student |

(6.8L)/student* |

*Per day of operation. |

|

|

|

< previous page page_95

next page >

Page 95

next page >

< previous page |

page_96 |

Table 6-2. Approximate requirements of hot water for various fixtures and devices. Source: American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE),

ASHRAE Handbook, 1991.

Demand is given in terms of gallons (liters) per hour per fixture, calculated at a final temperature of 140°F (60°C).

Fixture |

Apartment house |

Hotel |

Office |

Private |

School |

|||||

|

|

building |

residence |

|||||||

Basins, private lavatory |

2 (7.6) |

2 (7.6) |

2 (7.6) |

2 (7.6) |

2 (7.6) |

|||||

Basins, public lavatory |

4 (15) |

8 (30) |

6 (23) |

|

|

15 |

(57) |

|||

Bathtubs |

20 |

(76) |

20 |

(76) |

|

|

20 |

(76) |

|

|

Dishwashers* |

15 |

(57) |

50-200 |

|

|

15 |

(57) |

20 |

(100) |

|

Kitchen sink |

10 |

(38) |

30 |

(114)20 |

(76) |

10 |

(38) |

20 |

(76) |

|

Laundry, stationary tubs 20 |

(76) |

28 |

(106) |

|

|

20 |

(76) |

|

|

|

Pantry sink |

5 (19) |

10 |

(38) |

10 |

(38) |

5 (19) |

10 |

(38) |

||

Showers |

30 |

(114) |

75 |

(284)30 |

(114) |

30 |

(114) |

225 (850) |

||

Service sink |

20 |

(76) |

30 |

(114)20 |

(76) |

15 |

(57) |

20 |

(76) |

|

Circular wash sinks |

|

|

20 |

(76) |

20 |

(76) |

|

|

30 |

(114) |

Semicircular wash sinks |

|

|

10 |

(35} |

10 |

(38) |

|

|

15 |

(57) |

Demand factor |

0.30 |

0.25 |

0.30 |

0.30 |

0.40 |

|||||

Storage capacity |

1.25 |

0.80 |

2.00 |

0.70 |

1.00 |

|||||

factor** |

|

|

|

|

|

|

|

|

|

|

*Dishwasher requirements should be taken from this table or from manufacturer's data [or the model to be used, If this is known.

**Ratio of storage tank capacity to probable maximum demand per hour. Storage capacity may be reduced where an unlimited supply of steam is available.

< previous page |

page_96 |

next page >

Page 96

next page >

< previous page page_97

Table 6-3. Representative hot water temperatures. Source: American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), ASHRAE Handbook, 1991.

|

Minimum temperature |

|

Use |

°F |

°C |

Lavatory |

|

|

Hand washing |

105 |

40 |

Shaving |

115 |

45 |

Showers and tubs |

110 |

43 |

Commercial and institutional laundry |

180 |

82 |

Residential dishwashing and laundry |

140 |

60 |

Commercial spray-type dishwashing as |

|

|

required by National Sanitation Foundation |

|

|

Single or multiple tank hood or rack type |

|

|

Wash |

150 min |

65 rain |

Final rinse |

180 to 195 |

82 to 90 |

Single-tank conveyor type |

|

|

Wash |

160 min |

71 rain |

Final rinse |

180 to 195 |

82 to 90 |

Single-tank rack or door type |

|

|

Single-temperature wash and rinse |

165 rain |

74 min |

Chemical sanitizing glasswasher |

|

|

Wash |

140 |

60 |

Rinse |

75 rain |

24 min |

< previous page page_97

next page >

Page 97

next page >

< previous page |

page_98 |

next page > |

Page 98

Finally, the facility is subject to some public code requirements if direct flame is used for heating the water. The codes require adequate amounts of fresh air for the flame and for a path of exhaust for the products of combustion in order to protect the building's occupants from carbon monoxide poisoning and fire.

The facility manager must keep these factors in mind while determining the best way to upgrade a hot water system. The facility manager must decide which resources to utilize in conducting the evaluation.

System Sizing and Design

Storage, variations of storage and recirculation and instantaneous supply are the three main methods of providing hot water. Each is discussed in the following paragraphs in order to inform the facility manager of the factors that must be considered in the system design.

Storage

The advantage of storing domestic hot water is that it provides an excellent combination of even temperatures and sufficient volume to respond to sudden peak demands.

With a storage system, the water is heated over a steady period of time and as demands are made on the supply, cold water flows into the tank to replace it. A general rule of thumb for tank sizing is that of the total tank capacity, only about 70 percent is usable before the incoming cold water drops the temperature significantly. For a storage system, ASHRAE provides guidance for sizing hot water tanks in typical facilities.

The facility manager typically delegates the authority to the designer to decide which sets of curves and standards to recommend. A typical design for a hot water system would be a bath/ change house in a factory.

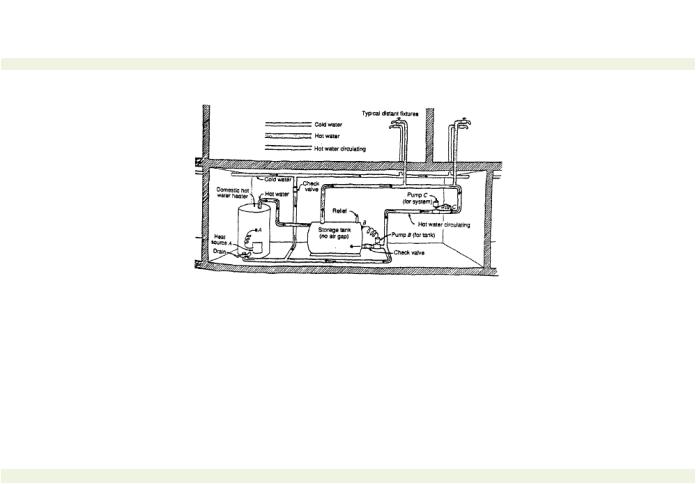

Recirculation

To eliminate waiting while the hot water recharges the lines between the storage tank and the tap, large facilities install a recirculation loop from the end of the supply line back to the hot water storage tank. This keeps the lines between the tank and the tap charged with hot water at all times. The disadvantage to this option is additional costs to run the return pipe back to the tank. In many

< previous page |

page_98 |

next page > |

< previous page |

page_99 |

next page > |

Page 99

Figure 6-2.

Recirculation hot water system. Courtesy: Stein And Reynolds, Mechanical

And Electrical Equipment for Buildings, 8th Edition. ©1992, John Wiley & Sons, Inc.

systems, this scenario requires an additional pump to push the hot water around the loop. The pump, of course, has to have electricity, which requires additional wiring. A recirculation hot water system is shown in Figure 6-2.

Instantaneous "Tankless" Heaters

The facility manager has the option to select an alternative method other than storage. The most commonly presented alternative is called instantaneous point-of-use heating. Here, the heat needed to increase the water temperature is added to the water immediately before it reaches the tap. Under this option, the hot water is available on demand when called for at the tap and little energy is wasted in heating water supplies that are not used. Disadvantages to this type of system are in providing an energy source to heat the water at the point of use. Either electricity or fuel must be supplied to wherever the heater is located. If fuel is supplied, fresh air and an exhaust vent must be provided as well. If electricity is the source, additional wires and outlets may be needed if the unit requires more than the traditional electrical outlet.

To get the energy into the water quickly, some of these tankless

< previous page |

page_99 |

next page > |

< previous page |

page_100 |

next page > |

Page 100

heaters divide the flow into very fine streams, akin to the radiator of an automobile. By dividing the flow to make it easy to get the heat into the water, energy is required to push the water through the fine tube finsso much so that installation of a tankless heater can restrict the total flow to the user.

Heat

Anywhere there is heat in a facility, hot water can be produced. If the plant is making steam or hot water for building heat, a portion of this heat can be used to heat domestic hot water if there is enough excess capacity in the heating equipment.

Heat, in the form of electricity, can be brought to the hot water tank or to the tankless heaters, provided there is enough power in the electrical system.

Fuel can be provided to where the water is going to be heated. Fuel can be anything that burns. See Table 6-5 for a list of the heating values in most common fuels. For most facilities the fuel selected will be a fuel commonly used in that area. Either fuel oils, natural gas, or liquefied petroleum gas (LPG) can be brought to where the water is to be heated. If fuels are to be burned inside a building, then fire and ventilation codes apply to the rooms or portion of the building where the heating equipment is installed. Normally, the costs of fuels for heating are much less than electrical energy costs, and it is economical to provide the necessary clearances, ventilation, fire protection and air quality permits in order to burn fuels instead of heating with electricitybut this decision is subject economic evaluation (see Chapter 12).

Finally, energy from the sun can be used to provide hot water as in a solar hot water heating system if there is enough space at the facility for placing the solar collectors and if there is enough direct sunlight.

One of the major advantages of electrical or fuel-type supplies is the heat is available on demand. In the case of heat recovery or solar energy, the heat is available when the heat is on or when the sun is shining, respectively. Many facilities who heat domestic water with the same boilers that provide winter heat find they do not have hot water in the summer when the heating boilers have to be

< previous page |

page_100 |

next page > |

< previous page |

page_101 |

next page > |

Page 101

shut down for maintenance. Most facilities get around this problem by providing backup boilers. When one is running, the other is idle. If the first breaks down, the second one starts up to provide the necessary heat.

Piping

After the water is heated, there remains the problem of getting it to where the users want it. The same principles for plumbing cold water apply to hot water.

Friction losses, the loss of pressure with distance and water hammer are exactly the same for hot and cold water systems. Hot water must have enough pressure to arrive at the tap in sufficient flow to meet the user needs. If the flow is restricted, the temperature of the water can be raised, giving the same resultsbut again, if the hot water alone is too hot, users can scald themselves. The facility manager has a responsibility to keep the temperatures under control.

Table 6-4. How energy of fuels is figured to heat water. Energy for heating water in the English system of units is measured in British Thermal Units (BTU). A BTU is the amount of energy required to heat one pound of water one degree Fahrenheit.

Therefore, if one pound of water is 40 degrees and we want to heat it to 140 degrees, it would take 100 BTUs to do it. Fuels are rated by the number of BTUs that are released when heated. So when a fuel burns, the heat released is known.

The science of studying fuels and heat released is called combustion engineering. It requires a lot of chemistry and math to work out the details because it boils down to figuring out how much released is released at the molecular level.

Fuel |

Heat Content |

|

Propane |

90,000 |

BTU per gallon |

Natural Gas |

1,000 BTU per cubic ft. |

|

Wood |

8,800 BTU per pound dry, 7,000 BTU/lb. at 20% moisture content |

|

Fuel Oil |

19,000 |

BTU per pound, or 142,500 BTU per gallon |

Coal |

10,000 |

BTU per pound (average) |

Kerosene |

19,810 |

BTU per pound, or 135,000 BTU per gallon |

< previous page page_101 next page >

< previous page |

page_102 |

next page > |

Page 102

After the correct volume of the right temperature water has been generated, it still has to be delivered to the tap at the right pressures and flows. For small facilities and for domestic use, the incoming cold water provides enough natural pressure to force the hot water from the tank, through the pipes and to the users. However, there is often less pressure in the hot water system, the result of losses in the pipes and tanks.

For a simple experiment, turn the cold water on full at a residence. Now turn the cold water off and turn the hot water on full. The slower release of hot water is the result of pressure lost in the hot water supply.

Pumps are added to the hot water system to make the pressures more equal. When taps are turned on, the pumps sense reduced pressure in the tank and boost the hot water supply.

Mostly for ease of installation hot water is piped with the same type of pipe and the same diameter as the cold water. This is a practical solution since engineering calculations will yield a larger pipe size for the hot water to make up for the additional losses. However, when installing the pipe, if one is a different size from the other, the plumber's efforts increase significantly since he must plumb different pipe for the two lines.

Hot water pipe is usually copper because it has been shown to be cost effective, easy to install, and most generally meets the system needs. Copper hot water pipe is sufficient up to and including the 3-inch size. Above this diameter, there are problems with fitting the joints together because typical field torch used to heat the joint is not big enough to provide uniform temperature throughout the entire fitting. For hot water piping above 3 inches in diameter, steel pipe is usually used. However, hot water piping that requires pipe in excess of 3-inch diameter would be rare and re-evaluation would be recommended.

Because hot water piping temperatures range between 105°F and 180°F, other types of pipes are not generally recommended. Plastic pipe can meet the requirement, but plastic tends to soften when warmed unless special resins are used which make the plastic hot water pipe more expensive than copper pipe.

Galvanized pipe (pipe coated with zinc) is not recommended for hot water systems because a chemical reaction takes place between the zinc and water at elevated temperatures.

Hot water pumps have internal workings resistant to hot water and are usually bronze or brass.

< previous page |

page_102 |

next page > |