water quality and system

.pdf

< previous page |

page_175 |

next page > |

Page 175

< previous page |

page_175 |

next page > |

< previous page |

page_176 |

next page > |

Page 176

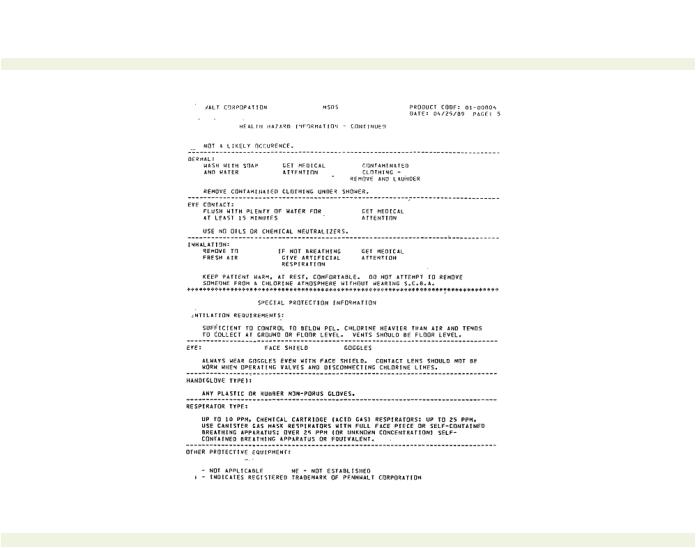

Figure 10-5 (continued).

< previous page page_176 next page >

< previous page |

page_177 |

next page > |

Page 177

Figure 10-6.

Simple chlorine leak contingency procedure.

where they are used should be well-ventilated, and personal protective equipmentincluding safety goggles, gloves and other equip-ment-must be made available for the facility staff.

UV Light Purifiers. As an alternative to chemical treatment to purify water with gas, ultraviolet (UV) light can be used. Water is passed through a clear plastic tube where ultraviolet bulbs have been placed shining the UV light through the clear wall and into the water. The UV light kills microorganisms. Unfortunately, UV light requires electrical power, presenting another operating cost component, while the other systems do not. Other drawbacks to UV light water purifiers include turbidity. If the fluid is not clear, the UV light will not pass all the way through and sterilize the whole stream. Another drawback is that the UV light does not work beyond the clear plastic section. Note that another advantage of chlorine and ozone injection over UV light is that there is some residual treatment that carries over into the downstream piping.

Reverse Osmosis Units

Similar in size, shape and style to the cartridge filter unit, a reverse osmosis unit can also be used to purify water. Reverse

< previous page |

page_177 |

next page > |

< previous page |

page_178 |

next page > |

Page 178

osmosis works differently from chemical or ultraviolet protection.

The heart of a reverse osmosis (RO) unit is a cartridge/membrane that has very fine pores. The RO unit is sized to pass pure water and to prevent other molecules such as salts, carbonates, microorganisms and similar big objects from passing through the membrane. If there is not enough water pressure naturally in the system to force the water through the reverse osmosis membrane, a powerful pump is required to give the water enough energy to go through the reverse osmosis unit.

Problems associated with RO units include the high energy costs to force the water through the membrane and the waste water stream necessary to strip the membranes. Because RO units are, in effect, an extremely fine filter, a lot of water is lost when backwashing the membrane to remove the filtered materials. Lastly, the membranes can sometimes become ineffective. Water operators call this ''poisoning" the membrane. That is, the membranes pores become clogged with material and cannot be cleared, causing increased energy costs. Sometime the membrane itself becomes contaminated with microorganisms and adds, rather than removes, live bacteria.

RO units will remove water hardness, rather than letting it be replaced with sodium, so for occupants concerned about low sodium diets, an RO unit will soften the water as well. Usually to protect the RO unit membrane, one of the other filter types is installed upstream. Some living microorganisms can get through the RO unit filter. Most notably, this includes viruses.

Deionizers

Another method of treatment of specialty water is a deionizersometimes called a demineralizer.

A deionizer looks similar to a twin-bed water softener, and it works on much the same principles. Like a water softener, a deionizer uses resins through which water flows and the resins exchange or remove the ions from the stream. When the ions in the supply water are removed the water has been deionized, hence the name. There are two basic types of deionizers, named for the types of resins used.

The first type is usually two vessels with separate types of resins. The two types are cation and anion resins. The first resin vessel removes the positively charged ions (the anions) and the second removes the negatively charged ions (the cations.)

The other type of deionizer is a mixed-bed deionizer that has

< previous page |

page_178 |

next page > |

< previous page |

page_179 |

next page > |

Page 179

MSDS And The Worker's Right To Know Law

The Worker's Right to Know Law (OSHA 1910) provides that employers and managers have the obligation to make sure that workers know what chemicals are used and what the dangers to workers potentially may be. In addition, workers are to be provided with access to this information and necessary personal protective equipment must be provided to the workers around chemicals that are potentially hazardous.

Reading MSDS and for deciding what personal protective equipment is necessary is usually the role of the safety department but facility managers should know that the real professional in this area is the certified industrial hygienist, Industrial hygienists are trained in exposure limits, time-weighted averages, personal protective equipment and other worker safety-related interpretations.

The MSDS, provided usually by the manufacturer, provides a method of determining the hazards and risks of the chemicals. The MSDS lists the names of the chemical, the hazards of the chemical (whether corrosive, toxic, flammable or physical), the exposure levels and the recommended personal protective equipment.

Unfortunately, MSDS have become a type of legal document, protecting the manufacturer from all types of liability. As such, they are becoming increasingly difficult to read and trying to grab an MSDS in a contingency drill or real emergency and read and respond in a timely fashion is difficult at best. The MSDS is best used for training and reference. Most plants prepare several thick 3-ring notebooks that contain all of the MSDS for the site and post them in conspicuous places throughout the plant where workers can access and refer to the specific chemical being used. It is not recommended the book be posted where the public can access it, however, since portions of it may disappear over time (unless posted in an inaccessible place, such as a glass-covered cabinet holding a bulletin board). Supervisors and managers should make sure the MSDS are posted and be familiar with the contents.

both the cation and anion resins mixed in one vessel. The mixed-bed unit is smaller and is even used to polish water from the single-bed deionizer. As with all deionizers, the water should be run through a reverse osmosis unit before being sent to the deionizer to protect the life of the resin bed.

Deionized water is used in laboratories and in making sterile medical devices. It is also used in manufacturing computer/silicon/

< previous page |

page_179 |

next page > |

< previous page |

page_180 |

next page > |

Page 180

wafer chips. This is because the presence of ions in the rinse water can ruin the results of months of laboratory work or years of silicon chip manufacturing.

Since deionized water has had all of the ions removed, the water becomes a very poor conductor of electricity. This inability to act as a conductor, when water is usually a good conductor, is the method by which deionizers are specified and by which operations personnel can verify the unit is working properly.

As with all previous discussions on instrumentation and operating records, data should be collected on a routine basis. The records should include instrument readings from the unit. And the instruments on the unit should be checked regularly to verify they are reading properly.

The test for deionization is performed by measuring the resistance to electricity passing through the water. The industry has even gone so far as to coin a phrase for deionized water quality readings. The micrmho (pronounced "mike-row-mow") is the inverse of reading of the ohm measuring the resistance. Good deionized water is any water reading better than 15 micromhos.

While regeneration of water softeners is performed with brines, regeneration of twin-bed and mixed-bed deionizers is accomplished using strong acids and bases. For the base, the regeneration fluid is usually 18 percent sodium hydroxide (NaOH), which has a pH of 14, while for the acid resins, regeneration liquid can either be hydrochloric (HCL) or sulfuric acid (H2SO4). The acids have a pH of 1. Needless to say, these strong acids and bases are hazardous chemicals and workers servicing these units need to be carefully trained to handle the chemicals and to respond to the spills should they occur.

The facility manager should be careful to make sure the area around the base of a demineralizer/deionizer is diked to prevent any spills of strong acids or bases from washing into the sanitary sewer. The strong chemicals will kill the microbes at the sewage treatment plant, and there are severe penalties for allowing this kind of hazardous waste to be released into the environment.

Maintenance Considerations - The physical size of a deionizer or demineralizer will vary with. the flows required. Depending upon the application, a demineralizer could be larger than the water softener for the same flow. In general, a demineralizer will be fairly small and could even be small enough fit on a desktop or similar-sized area. As with most of the other water quality enhancers and

< previous page |

page_180 |

next page > |

< previous page |

page_181 |

next page > |

Page 181

treatment units, a deionizer should be indoors toprotect the equipment from inclement weather effects and to allow maintenance personnel to work on the units if necessary during periods of winter weather and snow and ice conditions. Drains for washdown should be providedalthough for a deionizer, the drain should be protected just in case there is an acid or a base spill. Lighting and electrical power should be available on ground-fault- protected circuits. Operations logs and records should be maintained and recorded.

Stills

A still remains, today, one of the most effective water purifiers for removing both organic, inorganics and microorganisms. In a still, water is heated until it vaporizes, and the resulting steam is collected on the walls of a condensing vessel or in collection coils downstream, where it is cooled and condenses back into water.

Under this method of treatment, the undesirable components are either left behind or cook off early and do not condense back into the water because of a different volatility. Organics such as pesticides remain a gas and require cooling to a lower temperature than water so the materials that cook off do not condense back into the stock.

The disadvantages of a still are its high energy costs associated with vaporizing the water either with electrical energy or by burning hydrocarbons (coal, oil, gas, wood). These high energy costs limit the use of stills to very specified uses. Some laboratories utilize a still for making pure, reagent grade water for research.

Stills have to be dismantled and cleaned periodically but maintenance and repair costs with still-type units are relatively low. More maintenance time is spent on the burners, fuel, or electrical supply than on cleaning the still.

The hazard of operating a still is with the heat since steam and the materials associated with a still get very hot and the possibility of injury exists from maintenance personnel working on the still before it has completely cooled and getting burned.

Use of home-made stills and other non-engineered equipment has also resulted in injury when the pressure from steam that results from boiling water exceeds the strength of the vessel. The vessel ruptures and the hot water spills and sprays violently. As a protective device stills have temperature and pressure controls similar to hot water systems.

Personal protective equipment when working around a still includes leather gloves, goggles, aprons and a face shield.

< previous page |

page_181 |

next page > |

< previous page |

page_182 |

next page > |

Page 182

Instrumentation for stills includes temperature gauges and pressure gauges since we need to know if boiling rates and condensation rates are being maintained. Elevation is also an important consideration in still operation since water boils and condenses at different temperatures depending upon the elevation. Cooling is usually accomplished with water being fed into the stillthis way, the incoming water is being preheated by the steam gases before flowing into the still to be vaporized.

Water Coolers

Principally used for drinking, a facility will install a water cooler, usually near the restroom because the plumbing is close to the outside wall at that point. Water coolers are usually wall-mounted and are plumbed in with a supply of cold water. The cooler uses a refrigeration unit to cool the water as it comes in and distributes it up through a fountain. A drain line is provided from the water cooler to the sewer system. Little effort is required to maintain a water cooler but they should be routinely checked to make sure their electrical connections are sound. Ice makers function in a similar way to water coolers and require the same utilities.

< previous page |

page_182 |

next page > |

< previous page |

page_183 |

next page > |

Page 183

Chapter 11

Putting It All Together: Applications

This is where we get to the "nitty gritty" of water system management, by individual application. Recognizing that a well-designed system is less costly to operate and maintain, and armed with the proper knowledge, the facility manager and his team are ready to examine the facility's waterusing areas on an existing floor plan or blueprint of a future facilityand begin making quality and cost enhancements.

Combining Systems

Now that the facility manager is more conscious of the many individual elements that make up his water system, he is ready to begin combining some elements into performing the central focus of facility managersproviding for the interface of where people and water systems interact.

Initially, the discussion will be for bathrooms and restrooms since this is one of the more common areas of interface that a facility manager must manage. Following the discussion on bathroom/ restroom facilities are similar discussions for kitchens, mechanical rooms, swimming and bathing facilities, fountains and spas, clinics and laboratories.

Lavatories

Almost every facility has some type of restroom, whether it be a small one-person unit or a large facility for a ballpark, sports arena, church or office complex. The restroom is going to have water

< previous page |

page_183 |

next page > |

< previous page |

page_184 |

next page > |

|

|

|

|

Page 184 |

Codes And Standards For Various Facilities |

|

|

|

Hospitals |

Joint Committee for The Accreditation of Hospitals |

|

|

Swimming Pools National Swimming Pool And Spa Institute |

|

|

|

Medical Clinics |

American Medical Association |

|

|

Kitchens |

American Institute of Architects |

|

|

Restrooms |

American Institute of Architects, National Sanitation Foundation |

|

|

closets and sinks. In addition, the men's room will have urinals.

The layout of the restroom is largely a matter of design with many human factors incorporated. Some of these factors are driven by the fixtures, some by the plumbing, and still others by less tangible factors.

Table 11-1 shows the approximate number of plumbing fixtures needed based upon the estimated number of facility users for office and public buildings. Each fixture requires enough water supply to operate correctly.

Water Closets And Urinals - The water closets and urinals can have tank flush or flush valves. In general, the tank type has problems in a public facility and are not recommended. For users, the seat should be smooth and comfortable and made from plastic or other nonporous material that will warm quickly. Metal seats, obviously, are not practical.

As discussed in Chapter 3, water closets can be either wallor floor-mounted. If feasible, the water closets should be wall-mounted which aids in cleaning the bath facility by cleaning personnel.

Each water closet in a public restroom is enclosed by wall panels and a simple lock is fixed to the door. Inside, there should be a hook for a jacket, usually affixed to the inside of the door but not necessaryand, of course, hangers for toilet paper, usually two.

The number of people at the facility determines both the number of water closets or urinals and the number of sinks. Codes require a minimum number of sinks for people to wash their hands

< previous page |

page_184 |

next page > |