water quality and system

.pdf

< previous page |

page_165 |

next page > |

Page 165

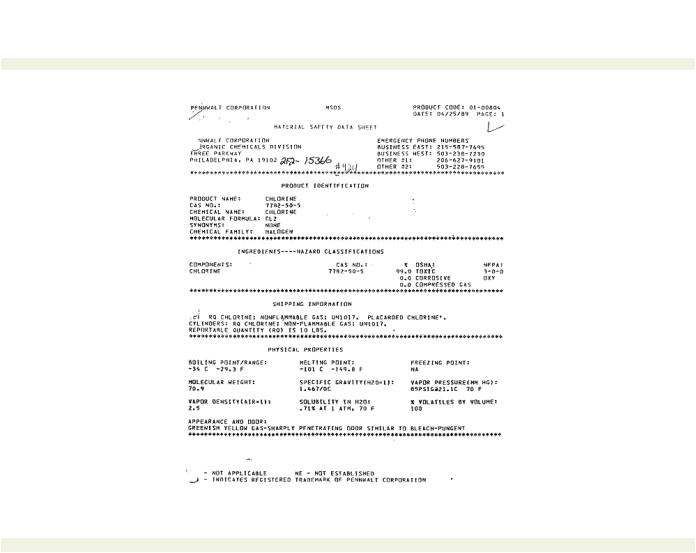

Figure 10-3.

A rapid sand filter for a large swimming pool.

Sand Filters - In the rapid sand filter, sand and gravel are used as the filter medium. Figure 10-3 shows a rapid sand filter for a large swimming pool. Water flows down through the sand and gravel and the unwanted particles are captured on the sand particles. Periodically, the sand is backwashed, stirring up the bed and carrying away the materials that have been filtered out.

Rapid sand filters are limited to a fixed amount of flow per cubic foot of sand and a flow rate (speed) through the sand. Sand particle sizes are clearly defined in the beds of the filter. Usually, the fine sand is fixed on top of the large grained sand.

Like the water softeners, the sand and gravel beds are inside a pressurized tank.

Maintenance considerations for rapid sand filters are similar to considerations for softeners. Occasionally the sand bed has to be repacked with a necessary entry into the tank with bags of sand. A storm or sanitary drain is needed near the filter to allow the crews to drain the tanks. In cold climates, the filter should be enclosed and heating and lighting provided. Lastly, the electrical circuits should be protected with ground fault interrupter breakers to reduce the chances of electrical shock to maintenance personnel.

< previous page |

page_165 |

next page > |

< previous page |

page_166 |

next page > |

Page 166

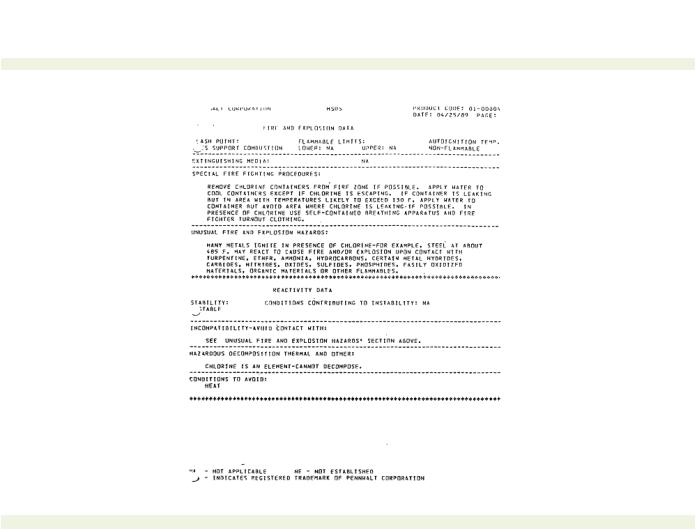

Diatomaceious Earth Filters - Similar to sand filters, a diatomaceous earth filter performs the same function and operates similarly. The advantage of diatomaceous earth is that overall size of the filter is usually smaller than a sand filter for the same flow of water. Diatomaceous earth is a very fine material, similar to clay or flour in consistency. Because of the fine particles, a greater flow per unit area or thickness is calculated compared with the sand. Diatomaceous earth filters are more difficult to operate than sand and are often used in areas of the country where sand is not abundant. Valves and backwashing is similar to sand filters. Figure 10-4 shows a diatomaceous earth filter for a small heated spa.

As with softeners and sand filters, maintenance and operations of diatomaceous earth filters require an enclosed facility in cold climates. However, as a result of the smaller size of the components for diatomaceous earth filters, the corresponding facility size can be smaller as well. Again, drains, heat and lighting are necessary and electrical outlets should be protected.

Both sand and diatomaceous earth filters require a large drain pipe for backwashing. The flow of the backwashing process should be known before installing the drain piping for the systemother-wise, backwashing can cause flooding of the room or equipment where it installed until the drain line can catch up with the backwash cycle.

Cartridge Filters - Small pools, tubs, and other systems use cartridge-type filters. The cartridge filter uses a fiber (usually paper) to filter out unwanted particles. The fiber cartridge is housed in a metal or plastic cylinder. Note that some local codes require that the filter housing cylinder be made from stainless steel. This has been thought to keep the water sterilized better than the plastic housing. The paper cartridge is chosen based upon the number of square feet per gallon-per-minute of flow.

Regarding maintenance, the paper cartridges can be removed and changed, but while the cartridge is changed, the water supply system has to either bypass the filter or the system has to be shut down. The cartridge can then be rinsed, washed down or replaced.

If the paper in the cartridge is torn, it will have to be replaced since unfiltered water will go through the hole at the tear. In terms of size, cartridge filters compare with diatomaceous earth filters.

As with the other filters, the facilities should provide for heat and light for maintenance during cold weather climates. Electrical equipment, if used, should be ground-fault-protected.

< previous page |

page_166 |

next page > |

< previous page |

page_167 |

next page > |

Page 167

Filter Instruments - Most filters do not require the use of electronic instruments. Sand and Diatomaceous Earth Filters can be backwashed to flush out contaminants either manually by an operator or automatically on a clock timer. The clock and valve control mechanisms can be operated mechanically where electricity is not available, but since most modern installations are located near a power source, manufacturers have gone forward with electronic instruments for most installations.

Figure 10-4.

A diatomaceous earth filter used for a small heated spa.

Filter efficiency is measured with the use of a differential pressure gauge. The gage is set up to read the pressure in the water lines upstream and downstream of the filtration equipment. As the filter becomes plugged and fouled with debris to be filtered, the pressure needed to push the water increases.

Most filters are designed to operate with about a 1-2 pounds per square inch (psi) drop across the filter and to backwash or be cleaned when the pressure difference increases to 5-7 psi.

Facility managers should know that a plugged filter can severely lower downstream system pressures. If the downstream pressure gets too low, air can get into the piping creating flow and contamination problems. In addition, filters specified with a high pressure drop can lead to increased energy costs from pumping, making the filter a cost burden in facility operation.

Chlorinators

Facility managers do not get involved with chlorinators too often since most chlorination is performed by the utility. But on occasion, special chlorination is required. Chlorinators for facility managers are most often associated with pools, jacuzzi/hot tub baths or other public bathing facilities. When chlorinators are used in conjunction with filters, the filters work on the flows first, then the chlorinators add the chlorine.

< previous page |

page_167 |

next page > |

< previous page |

page_168 |

next page > |

Page 168

A chlorinator will inject free chlorine into the water, with various benefits (see Chapter 8). Chlorination systems consist of bottles of chlorine gas, under pressure, that gently vent the gas into water supplies downstream from pump discharges. The chlorine gas reacts with free hydrogen radicals to make hydrochloric acid (HCL).

The free chlorine and the hydrochloric acid in the water kills living microorganisms and purifies the water supplies. Most chlorinators use a needle valve in the lines from the chlorine bottle to regulate the flow of the chlorine into the supply. The pump curve (see Chapter 3) is used to estimate the flow, and the needle valve injects an amount approximately equivalent to 0.8 milligrams per liter into the water. At this low level, the amount of hydrochloric acid is extremely small so that it is diluted by a large amount of water and the risks of too much chlorine are low.

However, the chlorine does form an acid and acid is corrosive. If the mixing is not done properly, therefore, too much or too little chlorine gets into the water. Too much, of course, will make the water acidic, while too little will not kill the microorganisms.

One of the reasons chlorine has been the standard for the past 100 years is that the window between where the chlorine is successfully purifying the water to where it is potentially harmful to the piping and to humans is relatively large compared to the use of other chemicals.

Other methods of chlorination used for small pools consist of the use of tablets containing chloramine. With this type, the chlorinator is a cylinder or tank filled with these tablets, and water flows through the tablets into the main water stream. This type of system reduces the amount of chlorine gas and it is easier to operate. However, the operator costs to fill the vessel with tablets and the cost of tablets compared to the cost of chlorine gas is expensive. Many swimming pools use tablets instead of free gas because the training level required for the operators is lower.

Chlorine Gas Management - The decision to use bottled chlorine gas should be based upon economics. Chlorine gas is a poison but many utilities use and handle it often and have experience with this chemical. Chlorine gas bottles should always be chained up to prevent tipping over and only the bottle "on line" should be open. The others should be locked closed. No more chlorine than is necessary should be on site at any time.

Finally, if free chlorine gas is used at the facility, it should be stored under lock and key and the operators should be trained in

< previous page |

page_168 |

next page > |

< previous page |

page_169 |

next page > |

Page 169

rescue techniques and to recognize a leak if one occurs. And the facility manager should make sure that he has records that training, quantity control and tests (with results recorded) have been conducted. (See Chapter 7 for more information on OSHA rules and Chapter 14 for more information about maintenance.)

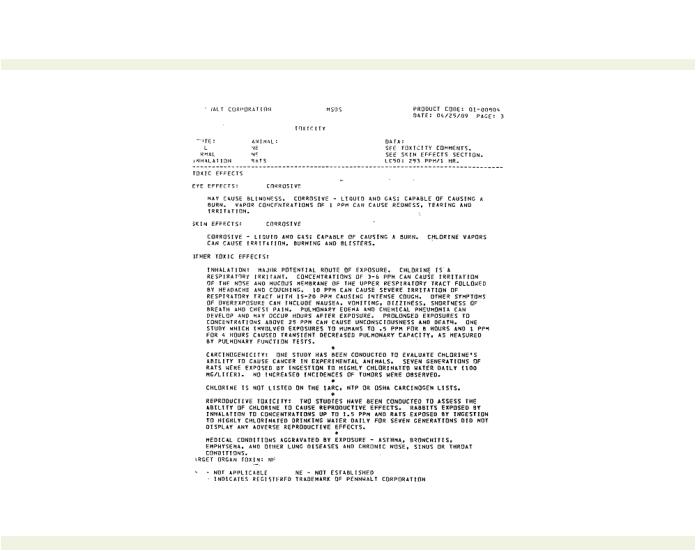

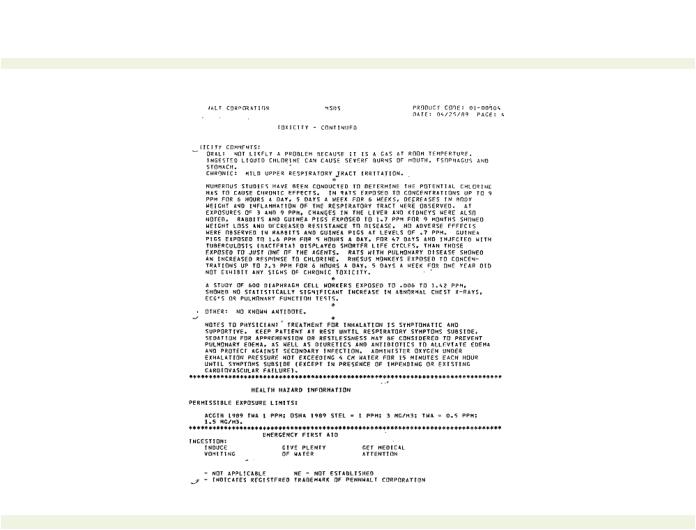

Chlorinator Maintenance - Facility managers should make sure that the staff has been trained in the safe operation and maintenance of chlorination equipment. Water tests should be taken and logged to provide a record of the adequacy of the water. In addition, if free chlorine is present at the facility, the managers should make sure that the Material Safety Data Sheets (MSDS) for chlorine are posted where they can be read by the staff.

Finally, because chlorine gas is poisonous, workers must be trained in safe rescue techniques and OSHA-approved Level A back-packs must be available for rescue. Facility managers should make sure that the staff has been trained to use the rescue equipment. It might not hurt to practice a drill periodically; it can be coordinated so that it does not interfere with business. Drills should not be conducted in front of clients or customers, unless of course, they want to see it. An MSDS for chlorine is shown in Figure 10-5. In addition, a simple contingency procedure has been provided for facility managers to see the simple, effective steps that can be taken in the event of a chlorine leak (see Figure 10-6).

Alternatives To Chlorinators - In the late 1980s, there was a movement in this country to stop the use of chlorine in water supplies because of some of these potential health risks. In addition, chlorine gas reacts with organic compounds in surface supplies to release tri-halomethanes (THM) which are suspected carcinogens. However, alternatives to chlorine have still not proven as effective for similar costs.

Several other types of water sterilizers are available that will be briefly mentioned here, including ozone and UV light purifiers.

Ozone. Ozone, like chlorine, can be injected into water supplies and performs the same functions. And like chlorine, ozone will make the water acidic, thereby killing the living microorganisms. Ozone is not as poisonous as chlorine, but still requires safe handling procedures similar to chlorine.

Maintenance of ozone systems requires staff training and records. Since both ozone and chlorine are reactive gases, the rooms

< previous page |

page_169 |

next page > |

< previous page

< previous page

page_170

Figure 10-5.

Material Safety Data Sheet for chlorine gas. Courtesy: Pennwalt Corporation.

page_170

next page >

Page 170

next page >

< previous page |

page_171 |

next page > |

Page 171

< previous page |

page_171 |

next page > |

< previous page |

page_172 |

next page > |

Page 172

Figure 10-5 (continued).

< previous page page_172 next page >

< previous page |

page_173 |

next page > |

Page 173

< previous page |

page_173 |

next page > |

< previous page |

page_174 |

next page > |

Page 174

Figure 10-5 (continued).

< previous page page_174 next page >