water quality and system

.pdf

< previous page |

page_52 |

next page > |

Page 52

Diseases such as typhoid and cholera spread rapidly through water systems and to the people who use contaminated waters. In this country, diseases such as hepatitis, cryptodispodiea and Legionnaires disease have contaminated many individuals. See Chapter 8 for an explanation of some of the impurities and pathogens in water supplies and methods of treatment. The bathroom fixture, with easily sterilized porcelain or enamel basins and bowls, combined with pipes to remove the waste, have prevented many diseases and have contributed significantly to people's health in our country.

In the 1890s, most of the common plumbing fixtures discussed here were invented. Their design has been refined over the past years until now they are quite effective, commonly available and inexpensive.

Sinks and Bathtubs

Sinks have a smooth finish, a drain at the bottom, holes for a faucet at or near the top, and an overflow that drains the sink before spilling over. Sinks also come as slop sinks, a deep recessed sink placed closer to the floor than the standard sink height of 42 inches. Mop sinks are usually right on the floor in the corner of a janitorial closet. The janitorial staff can rinse mops and mop buckets without having to lift them high off the floor. These sinks are combined with a floor drain. (See Figure 3-11 for a manufacturer's standard catalog mop sink product).

Figure 3-11.

A mop sink. Courtesy: American Standard, Inc.

Like sinks, bathtubs come in all sizes and shapes. However, facility managers do not often deal with bathtub problems since a bath is more of a residential item. However, since the late 1970s, the jetted tub or spa has become a modern attraction at health clubs, gymnasiums, hotels and some corporate fitness centers at large facilities. The jetted tub is more like a spa than a bathtub, although they are similar in appearance. Spas are complex items combining pumps,

< previous page |

page_52 |

next page > |

< previous page |

page_53 |

next page > |

Page 53

jets, controls, drains and are not really fixtures but fall into another category (see Chapter 11).

Water Closets (Toilets)

It is unfortunate that the water closet/toilet is such a personal item, because it is not really celebrated for the truly marvelous invention that it is. The modern toilet with its smooth bowl to prevent sticking of wastes; rim flush to moisten and carry away solids and paper; and self-priming siphon to eliminate all of the material in a single flush is a tremendous improvement over its predecessor, the chamberpot, which was emptied out the back step every morning for several hundred years before. The fact that toilet design has changed very little since its invention over 100 years ago is evidence of its simple, effective design.

Recent attempts at water conservation have generated regulations to reduce the amount of water used per flush. The old standard was 3 gallons per minute flow. New U.S. EPA standards for water-saving efficiency has reduced this flow to 1.6 gallons per minute. However, concern exists within the industry that reducing the volume per flush has negative benefits in draining, carrying solids in flows and increased deposits inside piping. In addition, the fluid flowing to the treatment plant contains more solids compared to the water and affects the effective operation of the plants. See Figure 3-8 for a cutaway view of a pictorial description of how a water closet works.

Water closets can be either wall-mount (totally mounted to the wall) or floor-mount (totally mounted to the floor.) The great advantage to the wallmount is it is easier to plumb and the bathroom is easier to clean by maintenance personnel. The floor behind a floor-mount toilet in a public restroom is often an unsanitary place subject to scrutiny by health regulators.

The facility manager will be careful to choose the low-water-flow water closets when remodeling. However, the design should be coordinated with the plumbing to assure the flow of water is fast enough to carry away the wastes.

Urinals

Urinals perform many of the same functions as water closets. Essentially, they are for men only. As with water closets, urinals are smooth and completely rinse the inside surface each time to prevent buildup and allow disease to spread. Urinals are mounted onto the wall. In the past, urinals were recessed into the floor slightly,

< previous page |

page_53 |

next page > |

< previous page |

page_54 |

next page > |

Page 54

Figure 3-12.

Cutaway view of a water closet showing how a toilet works. Reprinted from Step by Step Guide Book on Home Plumbing with p ermission of Step By Step Guide Book Co., West Valley City, Utah.

but these types have not been installed in new construction for many years because of the difficulty of plumbing them while the concrete for the floor was placed in addition to the inability to service them once the concrete was cast in place.

Water flows for urinals are less than for water closets. The new standard for low-flow urinals is 1 gallon per minute.

Bidets

Not too common in the United States, the bidet is more common to European hotels. Similar to a toilet, the bidet is used for washing the genital areas. It can be either flooror wall-mounted, although the models are usually floor-mounted. Plumbing faucets are provided for fresh clean water for washing (see Figure 3-13).

Showers

Showers are provided as bathing facilities in exercise areas, plants where workers change after shift work, in hotels, schools and in public bathing/beach areas.

< previous page |

page_54 |

next page > |

< previous page |

page_55 |

next page > |

Page 55

Figure 3-13.

A bidet, not common in the United States, is often found in European hotels. Courtesy: American Standard, Inc.

Showers are provided with a faucet with a nozzle for controlling the flow. The shower area is usually separated from drying areas with a curb. A slight rise or a sloped floor greater than 1/8-inch in one foot will be too steep and bathers may trip.

The floors of showers are usually ceramic tile with a slip-resistant finish. Some old plants used wood slats called duckboards. These duckboards provided a breeding ground for bacteria underneath and have since been banned by most public health agencies. Showers have floor drains to carry away the water.

Shower fixtures in recent years have become sophisticated with some unique pedestal types that are free standing from the center of the floor. A drain is also designed into the foot to catch wastewater (see Figure 3-14).

A facility manager should be cautious and allow plenty of spacing between shower heads, as the bathers waving arms and bending over do not wish to bump into other bathers. Public health regulations require separate shower facilities for men and for women at public facilities.

< previous page |

page_55 |

next page > |

< previous page |

page_56 |

next page > |

Page 56

Combining Systems

Now that we have a basic concept of the water system's components, are ready to take the next step toward understanding how the overall water and piping system works. The individual components are combined into an integrated system. Proper system management requires knowledge of how the individual components work together.

Figure 3-14.

A center pedestal shower fixture, typical for what is installed in large dressing rooms.

< previous page |

page_56 |

next page > |

< previous page |

page_57 |

next page > |

Page 57

Chapter 4

Instrumentation, Hydraulics, Plumbing

Now that the fundamental components of a water system have been examined, a brief discussion of some of the science behind instrumentation is the next step to understanding the system in order to manage it effectively. Meters and gauges tell us how well the hydraulics systems are performing. And systems must be installed to meet certain standards that are the results of the flows, pressures and fluid properties.

Instrumentation

A good facility manager needs to receive constant information about how the water system is operating before it can be successfully managed. In order to provide this information and make it usable, instruments are used to provide managers with the information necessary to keep the system working in safe, efficient order. Instruments that provide this information include flow meters, pressure gauges and thermometers.

Flow Meters

Flow meters are installed in water systems to record the amount of water used. All flow meters work on the basic principles of fluid mechanics, some of which will be shared briefly in this chapter.

Water flow is measured with several types of instruments that provide varying degrees of accuracy depending upon the cost. Some meters are inexpensive and the more accurate the meters are the

< previous page |

page_57 |

next page > |

< previous page |

page_58 |

next page > |

Page 58

more costly. It has been said, ''Water is cheap." The point is that people should not have to pay for more elaborate systems than are necessary. The facility manager should not have to spend several thousand dollars for a flow meter when the costs of the water he is measuring are low. This philosophy is true in the areas of instrumentation and especially so in the application of flow meters. The least expensive instruments should be used, provided they are accurate enough to do the job adequately.

Basic Flow Metering Concepts - There are basically two types of economical flow meters for water systems. Each is chosen for cost, ease of application and accuracy. In the science of flow measurement, a meter causes a change in the shape of the flowing liquid. This change in shape causes a change in the pressures which is measured using pressure gauges. The changes in pressure and the known shapes are used to calculate the velocity of the fluid inside the pipe. Then the area of the flow is calculated as well as the volume, volume being the velocity of the liquid multiplied by the area.

In these calculations, the areas are fixed but as the flow increases or decreases, the pressures change. A meter is designed to change the shape of the flow significantlyotherwise the pressure readings do not fluctuate enough to allow the velocity to be accurately measured.

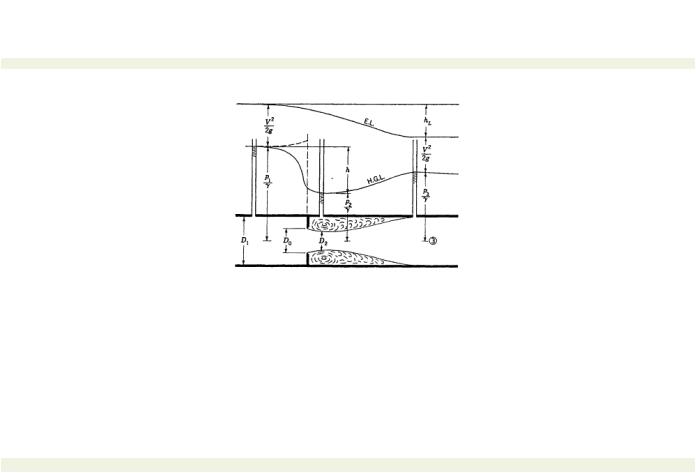

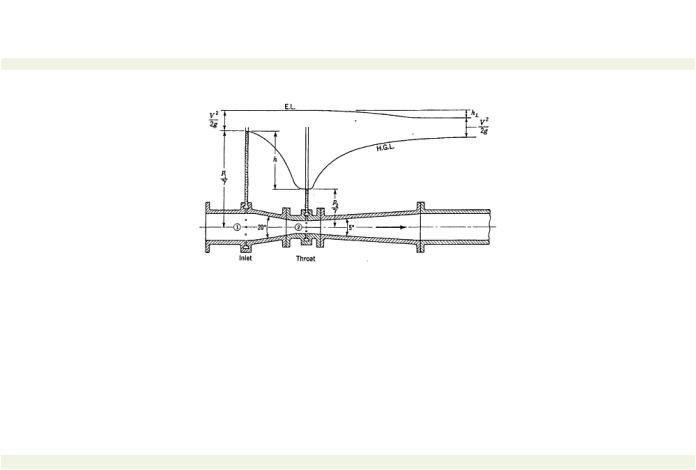

In the English System of units, it takes a bit of math to convert the pressures and inches into gallons but this is the quick and simplified version of how velocity meters indicate flows. This type of metering is one of the oldest and has proven reliable and practical for many years. These types of meters are called orifice meters, venturi meters, or pitot tube meters. Figure 4-1,4-2 and 4-3 show these meters respectively.

Another way to estimate volumes from the velocity is to insert a small propeller in the fluid stream. As the water passes over the propeller, the velocity is calculated. The method here was to build a propeller of a standard shape and, in a laboratory, push water through the pipe at a known speed. Using small gears, the turning propeller turned a dial that was hooked to a clock face or to an odometer face similar in many ways to one on an automobile. By reading the numbers on the dial, the volume of the flow was estimated. This type of meter is called a turbine meter. The advantage of the orifice meter over the turbine meter was that an object in the flow will damage the small propeller while the object will usually pass through an orificeor venturi-type meter.

< previous page |

page_58 |

next page > |

< previous page |

page_59 |

next page > |

Page 59

Figure 4-1.

Orifice meter, in a pipe. Reprinted from Fluid Mechanics with Engineering Applications with permission of McGraw-Hill Book Co., New York City.

The third type of common meter utilized in facility water systems is the disk meter. A disk meter more accurately measures flows by using a fiat disk that sits in the meter housing on an angle to the flow. As the water passes through the meter, the disk turns, similar to the propeller. The turning disk is geared to a clock face and the gears are designed to provide numbers that correspond directly to the number of gallons used.

Weirs - For outside water systems, a couple of types of devices are used to measure water flow in a canal or other open channel. Some of these types of water meters are installed in wastewater systems at treatment plants or in water lines inside manholes where flows can be measured. Flumes and weirs, as typical instruments, change the shape of the flowing water. The area is known from the depth and the shape of the weir. Most of these types of flow meters come in standard sizes with the flows computed based on depths. Typical weirs include the V-notch weir, Cipoletti weir and the box weir. Figure 4-4 Shows a typical box weir.

Parshall Flumes - Similar to weirs, but more accurate in flow measurement and more effective over a broad range of flows, is the

< previous page |

page_59 |

next page > |

< previous page |

page_60 |

next page > |

Page 60

Figure 4-2.

Venturi meter, with an entrance shaped like a cone. Reprinted from Fluid Mechanics with Engineering Applications with permission from McGraw-Hill Book Co., New York City.

Parshall flume. Like weirs, Parshall flumes are used to measure open channel flows in ditches or other irrigation or wastewater facilities.

Parshall flumes for small flows can be purchased from irrigation companies made from galvanized metal. They are lifted into place. For large flows, parshall flumes are constructed of concrete. Figure 4-5 shows a typical Parshall flume in a canal.

Electronic Metering - In the modern era of the computer chip, the pressure or depth is converted into an electric signal. The signal is used to carry forward all the high math, then translate the information into a direct reading of flow. At the push of a button, given the recording and processing capability of the computer chip, the flow can be read in gallons per minute, cubic feet per second, liters per minute, gallons per day and so on.

In the different industries connected with utility services, the units are all measuring a volume but the terms used are not all the same. For large sewage treatment plants, the units are discussed in millions of gallons per day, or MGD. For reservoirs and lakes which are much larger, services are discussed in terms of acre-feet per day,

< previous page |

page_60 |

next page > |

< previous page |

page_61 |

next page > |

Page 61

Figure 4-3

Pitot tube. Reprinted from Fluid Mechanics with Engineering

Applications with permission of McGraw-Hill Book Co., New York City.

or per month or year. For monthly billing for a customer, the facility might want to charge by simply the gallon. However, what the bill really means is gallons per month.

Throughout the day, week, month or year, the facility manager's flows are going to vary. Hence a totalizing flow meter is used to plot the highs and lows. These can be recorded using other instruments or strip charts. Another type records flows on a fiat disk, essentially a clock face that turns and the pen moves out from the inner circle depending upon the flow changes. These are called circle chart recorders.

More Sophisticated Meters - Other types of meters measure the velocity using ultrasonic sound, coriolis effect, vibration and magnetic force. Each of these types are more expensive and they have advantages and disadvantages in terms of price, accuracy, installation and service ability.

The most significant recent new trend in flow metering has been to install computers integral with the meter that includes a modem. The computer modem dials the home office every day and downloads the daily readings where it is tallied. A computer hooked up

< previous page |

page_61 |

next page > |