water quality and system

.pdf

< previous page |

page_10 |

next page > |

Page 10

laboratory even if they are not required to provide tests. A facility would want to spot check the supply once or twice a year to confirm water is satisfactory. More often these days, tests are required by local regulation. The manager can find these laboratories in the yellow pages of the telephone directory under water treatment. Most labs test water throughout the region and already know the most likely contaminants for which to test. The lab manager recommends the tests.

There are a great many chemicals to test for and the facility manager wants to be careful to test for only those that he needs. A full set of lab tests can cost up to $6,000 but most of the common tests can be provided by collecting a few sample bottles and sending them to the lab. These tests can cost $150-$300.

The best method of dealing with a lab is by letter contract. The lab will usually have one handy and will fax it to the manager. The basic tests take 2448 hours to run. More complex tests can take a few weeks.

Most laboratories will train the facility staff how to capture the water samples and a cooperative agreement between the lab manager and the facility managers is an excellent way to verify that the facility gets the right tests done in the right way. (For a more elaborate discussion of water tests and lab services, see Chapter 8.)

Table 1-3. Common water system complaints and most probable causes.

Problem |

Probable Cause(s) |

Water pressure is low.Excess demand, pumps off.

Water is too cold. |

Water cooler is out of adjustment. |

Water is rusty. |

Iron pipes, tanks. |

Water is cloudy. |

Aerators on faucets. Clay in water. |

Water is too hot. |

Thermostat is set too high. |

Too much water |

Pumps too close to faucet or elevation too low. |

pressure. |

|

Water tastes salty. |

Vague. Take sample and analyze. Recommend no |

|

drinking. Bathing OK. |

Worms/Bugs in water.Shut down system. Treatment has failed.

Dirt, sediment, debris.Shut down system. Treatment has failed.

< previous page |

page_10 |

next page > |

< previous page |

page_11 |

Case Study: Environmental spill

Here is an example of how a simple little spill of material can become a complex situation At a large construction site, a 40-ton crane was being used to move forms that were being assembled on the ground, then picked up with the crane and "walked" to where the forms could be erected for placing the walls. The assembled forms were large, some 40 ft. square. A gust of wind caught one of the forms as it was being carried by the crane to the site of the next concrefe pour. The operator was not able to set. the form down quickly and the wind. tipped the crane over. Fortunately, nobody was injured but the hydraulic fluid from the crane leaked onto the ground around the crane. After the crane was "righted, a large dark brown spot was noticed by personnel where the fluid had leaked into the dirt The dirt was scooped and placed into barrels and tested to confirm it was "not hazardous." The cost to test the barrels was about $1,000 per barrel for three barrels. The material was confirmed "not hazardous and taken to a landfill. Had the material not been placed in barrels and had an environmental regulator seen and tested the dirt with the oil in it, the company could have been fined up to $25,000 per day for each day the oil lay in the ground. As the incident was reported to the insurance company concerning the possible dam-age to crane, the regulator would have been able to determine the exact date of the spill

< previous page |

page_11 |

next page >

Page 11

next page >

< previous page |

page_13 |

next page > |

Page 13

Chapter 2

Water Sources and Management

Where does a facility's water come from? The river? Springs? A well? Conversely, where does water go: Back to the river? Into ponds or to a lake? Because water is a matter of community responsibility, the facility manager should have a basic under-standing of water sources.

Water Resources

People will do whatever is necessary to preserve their water source. People also get very angry if the integrity of their source of water is in doubt. A very small amount of water is consumedmost of it just passes through the facility. The chemistry of the water changes when the water is used.

The Hydrologic Cycle

Each day, the sun warms the sea and part of the water evaporates into the air as steam. Just because the steam is not hot does not mean the water is not there. This water in the air is called the humidity. For any temperature, only a fixed amount of water can evaporate into the air and no more. When too much water is in the air, the steam condenses and falls out in the form of rain.

Because the water evaporated by the sun does not pick up the salt in sea water, rain is fresh and, as it falls on the land, collects

< previous page |

page_13 |

next page > |

< previous page |

page_14 |

next page > |

Page 14

into lakes, rivers and streams. Some of the water evaporates when it comes into contact with the earth, some is consumed by plants, and if there is any remaining, it seeps into the ground and continues downward until underlying rock traps it so that it becomes a pool of deep fresh underground water.

When terrain changes and the water from underground is able to drain back out onto the surface, it is called a spring. Because the water was distilled from the sea, fell to earth and was filtered through the earth, this spring water is very clean and aside from minerals dissolved into the water from the surrounding rock spring water, is usually quite pure. If the spring has been there for a long time, any easily dissolvable minerals have long been washed away.

Eventually, water returns to the sea by flowing overland through rivers, underground, or by evaporating and falling as rain back upon the ocean. Scientists know approximately the total amount of water on the planet and have attempted to track the amount in the atmosphere or on land at any time. Compared to the total amount of water in the oceans, there is very little fresh water on land. But the amount of water used for drinking and human consumption is a very tiny amount compared to the total supply of fresh water.

Most fresh water is used for agriculture. Industry uses large amounts for washing and cooling. Cities use some of the water for bathing and washing and a small amount is used for drinking and food preparation. Only a very tiny fraction of the earth's total water is used as drinking water.

Supplies

Natural Lakes and River Supplies

Most major metropolitan areas obtain fresh water from lakes or rivers. Water is pumped from the fresh water body. Then it is treated, disinfected and distributed through pipes to storage tanks. From there it is distributed to individual homes, to businesses, campuses,

< previous page |

page_14 |

next page > |

< previous page |

page_15 |

next page > |

Page 15

factories, ball parks, etc. Since the source of water is a surface supply, treatment methods must remove debris, organic matter, microorganisms, and some chemicals. If someone upstream has contaminated the river or the lake, the water utility must treat the water to remove the contamination before distributing it to the users.

Withdrawal from natural lakes and rivers usually does not exceed supplyin the West, however, laws allow complete diversion of the entire stream or waterway. Total diversion has been challenged by environmental groups who claim this action is adverse to the environment. Evidence is reviewed in court who decides how much will be left behind, if any. The issue has never been resolved to anyone's complete satisfaction.

Man-Made Reservoirs

In order to store more water, man-made lakes have been constructed. Manmade lakes are called reservoirs. Reservoirs are constructed by building a perimeter of earth dikes or embankments and filling it will water from streams, springs or wells. In addition, dams have also been constructed across a river or natural waterway and the gates are closed, backing up the water behind the dam. Municipal water pipelines feed supply water from these lakes.

Reservoirs are carefully managed. Decisions are made each day about how much water is comes in, how much goes out and how much will be stored.

Reservoirs use an area-capacity table as a management tool. The table indicates the volume of water for each elevation of the water line. The facility managing the reservoir knows at any time how much water is being stored by comparing the water level in the lake to the volume shown in the area capacity table. Unless the reservoir is very small, man-made reservoirs also provide recreation opportunities such as boating and fishing. Since water is treated before distributing it to users, this has proven to be an acceptable practice.

Reservoir water must be treated for the same pollutants as the contaminants in natural rivers and lakes.

Springs

Springs are a wonderful natural phenomena, and for hundreds or years, cities were built near springs because the water there was reliable, plentiful and clean. The spring could not be contaminated and it was the central gathering place for the city's most important

< previous page |

page_15 |

next page > |

< previous page |

page_16 |

next page > |

Page 16

citizens. Today, few springs are located in a good place for a city as there is not enough access for all of the people who need to use it. Springs are an excellent source of supply if there is enough water.

Another problem with springs is that they occasionally dry up. Spring water, if it has been tested and the components are known, may not have to be treated. However, past animal grazing practices have led to the contamination of many springs. For some utility companies, spring water is captured right at the source and is immediately fed into the distribution system. For other cities, the water is disinfected. Springs sometimes have objectionable odor or color, the result of minerals dissolving in the water.

Wells

Wells are drilled to tap underground water supplies. A well is constructed using drilling equipment to bore a hole through the soil and surrounding rock and into water bearing layers deep underground. Not all wells will produce water. Some do not produce enough water, or the quality of the water is not adequate for drinking. Geologists and scientists use maps, and study rock and geologic formations to determine if there is water present. The presence of other producing wells nearby is a good sign.

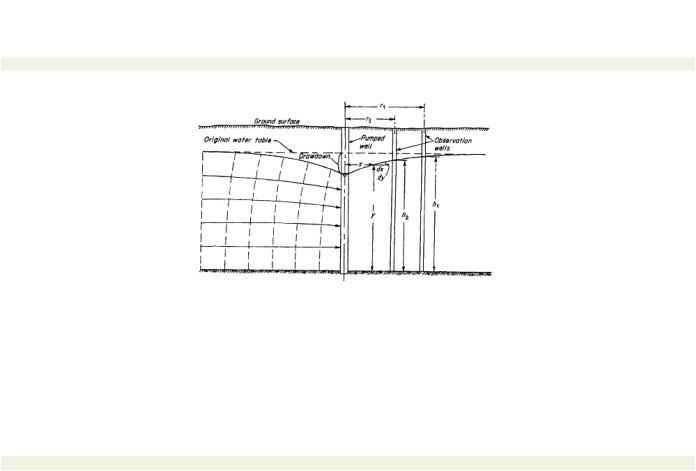

The drilling of a well is subject to regulation because the water-bearing layer below the surface may have already been tapped by other users. Drawing water from the ground at one well has the potential to affect other wells bored into the same water table. Figure 2-1 shows a typical well and drawdown curve.

Artesian Wells - An artesian well is one where the natural pressure of the water forces it up through the hole without having to pump it. Few artesian wells remain any longer since the growth of the surrounding communities has put such demands on the well that they now have to be pumped.

After a well is drilled, pumping determines the amount of water the well produces and measures what is called the drawdown. Draw-down is the depth the water table falls while the well is being pumped.

Wells have capacities from 2-3 gallons per minute to several thousand gallons per minute. Pumped wells require electrical energy to draw the water from the ground. The cost of the electricity is factored into the costs of providing the water. The deeper the well is to the water table, the more expensive the pumps and the

< previous page |

page_16 |

next page > |

< previous page |

page_17 |

next page > |

Page 17

Figure 2-1.

Well drawdown. Reprinted from Hydrology for Engineers by Ray K.

Linsley et al. with permission from McGraw-Hill Book Co., New York City.

energy costs are to draw water to the surface. Over time, the water table can be depletedthat is, the water is being drawn out faster than it can run back in. As the depth to the water table increases, the energy required to draw it to the surface increases, raising the cost to provide the water.

Shallow wells, less than 100 ft. deep, are recharged by the immediate surrounding area. Deep wells, 100-300 ft. deep, are recharged over a much larger area. When a deep well has a layer of impervious rock or clay above the water table, it is said to be a protected aquifer. This means that impurities from the surface have difficulty leaching down into the water-bearing layer.

To protect the deep water layer from impurities at higher levels, a well is usually lined with pipes that will prevent contaminated water above from leaking down into the well. The pipe used is called a casing and the wells are called cased wells. Casing a well is expensive because the pipe remains in the ground and becomes part of the total cost of the well. An uncased well, on the other hand, is less costly because the pipe used to bore the well is withdrawn after the drilling is completed.

< previous page |

page_17 |

next page > |

< previous page |

page_18 |

next page > |

Page 18

Wastewater

After the facility has used the water, it is wasted. Again, it is rare to completely consume waterusually, it passes through the facility and in the process becomes polluted. Almost all wastewater is treated in some way or another, except for the water from graywater systems. (Wastewater systems are discussed fully in Chapter 9.)

Wastewater is carried out of a facility through free-flowing pipes, as opposed the pressurized pipes used to supply fresh water. By designing the wastewater as free-flowing pipe that does not flow full, wastewater is less likely to leak out of the pipes and into the surrounding soils as it would in a pressurized pipe system.

The decomposition of sanitary wastes generates the gases carbon dioxide and methane. These sewer gases vent through that portion of the pipe that has no sewer water flowing inside. Provision has to be made to release the gases or else the pipes will become plugged.

Sewer mains are buried in the ground below the supply water mains. This reduces the chances of water flowing from the sewer into the fresh water.

At the sewage treatment plant, the natural processes that break down the solid matter in sewage are encouraged. Basic sewer treatment allows the growth of microorganisms that consume the solid matter, breaking it down into inert solids, sludge, and gases.

The wastewater treatment process is upset when chemicals harmful to the microorganisms (bacteria) enter the treatment process. To prevent this contamination, wastewater treatment plants have a series of tanks, filters and digesters.

If wastewater comes in that contains harmful chemicals, the flow is switched to a backup pond or another treatment tank where the harmful chemicals can be removed before treatment begins.

Stormwater

The facility manager has to deal with the stormwater that runs onto the parking lot or drains off the building roof during rainfalls or thundershowers.

Provision must be made for adequate flow, or a combination of ponding and flow such that the water does not flood. Stormwater usually channels naturally into gullies, washes or to natural rivers or streams.

< previous page |

page_18 |

next page > |

< previous page |

page_19 |

next page > |

Page 19

Rainfall

The volume of rainfall is calculated from weather data. Stormwater is a function of rainfall intensity, the duration, the vegetation, and the porosity of the soil. For buildings, the rain water runs off. There is a structural calculation that allows for fiat roofs to sag slightly and pond some of the water, but this type of design is only for a worst case scenario.

Statistical methods are used by the U.S. Weather Service to predict the storms.

A flood calculated on the basis of a heavy rainfall once in 25 years would be a 25-year storm. For most facility stormwater runoff and storage calculations, a five-year or a 25-year storm is used. The facility manager needs to understand the significance of the storm period.

As the time increases between the assumed heavy storms, the size of the works to carry the water away increases. Culverts and drains for a parking lot or road designed for five-year storms (a storm that happens once every five years) are less expensive than culverts and drains designed for a 25-year storm (a storm that happens once every 25 years).

Parking lots, fiat roofs and ball fields must be able to account for most of the major storm expected during the facility life. In addition, culverts and drains must be sized correctly to allow the flow to pass through and prevent flooding.

In practice, engineering designs and codes provide for typical standards acceptable to that area. Engineers that estimate design storms and floods are called hydrologists and can be located in the yellow pages of the telephone directory.

Figure 2-2 shows typical rainfall intensities for estimating stormwater runoff.

< previous page |

page_19 |

next page > |

< previous page |

page_20 |

next page > |

Page 20

Figure 2-2.

Rainfall intensity for the continental United States. The numbers represent total amount of rain, measured in inches, that is expected to fall over a one-hour period every 100 years on average. Courtesy:

U.S. Weather Bureau, Technical Papers.

Stormwater Ponds

For most facility managers, the problem of stormwater control is one of erosion control. If the campus or property has a tendency to pond, then it is a poor site and steps have to be taken to channel or pump the water to another location.

Because of the tendency of many facilities to be near large cities, there is not any easy location for the runoff water. Hence in recent years ball fields, parks and other grassy recreation areas are recessed slightly to allow rainwater to pond when a large storm dumps rainwater onto the complex.

Erosion Control - For large runoffs, the facility manager must be prepared to deal with erosion of soil on the facility. Erosion caused by stormwater can be halted or arrested. In addition, the construction of underground works to allow the water to pond below the facility is an available option.

Soil Types - Erosion control requires an understanding of the types of soils at a facility. Sand is a granular material. It has no ''sticky" material in it to bind up with adjacent grains. Therefore, it

< previous page |

page_20 |

next page > |