water quality and system

.pdf

< previous page |

page_32 |

next page > |

Page 32

larger sizes. In general, steel pipe has excellent strength, but is more subject to corrosion than ductile iron pipe. Unless kept completely full of water, the inside of steel pipe rusts, resulting in the red color of water when pipes are initially turned on for a few moments. New steel pipe can be coated both inside and outside. Often, steel pipe can be identified on the job site because the outer coating is wrapped with paper. The most common steel pipe is referred to in the field as "black iron" pipe. Most black iron pipe is more specifically referred to as A53 Grade B pipe. This vernacular stands for pipe fabricated to the specifications in ASTM Standard A53, using the chapters for Grade B.

One thing to note about steelsthey come in many alloyed forms. The facility manager should recognize that there are hundreds of other pipe and tube standards for steels. These other standards are for more special applications such as chemical and nuclear power plants. The specialty applications require more strength, corrosion resistance, thermal expansion and numerous other characteristics.

Common black iron pipe strengths are referred to by schedule. The most common is Schedule 40, but Schedules 20, 80 and 120 are also used. The difference in schedules refers to the thickness of the pipe wall, with Schedule 20 the least thick, next Schedule 40 and so on. It is quite common to see Schedule 40 black iron pipe used for water service and Schedule 80 black iron used for steam.

Copper Pipe

Like steel pipe, copper pipe is most commonly used in buildings for hot and cold water supply piping. Copper, while not as strong as steel pipes, is much lighter and easier to fit together than heavy steel pipe. In addition, the lighter pipe allows the use of lighter pipe hangers and supports which further reduce costs in this system. Copper pipe joints and fittings are usually brazed together using a process called "sweating." Because the copper pipe is thin-walled, its size is limited to about 4 inches in diameter. In addition, it is difficult to braze copper pipe in larger diameters. Copper pipe is rarely screwed, except where special fittings are used.

Copper pipe comes in special classes designated by letter, with the most common being type K, type L or type M. The thickest and strongest of these is type K. The outside diameter of each type of copper pipe stays the same so that the same fittings can be used for each type.

Finally, copper pipe does not work well in underground service because of the conductivity of copper metal.

< previous page |

page_32 |

next page > |

< previous page |

page_33 |

next page > |

Page 33

Abs Pipe

Acrylonitrile Butadiene Styrene (ABS) pipe is a black plastic pipe used for drain and vent piping in buildings. ABS is used because it is lightweight and easy to cut, install and hang. Generally, ABS is not used below ground. It is also not used for outside service because sunlight's ultraviolet waves tend to break down the plastic and make it brittle over time. ABS pipe is used as a vent pipe to project through the roofs of many buildings. Since this vent pipe carries air and sewer gases, the brittlement from sunlight exposure is ignored for this short few feet of pipe. ABS pipe can be painted if necessary to protect it.

Since the pressures of drain pipes is nearly zero, compared to 20-90 pounds per square inch for pressure pipe, ABS is much cheaper than copper or steel pipe would be in the same diameters.

Pvc Pipe

Polyvinyl Chloride (PVC) pipe is sometimes used for water supplies and is often the pipe of choice for lawn sprinkler systems. It can also be used for inside building supply lines. Joints and fittings of PVC pipe are glued together, although some special fittings are used to make screwed joints. As with copper, steel and ductile iron, PVC pipe comes in different strengths called pressure classes. The thinnest is called class 200 but the most common type used is Schedule 40. Schedule 20, Schedule 80 and Schedule 120 Plastic pipe is also available.

Schedule 40 PVC pipe is almost as expensive as steel pipe, but the advantage of PVC pipe is that it is easier to cut and glue together in the field than steel pipe, which has to either be welded or threaded and screwed together. In general, the fittings for PVC pipe are much less costly than fittings for steel pipe until the size gets up to about 6 inches in diameter. Then the steel fittings are less than the plastic fittings.

Other Plastic Pipes

There are several other types of plastic pipes that have advantages and tradeoffs similar to the ones mentioned for steel, copper, ABS and PVC. These other more sophisticated pipes are generally identified by their color since manufacturers want to make it easy to identify their product in the field. The two most common to be encountered by a facility manager are made from blue plastic and orange plastic. Similar to PVC, blue plastic pipe is used for underground water supplies. The resins in this "blue brute" pipe have been

< previous page |

page_33 |

next page > |

< previous page |

page_34 |

next page > |

Page 34

designed to be more corrosion-resistive than the white PVC pipe. Orange plastic pipe is used as an alternative to Schedule 40 black iron pipe for fire sprinklers in residential construction. The advantage of the orange plastic has been that it is specially fabricated to be fire-resistive.

Fiberglass Pipe

Fiberglass pipe is often used as an alternative to steel pipe but in general it is more expensive. Fiberglass pipe is used more often for chemical and refinery operations. One example where fiberglass pipe might be encountered by a facility manager is in the acid piping used for regeneration of mixed bed deionizers (see Chapter 10).

Concrete Pipe

Concrete pipe is often used for underground sewer service, although it has been losing ground in recent years to PVC pipe. The big advantage to concrete pipe has been its resistance to buckling under roadways. The smallest size for concrete pipe would be 4 inches, with 6 inches being more common. Concrete pipe is also used for pressure pipe lines and there is a lot of competition between the concrete pipe manufacturers and the ductile iron pipe manufacturers to bid and install their types of pipe. A facility manager may be able to take advantage of this competition by instructing the engineering staff to prepare contracts in such a way that either type of pipe can be installed. One note of caution, however, has been the preference of utilities located in areas subject to earthquakes to prefer steel pipes over concrete for water supplies because of its flexibility.

Clay Pipe

Clay pipe is sometimes used for drainage applications instead of concrete pipe. Clay pipe can be less costly than concrete, particularly in areas where there are lots of clay soils and not much in the way of sands and gravel for making concrete. Clay is smoother on the inside than concrete pipes. Clay is used in some areas of the country, while in other areas it is rarely used.

There are many other pipe types that will commonly be encountered by water managers of facilities, and the facility manager should keep an open mind in considering options provided he can meet the city or state building codes.

< previous page |

page_34 |

next page > |

< previous page |

page_35 |

next page > |

Page 35

Pipe in Older Facilities and Buildings

In many buildings, particularly buildings constructed using copper pipe during the 1940s1960s, lead was used in joints or even for the pipe itself. U.S. EPA studies revealed that lead in small amounts can have adverse health effects on humans (see Chapter 8, concerning water purity). As a result, lead has been banned from piping materials. Water quality tests from the taps in the building or on the property will reveal if trace amounts of lead are present. (Water quality testing is also included with Chapter 8.) Other old pipe materials include galvanized steel pipe, plain steel, and copper.

Remodeling/New Pipe

Many, many professionals in the engineering business make their living making pipe and there is not any way, without years of study, to learn this information quickly. The American Society for Testing and Materials, the American Society of Mechanical Engineers, and the American Water Works Association are a few agencies that write general material specifications for most types of pipes.

These standard specifications, some of which are several hundred pages long, define the materials, the stretch and break tests, the pressure tests, the penetration resistance, corrosion resistance and so on. The facility manager should make sure that the engineer designing the pipe system is familiar with these requirements when starting a major job.

Water Supply Piping

Wastewater Piping

< previous page |

page_35 |

next page > |

< previous page |

page_36 |

next page > |

Page 36

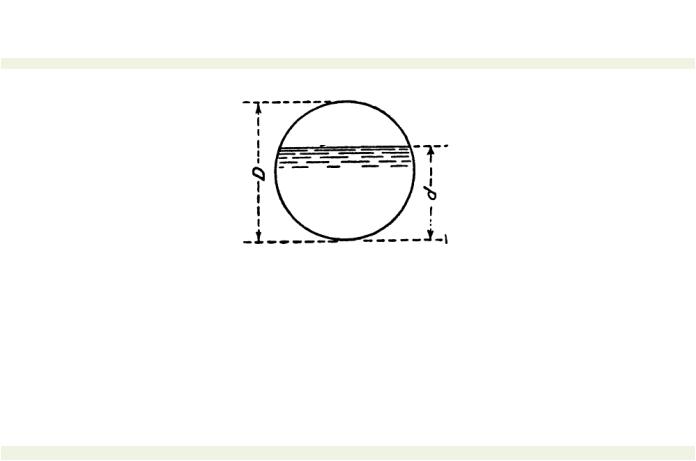

that supply water piping is designed to flow full while wastewater piping, because it carries debris and other solids, is designed to flow only partially full (see Figure 3-2).

Stormwater Pipe

Stormwater drainage runs down the curb and gutter, off the roofs of major buildings, down streets during summer rainstorms. It carries snowmelt and sometimes salt that has been added to roads, excess irrigation water from watering lawns and gardens, and in general simply allows the water that falls on the property in the form of rain to run off.

Stormwater designs are unique because they are really only used during those times of the year when rainfall or snowmelt occur. Some stormwater is channeled to ponds where it collects and evaporates, while other stormwater is channeled into rivers or gullies. Stormwater runoff carries its own types of problems which include debris and chemicals.

Stormwater will carry debris that can be moved by the flowing water. Wood, trash, paper and small stones are all types of wastes carried by stormwater flows. These wastes, if carried into a neighboring property, have the potential to impact the facility manager and his operation. By concentrating the flows from a large complex into a single source, if water flowed onto an adjacent property as sheet flow it could have little impact on the neighbor. Concentrating the flow from a large area into a single pipe, however, can cause significant erosion over time that might require mitigation by the facility manager.

The second potential problem with stormwater piping is the chemicals that become mixed into the water as it runs off of the land. For example, if a lawn is chemically treated for preventing weeds with a commercial herbicide and rain causes the chemical to rinse off onto an adjacent property that is growing a crop, the chemical may kill or otherwise reduce the yield of the adjacent property owner's crop.

As a result of these problems, many facilities have special ponds designed to capture stormwater where it can the tested before being released. Other facilities have written understandings and agreements with the property owners downstream.

The same types of pipe used for supply water can be used for

< previous page |

page_36 |

next page > |

< previous page |

page_37 |

next page > |

Page 37

Figure 3-2.

Pipe partial-flow cross section. Courtesy: U.S. Bureau of Reclamation,

Denver, CO, Earth Manual: A Guide to The Use of Soils as Foundations

And as Construction Materials for Hydraulic Structures, First Edition.

stormwater runoff but, because they are not designed for full flow, stormwater drain pipes will be larger in diameter than supply pipes.

Sanitary Sewer Pipe

Wastewater from kitchens, bathrooms and toilets carry washwater, garbage and human or animal sanitary waste. Because these sewer lines are for sanitary purposes, they are called sanitary sewer lines. Like stormwater piping, sanitary lines are also designed for partial flow and can carry debris such as garbage, excrement, sanitary napkins and paper.

The pipe materials are the same as the ones used for stormwater and since both stormwater and sanitary sewer flow partially full their sizes are larger than the supply water pipe for the same buildings or area served.

Along with the drain pipes flowing partially full, designs for drainage pipes keep them purposefully at zero pressure. In this way, a leak in the pipe will not flow out of the pipe as fast as it would if it were a pressurized pipe.

< previous page |

page_37 |

next page > |

< previous page |

page_38 |

next page > |

Page 38

Buried Pipe

Pipe buried below ground is usually placed with the drain pipe below the level of the supply pipe so that a leaking wastewater pipe will not contaminate the supply pipe. Having the supply pipe pressurized also prevents wastewater from getting into supply water. Occasionally, however, the supply water pipeline has to be drained in order to work on it. When a drained supply water pipe is filled, codes require the supply pipe to be sterilized (see Chapter 13).

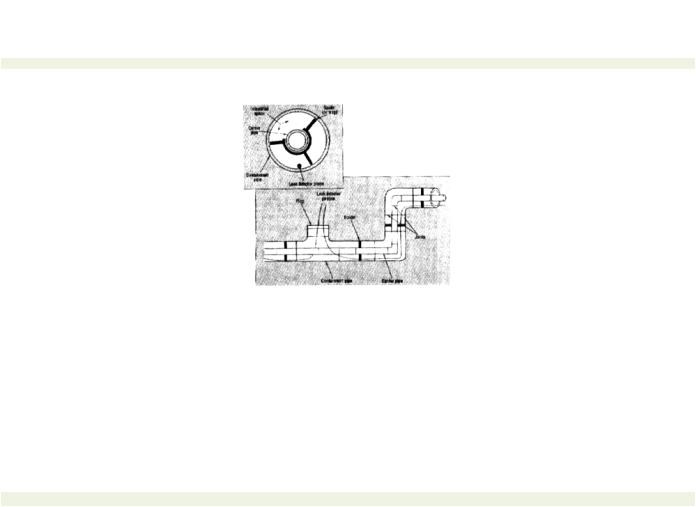

Double-Walled Pipe

Occasionally, although for water systems the need is rare, the facility will install double-walled pipe (see Figure 3-3). Double-walled pipe is more often associated with hazardous materials, but non-industrial facility managers may benefit from knowing it is available. Double-walled pipe is essentially two pipe systems, one inside the other. The inner pipe is called the carrier pipe, while the outer pipe is called the containment pipe.

Double-walled pipe is expensive and is made from some elaborate materials like fiberglass and plastic. Steel is also used. A clip is used to keep the inner pipe separated from the outer pipe (see Figure 3-3). The area between the two pipes is called the interstitial space. Usually the interstitial space is air, and often an electronic cable is run through the interstitial space to determine and pinpoint leaks in the carrier pipe.

Corrosion

Pipes, especially pipes installed in the ground, are subject to corrosion from both the outside and the inside. Usually corrosion from the inside is minimal because water or sanitary waste is not highly corrosive.

From the outside, pipe is subject to corrosion from acidic chemicals in the surrounding soil. Pipe buried in the ground is subject to corrosion from a process called galvanic action.

Galvanic action is the result of magnetic forces on the pipe that cause the joints to become either positively or negatively charged. What happens, in effect, is that the pipe joint acts like a low-grade battery and over a long time the ends corrode in the same way that flashlight and car battery terminals corrode. Eventually, pinhole leaks develop in the pipe.

< previous page |

page_38 |

next page > |

< previous page |

page_39 |

next page > |

Page 39

Figure 3-3.

Double-walled pipe. Courtesy: Heating, Piping And Air Conditioning

Magazine, April 1993, original manuscript by the author.

Corrosion in a pipe system is reduced by providing coatings to prevent the batterylike phenomena from occurring. The coatings insulate the pipe from the electrical charges and reduce the corrosive action. Metal pipe is subject to the worst types of corrosion but other pipe types are subject to corrosion as well. The biggest advantage of concrete and plastic drain pipes is that they are more resistant to corrosion than metal pipe types.

All types of pipes are subject to corrosion and all kinds of pipes are offered with corrosion-resistant insulation.

Coatings

Corrosion-resistant pipe coatings take several forms, which are chosen for their properties to resist corrosion. Coatings can be paintsincluding enamel and epoxy resin coatings; plasticsincluding Teflon and PVC; or common elements such as cement and coal tar. Almost all of these coatings are applied to steel pipes used for underground applications.

Most corrosion linings are added independently from the pipe manufacture. This means that to purchase new pipe or fittings that have a corrosion lining, the facility manager has to wait while the

< previous page |

page_39 |

next page > |

< previous page |

page_40 |

next page > |

Page 40

manufacturer fabricates the pipe, then ships it to a subcontractor who lines it with the corrosive resistant coating and then forwards it on the to facility.

Pipe Joints

In all pipe types, there is a decision to be made about the types of joints used between the different pieces of pipe. Almost anybody will recognize the joints used in residences, especially homeowners who have crawled under the sink to fix a drain. Joints are chosen for service and economy.

Screwed Joints

A screwed joint in pipe is made with a coupling that has been threaded at each end. Female threads in the coupling are ''made up" with male ends screwed onto the ends of the female coupling. "Made up" is a plumbing piping expression meaning "connect to the next piece."

On screwed piping, the fittings are connected the same way. With a pipe system of entirely screwed fittings, it can be put together from one end to the other, but a repair means the pipe has to be cut and unscrewed in reverse sequence of assembly. This time-consuming process led to the development of other joint types. The advantage of a system with screwed joints is that tools to assemble the system consist of a pair of pipe wrenches. The joints make up quickly, experience few leaks and can be unscrewed and rescrewed repeatedly without leakage. Usually, Teflon tape or Teflon pipe dope is applied to the joint before assembly to assure a leak-tight joint and to make the joint easy to take apart when service is necessary. For large-diameter pipe systems, above six inches say, the costs of the fittings becomes expensive compared to other joint types.

Sweated Or Brazed Joints

With the advent of copper pipe, holding the advantage of a thinner wall which made the pipe lighter and easier to fit up, the wall was not thick enough for cutting in the threads. Hence a coupling composed of the same material with a slightly larger diameter was developed. Copper pipe is inserted into the larger fitting and the joint is heated with a propane torch. When the joint reaches the correct temperature, solder is applied. The heat melts the solder and as the joint cools, the solder is drawn into the fitting, sealing it.

< previous page |

page_40 |

next page > |

< previous page |

page_41 |

next page > |

Page 41

The disadvantage of this type of joint has been getting the pipe hot enough without inadvertently setting the adjacent construction materials on fire. In addition, if there is water in the pipe, the water boils into steam and can pressurize the pipe beyond its strength. Water can also carry away the heat, preventing the joint from reaching the right temperature and resulting in the solder not being drawn completely around the joint. Hence, it leaks.

Brazed joints can be heated, pulled apart, sanded and reassembled without adverse affects.

There are several types of solder used for brazing joints. These solders have different melting temperatures and the correct type of solder is used to make up the right joints.

Glued Joints (Plastic Pipe)

PVC and ABS pipe are joined with glue. The glue is usually a special epoxy resin made specifically for that pipe and is applied to both the coupling and the pipe end. The two ends are pressed together and the glue forms a permanent bond between the pipe components. The disadvantage of this type of joint is that it cannot be used again. If the pipes are taken apart, the joint is ruined. The fittings of this type of pipe are inexpensive and are discarded and replaced with new ones when the joint is worked.

Bell and Spigot Joints

All types of pipe can be fabricated with a joint called a bell and spigot joint. The bell, so called from the bell shape at one end of a section of pipe, is fitted over the spigot end. A gasket is installed in the bell to prevent leaks. Bell and spigot pipe joints are used on pipe placed end-to-end and buried underground. The bell shape, when buried, prevents movement. There is a little flexibility in the joints of this type of pipe and long radius bends can be made by "pulling" the joints. That is, each joint is pulled out of line slightly from the preceding joint. Depending upon the bell, an angle of 5 degrees or less can be made between successive joints. For short radius bends in bell and spigot pipe a thrust block is poured. The thrust block, usually concrete, is placed between the outer wall of the pipe and the trench wall to prevent the pressure from pushing the two pipe joints apart when pressurized.

< previous page |

page_41 |

next page > |