Environmental Biotechnology - Jordening and Winter

.pdf

36614 Anaerobic Fermentation of Wet and Semidry Garbage Waste Fractions

Table 14.5 Comparison of oneand two-stage processes.

Process Operation |

One-Stage |

Two-Stage |

|

|

|

Operational reliability |

in the same range |

|

Technical equipment |

relatively simple |

very complex |

Process control |

compromise solution |

optimal |

Risk of process instability |

high |

minimal |

Retention time |

long |

short |

Degradation rate |

reduced |

increased |

|

|

|

action conditions for the overall process, due to slightly different environmental requirements during the different stages of the fermentation. Therefore, the degradation rate is reduced and the retention time increases. The basic advantage of onestage process operation is the relatively simple technical installation of the anaerobic digestion plant and lower costs.

In two-stage processes (Table 14.5), hydrolysis and acidification on the one hand and methane formation on the other hand take place in different reactors so that, e.g., mixing and adjustment of the pH can be optimized separately, permitting higher degradation degrees and loading rates. As a result, the detention time of the material can be decreased significantly. This, of course, involves a more sophisticated technical design and operation, resulting in higher costs.

During the first stage the organic fraction is hydrolyzed. As a result, dissolved organics and mainly organic acids, as well as CO2 and low concentrations of hydrogen, are produced. In the second stage the highly concentrated water is supplied to an anaerobic fixed-film reactor, sludge blanket reactor, or other appropriate system where methane and CO2 are produced as final products. Reciprocal inhibiting effects are excluded so that high process stability with a better methane yield is obtained.

14.3.2.1 Dry and Wet Fermentation

Different anaerobic digestion systems can handle wastes with different moisture contents; they are classified as dry fermentation processes (water content between 55% and 75%) and wet fermentation processes (water content >85%.) Table 14.6 shows advantages and disadvantages of dry and wet fermentation.

With the dry fermentation process, little or no water is added to the biowaste. As a consequence, the material streams to be treated are minimized. The resulting advantages are smaller reactor volumes and easier dewatering of the digested residue. On the other hand, operating with high contents of dry matter places higher requirements on mechanical pretreatment and conveyance, on the gas-tightness of charge and discharge equipment, and, if planned, on mixing in the reactors. Bridging of the material and the possibility of clogging have to be avoided. Because of the low mobility is dry fermentation, a defined residence time can be reached by approximating plug flow, which is particularly important under the aspect of product hygiene in the thermophilic operation mode. The degradation rates in dry fermentation processes

14.3 Processes of Anaerobic Waste Treatment 367

Table 14.6 Comparison of wet and dry fermentations.

Process Mode |

Dry |

Wet |

|

|

|

Total solids content |

high |

low |

|

25–45% |

2–15% |

Reactor volume |

minimized |

increased |

Conveyance technique |

expensive |

simple |

Agitation |

difficult |

easy |

Scumming |

little risk |

high risk |

Short circuit flow |

little risk |

high risk |

Solid–liquid separation |

simple |

expensive |

Variety of waste components |

small |

great |

|

|

|

are lower than in wet fermentation, due to the larger particle size and reduced substrate availability.

When wet fermentation processes are used, the organic wastes are ground to a small particle size and mixed with large quantities of water so that sludges or suspensions are obtained. This allows the use of simple, established mechanical conveyance techniques (pumping) and the removal of interfering substances by sink–float separation. At the same time, the reactor contents can be easily mixed, which permits controlled degassing and defined concentration equalization in the fermenter. As a consequence, the degradation performance of the microorganisms is optimized. The mean substrate concentrations and thus also the related degradation rates are lower than in plug flow systems, since, for completely mixed systems, the concentrations in the system are equal to the outlet concentrations. Mixing is limited by the shear-sensitivity of methane bacteria; however, too-low a degree of mixing may result in floating and sinking layers. Homogeneity and a fluid consistency permit easier process control. By fluidizing the biowaste, the mass to be treated increases until the 5-fold, depending on the total solids content of the substrate with the consequence that the aggregates and reactors have to be made much larger. Fluidization and dewatering of the fermentation suspension especially require considerable technical and energetic expenditures. But if the degrees of degradation are the same, recycling the liquid phase from the dewatering step to the fluidization of the input material, makes it possible to reduce the wastewater quantity to an amount comparable to that used in dry fermentation and to keep a considerable part of the required thermal energy within the system.

14.3.2.2Continuous and Discontinuous Operation

When an anaerobic process is run in continuous operation mode, the reactor is fed and discharged regularly. Completely mixed and plug flow systems are available. Enough substrate is fed into the reactor to replace the putrefied material as it is discharged. Therefore, the substrate must be flowable and uniform. Steady provision of

368 14 Anaerobic Fermentation of Wet and Semidry Garbage Waste Fractions

nutrients in the form of raw biodegradable waste enables stable process operation and constant biogas yield. Depending on the reactor design and the means of mixing, short circuits may occur, and the retention time therefore cannot be guaranteed for each part of the substrate in completely mixed systems.

In the discontinuous operation mode (batch process), the fermentation vessel is completely filled with raw garbage mixed with inoculum (e.g., digestate from another reactor) and then completely discharged after a fixed detention time. Batch digesters are easy to design, comparatively low in cost, and suitable for all wet and dry organic wastes (Table 14.7).

14.3.2.3 Thermophilic and Mesophilic Operation

The optimal process temperatures for methane fermentation are in the mesophilic temperature range (about 35 °C) and in the thermophilic temperature range (about 55 °C).

Reactors designed for mesophilic operation are heated to 30 to 40 °C. According to the experience gained with this way of operation, the process stability is high. Minor temperature variations have only a small effect on mesophilic bacteria.

The advantages of mesophilic process operation result from the lower amount of heat to be supplied and the related higher net energy yield. In addition, higher process stability is achieved, since a broad spectrum of mesophilic methane bacteria that show low sensitivity to temperature changes exist.

The thermophilic range requires temperatures between 50 and 60 °C. Under certain circumstances thermophilic process operation allows faster substrate turnover, so that the residence times can be shorter. The higher expenditure of energy to maintain the process temperature is a disadvantage.

When the process is run under thermophilic conditions for a defined residence time, sanitation in the reactor is possible,; otherwise, sanitation has to be achieved in a separate treatment step or by aerobic after-composting. On the other hand, the net energy yield is lower, due to the higher heat requirement, and the temperature sensitivity of the microorganisms reduces the process stability. Table 14.8 lists the advantages and disadvantages of mesophilic and thermophilic process operations.

14.3.2.4 Agitation

For a high degradation activity of the bacteria, it is necessary to provide the active biomass with sufficient degradable substrate. Simultaneously, the metabolic products

Table 14.7 Comparison of continuous and discontinuous feed.

Process Operation |

Continuous |

Discontinuous |

|

|

|

Retention time |

shorter |

longer |

Technical equipment |

complex |

simple |

|

|

|

14.3 Processes of Anaerobic Waste Treatment 369

Table 14.8 Comparison of mesophilic and thermophilic process operation.

Process Operation |

Mesophilic (35 °C) |

Thermophilic (55 °C) |

|

|

|

Process stability |

higher |

lower |

Temperature sensitivity |

low |

high |

Energy demand |

low |

high |

Degradation rate |

decreased |

increased |

Detention time |

longer or the same |

shorter or the same |

Sanitation |

no |

possible |

|

|

|

of the organisms have to be removed (Dauber, 1993). These requirements can be met by mechanical mixing or other agitation of the reactor contents. Another possibility is to install a water recirculation system, by which the process water, which ensures nutrient provision and the removal of metabolic products, trickles through the biowaste in the reactor (Rilling and Stegmann, 1992). Other processes use compressed biogas for total or partial mixing of the material.

14.3.3

Survey of Anaerobic Fermentation Processes

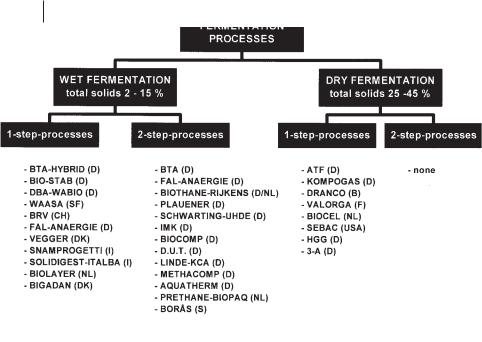

During the past few years several anaerobic processes for the utilization of solid waste have been developed. Each has its own benefits. Currently, the European market offers at least 30 different processes or process variants. Figure 14.4 shows (without claiming to be complete) the processes organized according to water content and number of fermentation stages and indicates that most of the offered processes are oneor two-stage wet fermentation systems. The number of dry fermentation processes is comparatively small. One primary reason for this situation is the higher technical effort required for dry fermentation. Although wet fermentation can be based on the well known and successful technology used in sewage sludge treatment and the digestion of manure, dry fermentation requires the employment of new, innovative technologies, especially in the field of gas-tight filling and emptying, as well as in conveyance systems.

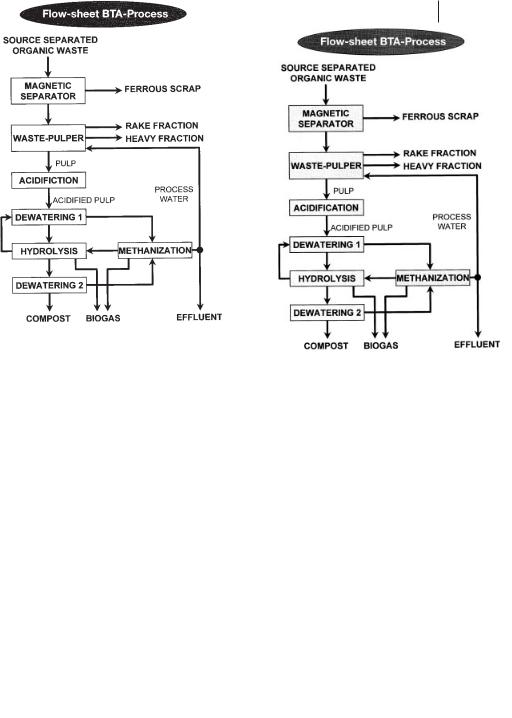

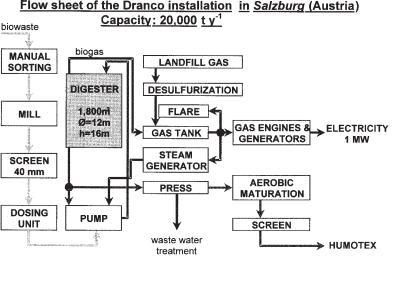

An example of a one-step wet fermentation system is the DBA–Wabio process (Fig. 14.5); an example of a two-step wet fermentation system is the BTA process (Fig. 14.6); and examples of one-step dry fermentation systems are the ATF process (Fig. 14.7) and the Dranco process (Fig. 14.8).

14.3.4

Feedstock for Anaerobic Digestion

The feedstock for an anaerobic digestion plant can be organic wastes that have been separately collected and delivered to the plant ready for processing or, alternatively, municipal solid waste (MSW) or a fraction of MSW (e.g., <100 mm) from a mechanical sorting plant in which the other fraction is a kind of refuse-derived fuel. A fur-

370 14 Anaerobic Fermentation of Wet and Semidry Garbage Waste Fractions

Fig. 14.4 Classification of available processes of anaerobic waste fermentation (according to Rilling, 1994a, updated).

ther source of organic waste is ‘green wastes’ collected at centralized collection points.

At least the purity of the raw material fed into the anaerobic digestion process dictates the quality of the horticultural product coming out at the end of the process.

The range of application of the anaerobic digestion process is very broad. In principle, any organic material can be digested, i.e. (Rilling, 1994b):

•organic municipal solid waste

•waste from central markets (e.g., fruit, vegetable, and flower residuals)

•slaughterhouse waste (paunch manure)

•residues from the fish processing industry

•food wastes from hotels, restaurants, and canteens

•bleaching soil

•drift materials such as seaweed or algae

•agricultural waste

•manure

•beer draff

•fruit or wine marc

•sewage sludge

372 14 Anaerobic Fermentation of Wet and Semidry Garbage Waste Fractions

Fig. 14.8 Example of a one-step dry fermentation plant (Dranco process) (Six et al., 1995)

14.4 Conclusions

The separate collection of biological wastes and their biological treatment are an important part of waste utilization. There is no universal process for the biological treatment of biological waste, nor will there be. Nevertheless, composting anaerobic digestion is turning out to be a useful technology in both its economic and ecological aspects.

The basic aims of anaerobic biological waste treatment are

•decrease of waste volume

•mass reduction of organic substance for stabilization of waste

•conservation of nutrients and recycling of organic substances (fertilizer or soil improvement)

•energy recovery by generation of biogas

•odor reduction

•sanitation

Anaerobic digestion is a sustainable treatment technique for many kinds of organic wastes. Based on the expectations of its future rising market share, the increasing number of processes offered shows the dynamic and innovative force of anaerobic fermentation technology.

376 15 Landfill Systems, Sanitary Landfilling of Solid Wastes, and Long-term Problems with Leachate

The first two categories of mechanisms, which have greater influence on the quality of leachate produced, are included in the more general concept of waste stabilization in landfills.

15.2.1

Aerobic Degradation Phases

The first phase of aerobic degradation of organic substances is generally of limited duration, due to the high oxygen demand of waste relative to the limited quantity of oxygen present inside a landfill (Phase I, Figure 15.1). The only layer of a landfill involved in aerobic metabolism is the upper layer, where oxygen is trapped in fresh waste and is supplied by diffusion and rainwater. Usually the aerobic phase is quite short, and no substantial leachate generation takes place.

In very old landfills, for which only the more refractory organic carbon material remains in the landfilled wastes, a second aerobic phase may appear in the upper layer of the landfill. In this phase the methane production rate is very low and air stars diffusing from the atmosphere, giving rise to aerobic zones and zones with redox potentials too high for methane formation (Christensen and Kjeldsen, 1989).

15.2.2

Anaerobic Degradation Phases

Three different phases can be identified in the anaerobic decomposition of waste:

•acid fermentation

•intermediate anaerobic phase

•methanogenic fermentation

The first phase of anaerobic degradation is acid fermentation, which causes a decrease in leachate pH, high concentrations of volatile acids, and considerable concentrations of inorganic ions (e.g., Cl–, SO42–, Ca2+, Mg2+, Na+). The initial high content of sulfates may be slowly reduced as the redox potential drops and metal sulfides are gradually generated that are of low solubility and precipitate iron, manganese, and other heavy metals that were dissolved by the acid fermentation (Christensen and Kjeldsen, 1989). The decrease in pH is caused by the high production of volatile fatty acids and the high partial pressure of CO2. The increased concentration of anions and cations is due to leaching of easily soluble materials, consisting of original waste components and degradation products of organic substances. Initial anaerobic processes are elicited by a population of mixed anaerobic microbes, composed of strictly anaerobic bacteria and facultative anaerobic bacteria. The facultative anaerobic bacteria reduce the redox potential with the result that methanogenic bacteria can grow. In fact, the latter are sensitive to the presence of oxygen and require a redox potential below –330 mV. Leachate from this phase is characterized by high BOD5 values (commonly >10 000 mg O2 L–1), high BOD5/COD ratios (commonly >0.7), acidic pH values (typically 5–6), and ammonia (often 500–1000 mg L–1) (Ro-