Environmental Biotechnology - Jordening and Winter

.pdf

346 13 Composting of Organic Waste

Fig. 13.9 Self-driven windrow turning machine (drawing: Backhus GmbH, Edewecht).

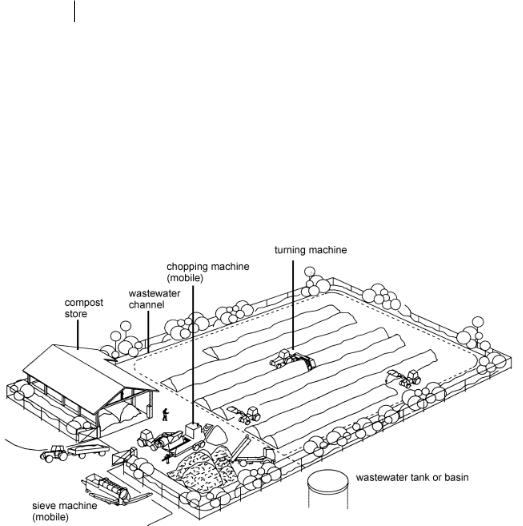

Fig. 13.10 Open windrow composting plant with turning machine [3].

reused in the compost plant, and the finished compost is stored under a roof until it is sold.

13.5.2

Reactor Composting

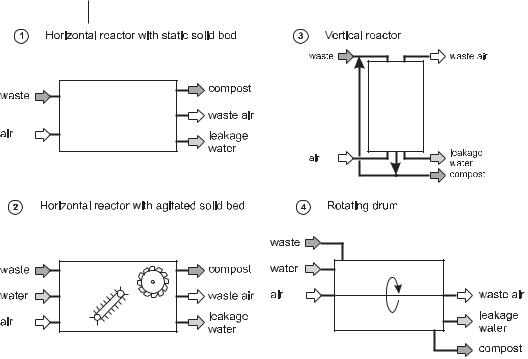

Every method of composting in an enclosed space (e.g., container, box, bin, tunnel, shed) with forced exchange of respiration gases is a type of reactor composting. Composting reactors (Fig. 13.12) can be classified according to the manner of material flow as

13.5 Composting Systems 347

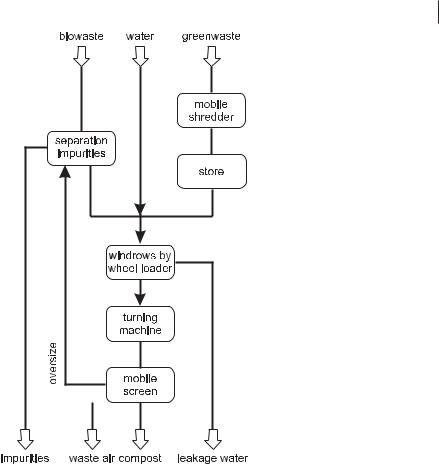

Fig. 13.11 Flow sheet of an open windrow composting plant.

•horizontal-flow reactors having

–a static solids bed or

–an agitated solids bed

•vertical-flow reactors

•rotating-drum reactors

With few exceptions, all reactors have a means of controlled forced aeration and enable the waste air and the drainage water to be collected and treated. Addition of water or other additives is possible only when the waste material is mixed in the reactor. If possible, composting processes are used only for precomposting, because of the high costs of reactor composting compared to windrow composting.

Horizontal-flow reactors with static solids bed: This is a batch system in which the waste material is loaded with a wheel loader or transport devices into a horizontal reactor or is covered by a foil or textile material. The forced aeration, in positive or neg-

348 13 Composting of Organic Waste

Fig. 13.12 Reactor composting systems.

ative mode or alternating, issues from pipes at the bottom of the material or from holes in the floor. The waste air, with its odor components and water, can be treated in a biofilter or biowasher. In some systems some of the waste air is recycled. The air flow rate can be controlled according to the temperature in the material or the oxygen/carbon dioxide concentration in the air. The retention time in the reactor is between several days (precomposting) and several weeks (mature compost). The end product can be inhomogeneous (partially too dry) and not biologically stabilized, because there is no turning/mixing and no water addition to the waste material and is forced aeration from only one direction.

Horizontal-flow reactors with agitated solids bed: In this reactor type the waste material can be turned mechanically and water can be added, in contrast to a horizon- tal-flow reactor with a static solids bed. The devices for mixing the wastes can be horizontally or vertically operating rotors or screws, scraper conveyors, or shovel wheels. Fully automated functioning of the whole process is possible.

Vertical-flow reactors: In this reactor type the waste material flows vertically, with or without stages, with mass flow from the top to the bottom as a plug flow system or, if the material from the outlet at the bottom is loaded back in at the top, as a mixed system. Forced aeration occurs from the bottom or from vertical pipes in the material. This process can also be run in a fully automated way.

13.6 Compost Quality 349

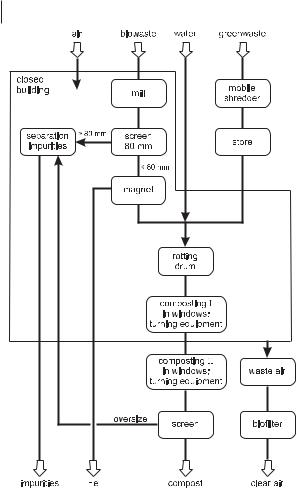

Fig. 13.13 Composting plant with rotting drum in closed shed [3].

Rotating-drum reactor: The waste material is loaded into a horizontal slowly rotating drum with forced aeration. The filling capacity is approximately 50%. The material is transported (plug flow) in the helical pathway from one end of the drum to the other and is mixed intensively. Self-heating starts after a short time. Water addition is possible. Rotating-drum reactors can also be used as mixing equipment.

An example of a composting plant with a rotating-drum reactor is shown in Figures 13.13 and 13.14. This plant is characterized by an enclosed building for receiving the biowaste, preparing it for the rotting process (disintegration, separation of impurities), pre-rotting in a drum, and main-rotting in turned windrows (composting I, Figure 13.14). All highly contaminated waste air can be collected and treated with a biofilter. Only the maturing phase of the compost (composting II, Figure 13.14) occurs under natural climatic conditions in windrows under a roof. In a fully enclosed composting plant, even the maturing phase takes place in a closed shed.

13.6

Compost Quality

To be used as a fertilizer and soil conditioner, compost must meet certain quality requirements, such as (1) optimal maturity, (2) favorable contents of nutrients and organic matter, (3) favorable C/N ratio, (4) neutral or alkaline pH, (5) low contents of heavy metals and organic contaminants, (6) no components that interfere with plant growth, (7) mostly free from impurities, (8) mostly free from germinatable seeds and living plant parts, (9) low content of rocks, (10) typical smell of forest soil, and (11) dark brown to black.

‘Maturity’ and ‘stability’ are different properties of compost. Stability is defined in terms of the bioavailability of organic matter, which relates to the rate of decompo-

350 13 Composting of Organic Waste

Fig. 13.14 Flow sheet of a composting plant with rotting drum in closed shed.

sition. Maturity describes the suitability of the compost for plant growth and has been associated with the degree of humification. Several methods are used in practice to determine maturity and stability: e.g., simple field tests in Dewar flasks, tests on plants, respiration activity, chemical analyses, nuclear magnetic resonance (NMR) [1 to 26]. The various procedures for determining the maturity and stability of compost are discussed in the literature; general, final tests have not been agreed upon.

Concerning the compost quality factors that relate to human health, such as the contents of heavy metals, hazardous organic compounds, parasites, and other disease organisms, several countries have passed laws, ordinances, regulations, and norms.

References

Section 13.1: Introduction

1DeBertoldi M (ed.), Compost: Production, Quality and Use. London 1987: Elsevier.

2Haug RT, The Practical Handbook of Composting. Boca Raton, FL 1993: Lewis.

3Thomé-Kozmiensky KJ (ed.), Biologische Abfallbehandlung. Berlin 1995: Erich Frei-

tag.

4White P, Franke M, Hindle P, Integrated Solid Waste Management: A Lifecycle Inventory. London 1995: Blackie.

5DeBertoldi M, Sequi P, Lemmes B, Papi T (eds.), The Science of Composting. London 1996: Blackie.

6Epstein E, The Science of Composting. Lancaster, Basel 1997: Technomic.

7Bidlingmaier W (ed.), Biologische Abfallverwertung. Stuttgart 2000: Ulmer.

8Insam H, Riddech N, Klammer S (eds.),

Microbiology of Composting. Berlin/Heidelberg 2002: Springer.

Section 13.2: Waste Materials for Composting

1Fricke K, Stellenwert der biologischen Abfallbehandlung in integrierten Entsorgungskonzepten, in: Biologische Verfahren der Abfallbehandlung (Dott W, Fricke K, Oetjen R, eds.), pp. 1–58. Berlin 1990: Erich Freitag Verlag.

2Fricke K, Turk T, Stand und Stellenwert der Kompostierung in der Abfallwirtschaft, in: Bioabfallkompostierung – Flächendeckende Einführung (Wiemer K, Kern M, eds.), pp. 13–98. Witzenhausen 1991: M.I.C. Baeza.

3Bidlingmaier W, Anlageninput und erzeugte Kompostqualität. in: Biologische Abfallbehandlung II (Wiemer K, Kern M., eds.), pp. 109–120. Witzenhausen 1995: M.I.C. Baeza

4Thomé-Kozmiensky KJ (ed.), Biologische Abfallbehandlung. Berlin 1995: Erich Freitag

5Schuchardt F, Composting of plant residues and waste plant materials. in: Bio- technology (Rehm HJ, Reed G, eds.) Vol. 11c: Environmental Processes III, pp. 101–125, Weinheim 2000: Wiley-VCH

References 351

Section 13.3: Fundamentals

of Composting Process

1Edwards CA, Neuhauser EF (eds.), Earth- worms in Waste and Environmental Management. The Hague 1988: SPB Academic

2Michel FC, Reddy CA, Effect of oxygenation level on yard trimmings composting

rate, odor production, and compost quality in bench-scale reactors. Compost Sci Util 1998, 6(4), 6–14

3Schaub-Szabo SM, Leonard JJ, Compost Sci Util 1999, 7(4), 15–24

4Shi W, Norton JM, Miller BE, et al., Appl Soil Ecol 1999, 11(1), 17–28

5Sommer SG, Dahl P, J Agric Eng Res 1999, 74(2), 145–153

6Van Ginkel JT, Raats PAC, Van Haneghem IA, Neth J Agric Sci 1999, 47(2), 105–121

7Chamuris GP, Koziol-Kotch S, Brouse TM,

Compost Sci Util 2000, 8(1), 6–11

8Dominguez J, Edwards CA, Webster M, Vermicomposting of sewage sludge: effect of bulking materials on the growth and reproduction of the earthworm Eisenia andrei. Pedobiologia 2000, 44(1), 24–32

9El-Din SMSB, Attia M, Abo-Sedera SA, Field assessment of composts produced by highly effective cellulolytic microorganisms. Biol Fert Soils 2000, 32(1), 35–40

10Kutzner HJ, Microbiology of composting. in: Biotechnology (Rehm HJ, Reed G. eds.)

Vol. 11c: Environmental Processes III,

pp 35–100, Weinheim 2000: Wiley-VCH

11Larney FJ, Olson AF, Carcamo AA et al., Physical changes during active and passive composting of beef feedlot manure in winter and summer. Bioresource Technol 2000,

75(2), 139–148

12Moller HB, Sommer SG, Andersen BH, Nitrogen mass balance in deep litter during the pig fattening cycle and during composting. J Agric Sci 2000, 135, 287–296

13Schuchardt F, Composting of plant residues and waste plant materials. in: Biotech- nology (Rehm HJ, Reed G eds.) Vol. 11c: Environmental Processes III, pp 101–125, Weinheim 2000: Wiley-VCH

14Amon B, Amon T, Boxberger J, et al., Emissions of NH3, N2O and CH4 from dairy cows housed in a farmyard manure tying stall (housing, manure storage, ma-

352 13 Composting of Organic Waste

nure spreading). Nutr Cycl Agroecosys

2001, 60, 103–113

15Beck-Friis B, Smars S, Jonsson H, et al., Gaseous emissions of carbon dioxide, ammonia and nitrous oxide from organic household waste in a compost reactor under different temperature regimes J Agric Eng Res 2001, 78, 423–430

16Elwell DL, Keener HM, Wiles MC, et al., T ASAE 2001, 44, 1307–1316

17Hao XY, Chang C, Larney FJ, et al., J Environ Qual 2001, 30, 376–386

18Hassen A, Belguith K, Jedidi N, et al., Microbial characterization during composting of municipal solid waste. Biore- source Technol 2001, 80, 217–225

19Huang GF, Wu QT, Li FB, et al., Nitrogen transformations during pig manure composting. J Environ Sci China 2001,

13, 401–405

20Ndegwa PM, Thompson SA, Integrating composting and vermicomposting in the treatment and bioconversion of biosolids. Bioresource Technol 2001, 76, 107–112

21Barrington S, Choiniere D, Trigu, M, et al., Effect of carbon source on compost nitrogen and carbon losses. Bioresource Technol 2002, 83(3), 189–194

22(Barrington S, Choiniere D, Trigui M, et al., Compost airflow resistance. Biosyst Eng 2002, 81, 433–441

23Hart TD, De Leij FAAM, Kinsey G, et al., Strategies for the isolation of cellulolytic fungi for composting of wheat straw.

World J Microb Biot 2002, 18, 471–480

24Jensen HEK, Leth M, Iversen JJL, Effect of compost age and concentration of pig slurry on plant growth. Compost Sci Util 2002, 10(2), 129–141

25Noble, R, Hobbs, PJ, Mead, A, et al., Influence of straw types and nitrogen sources on mushroom composting emissions and compost productivity. J Ind Microbiol Biot 2002, 29(3), 99–110

26Richard TL, Hamelers HVM, Veeken A, et al., Moisture relationships in composting processes. Compost Sci Util 2002, 10(4), 286–302

27Singh A, Sharma S, Composting of a crop residue through treatment with microorganisms and subsequent vermicomposting. Bioresource Technol 2002,

85(2), 107–111

28Tiquia SM, Tam NFY, Characterization and composting of poultry litter in forcedaeration piles. Process Biochem 2002, 37, 869–880

29Veeken A, de Wilde V, Hamelers B, Passively aerated composting of straw-rich pig manure: effect of compost bed porosity.

Compost Sci Util 2002, 10(2), 114–128

30Wolter M, Prayitno S, Schuchardt F, Comparison of greenhouse gas emissions from solid pig manure during storage versus during composting with respect to different dry matter contents. Landbauforsch Volk 2002, 52(3), 167–174

31Agnew JM, Leonard JJ, The physical properties of compost. Compost Sci Util 2003, 11, 238–264

32Barrington S, Choiniere D, Trigui M, Knight W, Compost convective airflow under passive aeration Bioresource Technol 2003, 86, 259–266

33Bolta SV, Mihelic R, Lobnik F, et al., Microbial community structure during composting with and without mass inocula.

Compost Sci Util 2003, 11, 6–15

34Fukumoto Y, Osada T, Hanajima D, Haga K, Patterns and quantities of NH3, N2O and CH4 emissions during swine manure composting without forced aeration: effect of compost pile scale. Bioresource Technol 2003, 89(2), 109–114

35Liang C, Das KC, McClendon RW, The influence of temperature and moisture contents regimes on the aerobic microbial activity of a biosolids composting blend. Bio- resource Technol 2003, 86(2), 131–137

36Principi P, Ranalli G, da Borso F, et al., Microbiological aspects of humid husk composting. J Environ Sci Heal B 2003, 38, 645–661

Section 13.4: Composting Technologies

1Schuchardt F, Composting of plant residues and waste plant materials. in: Biotech- nology (Rehm HJ, Reed G, eds.) Vol. 11c: Environmental Processes III, 101–125, Weinheim 2000: Wiley-VCH

Section 13.5: Composting Systems

1Haug RT, The Practical Handbook of Composting. Boca Raton, FL 1993: Lewis.

2Thomé-Kozmiensky KJ (ed.), Biologische Abfallbehandlung. Berlin 1995: Erich Freitag Verlag.

3Gronauer A, Claassen N, Ebertseder T et al., Bioabfallkompostierung. BayLfU 139 (1997)

4Bidlingmaier W (Ed.), Biologische Abfallverwertung. Stuttgart 2000: Ulmer Verlag

5Krogmann U, Körner I, Technology and strategies of composting. in: Biotechnolo- gy (Rehm HJ, Reed G, eds.) Vol. 11c: Environmental Processes III, pp 127–150, Weinheim 2000: Wiley-VCH

6Schuchardt F, Composting of plant residues and waste plant materials. in: Bio- technology (Rehm HJ, Reed G, eds.) Vol. 11c: Environmental Processes III, 101–125, Weinheim 2000: Wiley-VCH

Section 13.6: Compost Quality

1Adani F, Genevini PL, Gasperi F, Zorzi G, Organic matter evolution index (OMEI) as a measure of composting efficiency. Compost Sci Util 1997, 5(2), 53–62

2Popp L, Fischer P. Claassen N, Biolo- gisch-biochemische Methoden zur Reifebestimmung von Komposten. Agrobiol Res 1998, 51(3), 201–212

3Saharinen MH, Evaluation of changes in CEC during composting. Compost Sci Util 1998, 6(4), 29–37

4Fauci MF, Bezdicek DF, Caldwell D, et al., Compost Sci Util 1999, 7(2), 17–29

5Namkoong W, Hwang EY, Cheong JG, et al., Compost Sci Util 1999, 7(2), 55–62

6Warman PR, Compost Sci Util 1999, 7(3), 33–37

7Koenig A, Bari QH, Application of selfheating test for indirect estimation of respirometric activity of compost: theory and practice. Compost Sci Util 2000, 8(2), 99–107

8Ouatmane A, Provenzano MR, Hafidi M, et al., Compost Sci Util 2000, 8(2), 124–134

9Wu L, Ma LQ, Martinez GA, J Environ Qual 2000,. 29, 424–429

References 353

10Butler TA, Sikora LJ, Steinhilber PM, et al., Compost age and sample storage effects on maturity indicators of biosolids compost. J Environ Qual 2001, 30, 2141–2148

11Eggen T, Vethe O, Stability indices for different composts. Compost Sci Util 2001, 9(1), 19–26

12Provenzano MR, de Oliveira SC, Silva MRS, et al., Assessment of maturity degree of composts from domestic solid wastes by fluorescence and Fourier transform infrared spectroscopies. J Agric Food Chem 2001, 49, 5874–5879

13Smith DC, Hughes JC, A simple test to determine cellulolytic activity as indicator of compost maturity. Commun Soil Sci Plan

2001, 32, 1735–1749

14Levanon D, Pluda D, Chemical, physical and biological criteria for maturity in composts for organic farming. Compost Sci Util 2002, 10, 339–346

15Weppen P, Determining compost maturity: evaluation of analytical properties.

Compost Sci Util 2002, 10(1), 6–15

16Wu L, Ma LQ, Relationship between compost stability and extractable organic carbon. J Environ Qual 2002, 31, 1323–1328

17Adani F, Gigliotti G, Valentini F, Laraia R, Respiration index determination: a comparative study of different methods. Com- post Sci Util 2003, 11, 144–151

18Benito M, Masaguer A, Moliner A, Arrigo N, Palma RM, Chemical and microbiological parameters for the characterisation of the stability and maturity of pruning waste compost. Biol Fert Soils 2003, 37, 184–189

19Brewer LJ, Sullivan DM, Maturity and stability evaluation of composted yard trimmings. Compost Sci Util 2003, 11, 96–112

20Changa CM, Wang P, Watson ME, et al., Assessment of the reliability of a commercial maturity test kit for composted manures. Compost Sci Util 2003, 11, 125–143

21Chen YN, Nuclear magnetic resonance, in- fra-red and pyrolysis: application of spectroscopic methodologies to maturity determination of composts. Compost Sci Util 2003, 11, 152–168

22Chica A, Mohedo JJ, Martin MA, Martin A., Determination of the stability of MSW compost using a respirometric technique.

Compost Sci Util 2003, 11, 169–175

35413 Composting of Organic Waste

23 Cooperband LR, Stone AG, Fryda MR, Ravet JL., Relating compost measures of stability and maturity to plant growth.

Compost Sci Util 2003, 11, 113–124

24 Korner, I, Braukmeier, J, Herrenklage, J, et al., Investigation and optimization of composting processes: test systems and practical examples. Waste Manage 2003, 23, 17–26

25Rynk R, The art in the science of compost maturity. Compost Sci Util 2003, 11, 94–95

26Zubillaga MS, Lavado RS, Stability indexes of sewage sludge compost obtained with different proportions of a bulking agent.

Commun Soil Sci Plan 2003, 34, 581–591

355

14

Anaerobic Fermentation of Wet

and Semidry Garbage Waste Fractions

Norbert Rilling

14.1 Introduction

During the last 30 years the amount of solid wastes has rapidly increased. Now one of the primary aims in waste management is to reduce the amount of waste to be disposed by prevention, reduction, and utilization (KrW-/AbfG, 1994).

By means of separate collection and biological treatment of biowaste, the amount of municipal solid waste (MSW) to be incinerated or landfilled will be significantly reduced.

Biological treatment of garbage waste fractions can be carried out aerobically (composting) or anaerobically (anaerobic digestion). Each technique is appropriate for a certain spectrum of wastes. Today, most biological waste is composted because this technology is already well developed, with quite a lot of experience at hand, but anaerobic processes advance in their importance for the utilization of solid organic waste.

Anaerobic digestion, which is typically conducted inside a closed vessel in which the temperature and moisture are controlled, is particularly suited to wastes with a high moisture content and a high amount of readily biodegradable components. In Sections 14.2 and 14.3 the characteristics of the anaerobic process are discussed with respect to their ecological and economical aspects.

14.2

Basic Aspects of Biological Waste Treatment

The leading aim of separate collection and treatment of biological wastes is stabilization of the waste by microbial degradation. The product is a compost that, if its pollutant content is low, can be used as a fertilizer or soil conditioner and thus be fed back into the natural cycle.

In contrast to the commonly established composting processes, the technique of anaerobic fermentation of waste is relatively young and dynamic. With great scien-

Environmental Biotechnology. Concepts and Applications. Edited by H.-J. Jördening and J. Winter Copyright © 2005 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

ISBN: 3-527-30585-8