s90mec7

.pdf

MAN B&W |

18.04 |

|

|

|

Page of 7 |

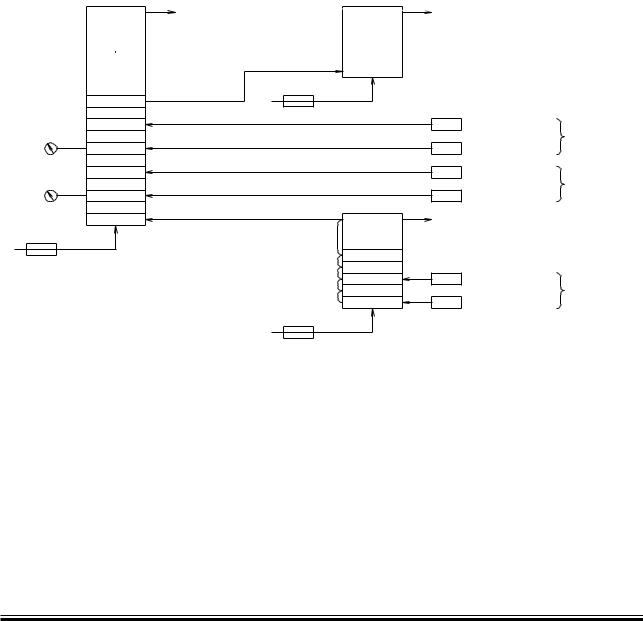

General outline of the electrical system

The figure shows the concept approved by all classification societies.

The shut down panel and slow down panel can be combined for some makers.

The classification societies permit having common sensors for slow down, alarm and remote indication.

One common power supply might be used, instead of the three indicated, provided that the systems are equipped with separate fuses.

/UTPUTæSIGNALS |

/UTPUTæSIGNALS |

3LOWæDOWNæPANEL |

|

|

AND |

!LARM |

3LOWæDOWN |

3HUTæDOWNæPANEL |

/PTION |

||

PANEL |

PANEL |

æ æ |

9ARDæS |

|

OR |

SUPPLY |

|

æ æ |

|

|

OR |

|

0OWERæSUPPLYæ |

æ æ |

|

|

|

|

"INARYæSENSOR |

2EQUIREDæBY |

2EMOTE |

CLASSIFICATIONæ |

|

INDICATION |

|

SOCIETYæAND |

|

!NALOGæSENSOR |

-!.æ$IESEL |

|

OPTION æ æ æ |

|

|

|

|

|

"INARYæSENSOR |

!DDITIONALæSENSORS |

|

OPTION |

|

|

|

|

|

|

æ æ |

|

!NALOGæSENSOR |

OR |

|

|

æ æ |

|

/UTPUTæSIGNALS |

|

|

3HUTæDOWN |

|

0OWERæSUPPLYæ |

PANEL |

|

|

"INARYæSENSORS |

)NCLUDEDæIN |

|

|

|

|

!NALOGæSENSORS |

OPTION æ æ æ |

|

|

|

|

0OWERæSUPPLYæ |

|

|

|

178 30 10 0.5 |

Fig. 18.04.01: Panels and sensors for alarm and safety systems

MAN B&W ME/ME C/ME GI/ME-B engines

MAN Diesel |

198 45 83 8.4 |

|

MAN B&W |

18.04 |

|

|

|

Page of 7 |

Alarms for UMS – Class and MAN Diesel requirements

ABS |

BV |

CCS |

DNV |

GL |

KR |

LR |

NK |

RINA |

RS |

IACS |

MAN Diesel |

Sensor and |

|

function |

Point of location |

|

Fuel oil |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

PT 8001 AL |

Fuel oil, inlet engine |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

LS 8006 AH |

Leakage from high pressure pipes |

|

|

|

|

|

|

|

|

|

|

|

|

|

Lubricating oil |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

|

1 |

1 |

1 |

1 |

PT 8103 AL |

Lubricating oil inlet to turbocharger/turbocharger |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

TE 8106 AH |

Thrust bearing segment |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

PT 8108 AL |

Lubricating oil inlet to main engine |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

TE 8112 AH |

Lubricating oil inlet to main engine |

1 |

1 |

1 |

1 |

1 |

1 |

|

1 |

1 |

1 |

1 |

1 |

TE 8113 AH |

Piston cooling oil outlet/cylinder |

1 |

1 |

1 |

1 |

1 |

1 |

|

1 |

1 |

1 |

1 |

1 |

FS 8114 AL |

Piston cooling oil outlet/cylinder |

1 |

1 |

1 |

|

1 |

1 |

1 |

|

1 |

1 |

1 |

1 |

TE 8117 AH |

Turbocharger lubricating oil outlet from |

|

|

|

|

|

|

|

|

|

|

|

|

|

turbocharger/turbocharger 2) |

|

|

|

|

|

|

|

|

|

|

|

1 |

TE 8123 AH |

Main bearing oil outlet temperature/main bearing |

|

|

|

|

|

|

|

|

|

|

|

|

|

(S40/35ME-B9 only) |

|

|

|

|

|

|

|

|

|

|

|

1 |

XC 8126 AH |

Bearing wear (All types except S40/35ME-B9) |

|

|

|

|

|

|

|

|

|

|

|

1 |

XS 8127 A |

Bearing wear detector failure (All types except S50- |

|

|

|

|

|

|

|

|

|

|

|

|

|

35ME-B) |

|

|

1 |

|

1 |

|

1 |

1 |

|

|

|

1 |

PDS8140AH |

Lubricating oil differential pressure – cross filter |

|

|

|

|

|

|

|

|

|

|

|

1 |

XS 8150 AH |

Water in lubricating oil |

|

|

|

|

|

|

|

|

|

|

|

1 |

XS 8151 AH |

Water in lubricating oil – too high |

|

|

|

|

|

|

|

|

|

|

|

1 |

XS 8152 A |

Water in lubricating oil sensor not ready |

1Indicates that the sensor is required.

The sensors in the MAN Diesel column are included for Unattended Machinery Spaces (UMS), option: 4 75 127, subject to class requirements and will be finally specified in the Guidance Values Automation for the specific engine plant.

The sensor identification codes and functions are listed in Table 18.07.01.

The tables are liable to change without notice, and are subject to latest class requirements.

2) For turbochargers with slide bearings

Table 18.04.02a: Alarm functions for UMS

MAN B&W ME/ME C/ME GI/ME-B engines

MAN Diesel |

198 45 83 8.4 |

|

MAN B&W |

18.04 |

|

|

|

Page of 7 |

Alarms for UMS – Class and MAN Diesel requirements

ABS |

BV |

CCS |

DNV |

GL |

KR |

LR |

NK |

RINA |

RS |

IACS |

MAN Diesel |

Sensor and |

|

function |

Point of location |

|

Hydraulic Power Supply |

|

|

|

|

|

|

|

|

|

|

|

|

1 |

XC 1231 A |

Automatic main lube oil filter, failure (Boll & Kirch) |

|

|

|

1 |

|

|

|

|

|

|

|

|

1 |

LS 1235 AH |

Leakage oil from hydraulic pipes |

|

|

|

|

|

|

|

|

|

|

|

|

1 |

LS 1236 AH |

Leakage oil from hydraulic power supply unit |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cooling water |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

PT 8401 AL |

Jacket cooling water inlet |

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

PDS/PDT |

Jacket cooling water across engine; to be calculated |

|

|

|

|

|

|

|

|

|

|

|

|

|

8403 AL |

in alarm system from sensor no. 8402 and 8413 |

|

|

|

|

1 |

|

|

|

|

|

|

|

1 |

TE 8407 AL |

Jacket cooling water inlet |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

TE 8408 AH |

Jacket cooling water outlet, cylinder |

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

PT 8413 I |

Jacket cooling water outlet, common pipe |

1 |

1 |

1 |

|

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

PT 8421 AL |

Cooling water inlet air cooler |

|

|

|

|

|

1 |

|

|

|

|

|

|

|

1 |

TE 8422 AH |

Cooling water inlet air cooler/air cooler |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Compressed air |

1 |

1 |

1 |

|

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

PT 8501 AL |

Starting air inlet to main starting valve |

|

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1+ |

1 |

1 |

1 |

PT 8503 AL |

Control air inlet and finished with engine |

|

|

|

|

1 |

|

|

|

|

|

|

|

|

1 |

PT 8505 AL |

Air inlet to air cylinder for exhaust valve |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Scavenge air |

|

|

|

|

1 |

|

|

|

|

|

1 |

|

1 |

PS 8604 AL |

Scavenge air, auxiliary blower, failure (Only ME-B) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

1 |

|

1 |

|

|

1÷ |

|

|

|

1 |

TE 8609 AH |

Scavenge air receiver |

|

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

TE 8610 AH |

Scavenge air box – fire alarm, cylinder/cylinder |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

1 |

1 |

|

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

LS 8611 AH |

Water mist catcher – water level |

|

1Indicates that the sensor is required.

The sensors in the MAN Diesel column are included for Unattended Machinery Spaces (UMS), option: 4 75 127, subject to class requirements and will be finally specified in the Guidance Values Automation for the specific engine plant.

The sensor identification codes and functions are listed in Table 18.07.01.

The tables are liable to change without notice, and are subject to latest class requirements. Select one of the alternatives

+Alarm for high pressure, too

÷Alarm for low pressure, too

Table 18.04.02b: Alarm functions for UMS

MAN B&W ME/ME C/ME GI/ME-B engines

MAN Diesel |

198 45 83 8.4 |

|

MAN B&W |

18.04 |

|

|

|

Page of 7 |

Alarms for UMS – Class and MAN Diesel requirements

ABS |

BV |

CCS |

DNV |

GL |

KR |

LR |

NK |

RINA |

RS |

IACS |

MAN Diesel |

Sensor and |

|

function |

Point of location |

|

Exhaust gas |

1 |

1 |

1 |

1 |

1 |

1 |

(1) |

1 |

1 |

1 |

1 |

1 |

1 |

|

1 |

|

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1

1

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

|

1 |

|

|

|

|

|

|

|

|

1 |

TC 8701 AH |

Exhaust gas before turbocharger/turbocharger |

1 |

TC 8702 AH |

Exhaust gas after exhaust valve, cylinder/cylinder |

|

TC 8707 AH |

Exhaust gas outlet turbocharger/turbocharger (Yard’s |

|

supply) |

|

|

|

Miscellaneous |

|

ZT 8801 AH |

Turbocharger overspeed |

|

WT 8805 AH |

Vibration of turbocharger |

1 |

WT 8812 AH |

Axial vibration monitor 2) |

1 |

XS 8813 AH |

Oil mist in crankcase/cylinder |

1 |

XS 8814 AL |

Oil mist detector failure |

1 |

XC 8816 I |

Shaftline earthing device |

|

|

|

|

|

|

|

|

|

|

|

|

Engine Control System |

1 |

1 |

1 |

1 |

1 |

1 1 |

1 |

1 |

1 |

1 |

1 |

XC 2201 A |

Power failure |

1 |

1 |

|

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

XC 2202 A |

ME common failure |

1Indicates that the sensor is required.

The sensors in the MAN Diesel column are included for Unattended Machinery Spaces (UMS), option: 4 75 127, subject to class requirements and will be finally specified in the Guidance Values Automation for the specific engine plant.

The sensor identification codes and functions are listed in Table 18.07.01.

The tables are liable to change without notice, and are subject to latest class requirements.

(1) May be combined with TC 8702 AH where turbocharger is mounted directly on the exhaust manifold.

2) Required for: K-ME-C6/7 and K98ME6/7 engines with 11 and 14 cylinders. S-ME-C7/8, S-ME-GI7/8, and L-ME-C7/8 engines with 5 and 6 cylinders. S-ME-B8/9 engines with 5 and 6 cylinders mainly.

(For K90ME9, K/S-ME-C9, and S50ME-B9 data is available on request).

Alarm for overheating of main, crank and crosshead bearings, option: 4 75 134.

Alarm for overheating of main, crank and crosshead bearings, option: 4 75 134.

Table 18.04.02c: Alarm functions for UMS

MAN B&W ME/ME C/ME GI/ME-B engines

MAN Diesel |

198 45 83 8.4 |

|

MAN B&W |

18.04 |

|

|

|

Page of 7 |

Slow down for UMS – Class and MAN Diesel requirements

ABS |

BV |

CCS |

DNV |

GL |

KR |

LR |

NK |

RINA |

RS |

IACS |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1* |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

|

|

|

|

1 |

|

1 |

|

|

|

|

1 |

1 |

1 |

1 |

1 |

1 |

|

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

|

1 |

1 |

1 |

1 |

Diesel |

|

|

MAN |

Sensor and |

|

function |

Point of location |

|

1 |

TE 8106 YH |

Thrust bearing segment |

1 |

PT 8108 YL |

Lubricating oil inlet to main engine |

|

TE 8112 YH |

Lubricating oil inlet to main engine |

1 |

TE 8113 YH |

Piston cooling oil outlet/cylinder |

1 |

FS 8114 YL |

Piston cooling oil outlet/cylinder |

1 |

TE 8123 YH |

Main bearing oil outlet temperature/main bearing |

|

|

(S40/35ME-B9 only) |

1 |

XC 8126 YH |

Bearing wear (All except S40/35ME-B9) |

1 |

1 |

1 |

1 |

|

1 |

1 |

1 |

1 |

1 |

1 |

1 |

PT 8401 YL |

Jacket cooling water inlet |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

TE 8408 YH |

Jacket cooling water outlet, cylinder/cylinder |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

1 |

|

|

|

|

1 |

|

|

|

|

TE 8609 YH |

Scavenge air receiver |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

TE 8610 YH |

Scavenge air box fire-alarm, cylinder/cylinder |

|

|

1 |

1 |

|

|

|

|

|

1 |

|

|

TC 8701 YH |

Exhaust gas before turbocharger/turbocharger |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

1 |

|

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

TC 8702 YH |

Exhaust gas after exhaust valve, cylinder/cylinder |

|

|

|

1 |

1 |

|

|

|

|

|

|

|

TC 8702 YH |

Exhaust gas after exhaust valve, cylinder/cylinder, |

|

|

|

|

|

|

|

|

|

|

|

|

|

deviation from average |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

WT 8812 YH |

Axial vibration monitor 2) |

1 |

1 |

|

1* |

|

1 |

1 |

1 |

1 |

1 |

1 |

1 |

XS 8813 YH |

Oil mist in crankcase/cylinder |

1Indicates that the sensor is required.

The sensors in the MAN Diesel column are included for Unattended Machinery Spaces (UMS), option: 4 75 127, subject to class requirements and will be finally specified in the Guidance Values Automation for the specific engine plant.

The sensor identification codes and functions are listed in Table 18.07.01.

The tables are liable to change without notice, and are subject to latest class requirements.

2)Required for: K-ME-C6/7 and K98ME6/7 engines with 11 and 14 cylinders.

S-ME-C7/8, S-ME-GI7/8, and L-ME-C7/8 engines with 5 and 6 cylinders. S-ME-B8/9 engines with 5 and 6 cylinders mainly.

(For K90ME9, K/S-ME-C9, and S50ME-B9 data is available on request).

Select one of the alternatives |

* |

Or shut down |

Or alarm for low flow |

* |

Or shut down |

Or alarm for overheating of main, crank and crosshead bearings, option: 4 75 134. See also Table 18.04.04: Shut down functions for AMS and UMS

Or alarm for overheating of main, crank and crosshead bearings, option: 4 75 134. See also Table 18.04.04: Shut down functions for AMS and UMS

Table 18.04.03: Slow down functions for UMS

MAN B&W ME/ME C/ME GI/ME-B engines

MAN Diesel |

198 45 83 8.4 |

|

MAN B&W |

18.04 |

|

|

|

Page of 7 |

Shut down for AMS and UMS – Class and MAN Diesel requirements

ABS |

BV |

CCS |

DNV |

GL |

KR |

LR |

1 |

1 |

1 |

1* |

1 |

1 |

1 |

1 |

1 |

1 |

1* |

1 |

1 |

1 |

1 |

1 |

1 |

|

|

1 |

|

|

|

|

|

1 |

|

|

|

|

|

* |

1 |

|

|

NK |

RINA |

RS |

IACS |

Diesel |

function |

Point of location |

MAN |

||||||

|

|

|

|

|

Sensor and |

|

1 |

1 |

1 |

1 |

1 |

PS/PT 8109 Z |

Lubricating oil inlet to main engine and thrust |

|

|

|

|

|

|

bearing |

1 |

1 |

1 |

1 |

1 |

ZT 4020 Z |

Engine overspeed |

|

1 |

1 |

1 |

1 |

TE/TS 8107 Z |

Thrust bearing segment |

|

|

|

|

|

PS/PT 8402 Z |

Jacket cooling water inlet |

|

|

|

|

|

XS 8813 Z |

Oil mist in crankcase/cylinder |

1Indicates that the sensor is required.

The sensors in the MAN Diesel column are included for Unattended Machinery Spaces (UMS), option: 4 75 127, subject to class requirements and will be finally specified in the Guidance Values Automation for the specific engine plant.

The sensor identification codes and functions are listed in Table 18.07.01.

The tables are liable to change without notice, and are subject to latest class requirements.

Or alarm for overheating of main, crank and crosshead bearings, option: 4 75 134.

Or alarm for overheating of main, crank and crosshead bearings, option: 4 75 134.

See also Table 18.04.03: Slow down functions for UMS

*Or slow down

International Association of Classification Societies

The members of the International Association of Classification Societies, IACS, have agreed that the stated sensors are their common recommendation, apart from each class’ requirements.

The members of IACS are:

ABS |

American Bureau of Shipping |

BV |

Bureau Veritas |

CCS |

China Classification Society |

DNV |

Det Norske Veritas |

GL |

Germanischer Lloyd |

KR |

Korean Register |

LR |

Lloyd’s Register |

NK |

Nippon Kaiji Kyokai |

RINA |

Registro Italiano Navale |

RS |

Russian Maritime Register of Shipping |

and the assosiated member is: |

|

IRS |

Indian Register of Shipping |

Table 18.04.04: Shut down functions for AMS and UMS, option: 4 75 124

MAN B&W ME/ME C/ME GI/ME-B engines

MAN Diesel |

198 45 83 8.4 |

|

MAN B&W |

18.05 |

|

|

|

Page of 3 |

Local Instruments

The basic local instrumentation on the engine, options: 4 70 119 comprises thermometers, pressure gauges and other indicators located on the piping or mounted on panels on the engine. The tables 18.05.01a, b and c list those as well as sensors for slow down, alarm and remote indication, option: 4 75 127.

Local instruments |

Remote sensors |

Point of location |

Thermometer, |

Temperature |

|

stem type |

element/switch |

|

|

|

Hydraulic power supply |

|

TE 1270 |

HPS bearing temperature (Only 98ME/ME-C) |

|

|

Fuel oil |

TI 8005 |

TE 8005 |

Fuel oil, inlet engine |

|

|

Lubricating oil |

TI 8106 |

TE 8106 |

Thrust bearing segment |

|

TE/TS 8107 |

Thrust bearing segment |

TI 8112 |

TE 8112 |

Lubricating oil inlet to main engine |

TI 8113 |

TE 8113 |

Piston cooling oil outlet/cylinder |

TI 8117 |

TE 8117 |

Lubricating oil outlet from turbocharger/turbocharger |

|

|

(depends on turbocharger design) |

|

TE 8123 |

Main bearing oil outlet temperature/main bearing (S40/35ME-B9 only) |

|

|

Cylinder lubricating oil |

|

TE 8202 |

Cylinder lubricating oil inlet |

|

TS 8213 |

Cylinder lubricating heating |

|

|

High temperature cooling water, jacket cooling water |

TI 8407 |

TE 8407 |

Jacket cooling water inlet |

TI 8408 |

TE 8408 |

Jacket cooling water outlet, cylinder/cylinder |

TI 8409 |

TE 8409 |

Jacket cooling water outlet/turbocharger |

|

|

Low temperature cooling water, seawater or freshwater for central cooling |

TI 8422 |

TE 8422 |

Cooling water inlet, air cooler |

TI 8423 |

TE 8423 |

Cooling water outlet, air cooler/air cooler |

|

|

Scavenge air |

TI 8605 |

TE 8605 |

Scavenge air before air cooler/air cooler |

TI 8608 |

TE 8608 |

Scavenge air after air cooler/air cooler |

TI 8609 |

TE 8609 |

Scavenge air receiver |

|

TE 8610 |

Scavenge air box – fire alarm, cylinder/cylinder |

Thermometer, |

Thermo couple |

|

dial type |

|

|

|

|

Exhaust gas |

TI 8701 |

TC 8701 |

Exhaust gas before turbocharger/turbocharger |

TI 8702 |

TC 8702 |

Exhaust gas after exhaust valve, cylinder/cylinder |

|

TC 8704 |

Exhaust gas inlet exhaust gas receiver |

TI 8707 |

TC 8707 |

Exhaust gas outlet turbocharger |

Table 18.05.01a: Local thermometers on engine, options 4 70 119, and remote indication sensors, option: 4 75 127

MAN B&W ME/ME-B/ME C/ME GI engines

MAN Diesel |

198 45 86 3.4 |

|

MAN B&W |

18.05 |

|

|

|

Page of 3 |

Local instruments |

Remote sensors |

Point of location |

Pressure gauge |

Pressure |

|

(manometer) |

transmitter/switch |

|

|

|

Fuel oil |

PI 8001 |

PT 8001 |

Fuel oil, inlet engine |

|

|

Lubricating oil |

PI 8103 |

PT 8103 |

Lubricating oil inlet to turbocharger/turbocharger |

PI 8108 |

PT 8108 |

Lubricating oil inlet to main engine |

|

PS/PT 8109 |

Lubricating oil inlet to main engine and thrust bearing |

|

PDS 8140 |

Lubricating oil differential pressure – cross filter |

|

|

High temperature jacket cooling water, jacket cooling water |

PI 8401 |

PT 8401 |

Jacket cooling water inlet |

|

PS/PT 8402 |

Jacket cooling water inlet (Only Germanischer Lloyd) |

|

PDS/PDT 8403 |

Jacket cooling water across engine |

|

PT 8413 |

Jacket cooling water outlet, common pipe |

|

|

Low temperature cooling water, seawater or freshwater for central cooling |

PI 8421 |

PT 8421 |

Cooling water inlet, air cooler |

|

|

Compressed air |

PI 8501 |

PT 8501 |

Starting air inlet to main starting valve |

PI 8503 |

PT 8503 |

Control air inlet |

|

PT 8505 |

Air inlet to air cylinder for exhaust valve |

|

|

Scavenge air |

PI 8601 |

PT 8601 |

Scavenge air receiver (PI 8601 instrument same as PI 8706) |

PDI 8606 |

PDT 8606 |

Pressure drop of air across cooler/air cooler |

|

PDT 8607 |

Pressure drop across blower filter of turbocharger (ABB turbochargers only) |

PI 8613 |

|

Pressure compressor spiral housing/turbocharger |

PDI 8614 |

|

Pressure drop across compressor spiral housing |

|

|

Exhaust gas |

PI 8706 |

|

Exhaust gas receiver/Exhaust gas outlet turbocharger |

|

|

Miscellaneous functions |

PI 8803 |

|

Air inlet for dry cleaning of turbocharger |

PI 8804 |

|

Water inlet for cleaning of turbocharger |

Table 18.05.01b: Local pressure gauges on engine, options: 4 70 119, and remote indication sensors, option: 4 75 127

MAN B&W ME/ME-B/ME C/ME GI engines

MAN Diesel |

198 45 86 3.4 |

|

MAN B&W |

18.05 |

|

|

|

Page of 3 |

Local instruments |

Remote sensors |

Point of location |

Other indicators |

Other transmitters/ |

|

|

switches |

|

|

|

Hydraulic power supply |

|

XC 1231 |

Automatic main lube oil filter, failure (Boll & Kirch) |

|

LS 1235 |

Leakage oil from hydraulic system |

|

LS 1236 |

Leakage oil from hydraulic system |

|

|

Engine cylinder components |

|

LS 4112 |

Leakage from hydraulic cylinder unit |

|

|

Fuel oil |

|

LS 8006 |

Leakage from high pressure pipes |

|

|

Lubricating oil |

|

FS 8114 |

Piston cooling oil outlet/cylinder |

|

XC 8126 |

Bearing wear (All types except S40/35ME-B9) |

|

XS 8127 |

Bearing wear detector failure (All types except S50-35ME-B) |

|

XS 8150 |

Water in lubricating oil |

|

XS 8151 |

Water in lubricating oil – too high |

|

XS 8152 |

Water in lubricating oil sensor not ready |

|

|

Cylinder lube oil |

|

LS 8208 |

Level switch |

|

|

Scavenge air |

|

LS 8611 |

Water mist catcher – water level |

|

|

Miscellaneous functions |

|

ZT 8801 I |

Turbocharger speed/turbocharger |

WI 8812 |

WT 8812 |

Axial vibration monitor (For certain engines only, see note in Table 18.04.04) |

|

|

(WI 8812 instrument is part of the transmitter WT 8812) |

|

XS 8813 |

Oil mist in crankcase/cylinder |

|

XS 8814 |

Oil mist detector failure |

|

XC 8816 |

Shaftline earthing device |

Table 18.05.01c: Other indicators on engine, options: 4 70 119, and remote indication sensors, option: 4 75 127

MAN B&W ME/ME-B/ME C/ME GI engines

MAN Diesel |

198 45 86 3.4 |

|

MAN B&W |

18.06 |

|

|

Other Alarm Functions

Drain Box for Fuel Oil Leakage Alarm

Any leakage from the fuel oil high pressure pipes of any cylinder is drained to a common drain box fitted with a level alarm. This is included for both AMS and UMS.

Bearing Condition Monitoring

Based on our experience we decided in 1990 that all plants, whether constructed for Attended Machinery Space (AMS) or for Unattended Machinery Space (UMS), must include an oil mist detector specified by MAN Diesel. Since then an Oil Mist Detector (OMD) and optionally some extent of Bearing Temperature Monitoring (BTM) equipment have made up the warning arrangements for prevention of crankcase explosions on two-stroke engines. Both warning systems are approved by the classification societies.

In order to achieve a response to damage faster than possible with Oil Mist Detection and Bearing Temperature Monitoring alone we introduce Bearing Wear Monitoring (BWM) systems. By monitoring the actual bearing wear continuously, mechanical damage to the crank-train bearings (main-, crankand crosshead bearings) can be predicted in time to react and avoid damaging the journal and bearing housing.

If the oil supply to a main bearing fails, the bearing temperature will rise and in such a case a Bearing Temperature Monitoring system will trigger an alarm before wear actually takes place. For that reason the ultimate protection against severe bearing damage and the optimum way of providing early warning, is a combined bearing wear and temperature monitoring system.

For all types of error situations detected by the different bearing condition monitoring systems applies that in addition to damaging the components, in extreme cases, a risk of a crankcase explosion exists.

Page of 5

Oil Mist Detector

The oil mist detector system constantly measures samples of the atmosphere in the crankcase compartments and registers the results on an optical measuring track, where the opacity (degree of haziness) is compared with the opacity of the atmospheric air. If an increased difference is recorded, a slow down is activated (a shut down in case of Germanischer Lloyd).

Furthermore, for shop trials only MAN Diesel requires that the oil mist detector is connected to the shut down system.

Four alternative oil mist detectors are available:

4 75 161 |

Oil mist detector Graviner MK6. |

|

Make: Kidde Fire Protection |

|

|

4 75 163 |

Oil mist detector Visatron VN 215/93. |

|

Make: Schaller Automation |

|

|

4 75 165 |

Oil mist detector QMI. |

|

Make: Quality Monitoring Instruments Ltd |

|

|

4 75 166 |

Oil mist detector MD-SX. |

|

Make: Daihatsu Diesel Mfg. Co., Ltd |

|

|

Diagrams of the two of them are shown for reference in Figs. 18.06.01a and 18.06.01b.

MAN B&W ME/ME C/ME GI/ME-B engines

MAN Diesel |

198 45 87 5.5 |

|