- •Главная

- •1.1 Напряжений и концентраторы

- •1.1.3 Концентраторы напряжения

- •1.3 Stress concentration factor

- •1.7 Elastic-plastic stress concentration

- •1.8 Joints: bolts and welds

- •3. Механические свойства конструкционных материалов

- •3.1 Напряженности испытания

- •3.2 Stress - strain diagram

- •3.3 Testing schemes

- •3.4 Strength

- •4 Прочность материалов

- •4.1 Tension and compression

- •4.2 Shear and torsion

- •4.3 Stress-strain state

- •4.4 Bending: force and moment diagrams

- •4.5 Geometrical characteristics of sections

- •4.6 Bending: stress and deformation

- •4.7 Mixed mode loading

- •4.8 Buckling

- •4.9 Statically indeterminate systems

- •4.10 Three-dimensional structures

- •References

- •5. Theory of elasticity

- •5.1 Deformation

- •5.2 Stress

- •5.3 Hooke's law

- •5.4 Plane problems

- •5.5 Torsion

- •5.6 Bending

- •5.7 Polar coordinates

- •5.8 Plates

- •5.9 Shells

- •5.10 Contact stresses

- •6.2 Distribution functions

- •6.3 Structural models of reliability

- •6.4 Limiting state

- •6.5 Dispersion

- •6.6 Durabilty

- •6.7 Design by reliability criterion

- •6.8 Risk

- •6.9 Safety classes

- •6.10 Risk : structural and social

- •References

- •7 Materials science

- •7.1 Crystalline solids

- •7.2 Mechanical properties

- •7.3 Failure

- •7.4 Phase diagrams

- •7.5 Heat treatment of metals and alloys

- •7.6 Corrosion of metals and alloys

- •7.7 Casting

- •7.8 Polymers

- •7.9 Composites

- •7.10 Forming of metals

- •8.2 Mechanical properties

- •8.3 Stress concentration

- •8.4 Defects

- •8.5 Residual Stress

- •8.6 Strength

- •8.7 Fatigue strength

- •8.8 Fracture

- •8.9 Weldability

- •References

- •9 Composites

- •9.1 Structure of composites

- •9.2 Fibers

- •9.3 Rigidity

- •9.4 Strength

- •9.5 Crack resistance

- •9.6 Optimization

- •9.7 Fatigue and temperature effect

- •9.8 Reliability

- •9.9 Joints

- •9.10 Material selection

- •References

- •10 Finite element analysis

- •10.1 Finite element method

- •10.2 Finite elements

- •10.3 Meshing

- •10.4 Boundary conditions

- •10.5 Deformation

- •10.6 Accuracy

- •10.7 Heat transfer analysis

- •10.8 Dynamics

- •10.9 Computational fluid dynamics

- •10.10 Design analysis

- •References

6.4 Limiting state

If

the probability density functions for strength and stress of a

structure are described by normal functions with known means mi and

standard deviation Di

the probability density function for difference in strength and

stress is also a normal distribution.

If

the probability density functions for strength and stress of a

structure are described by normal functions with known means mi and

standard deviation Di

the probability density function for difference in strength and

stress is also a normal distribution.

The

reliability is equal to 0.5 if the means of the distributions

coincide. It is larger than 0.5 if the mean for stress is smaller

than for strength.

The

reliability is equal to 0.5 if the means of the distributions

coincide. It is larger than 0.5 if the mean for stress is smaller

than for strength.

The

summed area under a density function is equal to 1.

The

probability of failure is equal to the integral over the range where

both functions f(s) and F'(s) are nonzero.

The

summed area under a density function is equal to 1.

The

probability of failure is equal to the integral over the range where

both functions f(s) and F'(s) are nonzero.

The

summation is over three intervals. The probability of failure of a

structure is 0.09 and its reliability is 0.91.

The

summation is over three intervals. The probability of failure of a

structure is 0.09 and its reliability is 0.91.

Engineering

changes can alter the positions of the probability density

functions.

A. Cross section area increase results in a

stress decrease.

B. Stress concentration results in a stress

increase.

C. Service in low temperatures results in brittle

fracture (strength decrease).

D. Heat treatment of welded joints

results in residual stress decrease (strength increase).

Engineering

changes can alter the positions of the probability density

functions.

A. Cross section area increase results in a

stress decrease.

B. Stress concentration results in a stress

increase.

C. Service in low temperatures results in brittle

fracture (strength decrease).

D. Heat treatment of welded joints

results in residual stress decrease (strength increase).

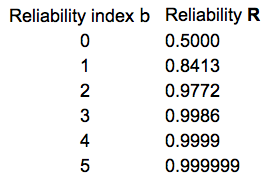

The

reliability index is a measure of the reliability of a structure. The

minimum reliability index of structural components corresponds to the

reliability index of the whole structure. The smaller the reliability

index bi, the more probable the failure.

The

reliability index is a measure of the reliability of a structure. The

minimum reliability index of structural components corresponds to the

reliability index of the whole structure. The smaller the reliability

index bi, the more probable the failure.

6.5 Dispersion

The

histogram shows how many specimens have strength in the corresponding

intervals. The experimental data and corresponding analytical

distributions can be characterized by mean value ms

and standard deviation Ds.

The standard deviation is expressed in terms of the same units of

measurement as the variable.

m

The

histogram shows how many specimens have strength in the corresponding

intervals. The experimental data and corresponding analytical

distributions can be characterized by mean value ms

and standard deviation Ds.

The standard deviation is expressed in terms of the same units of

measurement as the variable.

m

The

standard deviation does not depend on number of tests N if the number

is large. The shapes of the two histograms are similar.

The

standard deviations are approximately equal for both examples.

The

standard deviation does not depend on number of tests N if the number

is large. The shapes of the two histograms are similar.

The

standard deviations are approximately equal for both examples.

All

distributions (exponential A, uniform B, normal C and D) correspond

to the mean ms=200 MPa.

The areas under the curves are equal.

The larger part of the area is placed far from the mean, the

bigger standard deviation Ds:

All

distributions (exponential A, uniform B, normal C and D) correspond

to the mean ms=200 MPa.

The areas under the curves are equal.

The larger part of the area is placed far from the mean, the

bigger standard deviation Ds:

Ds(A) > Ds(B) > Ds(C) > Ds(D)

The

mean of the safety margin is equal to ratio of the means for strength

and stress:

mg = 40 / 20 = 2.0

There is probability

of failure for the structure

The

mean of the safety margin is equal to ratio of the means for strength

and stress:

mg = 40 / 20 = 2.0

There is probability

of failure for the structure

P(g) > 0 if g < 1 .

The

reliability index helps to compare two variants. If the acting stress

is constant (s = 180 MPa) the reliability index depends on variation

parameters of strength. The bigger the reliability index, the bigger

the reliability of the structure.

The

reliability index helps to compare two variants. If the acting stress

is constant (s = 180 MPa) the reliability index depends on variation

parameters of strength. The bigger the reliability index, the bigger

the reliability of the structure.

As

result of damage growth in a heat exchanger, the strength of the

material decreases by 10%. To keep the initial reliability the

engineers decrease the stress due to vapor pressure by 20% after 10

years of service. In this case the reliability index is equal for

both time t=0 and t=10 years.

t = 0 year : Dm = 200 - 100

= 100 MPa.

t = 10 years : Dm = 180 - 80 = 100 MPa.

As

result of damage growth in a heat exchanger, the strength of the

material decreases by 10%. To keep the initial reliability the

engineers decrease the stress due to vapor pressure by 20% after 10

years of service. In this case the reliability index is equal for

both time t=0 and t=10 years.

t = 0 year : Dm = 200 - 100

= 100 MPa.

t = 10 years : Dm = 180 - 80 = 100 MPa.

A

carbon-fiber reinforced plastic element of an airplane has

microdamages, its rigidity and strength decrease with time. The

maximum stress increases due to smaller rigidity of the elements.

There is a correlation between stress and strength. The correlation

coefficient affects the reliability index of the structural elements.

The negative correlation coefficient decreases the reliability

index. Positive correlation coefficient between stress and strength

is preferential.

A

carbon-fiber reinforced plastic element of an airplane has

microdamages, its rigidity and strength decrease with time. The

maximum stress increases due to smaller rigidity of the elements.

There is a correlation between stress and strength. The correlation

coefficient affects the reliability index of the structural elements.

The negative correlation coefficient decreases the reliability

index. Positive correlation coefficient between stress and strength

is preferential.