- •Главная

- •1.1 Напряжений и концентраторы

- •1.1.3 Концентраторы напряжения

- •1.3 Stress concentration factor

- •1.7 Elastic-plastic stress concentration

- •1.8 Joints: bolts and welds

- •3. Механические свойства конструкционных материалов

- •3.1 Напряженности испытания

- •3.2 Stress - strain diagram

- •3.3 Testing schemes

- •3.4 Strength

- •4 Прочность материалов

- •4.1 Tension and compression

- •4.2 Shear and torsion

- •4.3 Stress-strain state

- •4.4 Bending: force and moment diagrams

- •4.5 Geometrical characteristics of sections

- •4.6 Bending: stress and deformation

- •4.7 Mixed mode loading

- •4.8 Buckling

- •4.9 Statically indeterminate systems

- •4.10 Three-dimensional structures

- •References

- •5. Theory of elasticity

- •5.1 Deformation

- •5.2 Stress

- •5.3 Hooke's law

- •5.4 Plane problems

- •5.5 Torsion

- •5.6 Bending

- •5.7 Polar coordinates

- •5.8 Plates

- •5.9 Shells

- •5.10 Contact stresses

- •6.2 Distribution functions

- •6.3 Structural models of reliability

- •6.4 Limiting state

- •6.5 Dispersion

- •6.6 Durabilty

- •6.7 Design by reliability criterion

- •6.8 Risk

- •6.9 Safety classes

- •6.10 Risk : structural and social

- •References

- •7 Materials science

- •7.1 Crystalline solids

- •7.2 Mechanical properties

- •7.3 Failure

- •7.4 Phase diagrams

- •7.5 Heat treatment of metals and alloys

- •7.6 Corrosion of metals and alloys

- •7.7 Casting

- •7.8 Polymers

- •7.9 Composites

- •7.10 Forming of metals

- •8.2 Mechanical properties

- •8.3 Stress concentration

- •8.4 Defects

- •8.5 Residual Stress

- •8.6 Strength

- •8.7 Fatigue strength

- •8.8 Fracture

- •8.9 Weldability

- •References

- •9 Composites

- •9.1 Structure of composites

- •9.2 Fibers

- •9.3 Rigidity

- •9.4 Strength

- •9.5 Crack resistance

- •9.6 Optimization

- •9.7 Fatigue and temperature effect

- •9.8 Reliability

- •9.9 Joints

- •9.10 Material selection

- •References

- •10 Finite element analysis

- •10.1 Finite element method

- •10.2 Finite elements

- •10.3 Meshing

- •10.4 Boundary conditions

- •10.5 Deformation

- •10.6 Accuracy

- •10.7 Heat transfer analysis

- •10.8 Dynamics

- •10.9 Computational fluid dynamics

- •10.10 Design analysis

- •References

5.3 Hooke's law

For

elastic deformations the normal stress is directly proportional to

strain. The ratio of axial stress/strain is a constant. This constant

is known as Young's modulus or modulus of elasticity E. Young's

modulus is directly proportional to the axial stress and inversely

proportional to the axial strain.

For

elastic deformations the normal stress is directly proportional to

strain. The ratio of axial stress/strain is a constant. This constant

is known as Young's modulus or modulus of elasticity E. Young's

modulus is directly proportional to the axial stress and inversely

proportional to the axial strain.

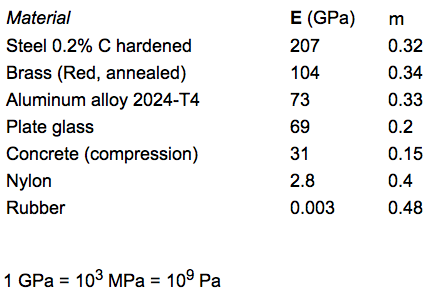

For

three-dimensional stress state the formulas include more than one

stress component. The expressions for isotropic elastic body include

three elastic constants of material: modulus of elasticity E,

Poisson's ratio m and shear modulus G. The elastic constants are

characteristics of the material. They do not depend on the shape or

size of the specimen.

The shear modulus G can be expressed

by the first two elastic constants. There are only two constants that

are independent parameters for an isotropic material.

For

three-dimensional stress state the formulas include more than one

stress component. The expressions for isotropic elastic body include

three elastic constants of material: modulus of elasticity E,

Poisson's ratio m and shear modulus G. The elastic constants are

characteristics of the material. They do not depend on the shape or

size of the specimen.

The shear modulus G can be expressed

by the first two elastic constants. There are only two constants that

are independent parameters for an isotropic material.

Poisson's

ratio m characterizes transverse deformation under axial tension or

compression. It is a dimensionless parameter. For m=0.3, axial

tension of 10% corresponds to a transverse compression of

3%.

Poisson's

ratio m characterizes transverse deformation under axial tension or

compression. It is a dimensionless parameter. For m=0.3, axial

tension of 10% corresponds to a transverse compression of

3%.

The

expressions show another form of the Hooke's law. Normal stress sx

depends on all three linear components of strain ex,

ey

and ez.

The

expressions show another form of the Hooke's law. Normal stress sx

depends on all three linear components of strain ex,

ey

and ez.

Volume

expansion e characterizes an increase of an element size, not a

change of its shape. It depends on the linear strains only. The

volume expansion e can be defined by the elastic constants of the

material E, m and the sum of the normal stresses sx,

sy

and sy.

Volume

expansion e characterizes an increase of an element size, not a

change of its shape. It depends on the linear strains only. The

volume expansion e can be defined by the elastic constants of the

material E, m and the sum of the normal stresses sx,

sy

and sy.

5.4 Plane problems

There

are two special states of stress: plane stress for thin plates and

plane strain for thick plates.

For plane stress there are

four non-zero strain components (ex

, ey

, ez

, gxy

) and three non-zero stress components (sx

, sy

, txy

). The plane stress is typical for thin-walled structures such as in

airplane wings.

For plane strain there are three non-zero

strain components (ex,

ey,

gxy)

and four non-zero stress components (sx,

sy,

sz,

txy).

Plane strain is typical for thick plates.

There

are two special states of stress: plane stress for thin plates and

plane strain for thick plates.

For plane stress there are

four non-zero strain components (ex

, ey

, ez

, gxy

) and three non-zero stress components (sx

, sy

, txy

). The plane stress is typical for thin-walled structures such as in

airplane wings.

For plane strain there are three non-zero

strain components (ex,

ey,

gxy)

and four non-zero stress components (sx,

sy,

sz,

txy).

Plane strain is typical for thick plates.

There

are two equilibrium equations that must be satisfied for absence of

mass forces. Elastic plates have stress fields that satisfy Hooke's

law and the strain compatibility equations. The two stress components

shown correspond to an embedded beam with a force applied to the

right end. The equilibrium equations help solve the plane problems of

the theory of elasticity.

There

are two equilibrium equations that must be satisfied for absence of

mass forces. Elastic plates have stress fields that satisfy Hooke's

law and the strain compatibility equations. The two stress components

shown correspond to an embedded beam with a force applied to the

right end. The equilibrium equations help solve the plane problems of

the theory of elasticity.

There

are two inclined principle planes where there is no shear stress and

normal stresses (s1

and s2)

are at a maximum.

There

are two inclined principle planes where there is no shear stress and

normal stresses (s1

and s2)

are at a maximum.

Principle

axes are inclined 45o

to the direction of shear stress t for pure shear. Indication A is

negative. There are zero indications for B and D.

Principle

axes are inclined 45o

to the direction of shear stress t for pure shear. Indication A is

negative. There are zero indications for B and D.

The

figure shows typical stress patterns for sx,

sy

and txy.

The normal stress sx is usually higher than other stress components

for a long beam, where Length >> Height.

The

figure shows typical stress patterns for sx,

sy

and txy.

The normal stress sx is usually higher than other stress components

for a long beam, where Length >> Height.

There

is concentration of shear stress in the area where force is applied.

Shear stress is equal to zero at the surface and is at a maximum in a

neighboring region.

There

is concentration of shear stress in the area where force is applied.

Shear stress is equal to zero at the surface and is at a maximum in a

neighboring region.

Normal

stress sy

at axis x can be positive outside the zone of compression. Here, the

compressive stress is significantly higher than the tensile

stress.

Normal

stress sy

at axis x can be positive outside the zone of compression. Here, the

compressive stress is significantly higher than the tensile

stress.

Saint-Venant's

principle. At a distance equal to width of the beam (2a), the maximum

stress does not exceed the nominal stress by 4%. The stress pattern

becomes practically uniform.

Saint-Venant's

principle. At a distance equal to width of the beam (2a), the maximum

stress does not exceed the nominal stress by 4%. The stress pattern

becomes practically uniform.