- •Preface

- •Acronyms

- •Introduction

- •Background and objectives

- •Content, format and presentation

- •Radioactive waste management in context

- •Waste sources and classification

- •Introduction

- •Radioactive waste

- •Waste classification

- •Origins of radioactive waste

- •Nuclear fuel cycle

- •Mining

- •Fuel production

- •Reactor operation

- •Reprocessing

- •Reactor decommissioning

- •Medicine, industry and research

- •Medicine

- •Industry

- •Research

- •Military wastes

- •Conditioning of radioactive wastes

- •Treatment

- •Compaction

- •Incineration

- •Conditioning

- •Cementation

- •Bituminisation

- •Resin

- •Vitrification

- •Spent fuel

- •Process qualification/product quality

- •Volumes of waste

- •Inventories

- •Inventory types

- •Types of data recorded

- •Radiological data

- •Chemical data

- •Physical data

- •Secondary data

- •Radionuclides occurring in the nuclear fuel cycle

- •Simplifying the number of waste types

- •Radionuclide inventory priorities

- •Material priorities

- •Inventory evolution

- •Assumptions

- •Errors

- •Uncertainties

- •Conclusions

- •Acknowledgements

- •References

- •Development of geological disposal concepts

- •Introduction

- •Historical evolution of geological disposal concepts

- •Geological disposal

- •Definitions and comparison with near-surface disposal

- •Development of geological disposal concepts

- •Roles of the geosphere in disposal options

- •Physical stability

- •Hydrogeology

- •Geochemistry

- •Overview

- •Alternatives to geological disposal

- •Introduction

- •Politically blocked options: sub-seabed and Antarctic icecap disposal

- •Sea dumping and sub-seabed disposal

- •Antarctic icesheet disposal

- •Technically impractical options; partitioning and transmutation, space disposal and icesheet disposal

- •Partitioning and Transmutation

- •Space disposal

- •Icesheets and permafrost

- •Non-options; long-term surface storage

- •Alternatives to conventional repositories

- •Introduction

- •Alternative geological disposal concepts

- •Utilising existing underground facilities

- •Extended storage options (CARE)

- •Injection into deep aquifers and caverns

- •Deep boreholes

- •Rock melting

- •The international option: technical aspects

- •Alternative concepts: fitting the management option to future boundary conditions

- •Conclusions

- •References

- •Site selection and characterisation

- •Introduction

- •Prescriptive/geologically led

- •Sophisticated/advocacy led

- •Pragmatic/technically led

- •Centralised/geologically led

- •Conclusions to be drawn

- •Lessons to be learned (see Table 4.2)

- •Site characterisation

- •Can we define the natural environment sufficiently thoroughly?

- •Sedimentary environments

- •Hydrogeology

- •The regional hydrogeological model

- •More local hydrogeological model(s)

- •Crystalline rock environments

- •Lithology and structure

- •Hydrogeology

- •Hydrogeochemistry

- •Any geological environment

- •References

- •Repository design

- •Introduction: general framework of the design process

- •Identification of design requirements/constraints

- •Concept development

- •Major components of the disposal system and safety functions

- •A structured approach for concept development

- •Detailed design/specifications of subsystems

- •Near-field processes and design issues

- •Design approach and methodologies

- •Design confirmation and demonstration

- •Interaction with PA/SA

- •Demonstration and QA

- •Repository management

- •Future perspectives

- •References

- •Assessment of the safety and performance of a radioactive waste repository

- •Introduction

- •The role of SA and the safety case in decision-making

- •SA tasks

- •System description

- •Identification of scenarios and cases for analysis

- •Consequence analysis

- •Timescales for evaluation

- •Constructing and presenting a safety case

- •References

- •Repository implementation

- •Legal and regulatory framework; organisational structures

- •Waste management strategies

- •The need for a clear policy and strategy

- •Timetables vary widely

- •Activities in development of a geological repository

- •Concept development

- •Siting

- •Repository design

- •Licensing

- •Construction

- •Operation

- •Monitoring

- •Research and development

- •The staging process

- •Attributes of adaptive staging

- •The decision-making process

- •Status of geological disposal programmes

- •Overview

- •Status of geological disposal projects in selected countries

- •International repositories

- •Costs and financing

- •Cost estimates

- •Financing

- •Conclusions

- •Acknowledgements

- •References

- •Research and development infrastructure

- •Introduction: Management of research and development

- •Drivers for research and development

- •Organisation of R&D

- •R&D in specialised (nuclear) facilities

- •Introduction

- •Inventory

- •Release of radionuclides from waste forms

- •Solubility and sorption

- •Waste form dissolution

- •Colloids

- •Organic degradation products

- •Gas generation

- •Conventional R&D

- •Engineered barriers

- •Corrosion

- •Buffer and backfill materials

- •Container fabrication

- •Natural barriers

- •Geochemistry and groundwater flow

- •Gas transport and two-phase flow

- •Biosphere

- •Radionuclide concentration and dispersion in the biosphere

- •Climate change

- •Landscape change

- •Underground rock laboratories

- •URLs in sediments

- •Nature’s laboratories: studies of the natural environment

- •General

- •Corrosion

- •Cement

- •Clay materials

- •Degradation of organic materials

- •Glass corrosion

- •Radionuclide migration

- •Model and database development

- •Conclusions

- •References

- •Building confidence in the safe disposal of radioactive waste

- •Growing nuclear concerns

- •Communication systems in waste management programmes

- •The Swiss programme

- •The Japanese programme

- •Examples of communication styles in other countries

- •Finland

- •Sweden

- •France

- •United Kingdom

- •Comparisons between communication styles in Finland, France, Sweden and the United Kingdom

- •Lessons for the future

- •What is the way forward?

- •Acknowledgements

- •References

- •A look to the future

- •Introduction

- •Current trends in repository programmes

- •Priorities for future efforts

- •Waste characterisation

- •Operational safety

- •Emplacement technologies

- •Knowledge management

- •Alternative designs and optimisation processes

- •Materials technology

- •Novel construction/immobilisation materials: the example of low pH cement

- •Future SA code development

- •Implications for environmental protection: disposal of other wastes

- •Conclusions

- •References

- •Index

Repository design |

131 |

The selected EBS is specified for a basic repository concept, which, in turn, is iteratively refined to specify logistics and infrastructure, including:

Shafts and/or ramps to provide access to the host formation for personnel and materials and for removal of broken-out rock. Additional requirements for ventilation, emergency escape routes, etc. are defined by normal mining regulations but may be redesigned based on assessment of operational phase radiological safety.

Tunnels and drifts for internal transportation of materials and services – possibly allowing separate construction and operation of different parts of the repository. Layout is specified by constraints set by the local geology (major structural features, stress fields, hydraulic gradients, etc.) and practical aspects of repository operation.

Emplacement tunnels or boreholes in a specified region (or regions/panels) of the repository. These are designed to be compatible with performance and quality assurance requirements.

Structures for backfilling and sealing the repository – including tunnel and shaft seals and plugs – optimised for the layout/host rock in question and demonstrated to provide the roles specified in the long-term performance assessment.

The depth range for practical construction of the disposal facility is determined by evaluating the mechanical stability and spatial extent of the host rock. Mechanical stability analyses support the prediction that, for hard rock, underground excavations would be stable without supports at greater depths. For soft rock, when the viability of realistic supports is taken into consideration, tunnels could reasonably be constructed at a depth greater than a few hundred metres.

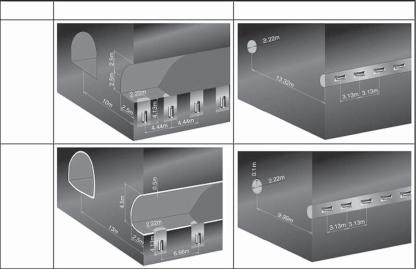

For HLW/SF, the scale of the underground facilities can be estimated approximately by multiplying the occupied area per waste package (given by the product of the disposal tunnel spacing and the waste package pitch) by the number of waste packages. A combination of the disposal tunnel spacing and waste package pitch should be specified such that the scale of the underground facilities and the total length of disposal tunnels will be reduced, thereby improving economic factors. To specify the disposal tunnel spacing and the waste package pitch, consideration should also be given to the thermal effects of waste on the EBS, in addition to the constraints due to the mechanical stability. An example of resulting disposal tunnel spacing and the waste package pitch for which the maximum temperature of buffer material would be below the constraint temperature (100LC in this particular design) is shown in Figure 5.7 (JNC, 2000).

The cross-section of a disposal tunnel and the spacing between tunnels can be designed based on mechanical stability for non-heat-generating, cementitious/bituminised L/ILW. The disposal tunnels for the hulls and ends would obviously be located so as to avoid any thermal effects on the cement-based materials.

5.5. Design confirmation and demonstration

5.5.1. Interaction with PA/SA

While the main safety functions of the repository are intrinsic to the design and location within a deep geological system, understanding the level of robustness of the proposed

132 |

H. Umeki |

Pit disposal |

Tunnel disposal |

Hard rock

Soft rock

Fig. 5.7. The EBS concept for the in-hole and in-tunnel disposal options for different types of host rock (JNC, 2000). Waste package dimensions and buffer thickness are the same for the in-hole and in-tunnel disposal options. In this PA, these options were considered to be equivalent. This assumption was based on a lack of consideration of either the emplacement hole plug or the excavation disturbed zone (EDZ) of the large tunnel or the deposition hole.

system in various geological conditions or under changes in system conditions can only be evaluated through long-term repository performance assessment. Ideally, over time, the iterative process of PA and repository design work should lead to a situation where the design has matured and become stable (relatively unchanging with each new iteration) and is consistent with the PA models. The same iterative process should lead to mature PA models that provide a reasonable (not overly simplified) representation of the disposal system. The general approach and methods for PA/SA have been developed to evaluate the safety functions and the level of robustness of the proposed system under various conditions (see Chapter 6). Results of PA/SA can be fed back to design confirmation or further modifications.

The behaviour of the EBS and the evolution of the near-field of a repository are critically dependent on the local-scale properties of the host rock and on the larger scale features of the surrounding geological environment. For many geological environments being considered for disposal, groundwater flow and chemistry will be significant factors affecting near-field performance. For example, according to McKinley (1985), based on the known potassium content of the groundwaters and the likely flux of water through the EBS, illitisation of bentonite in a HLW/SF repository in the crystalline basement of northern Switzerland would take about 1 million years at one site (west) and as much as 10 million years at another site (east).

As discussed previously, throughout the construction, operation and closure of the repository a sequence of various processes and events take place in one part or another, resulting in a dynamic evolution of the facility and its environment. Materials and equipment of many kinds are introduced underground for the sake of operational safety

Repository design |

133 |

and engineering efficiency. Furthermore, perturbations to the environment during construction and operation, together with the materials left after the closure of the repository, could affect the further evolution of the system and thereby affect near-field conditions that are of vital importance in assuring long-term safety. Evolution of the near-field environment should be attributed to a number of THMC processes and their mutual interactions, rather than being governed by a dominant process.

Coupling of processes is particularly important in the description and modelling of the near-field barriers. The temperature rise within the repository is a critical factor for a range of possible processes. Effects include the stress distribution within engineered barriers and the host rock. Additional phenomena that can be affected are the flow of fluids and biological activity, together with the physico-chemical and thermodynamic conditions. While coupling of processes is particularly important in the description and modelling of the near-field barriers, consideration of their potential impact will also be necessary in the far-field. A good understanding of such coupling of processes is essential for the reliable assessment of repository performance and for the production of a convincing safety case. In this context, a coupled THMC model has been developed as part of international projects such as DECOVALEX (Jing et al., 1996) and FEBEX (ENRESA, 2000). Along with these projects, coupled THMC tests, conducted on engineering scale or full scale, have been carried out to investigate the validity of the developed models (codes).

Analyses are performed to evaluate the long-term integrity of the EBS to confirm its performance after emplacement. These include an evaluation of the long-term structural mechanical stability of the EBS based on consideration of rock creep and the expansion of container corrosion products, the seismic stability of the EBS and the near-field, the EBS behaviour during resaturation and potential gas formation and migration through the EBS. Most systems would maintain integrity against expected phenomena over a long period of time (JNC, 2000).

The EBS within the near-field is intended to contain the radionuclides in the wastes completely for a certain period of time and then to control the rate at which they can be mobilised and released into the surrounding rock. The results from radionuclide release and transport calculations could be used as input to studies aimed at optimising the design and layout of the repository and the EBS. To do this, the radionuclide release and transport calculations are likely to need to be supported by a detailed model of groundwater flow around the repository, so that significant flowpaths can be identified. The importance of results from radionuclide release and transport calculations for optimisation studies would also depend on the relative significance of the far-field in the performance of the disposal system under consideration.

5.5.2. Demonstration and QA

Demonstration of technical reliability rests on two fundamental principles. First, that a properly sited and designed repository with a robust EBS is intrinsically safe because it avoids potential major disruptive processes and ensures that any releases of radionuclides in the far future will have no significant health effects. The second principle is that a PA of the engineered and natural barrier system can demonstrate a wide margin of safety for the proposed disposal concept.

134 |

H. Umeki |

An area that is less well defined, however, is the practicality of constructing an EBS under strict quality assurance controls in an operational repository environment (considering underground conditions of restricted space, humidity, emplacement rate, remote handling, operational safety, robustness to perturbations, etc.). Remaining design uncertainties relate mainly to issues of how to link EBS design and emplacement methods to disposal system performance. Key characterisation uncertainties include the THMC properties of buffer and backfill materials and the evolution of those properties, the effect of gas generation and the determination of parameter values for safety analysis.

Many programmes are actively involved in experiments in URLs. This is an area of extensive international collaboration and there are clear links between URL experiments, laboratory experiments, natural analogues, process modelling and data gathering. As noted in Chapter 8, some programmes include URL experiments in an iterative process of PA and design refinement. The objectives of the URL experiments are to demonstrate the function of deep repository components under realistic conditions and compare results with models and assumptions and to develop, test and demonstrate engineering standards and quality assurance methods.

Peer review is an important positive process that enhances confidence and should be an active part of the ongoing design and assessment process. Issues identified through peer reviews in different countries include the need for:

Demonstration of technical feasibility.

Further R&D on particular topics.

Balance between EBS and natural barriers.

Consideration of uncertainties in expected performance.

5.5.3. Repository management

The management of a disposal site covers all operations for constructing, operating and decommissioning the repository, including gathering the technical information necessary to support a decision to release the site from institutional control.

The process for implementation of geological disposal begins with selection of potential candidate sites, selection of candidate sites and characterisation of the candidate site(s), followed by demonstration of disposal technology, disposal facility design and safety assessment. Confirmation by the regulator of the selection of potential candidate sites is required. An application for regulatory approval is then submitted and, provided a safety review ultimately determines that the proposed site is suitable, the repository project will be granted an official permit. Operations to be conducted at the disposal site will be carried out in three stages of construction, operation and closure; a key decision will be the extent to which such operations proceed in parallel in different parts of the repository.

In each phase of work, consideration should be given to the following aspects of management of a disposal site:

Implementation of quality control for design, manufacturing, installation and construction of the EBS and the disposal facility (as specified in the previous section). Quality management procedures for most of the repository components utilise

Repository design |

135 |

conventional engineering practices, in some cases with the particularly strict constraints which apply to nuclear facilities (including operational radiation protection requirements).

Monitoring of geological conditions around the EBS and disposal facility to give an expanding information database on the geological environment.

Environmental management around the disposal site.

Monitoring for worker protection (conventional and radiological).

Proven technologies for management of these areas are already available. These can be applied based on the conditions at a selected site, established in particular from tests and experiments at a site-specific URL where possible4.

The need for monitoring of the repository during the active control phase is recognised in most programmes, but monitoring plans are generally in the pre-closure phase of development (IAEA, 2001). Some programmes are considering monitoring phases after closure (e.g., Thompson et al., 2003).

Technical and operational reliability, practicality, worker safety at potential repository depths, adaptability to geological changes, impacts on the host rock and economics are factors that should be considered in evaluating and selecting repository construction methods. Assessing construction methods for shafts, tunnels and pits, it is confirmed that existing technologies can be used for construction. Construction systems consisting of combinations of various technologies (e.g., excavation technology and tunnel support construction methods) will be further developed or modified as part of the construction of the underground research facilities planned separately and the underground repository facilities in support of site characterisation activities.

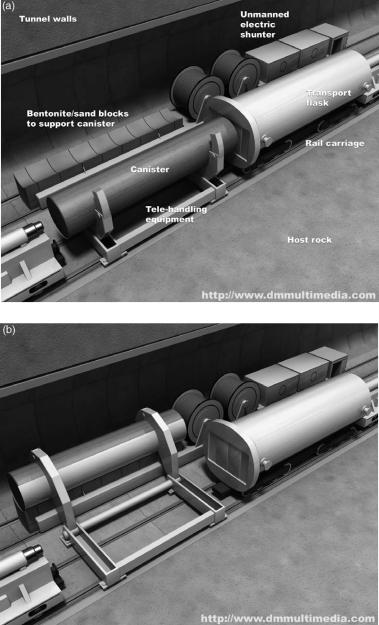

In repository operations, wastes are received and encapsulated in containers at the surface facility. Once sealed, these are considered as waste packages. The waste packages and buffer material are then transported through the access tunnels to the underground facility and then to the disposal panels and emplaced. In addition to experience gained in existing repositories, concepts for a remote-controlled transfer/ emplacement system of waste packages have been established to illustrate a series of operational procedures leading up to the emplacement of the waste packages and buffer materials (Figure 5.8).

To close the repository, access tunnels and boreholes should be appropriately backfilled to isolate underground facilities from the ground surface. In parallel with this, surface facilities should be decommissioned. Large amounts of debris will be produced from the excavation of tunnels and this could be used as backfill material because it is derived from the host rock and it can be procured easily and economically. Backfill materials with low hydraulic conductivity and swelling properties could be obtained from a mixture of such debris and bentonite (cf. GMT in Box 8.1). The backfilling methods for horizontal tunnels and inclines are identified. These methods include block laying, spreading/compacting of the backfill material, spraying and transverse compacting. For the shaft-type access tunnels, a backfilling method that applies compaction gradually from bottom of the shaft would be effective.

4 In some national programmes, this is a regulatory requirement.

136 |

H. Umeki |

Fig. 5.8. (Continued)