- •Preface:

- •1 Machine specification

- •Installation and transportation

- •9 Nozzle leveling process

- •10 Mold exchange process:

- •1 1 Confirm mold thickness method

- •4 Electric control box panel

- •5 The description of each switch function 4-5-1 Injection resistance scale

- •5 0 0 M 0 0 -6 Safety door magnet spring switch

- •Vacuum solenoid valve

- •5. The description of operating menu screen

- •The above screen image is only for reference

- •The above screen image is only for reference

- •The above screen image is only for reference

- •Injector I Speed

- •Injector 1 Pressure

- •The above screen image is only for reference

- •The above screen image is only for reference

- •4 Inj.-l temp, setting -1

- •The above screen image is only for reference

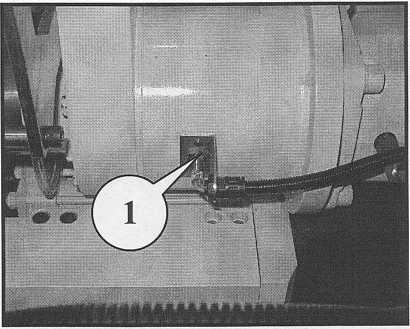

5 0 0 M 0 0 -6 Safety door magnet spring switch

No. |

Item |

Function |

Remark |

1 |

Magnet spring switch |

Control safety door UP stop |

|

2 |

Magnet spring switch |

Control safety door DOWN stop |

At ON position operate open/close mold action |

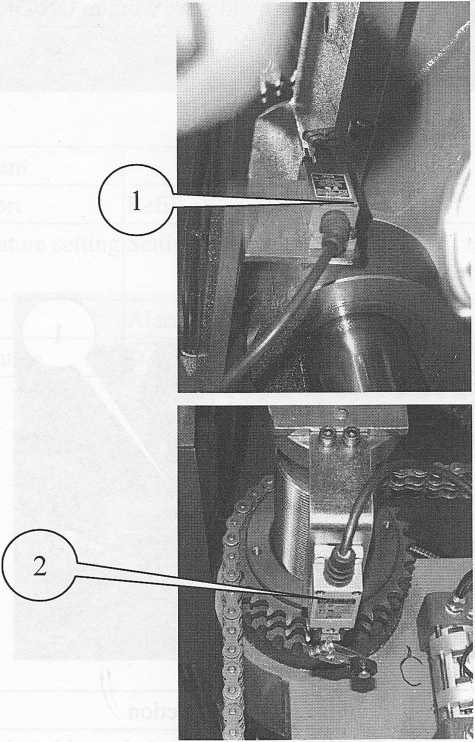

No. |

Item |

Function |

Remark |

1 |

Proximity switch |

Indicates feed motor speed |

|

5

4-5-7 Feeding speed proximity switch

-8

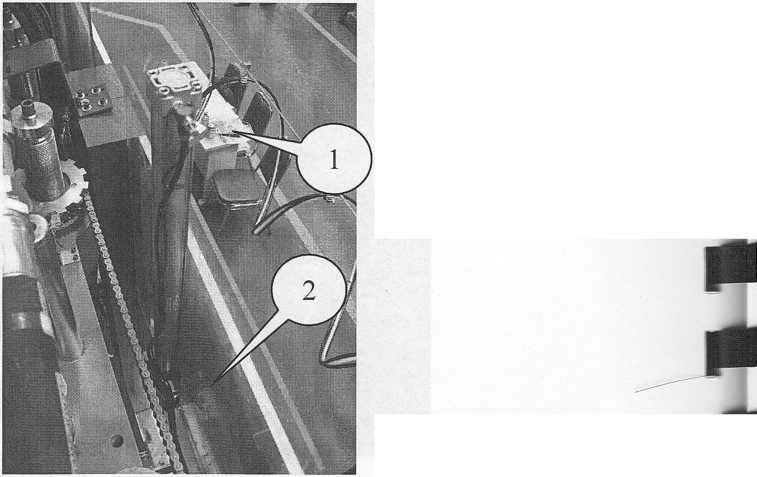

Adjusts mold limit switch

-8

Adjusts mold limit switch

No. |

Item |

Function |

Remark |

1 |

Limit switch |

Adjusts mold down limit switch |

|

2 |

Limit switch |

Adjusts mold up limit switch |

|

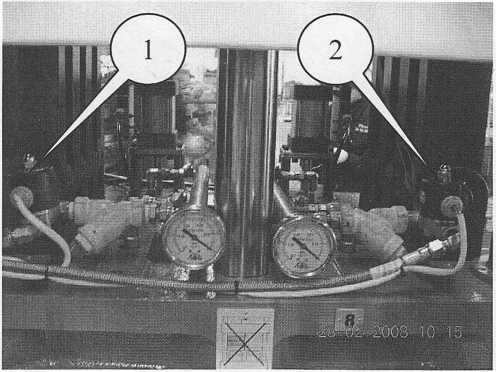

No. |

Item |

Function |

Remark |

1 |

Vacuum solenoid valve |

Control left mold suck vacuum ON/OFF |

|

2 |

Vacuum solenoid valve |

Control right mold suck vacuum ON/OFF |

|

V

4-5-10

4-4-9

Vacuum solenoid valve

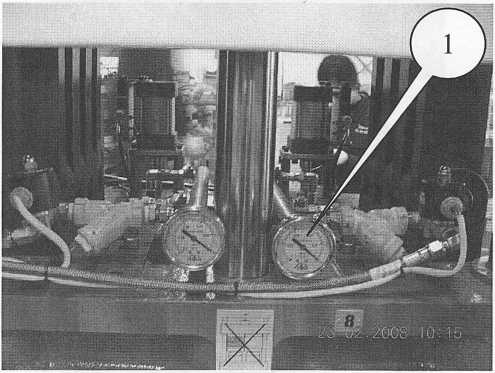

acuum pressure gauge

No. |

Item |

Function |

Remark |

1 |

Vacuum pressure gauge |

Display vacuum volume in mold cavity |

|

■

Pi Tienyu

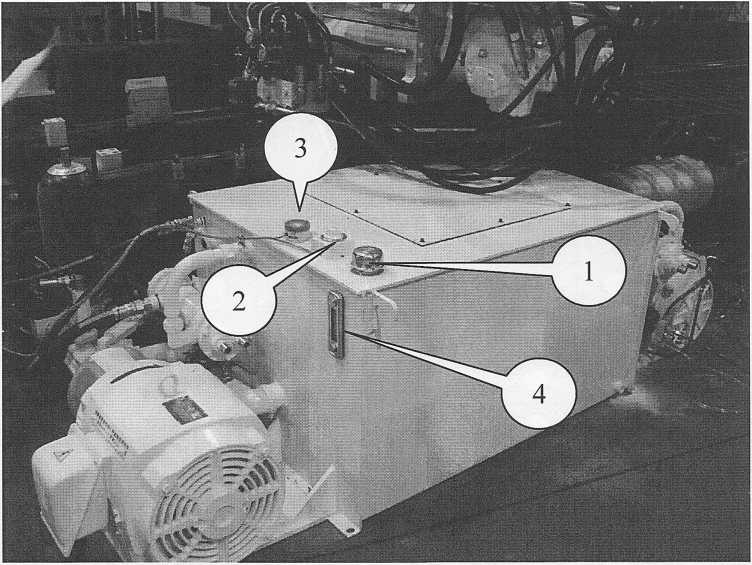

5-11 Inspect oil level switch

No. |

Item |

Function |

Remark |

1 |

Oil refill port |

Refill oil |

|

2 |

Oil temperature setting switch |

Setting oil tank temperature |

Oil temperature too high alarm occurs |

3 |

Buzzer |

Alarm oil temp, too high |

|

4 |

Oil level gauge |

Displays oil level |

|

■^==TienYu

5. The description of operating menu screen

Main screen

Menu item

D

H

A

Time

C

B

I

G

Date

vJJ. MONITOR

ST |

|

fllnl |

|

yr |

|

w |

fet |

1 l_i A |

|

ST.1 |

o |

o |

o |

o |

oo |

o |

o |

o |

o |

ST.2 |

o |

o |

o |

o |

oo |

o |

o |

o |

o |

ST.3 |

o |

o |

o |

o |

oo |

o |

o |

o |

o |

ST.4 |

o |

o |

o |

o |

oo |

o |

o |

o |

o |

ST.S |

o |

o |

o |

o |

oo |

o |

o |

o |

o |

ST.S |

o |

o |

o |

o |

oo |

o |

o |

o |

o |

ST.7 |

o |

o |

o |

o |

oo |

o |

o |

o |

o |

ST.S |

o |

o |

o |

o |

oo |

o |

o |

o |

o |

|

|

|

|

|

feSi |

|

|

|

Feeding Injection |

Injector I Slider |

Injector Temp. |

Curing /Time |

Mold Selectior |

Alarm |

- roduction ; Statistics |

General 1 Mold Parameter 1 memory; |

Main page |

Select

menu

The above screen is Main screen °

Press the function key at the select menu item on the screen to display the desire screen °

Return to main screen press main page at the select menu item

The above screen image is only for reference °

Symbol |

Description |

Symbol |

Description |

A |

Auto cycle |

F |

Vacuum |

B |

Safety door DOWN |

G |

Pressurize cylinder DOWN |

C |

Clamp mold |

H |

Open mold |

D |

Clamp mold pad block IN |

I |

Safety door UP |

E |

Pressurize |

|

|

5-1 FEEDING SETTING

Language |

|

10/28/2009 |

|||

|

|

|

UNLOCk| |

||

|

Iniecl o' 1 |

|

111|> ■> 11 ii |

||

Pre_ ^ o p c P rui P H 1 |

|

1 |

■ ~ g ^ p/poo |

||

1 \D3CI VGU St. Feed, Amount |

wm/farngtmsam |

MTIOU |

it l g . e3„ /'ir.LJit ■’ y |

||

o d |

1 o |

|

M risiSBlallli^ |

||

2 r ' |

0.0 I |

o.'o" |

I [I:: r ^ ; ' |

||

|

n:n ?“ |

0.0 |

1 0.0 I |

||

41 SfllSSB |

_ J Q Q | |

0.0 |

1 015 |

||

5 1 0.0 |

T _ |

0.0 |

i 0.0 |

||

|

^ ^ Eli |

0.0 |

ffii \ |

||

. 0.0 |

1 070 f- |

070" |

llliiiiii! riiiiiixi/ |

||

|

|

0.0 |

I - ^raiiniiir |

||

Inj-1 Current Amoun |

0.0 |

g |

Irij -2 Gj rrent Amount |

0.0 |

g |

Total Amount |

0.0 |

g |

r >1 -i Amount |

: o.o |

g- |

Feeding Speed |

0 |

rpm |

Feedln j f r sed |

1 |

rmp |

j Feeding j Injector j Injector Injection Slider Temp |

Curing Time |

Mold I Selector] |

Alarm |;Stalislics j parameter jjjasrrioryj |

Main page j |

|

~07cT

Select

menu

T

p

b

r

o7o

r o:o

fast

he above screen image is only for referenceAt select menu icon select the “feeding injection” icon to display the “ Feeding injection” screen.

The screen can set injector 1, 2 left and right mold feed amount.

Pre-reserve (g) : The actual feed amount is pre-reserve value plus feeding amount ° The

recommend pre-reserve value is 60g~ lOOg. (The default value is 80g)

Specific gravity : Setting material specific weight. When the material specific weight changes

it need to adjust this setting, the machine can control the material feed best condition.

Current Amount(g) : Current feed amount.

Total amount: Feed setting value + pre-reserve value.

Feeding speed: Displays injector feeding hydraulic motor speed.

Left/Right mold feed amount (g):

Numerical condition |

Description |

ONLY INPUT (Feed value) |

Feed value setting |

9. Fast : The input value will replace all row value.

5-2 Injector 1 speed

|

Red means open the setting 16:09:31 |

|

11 ijpww |

|

10/28/2009 |

||||||

|

|

lnj-1 |

Injection Volmue |

Setting g UNLQ^c/'Cj |

' ¥X \ |

|||||

|

Seg.2 |

|

Seg.3 |

ill p ii |

Seg.4 S^.5 |

|||||

|

c; |

| O.C |

|

0 r |

0.0 j |

(J 1 o'o O |

|

|||

|

|

Left Mold |

Injection Speed L/min Right Mold |

|||||||

ST. |

No.1 |

No .2 |

No.3 No .4 |

No.5 |

No.1 No.2 No .3 No 4 No.5 |

|||||

|

i |

f o |

I o |

1 0 |

r o |

| 0 Jj | 0 ■ 1 0 |0, fjo |

||||

2 |

ro~ |

I 0 || Q |

•l| 0 |

it |

r~o~~ ft- n |

r^cw |

||||

3 |

I 0 |

J... o 1 |

1 0 |

Jl 0 |

rift |

1 0 |0 | 0 | ! |

■PTit |

|||

4 |

I 0 |

1 0 1| |

] o |

Hr 0 :f 0 |

i o i o io n |

D 1 0 |

||||

5 |

I 1 |

1 0 |

ro |

[ 0 |

[ .o |

lo ro ro n |

H I 01 |

|||

6 |

rr~~ |

1 0 |

1 0 |

Bi mb |

nr~ |

1 0 | 0 I o 1 0 I 0 |

||||

7 |

r^~ |

1 .0.... |

ro |

|

1 0 |

! c jo lo io 1 o |

||||

8 |

1 o |

1 0 |

ro |

1 0 |

|

|

|

|||

|

|

|

|

|

|

|

|

|||

fast |

1 0 |

1 0 |

no |

1 0 |

1 0 |

io io io r |

d L.op- |

|||

injector I Speed |

Injector 1 Injector 1 I Pressure Monitor ! |

injector i1 Injector 2 | Injector 2: |

Main 1 Paqe 1 |

|||||||