- •3. Read the text and do the exercises.

- •The entire oil industry is often divided into three major sectors: upstream, midstream and downstream.

- •Downstream (oil industry)

- •Upstream (oil industry)

- •Midstream (oil industry)

- •The Seven Sisters of the petroleum industry is a term coined by an Italian entrepreneur, Enrico Mattei, that refers to seven oil companies that dominated mid-20th century oil production, refinement, and distribution.

- •ROYAL DUTCH SHELL

- •Founded: 1907

- •Products: oil, natural gas, petrochemicals

- •Products: natural gas, petroleum

- •Headquarters: the Netherlands, principal offices in Houston, Paris and the Hague

- •Pronunciation of the name

- •12. Translate into English.

- •12. http://www.fourmilab.ch/gravitation/foobar/

- •15. http://www.fe.doe.gov/education/energylessons/oil/oil2.html

- •Exploration Methods

- •Elements of a petroleum prospect

- •Terms used in petroleum evaluation

- •Drill Stem Tests

- •A. Electric, Radioactivity and Acoustic (Sonic) Logging

- •2. ______ _______ invades the rock surrounding the wellbore, affects the logging of the hole and must be accounted for.

- •3. ______ _______ measure formation radioactivity.

- •Acidizing

- •2. Pay attention to the underlined stress in the following words.

- •Completion

- •Production

- •Abandonment

- •3. Pay attention to the underlined stress in the following words.

- •4. Read the following text and do the exercises.

- •2. Pay attention to the underlined stress in the following words.

- •5. Fill in the gaps with the most suitable words or terms from the text.

- •6. Match the two parts of the sentences.

- •Terms and Vocabulary

- •People

- •9. Read the text “Drilling Rig” and fill in the missing words from the box. There is one extra word.

- •Drilling Rig

- •Drilling Rig Classification

- •4. Read the text “Hoisting system components” and do the exercises.

- •16. Read the text “PIPE (MATERIAL)” and fill in the missing information. The first sentence is done for you.

- •2. Pay attention to the stress in the following words. □ shows the position of stress.

- •2. Pay attention to the stress in the following words. □ shows the position of stress.

- •2. Pay attention to the underlined stress in the following words.

- •6. Fill in the gaps with the correct term.

- •Example: 7. relies upon

- •7. Scan through the following short definitions and do the after – task exercises.

- •Corrosion types

- •Crack characteristics can vary greatly depending on the cause of the crack, the materials being cracked, and the environment causing the cracking. The following photos show examples of crack profiles.

- •Applied coatings

- •15. Match the questions about “Cathodic protection” on the left with the answers on the right.

- •STEEL TANKS WITH FIXED ROOFS

- •STEEL TANKS WITH FLOATING ROOF

- •METHODS OF ERECTION OF CYLINDRICAL STEEL TANKS

- •APPENDIX 5

- •Dictionary of Pipeliner's Terms (SLANGS)

- •A. подаваемый ток

- •1. weakening

- •B. коррозионный элемент

- •2. rust

- •C. выходное напряжение

- •3. discoloration

- •D. интенсивность

- •4. impressed current

- •E. (удельная) проводимость

- •5. direct current

- •F. ослабление

- •6. corrosion cell

- •G. обезвоживание

- •7. output voltage

- •H. постоянный ток

- •8. severity

- •9. water removal

- •10. conductivity

- •K. толщина стенки

- •11. operating pressure

- •12. yield strength

- •L. ухудшения характеристик

- •M. рабочее давление

- •13. allowance

- •N. предел текучести

- •14. wall thickness

- •O. допуск

- •fracture

- •трещина

- •gradient

- •угол наклона, склон

- •circuitous

- •окольный, обходной

- •Reynolds number

- •число Рейнольда

- •interplay

- •взаимодействие

- •facet

- •сторона

- •aquifer

- •водоносный слой

- •porous media

- •пористая среда

- •pertinent

- •имеющий отношение

- •civil engineering

- •гражданское строительство

- •soil science

- •почвоведение

- •fluid mechanics

- •механика жидкости

- •inertia

- •инерция

- •Laplace equation

- •уравнение Лапласа

- •simulate

- •имитировать

- •heat conduction

- •теплопроводность

- •heat transfer

- •теплообмен

- •uncoupled processes

- •несвязанные процессы

- •soil moisture

- •влажность почвогрунта

- •viscous

- •вязкий

- •viscosity

- •вязкость ( жидкости, газа )

- •diffusion

- •диффузия

- •steady flow

- •transient flow

- •неустановившийся поток

- •15. deterioration

- •UNIT 1

- •Introduction to Economics and management

- •UNIT 2

- •Finance

- •UNIT 3

- •STOCK

- •UNIT 4

- •THE ECONOMY OF PETROLEUM INDUSTRY

- •UNIT 5

- •Taxation and audit

- •UNIT 6

- •Production and Costs

- •UNIT 7

- •BUSINESS PLAN

- •UNIT 8

- •International Business Etiquette AND ETHICS

- •References

- •3. Read the text “Hydrogeology: Key Terms and Concepts”, do the exercises

- •Hydrogeology

- •7. What are the subjects of the following sciences?

- •12. Fill in the chart with the necessary information from the text.

- •13. Pay attention to the pronunciation of the following terms.

- •14. Read the following short texts and fulfill the after-reading exercises. Pay attention to the diagrams and underlined words.

- •Ground Water Aquifer

- •Confined or Artesian Aquifer

- •Drawdown – the vertical drop of the water level in a well caused by ground water pumping; also, the difference between the water level before pumping and the water level during pumping.

- •Make your own sentences with two of the expressions.

- •UNIT 4

- •THE GREENHOUSE EFFECT

- •Compose your own sentences with two of the expressions.

- •5. Translate from Russian into English.

- •10. Answer the following questions.

- •1. What are the functions of atmosphere?

- •1. The phenomenon known as El Niňo

- •A) is confined to the Pacific Ocean.

- •D) caused the disappearance of the dinosaurs.

- •2. It was named after

- •3. It is caused by

- •A) the wind changing direction.

- •D) occurs every four or five years.

- •5. The effect of El Niňo

- •Make your own sentences with two of the expressions.

UNIT 2

FLUID MECHANICS

Fluid mechanics is the discipline concerned with the behavior (movement / conduct) of liquids and gases at rest or in motion.

Lead-in

Free writing: Write down everything that comes to your mind about FLUID MECHANICS. Write only words. If you don’t know the English term, write down the Russian one. You have ONLY 1 minute to do it!

1. Pronounce the following words. Pay special attention to the letters in bold.

conduit |

laminar |

duct |

turbulent |

device |

roughness |

elbow |

profile |

restrain |

finite |

shear |

transient |

gradient |

excessive |

pressure |

channel |

cavitation |

momentum |

2. Pay attention to the stress in the following words. □ shows the position of stress.

device □ restrain □ laminar□ tur□bulent veloc □ ity pro□file

momen □tum mol□ecule cavita□tion repair□ relief□

replace□ment excess□ive expel□ collaps□ing reverse□

395

3. Read the following minitexts, do the exercises.

Typical Pipe System Components

The transport of a fluid (liquid or gas) in a closed conduit (commonly called a pipe, if it is of round cross section) or duct (if it is not round) is extremely important.

Some of the basic components of a typical pipe system are depicted in Fig. 1. They include the pipes themselves, various fittings used to connect the individual pipes to form the desired system, the flow rate control devices (valves), and pumps (turbines) that add energy to or remove energy from the fluid.

In general, fluids have a well-known tendency to move or flow. It is very difficult to restrain fluid from moving. The slightest shear stress will cause fluid to move. Similarly, appropriate imbalance of normal stresses (pressure) will cause fluid motion.

|

Terms and Vocabulary |

fluid |

флюиды |

conduit |

трубопровод; труба |

duct |

труба (не с круглым поперечным |

|

сечением) |

flow (move) |

поток; течение |

|

396 |

pipe |

трубопровод |

pipe system |

система трубопроводных линий |

fitting(s) |

фитинг |

flow rate control device |

регулятор скорости потока |

restrain |

удерживать |

valve |

клапан |

fluid motion |

движение флюидов |

shear stress |

напряжение сдвига |

General Characteristics of Pipe Flow

Although not all conduits used to transport fluid from one location to another are round in cross section. These include typical water pipes, hydraulic hoses and other conduits that are designed to withstand a considerable pressure difference. There are two situations where one pipe is completely filled with the fluid being transported (pipe flow) and one through which rainwater flows without completely filling the pipe (open-channel flow). The difference between open-channel flow and pipe flow is in the fundamental mechanism that drives the flow. For open-channel flow, gravity alone is the driving force. For pipe flow, gravity may be important, but the main driving force is likely to be a pressure gradient along the pipe.

|

Fig. 2. Pipe Flow |

|

Terms and Vocabulary |

pressure difference |

разность давлений |

pipe flow |

поток в трубопроводе (в полностью |

|

заполненной трубе) |

open-channel flow |

поток (в не полностью заполненной |

|

трубе) |

driving force |

движущая сила |

pressure gradient |

градиент давления |

397

Laminar or Turbulent Flow

The flow of a fluid in a pipe may be laminar or turbulent. The distinction between laminar and turbulent pipe flow was first pointed out by Osborne Reynolds (1883). The actual transition or turbulent flow may take place at various Reynolds numbers, depending on how much the flow is disturbed by vibrations of the pipe, roughness of the entrance region, etc.

Fig. 3. Fluid Flow in a Pipe

The region of flow near where the fluid enters the pipe is the entrance region. A boundary layer is produced along the pipe wall so that the initial velocity profile changes with distance along the pipe, until the fluid reaches the end of the entrance length. The flow in long, straight constant diameter sections of a pipe becomes fully developed, i.e. the velocity profile is the same at any cross section of the pipe. The details of velocity profile are different for laminar and turbulent flows. The nature of the pipe flow is strongly dependent on whether the flow is laminar or turbulent. This is a direct consequence of the differences in the nature of shear stress in laminar and turbulent flows. The shear stress in laminar flow is a direct result of momentum transfer among the randomly moving molecules. The shear stress in turbulent flow is largely a result of momentum transfer among the randomly moving molecules, finite-sized bundles of fluid particles.

398

Fig. 4. Entrance region, developing flow, and fully developed flow in a pipe system

|

Terms and Vocabulary |

laminar flow |

ламинарный поток |

turbulent flow |

турбулентный поток |

transition(al) flow |

переходный поток |

roughness |

шероховатость стенки трубы |

entrance region |

входной участок |

boundary layer |

граничный слой |

cross section |

поперечное сечение |

velocity profile |

скоростной профиль |

fully developed flow |

развитый поток |

developing flow |

развивающийся поток |

shear stress |

напряжение сдвига |

momentum transfer |

передача (перенос) импульса |

pipe system |

система трубопроводных линий, сеть |

|

трубопроводов |

|

Valves |

Valves are mechanical devices that are installed in pipelines to control flow or pressure. Valves are an important part of piping systems and if not properly selected and operated, they can cause operation problems. The primary valve types, classified by their function, are:

•control valves – used to control flow, pressure, liquid level, cavitation and pressure transients;

•isolation (block) valves – placed on each side of control valves and pumps, allowing them to be removed for repair or replacement;

399

•check valves – used to prevent reverse flow;

•relief valves – admit air to the pipe while the pipe is being drained to prevent excessive vacuum pressures and reduce the possibility of collapsing thin-walled pipes;

•air valves – designed to expel large amounts of air at low pressure during filling and release small amounts of pressurized air during operation.

(Kennedy, John L., Oil and Gas Pipeline Fundamentals, USA. 1999)

|

Terms and Vocabulary |

air valve |

воздуховыпускной клапан |

cavitation |

кавитация |

check valve |

обратный клапан |

control valve |

распределительный клапан |

flow control valve |

дроссель, регулятор потока |

repair |

ремонт |

excessive (pressure) |

избыточное давление |

expel (v) |

исключать |

operation |

работа / процесс |

collapsing |

разрушающий |

replacement |

замена |

pressure transient |

неустановившееся давление / давление в |

|

переходном режиме |

release valve |

выпускной клапан |

reverse flow |

обратный поток |

relief valve |

перепускной клапан |

isolation (block) valve |

стопорный (запорный) клапан |

4. Find terms which are used with the following words.

Example: flow control valve

•flow

•valve

•fluid

400

5. Compose collocations from the following words.

Example: fully developed

flow |

entrance |

velocity |

developed |

region |

cross |

mechanic |

motion fully profile boundary |

fluid |

section |

reverse |

layer |

laminar turbulent

6. Match the definitions with the following terms.

Example: 11. laminar flow – G. a smooth flow of fluid in which no turbulence or cross flow of fluid particles occurs between adjacent stream line

1. |

pipe flow |

A. |

the speed at which a fluid moves or passes |

|

|

|

through an object |

2. |

fluid |

B. |

nonlinear flow of a fluid, caused by high |

|

|

|

velocity |

3. |

flow |

C. |

a scale of pressure differences in which there |

|

|

|

is a uniform variation of pressure from point |

|

|

|

to point |

4. |

valve |

D. |

a pipe through which a fluid flows without |

|

|

|

completely filling the pipe |

5. |

velocity profile |

E. |

a pipe is completely filled with the fluid being |

|

|

|

transported |

6. |

shear stress |

F. |

a substance that flows and yields to any force |

|

|

|

tending to change its shape |

7. |

turbulent flow |

G. |

a smooth flow of fluid in which no |

|

|

|

turbulence or cross flow of fluid particles |

|

|

|

occurs between adjacent stream line |

8. |

fitting |

H. |

a current or stream of fluid |

9. |

open-channel flow |

I. |

a device used to control the rate of flow on a |

|

|

|

line to open or shut off a line completely or to |

|

|

|

serve as an automatic / semi-automatic safety |

|

|

|

device |

10. |

pressure gradient |

J. |

a smaller, standardized part (valve, gauge) |

|

|

|

installed in a larger part (device / apparatus) |

11. |

laminar flow |

K. |

force applied to a liquid to cause it to flow |

|

|

|

401 |

7.Replace the underlined words with a suitable variant from the text.

1.Fluid mechanics is the discipline concerned with behavior (the movement or conduct) of liquids and gases in quiescent state or when they are moving.

2.Some of the basic components of a typical pipe system include the pipes themselves, the various parts which connect the individual pipes to form the desired system, the flowrate control devices and the pumps.

3.For the situation when the pipe is not completely filled, gravity alone is the driving force for fluid. For other situations where the pipe is completely filled with the fluid being transported, gravity may be important, but the main driving force is likely to be a pressure gradient along the pipe.

4.The region of flow near where the fluid comes into the pipe is termed the inlet area.

5.The primary valve types are valves used to regulate flow, pressure, liquid level, cavitation and pressure transients, valves placed on each side of valves and valves which are designed to prevent reverse flow.

8.Answer the following questions.

1.What is the difference between the following terms:

•Pipe

•Conduit

•Duct

2.What are the pipe system components and give their definitions?

3.What is the difference between pipe flow and open-channel flow? Give examples.

4.What factors can affect the Reynolds number during the transition fro laminar to turbulent flow?

5.Why is velocity profile important in understanding different flows?

6.What is a valve? Give examples, indicating their functions.

7.What are the most important criteria for control valves?

402

9. Discussion. Complete the following diagrams and give all necessary explanations.

pipe system

flow

10. You will hear a part of a lecture series on Fluid Mechanics. For questions 1-10, complete the sentences with a word or phrase.

To discuss the dynamics we have to be able to describe |

(1) |

|||||

The description of motion is called |

|

(2) |

|

|

||

In the contracted flow |

|

(3) have been used to identify pieces of |

||||

fluid. |

|

|

|

|

|

|

In elementary mechanics we are used to describing a position of material

time as a |

(4) |

|

|

|

|

|

|

|

In infinity |

of mass |

point it is necessary to pick |

(5) |

called |

||||

initial time. |

|

|

|

|

|

|

|

|

Velocity is the function of |

|

(6) |

|

|

(7) |

|||

From the Lagrangian velocity it is easy to |

calculate |

|

|

|||||

As Lagrangian measurements are very complicated, it is more convenient to

make measurements at points fixed at |

(8) |

The fact that velocity at point of laboratory coordinates is not always referred to the same piece of matter leads to (9) between Lagrangian and Eularian representations.

(10) is an advantage of laboratory coordinates.

403

11.Prepare the following presentations.

1.Laminar and turbulent flows

2.Valve and their functions

3.General Characteristics of Pipe Flow

4.Pipe system components

5.Fluid mechanics

|

WORDLIST |

|

|

ENGLISH |

RUSSIAN |

air valve |

воздуховыпускной клапан |

cavitation |

кавитация |

check valve |

обратный клапан |

collapsing |

разрушающий |

conduit |

трубопровод; труба |

control valve |

распределительный клапан |

developing flow |

развивающийся поток |

driving force |

движущая сила |

duct |

труба (не с круглым поперечным сечением) |

excessive (pressure) |

избыточное давление |

expel (v) |

исключать |

flow (move) |

поток; течение |

flow control valve |

дроссель, регулятор потока |

fluid |

флюиды |

fully developed flow |

развитый поток |

isolation (block) valve |

стопорный (запорный) клапан |

momentum transfer |

передача (перенос) импульса |

open-channel flow |

поток (в не полностью заполненной трубе) |

operation |

работа / процесс |

pipe |

трубопровод |

pipe flow |

поток в трубопроводе (в полностью |

|

заполненной трубе) |

pipe system |

система трубопроводных линий, сеть |

|

трубопроводов |

pressure difference |

разность давлений |

pressure gradient |

градиент давления |

pressure transient |

неустановившееся давление / давление в |

|

переходном режиме |

release valve |

выпускной клапан |

|

404 |

relief valve |

перепускной клапан |

repair |

ремонт |

replacement |

замена |

reverse flow |

обратный поток |

shear stress |

напряжение сдвига |

velocity profile |

скоростной профиль |

405

UNIT 3

JOINING PIPES

Piping refers to the overall network of pipes, fittings, flanges, valves and other components that comprise a conduit system to convey liquids. Whether a piping system is used to convey fluids from one point to another or to process and condition the fluid, piping connections serve an important role in the operation of the system.

Pipes can conduit fluid under gravity, vacuum, low-pressure, or high pressure in a process, pneumatic or hydraulic system. Depending on the application, pipe connections can take a variety of forms.

Lead-in

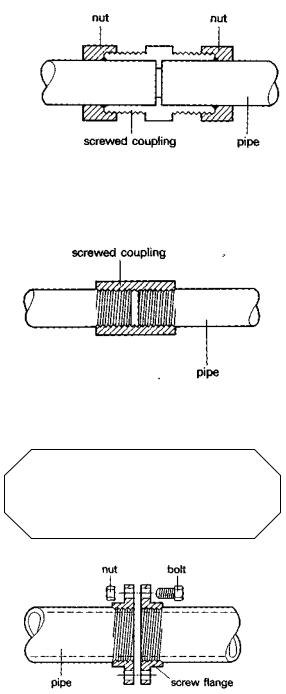

Many different kinds of joint are used to connect pipes. Three types of fittings for small D pipes and three for large D pipes are shown in the below diagrams. Fill in the missing words. Describe pipe joint types (WHAT DO YOU KNOW?)

are pushed |

is soldered |

is pushed |

is screwed |

Small diameter pipes

A.Each pipe ___ _______ into the connector; the connector _____ ________ to the pipes.

406

B. The pipes _____ _______ into the coupling; then the nuts ___on.

C. Each pipe ______ ________ into the threaded coupling.

Large diameter pipes

are clamped are bolted(x3)

are welded (x2)

D. The flanges ____ _______ onto the pipe.

Then they ____ _______ together.

407

E. The ends of the two pipes ____ ____ together.

F. The flanges _____ _______. Then ______ ________.

G. The two flanges _____ ____ together. Then the clamps ______

_________ together.

1.What are the joining processes?

2.What are the joining devices and materials?

(Basic Technical English, Oxford University Press. 2002)

408

|

Terms and Vocabulary |

flange |

фланец |

convey (v) |

переправлять |

ductile or cast iron |

чугун с шаровидным графитом (чугун) |

malleable iron |

ковкий чугун |

cast steel |

литая сталь |

brass |

латунь |

disconnection |

разделение |

welding |

сварка |

crimping |

гофрирование |

threaded |

с резьбой |

flanged |

ребристый |

coupled |

сдвоенный |

loose |

неприкрепленный |

tapered male fitting |

фитинг с наружной резьбой |

tapered |

конусообразный/клиновидный/ |

|

скошенный/заостренный |

female fitting |

фитинг с внутренней резьбой |

resin |

смола |

capillary action |

капиллярное действие |

compression |

прокладка / набивка / уплотнение |

couplings |

соединение (муфта) |

(elastometric) gasket |

прокладка/набивка/уплотнение/сальник |

grooved |

гофрированный |

vinyl (pipe) |

винил |

(heat) fusion |

плавка |

impregnated |

пропитанный |

adhesive |

связывающий |

circumferential |

периферический |

polyolefin |

полиолефин |

crimped joint |

опрессованное соединение |

sleeve |

рукав / муфта |

brazing |

пайка твердым припоем |

annular space |

кольцевое пространство |

yielding (metal) |

пластичный металл |

seal |

перемычка |

seating surface (seal weld) |

монтажный фланец (сварная перемычка) |

tightness |

герметичность |

dismantle |

разбирать |

union |

соединение |

prone |

свойственный |

|

409 |