- •GENERAL INFORMATION

- •SERVICE ADJUSTMENTS

- •MASTER CYLINDER FLUID LEVEL

- •ABS BRAKES

- •ADJUSTING REAR SERVICE BRAKES

- •TESTING APPLICATION ADJUSTER OPERATION

- •BLEEDING BRAKE SYSTEM

- •PRESSURE BLEEDING

- •BLEEDING WITHOUT A PRESSURE BLEEDER

- •TEST FOR FLUID CONTAMINATION

- •WHEEL STUD NUT TIGHTENING

- •BRAKE HOSE AND TUBING

- •INSPECTION OF BRAKE HOSE AND TUBING

- •FIG. 10 BRAKE LINE ROUTING NON ABS BRAKES

- •INSTALLATION OF BRAKE HOSE

- •TYPES OF TUBING FLARES

- •TO REPAIR OR FLARE TUBING

- •ISO TUBING FLARES

- •BASIC DIAGNOSIS GUIDE

- •BRAKE SYSTEM DIAGNOSTICS

- •BRAKE SYSTEM DIAGNOSTICS

- •BRAKE SYSTEM DIAGNOSTICS

- •BRAKE SYSTEM DIAGNOSTICS

- •REAR WHEEL DRUM BRAKES

- •DESCRIPTION

- •SERVICE PROCEDURES

- •REAR BRAKE DRUM REMOVAL

- •BRAKE DRUM INSTALLATION

- •BRAKE SHOE ASSEMBLIES

- •REMOVAL

- •CLEANING AND INSPECTION

- •BRAKE SHOE INSTALLATION

- •KELSEY HAYES REASSEMBLE

- •VARGA REASSEMBLE

- •BRAKE DRUM REFACING

- •WHEEL CYLINDERS

- •GENERAL INFORMATION

- •SERVICE PROCEDURES

- •REMOVING WHEEL CYLINDERS FROM BRAKE SUPPORT PLATES

- •DISASSEMBLING WHEEL CYLINDERS

- •ASSEMBLING WHEEL CYLINDERS

- •INSTALLING WHEEL CYLINDERS

- •BRAKE SUPPORT ASSEMBLY

- •REMOVAL

- •INSTALLATION

- •HYDRAULIC SYSTEM CONTROL VALVES

- •GENERAL INFORMATION

- •PRESSURE DIFFERENTIAL WARNING LIGHT SWITCH

- •ABS BRAKE PROPORTIONING VALVE OPERATION

- •HYDRAULIC SYSTEM SERVICE PROCEDURES

- •BRAKE WARNING SYSTEM

- •PROPORTIONING VALVES

- •PROPORTIONING VALVE APPLICATIONS

- •TESTING ABS PROPORTIONING VALVES

- •FRONT DISC BRAKES

- •GENERAL INFORMATION

- •SHOE AND LINING WEAR

- •SERVICE PRECAUTIONS

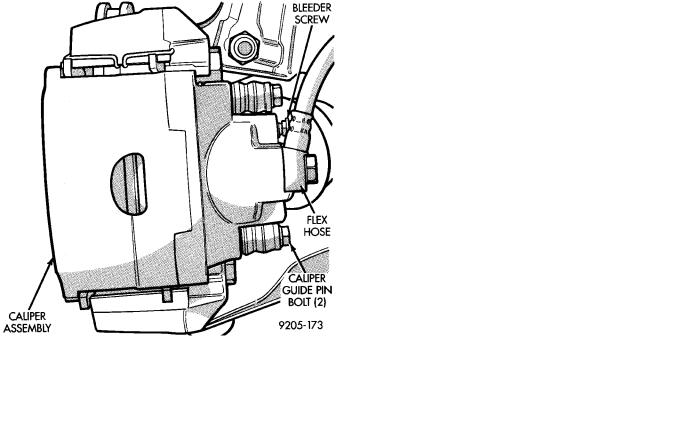

- •KELSEY HAYES DOUBLE PIN FAMILY CALIPER

- •BRAKE SHOE SERVICE PROCEDURES

- •REMOVAL

- •INSTALLATION

- •SERVICE PROCEDURES

- •BRAKE SHOES REMOVE

- •CLEANING AND INSPECTION

- •BRAKE SHOES INSTALL

- •DISC BRAKE CALIPER DISASSEMBLY

- •CLEANING AND INSPECTION

- •CLEANING AND INSPECTION OF BRAKE CALIPER

- •ASSEMBLING DISC BRAKE CALIPER

- •REAR DISC BRAKES

- •GENERAL INFORMATION

- •LINING WEAR

- •SERVICE PRECAUTIONS

- •BRAKE SHOE REMOVAL

- •CLEANING AND INSPECTION

- •BRAKE SHOE INSTALLATION

- •DISASSEMBLING REAR CALIPER ASSEMBLY

- •CLEANING AND INSPECTION

- •CLEANING AND INSPECTION

- •ASSEMBLING REAR DISC BRAKE CALIPER

- •BRAKE DISC (ROTOR)

- •GENERAL INFORMATION

- •INSPECTION DIAGNOSIS

- •SERVICE PROCEDURES

- •CHECKING BRAKING DISC FOR RUNOUT AND THICKNESS

- •BRAKING DISC REMOVAL

- •INSTALLING BRAKING DISC

- •REFINISHING BRAKING DISC

- •REFACING BRAKING DISC

- •RESURFACING BRAKING DISC

- •BRAKING DISC (ROTOR) REFINISHING LIMITS

- •PARKING BRAKES

- •GENERAL INFORMATION

- •SERVICE PROCEDURES

- •ADJUSTING PARKING BRAKE

- •FIG. 2 PARKING BRAKE CABLE ROUTING AA AND AP BODY

- •FIG. 4 PARKING BRAKE CABLE ROUTING AG AND AJ BODY

- •SELF ADJUSTING PROCEDURES

- •TO RELOAD SELF ADJUSTER

- •ADJUST PARKING BRAKE

- •REAR PARKING BRAKE CABLE REMOVAL

- •DRUM BRAKES

- •DISC BRAKES

- •INSTALLING PARKING BRAKE REAR CABLE

- •DRUM BRAKES

- •DISC BRAKES ALL

- •REMOVING PARKING BRAKE FRONT CABLE

- •INSTALLING PARKING BRAKE FRONT CABLE

- •REMOVAL AG AND AJ BODY

- •INSTALLATION AG AND AJ BODY

- •REMOVAL AND INSTALLATION PARKING BRAKE SHOES

- •ALL WITH REAR DISC BRAKES

- •INSTALLING PARKING BRAKE SHOES

- •MASTER CYLINDER

- •GENERAL INFORMATION

- •BRAKE FLUID LEVEL SENSOR

- •TESTING THE MASTER CYLINDER

- •MASTER CYLINDER SERVICE PROCEDURES

- •MASTER CYLINDER REMOVAL

- •BRAKE FLUID RESERVOIR REPLACEMENT

- •BLEEDING MASTER CYLINDER

- •INSTALLING MASTER CYLINDER

- •POWER BRAKES

- •GENERAL INFORMATION

- •SERVICE PROCEDURES

- •POWER BRAKE BOOSTER ASSEMBLY

- •WHEEL BEARINGS

- •FRONT WHEEL BEARINGS

- •REAR WHEEL BEARINGS

- •NORMAL SERVICE

- •INSPECTION

- •REMOVAL AND INSTALLATION

- •GENERAL INFORMATION

- •NORMAL BRAKING SYSTEM FUNCTION

- •MAJOR ABS COMPONENTS

- •HYDRAULIC ASSEMBLY

- •WHEEL SPEED SENSORS

- •NORMAL BRAKING SYSTEM FUNCTION

- •PEDAL FEEL

- •TIRE NOISE & MARKS

- •ABS EQUIPPED VEHICLE PERFORMANCE

- •ABS WARNING SYSTEMS OPERATION

- •RED BRAKE WARNING LAMP

- •NORMAL OPERATION OF WARNING LAMPS

- •HYDRAULIC ASSEMBLY

- •HYDRAULIC BLADDER ACCUMULATOR

- •DUAL FUNCTION PRESSURE SWITCH

- •PRESSURE TRANSDUCERS

- •DIFFERENTIAL PRESSURE SWITCH

- •PROPORTIONING VALVES

- •FLUID LEVEL SWITCH

- •DUAL FUNCTION PRESSURE SWITCH WIRING DIAGRAM

- •WHEEL SPEED SENSORS

- •PRESSURE SWITCH AND PRESSURE TRANSDUCER WIRING

- •ABS SYSTEM WIRING SCHEMATIC

- •ABS SYSTEM DIAGNOSTIC CONNECTOR

- •SYSTEM RELAY

- •ABS HYDRAULIC CIRCUITS AND VALVE OPERATION

- •NORMAL BRAKING

- •ABS BRAKING SYSTEM DIAGNOSIS

- •GENERAL INFORMATION

- •DEFINITIONS

- •ABS SYSTEM GENERAL SERVICE PRECAUTIONS

- •TEST DRIVING ABS COMPLAINT VEHICLES

- •WHEEL SPEED SENSOR CABLES

- •SPECIAL SERVICE TOOLS

- •INTERMITTENT FAULTS

- •ABS BRAKE SYSTEM DIAGNOSTIC FEATURES

- •SYSTEM SELF DIAGNOSIS

- •BENDIX ABS SYSTEMS DIAGNOSTICS

- •ON CAR HYDRAULIC ABS COMPONENT SERVICE

- •GENERAL SERVICE PRECAUTIONS

- •CHECKING BRAKE FLUID LEVEL

- •BLEEDING ABS BRAKE SYSTEM

- •BRAKE FLUID PRESSURE AND RETURN HOSES (FIG. 6)

- •INSTALL

- •HYDRAULIC ASSEMBLY

- •BRAKE FLUID RESERVOIR

- •HYDRAULIC BLADDER ACCUMULATOR

- •PROPORTIONING VALVES (FIG. 17)

- •ELECTRONIC COMPONENTS

- •WHEEL SPEED SENSORS

- •FRONT WHEEL SPEED SENSOR

- •REAR WHEEL SPEED SENSOR (FIGS. 13 AND 15)

- •GENERAL INFORMATION

- •NORMAL BRAKING SYSTEM FUNCTION

- •MAJOR COMPONENTS

- •MASTER CYLINDER AND VACUUM BOOSTER

- •WHEEL SPEED SENSORS

- •PEDAL FEEL

- •TIRE NOISE & MARKS

- •VEHICLE PERFORMANCE

- •WARNING SYSTEMS OPERATION

- •NORMAL OPERATION OF WARNING LAMP

- •MODULATOR ASSEMBLY

- •ISOLATION VALVES

- •SHUTTLE ORIFICE

- •FLUID SUMPS

- •HYDRAULIC SPRING ACCUMULATOR

- •PROPORTIONING VALVES

- •WHEEL SPEED SENSORS

- •DIAGNOSTIC CONNECTOR

- •SYSTEM RELAY

- •HYDRAULIC CIRCUITS AND VALVE OPERATION

- •NORMAL BRAKING

- •ABS BRAKE SYSTEM DIAGNOSIS

- •GENERAL INFORMATION

- •DEFINITIONS

- •ABS COMPUTER SYSTEM SERVICE PRECAUTIONS

- •ABS GENERAL SERVICE PRECAUTIONS

- •TEST DRIVING ABS COMPLAINT VEHICLES

- •ABS BRAKE SYSTEM ON VEHICLE SERVICE

- •WHEEL SPEED SENSOR CABLES

- •SPECIAL SERVICE TOOL

- •INTERMITTENT FAULTS

- •ABS BRAKE SYSTEM DIAGNOSTIC FEATURES

- •ABS SYSTEM SELF DIAGNOSIS

- •BENDIX ABS SYSTEMS DIAGNOSTICS

- •GENERAL SERVICE PRECAUTIONS

- •CHECKING BRAKE FLUID LEVEL

- •MODULATOR ASSEMBLY (FIG. 2)

- •MASTER CYLINDER AND POWER BOOSTER

- •PROPORTIONING VALVES (FIG. 5)

- •ELECTRONIC COMPONENTS

- •WHEEL SPEED SENSORS

- •FRONT WHEEL SPEED SENSOR (FIG. 12)

- •REAR WHEEL SPEED SENSOR (FIGS. 13 AND 14)

- •SPECIFICATIONS

- •SPECIFICATIONS METRIC

- •BRAKE ACTUATION SYSTEM

- •TIGHTENING REFERENCE

Ä |

|

BRAKES 5 - 7 |

|

Swollen rubber parts indicate the presence of petroleum in the brake fluid.

To test for contamination, put small amount of drained brake fluid in clear glass jar. If fluid separates into layers, there is mineral oil contamination.

If contaminated, drain and thoroughly flush system. Replace master cylinder, proportioning valve, caliper seals, wheel cylinder seals and all hoses.

WHEEL STUD NUT TIGHTENING

When tightening wheel stud nuts, a criss-cross tightening sequence should be followed (Fig. 9).

Fig. 8 Open Bleeder Screw at Least One Full Turn

(Typical)

Repeat the procedure at all the other remaining bleeder screws. Then check the pedal for travel. If pedal travel is excessive or has not been improved. Enough fluid has not passed through the system to expel all the trapped air. Be sure to monitor the fluid level in the pressure bleeder. It must stay at the proper level so air will not be allowed to reenter the brake system through the master cylinder.

BLEEDING WITHOUT A PRESSURE BLEEDER

If a pressure bleeder is not available. A good brake fluid flow can be obtained by manual bleeding of the brake hydraulic system, following these steps.

(1)Pump the brake pedal three or four times and hold it down before the bleeder screw is opened.

(2)Then open the bleeder screw at least 1 full turn. When the bleeder screw opens the brake pedal will drop all the way to the floor.

(3)Release the brake pedal only after the bleeder screw is closed.

(4)Repeat steps 1 through 3, four or five times, at each bleeder screw. This should pass a sufficient amount of fluid to expel all the trapped air from the brake system. Be sure to monitor the fluid level in the master cylinder, so it stays at a proper level so air will not reenter the brake system through the master cylinder.

Test drive vehicle to be sure brakes are operating correctly and that pedal is solid.

TEST FOR FLUID CONTAMINATION

Fig. 9 Wheel Stud Nut Tightening Sequence

Tighten all stud nuts to one-half specified torque. Repeat, fully tightening to 129 NIm (95 ft. lbs.).

BRAKE HOSE AND TUBING

INSPECTION OF BRAKE HOSE AND TUBING

Flexible rubber hose is used at both front brakes and at the rear axle. Inspection of brake hoses should be performed whenever the brake system is serviced and every 7,500 miles or 12 months, whichever comes first (every engine oil change). Inspect hydraulic brake hoses for severe surface cracking, scuffing, or worn spots. Should the fabric casing of the rubber hose be exposed due to cracks or abrasions in the rubber hose cover, the hose should be replaced immediately. Eventual deterioration of the hose can take place with possible burst failure. Faulty installation can cause twisting and wheel, tire or chassis interference (Figs. 10, 11 and 12).

The steel brake tubing should be inspected periodically for evidence of physical damage or contact with moving or hot components.

Indications of fluid contamination are swollen or deteriorated rubber parts.

5 - 8 BRAKES |

|

Ä |

|

FIG. 10 BRAKE LINE ROUTING NON ABS BRAKES

Ä |

|

BRAKES 5 - 9 |

|

FIG. 11 BRAKE LINE ROUTING WITH ANTI-LOCK 10 BRAKES

5 - 10 BRAKES |

|

Ä |

|

FIG. 12 BRAKE LINE ROUTING WITH ANTI-LOCK 6 BRAKES