accounting and control procedures, arrange for maintenance and control of the system operations and so on. Said NM A&C system components are expected to be present in the model such that to make the system meeting the defined tasks to the highest extent possible.

It is at the closing work phase that it is decided on to what extent the developed NM A&C system version meets the tasks it is assigned to. The purpose of this design stage is to estimate the efficiency of the system operations to the selected criterion. It is a general knowledge that efficiency is the property of a system showing to what extent it fits the tasks at hand. Different approaches are under consideration for use to estimate NM A&C system efficiency. Thus, confidence of data on NM attributes is considered to be the efficiency index.

It should be however noted that NM A&C system efficiency is not easy to estimate universally. It is normally estimated on computer models with estimates relating to the quality of NM balances in the MBA (say, requirements to the accuracy of NM balances in the MBA).

The NM A&C system functional efficiency can be also indicated by how credibly the MBA NM accounting and control system presents data on identifiers of items, TID identifiers and locations of items. This indicator value should not be below 99%. If a system model estimate fails to satisfy to the criterion chosen, it is to be changed. So, if the share of erroneous data on attributes exceeds 1%, respective automated procedures may be used instead of manual data entry/processing. Therefore, building the final NM A&C system model version is an iterative process. The number of iterations depends on how rigid the adopted design estimator is.

CHAPTER 10

CONTROL OF NUCLEAR MATERIAL

Hereinabove, attention was focused on the NM accounting system. This serves to ensure the knowledge and the integrity of nuclear material. Balance closing is the procedure which helps getting the required confidence of the knowledge. In the context of accounting, however, confidence and integrity of NM are verified exclusively through physical inventory takings which are quite periodic (e.g., annual for NM of category IV). So control of nuclear material is undertaken as a complement to accounting. NM control includes control of the NM inventory and movement; control of access to NM, equipment and information; surveillance of NM, and check of authorizations for disposition and movement of NM. Control of NM supports the integrity and proper handling of NM, as well as the confidence of our knowledge about NM [1]. The following levels of NM control will be looked at hereinafter:

Control of NM at enterprises, including organizational measures and engineered NM control features;

State control of NM through inspections by Rostekhnadzor of Russia; International control of NM.

10.1. NM control at enterprises

Localization of NM and identification (labeling) of NM-containing objects as prerequisites of efficient control of NM

Enterprises have NM controlled involving largely the two following controls:

∙Control of NM inventory. The binding requirement here is identification of facilities with NM;

∙Control of access to NM. The binding requirement in this is localization of NM.

With identification aspects having been dealt with in Chapter 9, we shall take a closer look at localization of NM.

Relative inaccessibility of NM (instructions on how to produce a primitive nuclear charge can be found in Internet) is believed to be the basic reasoning behind the efforts to curb the spreading of nuclear weapons. Localization, which supports this inaccessibility, means disposition of nuclear material inside special areas and facilities. Engineered features in these enable access to NM to be controlled. Secure

areas and material access areas (MAA) are specific examples of such special areas.

Secure areas. A secure area may be a protected, an inner and a vital area. Secure areas include barriers to delay intruders into the area (security perimeter). Barriers are formed by fencing, structural elements and so on. Each secure area also includes an access control point and is equipped with respective access controls.

NM and nuclear facility physical protection regulations prescribe that:

∙NM of categories 1 and 2 should be used and stored in the inner or the vital area;

∙nuclear facilities should be deployed within the inner or the vital area;

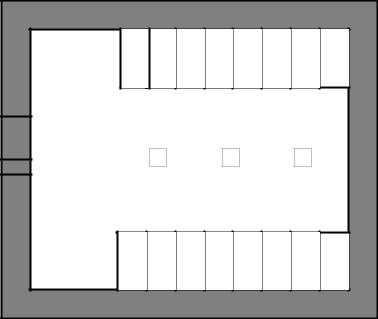

∙NM of category 3 should be used and stored within any secure area. Fig. 10.1 shows an example of localization areas layout for NM of

different categories.

Material access areas. Material accessibility areas are process department and NM storage areas.

A process department is where nuclear material is subject to physical and chemical changes. Most NM quantitative changes take place within process departments. Being where nuclear material is accessible directly, process departments are subject to special security regulations. This includes the requirement of permits to enter a process department to be granted only to personnel involved in running the process. The amount of the material within a department is normally limited to the quantity needed for one-day routine operations. Access control logs are kept at each process department with entries made therein on all persons granted access to the given department. This makes a starting point for anomalies to be investigated. In the absence of personnel, the intrusion detection system is active.

Apart from security features, it is important that process departments enable reliable control of the NM therein, including by way of localizing material.

ProtectedЗащищенная зонаarea

Category III NM

Хранилище ЯМ категории III

storage facility

|

Внутренняя зона |

|

|

Inner area |

|

|

Особо важная зона |

|

|

Vital area |

|

1 |

2 |

3 |

4 |

|

NM storage |

|

|

ХранилищеfacilityЯМ |

|

Fig. 10.1. Nuclear material localization areas: 1, 2, 3, 4 – process departments

For process departments, localization of NM suggests that NM should remain in equipment, pipelines, glove boxes, safes and containers. Therefore, material stays in these facility components when the process is run, thus making it harder to remove it in an unauthorized manner. Fig. 2.1 (Part II, Chapter 2) shows process departments for fabrication of lowenriched fuel. Each of these has nuclear material localized in equipment, safes and containers. Containers are commonly used to store NM and ensure efficient localization of bulk material (Fig.10.2). Practically, different container types are used (metal drums, cans, assemblies, packages, tanks, vessels and others).

424

Fig. 10.2. NM localization container

Safes, stores and containers are kept locked unless immediately watched by an authorized person. The material contained therein is accessible to the smallest reasonable number of personnel. The lock codes are updated whenever situation with NM changes within the department. Thus, this is done when a container is initially received or a personnel member who knows the code is transferred or dismissed.

It is also important that nuclear security measures, which are of a prime significance to any process department with NM, have also the goal of localizing nuclear material contributing so to better NM control conditions.

Localization in storage areas. Nuclear material may be also kept in storage areas at the facility or at NM storage points outside the facility. An NM storage point is a fixed standalone installation. Fig. 10.3 shows an example of how NM can be localized in a storage facility.

425

А

А

Fig. 10.3. An example of NM storage facility: A – c ontainer racks; B – NM safes

Storage facilities offer the best NM control solutions. The major elements of the storage facility structure (floors, walls, roofing and doors) normally satisfy to top-level material localization requirements, including reinforced-concrete floor, ceiling, roofing and walls of the thickness not less 20 cm. Any openings in storage facilities that permit unauthorized intrusion thereto are equipped with barriers. It is forbidden to process material and handle same other than for the purposes of NM storage (say, for experiments involving NM) within storage facilities. It is also forbidden to lay routes to other areas of operations through storage facilities.

NM access controls

An important feature of current accounting and control systems is the maximum use of access controls. All developed countries, including Russia, have their NM accounting and control systems relying on measured material balance. Furthermore, a measurement of NM inventory is in fact a

426

serious physical experiment. Still there is more to that. Measurements of nuclear materials as such are rather a time-taking and hazardous procedure (especially when it comes to plutonium). So it is required to make so that NM measurements be reduced to as small scope as it can be. In this, the continuity of knowledge about NM is ensured through using NM access controls.

Access controls include two types of provisions known as surveillance and containment measures.

Surveillance. The simplest and the most commonly used surveillance type is visual surveillance. This requires continuous presence of a number of persons. A two-person rule is used for NM handling when critical operations with nuclear material are done by not less than two persons. A three-person rule can be used to handle weapon-grade material.

For NM control, many countries make an extensive use of optoelectronic surveillance (OES) via TV monitors. Fig. 10.4 shows an option of the OES camera installation in a spent fuel pool.

For years, optical surveillance of NM has been used successfully in the context of international safeguards. The IAEA uses optical surveillance to control NM movements, survey spent fuel in storage facilities and for other purposes. Photographic surveillance systems (MINOLTA) were employed by the IAEA until 1988 when these were replaced for video systems of a greater efficiency. Table 3.2 (Part I, Chapter 3) gives examples of video systems used now by IAEA, which demonstrate the increasingly great capabilities of this nuclear material control technique.

Containment. Containment ensures continuity of the knowledge about NM at rest. Containment, first of all, means use of all kinds of sensors that detect unauthorized access (tamper indicating devices or TIDs) or respond to changes in the condition or the positions of nuclear material (hybrid NM containment techniques). Thus, if a container shift is detected, the sensor generates the message of the container having been moved.

TIDs represent seals of different types.

Seals have the role of detecting unauthorized access to NM (seals are used for containers, item packages, doors and so on).

There are three properties that characterize the efficiency of seals:

∙weakness: means that seals are easily breakable, serving so to forestall unauthorized activities with NM;

∙tamper indication: if broken, seals are hard to replace without traces of the tamper left;

∙ uniqueness: seals should possess unique identifiers (preferably concealed).

Fig. 10.4. An option of the OES camera installation in a spent fuel pool

Fig. 10.5 – 10.9 show examples of various seal type s used in practical NM handling: Е–cup, PS360 loop seal, Multi–lock, Cobra and Vacoss .

Fig. 10.5. Cup-Еseal design

Fig. 10.6. A plastic loop seal (PS360 model)

2 3

1

Fig. 10.7. Multi–Lock seal design: 1 – spring; 2 – aluminum ball; 3 – steel ball

Fig. 10.8. Cobra seal design:

1 – compression rod; 2 – shearing razor; 3 – fiber optic cable; 4 – seal body

429

Fig. 10.9. Reusable Vacoss seal design by Aquila, the USA

Adhesive seals (stamps). These seals have a paper, vinyl or lavsan base with an adhesive applied to it on the inside. Adhesive seals may contain one or more base layers.

Paper or vinyl adhesive seals have a single-layer base. After placement, these seals are hard to remove without traces of the tamper left because:

∙paper seals are based on rice paper so they can be broken easily when removed;

∙vinyl seals have cross cuts made along the entire base length, which makes it much more difficult to remove a seal without breaking it.

A lavsan seal has a transparent outer layer and a colored metallized inner layer. The inner layer bears a drawing and the ordinal number. The colored base layer of a lavsan seal has a seal breaking sign (the words Void or Open for example) preprinted across the base length on the adhesive side. When a seal is removed, this sign appears on the container surface and the stretched colored base fails to match the image left on the container.

Adhesive seals are used to seal containers with NM.

Hybrid containment techniques

Access control techniques include also US-developed hybrid methods used now also in Russia. These are gamma image memorization techniques. A detector is placed beneath a container with NM (e.g. HEU) for continuous gamma ray detection. The gamma ray spectrum comes further to the computer and is compared to the reference spectrum, i.e. the spectrum that was recorded when the material was placed under control. If the comparison fails to confirm the identity of the spectra, an alarm is on. A gamma image technology is used, which also ensures the confidence of knowledge about the status of nuclear material.

430