- •Unit 1 history of footwear text a

- •Read and remember the words and their translation:

- •Read and remember the following phrases:

- •Read and translate the following text: history of footwear

- •Answer the questions:

- •X. Speak on the topic using the following words and word-combinations:

- •I. Read and remember:

- •Read the text and define the main idea of it: from the history of the western boot

- •Make up a plan of the text.

- •Translate the paragraph in italics in a written form.

- •Questions for discussion:

- •Render the text in brief in a written form. Text c

- •I. Mind the following words and word-combinations:

- •II. Listen to the text ‘shoes in the costume institute’ and decide if the statements are true or false:

- •III. Listen to the text again and be ready to answer the questions:

- •Unit 2 footwear text a

- •I. Read and remember the words and their translation:

- •II. Read and remember the following phrases:

- •III. Read and translate the following text: footwear

- •IV. Answer the questions:

- •X. Speak on the topic using the following words and word-combinations:

- •I. Read and remember:

- •II. Read the text and define the main idea of it: footwear in summer and winter

- •III. Make up a plan of the text.

- •IV. Translate the paragraph in italics in a written form.

- •V. Questions for discussion:

- •Unit 3 footwear styles text a

- •Read and remember the following phrases:

- •Read and translate the following text: footwear styles

- •IV. Answer the questions:

- •V. Complete the sentences with the words from the text:

- •X. Speak on the topic using the following words and word combinations:

- •Read and remember:

- •Read the text and define the main idea of it: types of shoes

- •Make up a plan of the text.

- •Translate the paragraph in italics in a written form.

- •Questions for discussion:

- •Render the text in brief in a written form. Text c

- •Mind the following words and word-combinations:

- •Listen to the text “top types of women’s shoes” and decide if the statements are true or false:

- •Listen to the text again and be ready to answer the questions:

- •Unit 4 footwear for special purposes text a

- •Listen and remember the following words:

- •II. Read and remember the following phrases:

- •III. Read and translate the following text: footwear and work

- •IV. Answer the questions:

- •V. Complete the sentences with the words from the text:

- •X. Speak on the topic using the following words and word combinations:

- •Read and remember:

- •Read the text and define the main idea of it: athletic shoes

- •Make up a plan of the text.

- •Translate the paragraph in italics in a written form.

- •Questions for discussion:

- •Render the text in brief in a written form. Text c

- •Mind the following words and word-combinations:

- •Listen to the text ‘arch supports in orthopedic footwear’ and decide if the statements are true or false:

- •Listen to the text again and be ready to answer the questions:

- •Unit 5 footwear materials text a

- •Listen and remember the following words:

- •Read and remember the following phrases:

- •Read and translate the following text: footwear materials

- •Answer the questions:

- •Complete the sentences with the words from the text:

- •X. Speak on the topic using the following words and word combinations:

- •Read and remember:

- •Read the text and define the main idea of it: coated fabrics in footwear manufacture

- •Make up a plan of the text.

- •Translate the paragraph in italics in a written form.

- •Questions for discussion:

- •Render the text in brief in a written form. Text c

- •Mind the following words and word-combinations:

- •Listen to the text ‘soling materials’ and decide if the statements are true or false:

- •Listen to the text again and be ready to answer the questions:

- •Unit 6 leather and its preparation text a

- •Read and remember the words and their translation:

- •II. Read and remember the following phrases:

- •III. Read and translate the following text: leather

- •IV. Answer the questions:

- •X. Speak on the topic using the following words and word-combination:

- •I. Read and remember:

- •II. Read the text and define the main idea: forms of leather

- •III. Make up a plan of the text.

- •IV. Translate the paragraph in italics in a written form.

- •V. Questions for discussion:

- •VI. Render the text in brief in a written form. Text c

- •I. Mind the following words and word-combinations:

- •III. Listen to the text again and be ready to answer the questions:

- •Unit 7 Leather Types text a

- •Read and remember the words and their translation:

- •Read and remember the following phrases:

- •Read and translate the following text: leather types

- •IV. Answer the questions:

- •X. Speak on the topic using the following words and word-combinations:

- •1. Read and remember:

- •II. Read the text and define the main idea of it: the most common leathers

- •III. Make up a plan of the text.

- •IV. Translate the paragraph in italics in a written form.

- •V. Questions for discussion:

- •I. Mind the following words and word-combinations:

- •II. Listen to the text ‘leather from other animals’ and decide if the statements are true or false:

- •III. Listen to the text again and be ready to answer the questions:

- •Unit 8 footwear design and designers text a

- •Read and remember the words and their translation:

- •Read and remember the following phrases:

- •Read and translate the following text: footwear design

- •IV. Answer the questions:

- •V. Complete the sentences with the words from the text:

- •X. Speak on the topic using the following words and word combinations:

- •Read and remember:

- •Read the text and define the main idea of it: training and qualifications

- •Make up a plan of the text.

- •Translate the paragraph in italics in a written form.

- •Questions for discussion:

- •Unit IX footwear parts text a

- •I. Read and remember the words and their translation:

- •II. Read and remember the following phrases:

- •III. Read and translate the following text: Shoe uppers

- •IV. Answer the questions:

- •V. Complete the sentences with the words from the text:

- •X. Speak on the topic using the following words and word-combinations:

- •I. Read and remember:

- •II. Read the text and define the main idea of it: The bottom of the shoe

- •III. Make up a plan of the text.

- •IV. Translate the paragraph in italics in a written form.

- •V. Questions for discussion:

- •VI. Render the text in brief in a written form. Text c

- •I. Mind the following words and word-combinations:

- •II. Listen to the text ‘the major parts of a shoe’ and decide if the statements are true or false:

- •III. Listen to the text again and be ready to answer the questions:

- •Unit X lasts text a

- •I. Read and remember the words and their translation:

- •II. Read and remember the following phrases:

- •III. Read and translate the following text: Last

- •IV. Answer the questions:

- •V. Complete the sentences with the words from the text:

- •X. Speak on the topic using the following words and word-combinations:

- •I. Read and remember:

- •II. Read the text and define the main idea of it: Lasts in shoemaking

- •III. Make up a plan of the text.

- •IV. Translate the paragraph in italics in a written form.

- •V. Questions for discussion:

- •VI. Render the text in brief in a written form. Text c

- •I. Mind the following words and word-combinations:

- •II. Listen to the text ‘shoe last design’ and decide if the statements are true or false:

- •III. Listen to the text again and be ready to answer the questions:

- •Unit XI methods of shoe construction text a

- •I. Read and remember the words and their translation:

- •II. Read and remember the following phrases:

- •III. Read and translate the following text: Methods of shoe construction

- •IV. Answer the questions:

- •X. Speak on the topic using the following words and word-combinations:

- •I. Read and remember:

- •II. Read the text and define the main idea of it: Shoe сonstruction

- •III. Make up a plan of the text.

- •IV. Translate the paragraph in italics in a written form.

- •V. Questions for discussion:

- •VI. Render the text in brief in a written form. Text c

- •I. Mind the following words and word-combinations:

- •II. Listen to the text ‘moulded and non-moulded shoes’ and decide if the statements are true or false:

- •III. Listen to the text again and be ready to answer the questions:

- •Unit XII leather goods text a

- •I. Read and remember the words and their translation:

- •II. Read and remember the following phrases:

- •III. Read and translate the following text: Manufacture of gloves and handbags

- •IV. Answer the following questions:

- •X. Speak on the topic using the following words and word-combinations:

- •I. Read and remember:

- •II. Read the text and define the main idea of it: Some historical facts about women’s gloves and handbags

- •III. Make up a plan of the text.

- •IV. Translate the paragraph in italics in a written form.

- •V. Questions for discussion:

- •Unit XIII horse tack text a

- •I. Read and remember the words and their translation:

- •II. Read and remember the following phrases:

- •III. Read and translate the following text: Horse tack: saddles, stirrups and martingales

- •IV. Answer the following questions:

- •X. Speak on the topic using the following words and word-combinations:

- •I. Read and remember:

- •II. Read the text and define the main idea of it: Horse Tack: Bridles and Breastplates

- •III. Make up a plan of the text.

- •IV. Translate the paragraph in italics in a written form.

- •V. Questions for discussion:

- •I. Mind the following words and word-combinations:

- •II. Listen to the text ‘riding boots’ and decide if the statements are true or false:

- •III. Listen to the text again and be ready to answer the questions:

- •Unit XIV the genesis of shoe machinery text a

- •I. Read and remember the words and their translation:

- •II. Read and remember the following phrases:

- •III. Read and translate the following text: Shoe-making machines

- •IV. Answer the questions:

- •V. Complete the sentences with the words from the text:

- •X. Speak on the topic using the following words and word-combinations:

- •Read and remember:

- •Read the text and define the main idea of it: Shoe-sewing machines

- •III. Make up a plan of the text.

- •IV. Translate the paragraph in italics in a written form.

- •V. Questions for discussion:

- •VI. Render the text in brief in a written form. Text c

- •I. Mind the following words and word-combinations:

- •II. Listen to the text “mothers of invention” and decide if the statements are true or false:

- •III. Listen to the text again and be ready to answer the questions:

- •Unit XV

- •I. Read and remember the words and their translation:

- •II. Read and remember the following phrases:

- •III. Read and translate the following text: cad/cam in Footwear Manufacture

- •IV. Answer the questions:

- •X. Speak on the topic using the following words and word-combinations:

- •I. Read and remember:

- •II. Read the text and define the main idea of it: Shoe uppers and soles design

- •III. Make up a plan of the text.

- •IV. Translate the paragraph in italics in a written form.

- •V. Questions for discussion:

- •VI. Render the text in brief in a written form. Text c

- •I. Mind the following words and word-combinations:

- •II. Listen to the text ‘cad shoe last design’ and decide if the statements are true or false:

- •III. Listen to the text again and be ready to answer the questions:

- •Unit XVI footwear industry text a

- •Read and remember the words and their translation:

- •Read and remember the following phrases:

- •III. Read and translate the following text: Light industry of Ukraine

- •Answer the questions:

- •Complete the sentences with the words from the text:

- •X. Speak on the topic using the following words and word-combinations:

- •I. Read and remember:

- •II. Read the text and define the main idea of it: The European footwear industry

- •III. Make up a plan of the text.

- •IV. Translate the paragraph in italics in a written form.

- •V. Questions for discussion:

- •VI. Render the text in brief in a written form. Text c

- •I. Mind the following words and word-combinations:

- •II. Listen to the text ‘eu footwear industry regulation’ and decide if the statements are true or false:

- •III. Listen to the text again and be ready to answer the questions:

- •Texts for home reading module I

- •Read and translate the following text: high-heeled footwear

- •Module II

- •Read and translate the following text: stiletto heel

- •Module III

- •Read and translate the following text: the wellington boot

- •Module IV

- •Read and translate the following text: flip-flops

- •Module V

- •I. Read and translate the following text: The best shoe

- •Module VI

- •I. Read and translate the following text: Midsole

- •Module VII

- •I. Read and translate the following text: Outsole

- •Module VIII

- •I. Read and translate the following text: Shoe polish

III. Make up a plan of the text.

IV. Translate the paragraph in italics in a written form.

V. Questions for discussion:

What sections does a sole consist of?

What do you know about the insole?

Where and why is the insole board necessary?

What is the outsole?

What characteristics are desirable for soling materials?

What soling materials are preferred and why?

What is done to improve gripping qualities of soles?

What is the function of the shank?

How is the ground contact section of the heel called?

What functions does the welt bring?

VI. Render the text in brief in a written form. Text c

I. Mind the following words and word-combinations:

heel counter – задник

brevity – стислість

fit – посадка

enhancing – посилення, підвищення

flexibility – гнучкість

stability – стабільність, міцність

to support – підтримувати

Velcro – застібка ‘липучка’

midsole – прокладка між підошвою і устілкою

II. Listen to the text ‘the major parts of a shoe’ and decide if the statements are true or false:

The upper of the old shoes could be tied so as to hold the protective outsole on the foot.

All subcomponents are important to the overall performance of a shoe.

Designers and scientists have always paid much attention to how well footwear fit.

Heel counter holds the shoe firmly in place around the heel region.

The specific purpose the shoe is never taken into account when selecting upper materials.

III. Listen to the text again and be ready to answer the questions:

What does the overall quality of the shoe depend on?

What are the functions of the upper in relevance with the materials used?

Unit X lasts text a

I. Read and remember the words and their translation:

last – колодка

rough – грубий

footprint – слід, відбиток ноги

to mold (mould) – формовати

cordwainer – швець

curved – вигнутий

flared – вигнутий

inflared – вигнутий внутрішньо

outflared – вигнутий зовнішньо

II. Read and remember the following phrases:

CNC machine – computer numerical controlled machine – верстат з ЧПУ

custom molded – сформований на замовлення

cone – конус, носова частина

bass – американська липа

hard rock maple – клен, що росте у скелястому грунті

to swell – роздуватися, набухати

to accommodate – пристосовувати

to withstand – протистояти, витримувати

III. Read and translate the following text: Last

A

![]()

O

![]()

Traditionally, shoe lasts were made of such specially selected hardwoods as either European bass hard wood or hard rock maple such as grows in colder weather which did not increase in shape for the brief period when wet materials were laid on them during shoe manufacture. But now modern day shoe lasts are mainly made of special high-molecular-weight, high-density polyethylene plastic (HMW-HDPE) as they don't swell or shrink and that are 100% recyclable. Besides, lasts made of HMW-HDPE allow for many tack holes without repairs to the bottoms. Metal lasts are also used in some manufacturing processes. Today, high fashion shoe designers farm out shoe production to China, where lasts are commonly made of HMW-HDPE and the plastic is recycled and reformed for different seasons. The only cordwainers still using wood lasts are the few in Italy, Germany, Denmark, Sweden and England. And some older American cowboy boot makers prefer wood lasts to bottom custom footwear. The material of a last does not affect the fit; but the shape and size of a last do affect the fit, and must accommodate the factory machinery used to finish the shoe. The material used to make the last must be firm enough to withstand the pressure applied by the pullover machines when bottoming the shoe. Both plastic lasts and wood lasts easily hold small tacks (called lasting tacks) which are used to preliminarily fasten areas of the shoe onto the last during before the sole is added. The process of stretching upper on to last is called lasting. The upper is stretched over the last and attached at the bottom. Strain is applied at different points on the upper to stretch it on. All the stretch is taken out of leather during lasting, such that the shoe maintains the last shape.

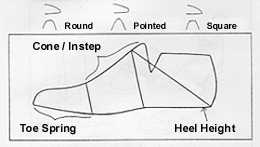

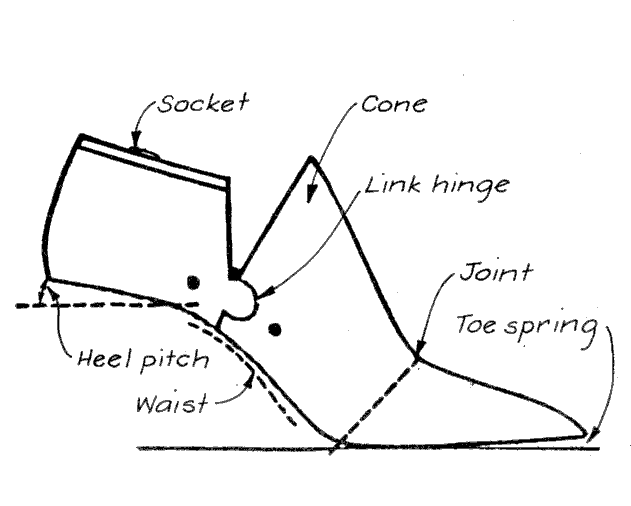

Almost all footwear is made on lasts, a form that creates the footwear's size, fit and style. There are many types of lasts which reflect the type of footwear and feet they are designed for. Different types of footwear require lasts with different characteristics. Open-toe sandal style will use a last that allows the toes to spread out, while a boot last is designed to hug the instep for a closer fit. In manufacturing today, last design is on a computer software platform like New Last Technology and includes the top pattern and toe styles.

Cordwainers or custom shoemakers use custom molded and other specialty lasts to produce shoes to meet the needs of their customers. These lasts are made from various modern materials that can withstand the constant tacking pinning and wet environment. Many custom footwear makers make lasts for their customers, shaped to maintain a form best suited to the customer's feet.