3728

.pdfIssue № 4 (40), 2018 |

ISSN 2542-0526 |

worth noting that a variety of strategic energy safety threats might be implemented particularly in case of possible emergencies.

Energy safety is a feeling of individual and state security from threats to reliable provision of necessary low-cost fuel and energy resources at the moment and in the long run [17].

In heat supply as the thickness of isolation increases, the higher maintenance and operational costs for a heat-insulated pipeline become. There are also fewer heat losses and thus annual heat costs [13, 14, 19]. It results in a growing sense of security.

In [2, 4, 8] we have dealt with how urgent this topic is. It was shown that the solution comes down to minimizing functions of costs of an operating variant [1, 2, 10, 20]. A minimal value of specific reduced costs must correspond with an optimal isolation thickness, mm.

As optimization depends on a large number of variables, it is viable to address it by means of software. In some studies solutions involving programming and software elements are discussed [7, 9]. Therefore a few algorithms to be solved are emerging. Let us look at one of them [3, 15].

1. Algorithm for evaluating the optimal thickness of thermal insulation of heat networks.

In order to identify certain technical solutions as a result of determining optimal thicknesses of heat pipelines, a number of algorithms as well as calculation software are developed. Let us consider the following algorithm [3, 12].

It comes down to minimizing the following function:

З Ен Киз Итп, |

(1) |

where Ен is the efficiency coefficient of financial investments, 1/year; φ is a proportion of annual deductions for the operation of a thermal insulation, 1/year; Киз are capital investments into thermal insulation, roubles; Итп is the cost of heat losses, roubles/year.

The solution of the problem will be investigated using a famous example of a two-pipe underground heat pipeline with a channel-free architecture [2, 16].

Capital costs for a thermal insulation 1 of a running meter of a two-pipe heat pipe is given by the formula

КИЗ 2СИЗ VИЗ 2СИЗ (d ИЗ ) ИЗ , |

(2) |

where Сиз is an actual limited cost of thermal insulation, roubles/m3; Vиз is a volume of thermal insulation, m3; d is an exterior diameter of a pipeline, m; δиз is the thickness of thermal insulation, m.

An annual cost of the amount of heat lost 1 by a running meter of a heat pipe is given by the formula

Итп qп q0 Cт 1 , |

(3) |

41

Russian Journal of Building Construction and Architecture

where qп, q0 are specific heat losses 1 by a running meter and reverse pipelines of a heat network, Watt/m; Ст are district insulating costs on thermal energy, roubles/(Watt h); τ is annual operation of a heat network, h/year; β is the coefficient that considers heat losses through uninsulated areas of a heat pipeline.

Specific heat losses in heat pipelines are found using the formulas:

|

|

|

(tср tср )R (tср |

tср )R |

|

||||||

q |

|

п |

гр |

o |

|

о |

гр |

инт |

, |

(4) |

|

|

|

R R R2 |

|

|

|||||||

п |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

п |

о |

инт |

|

|

|

|

|

|

|

(tср tср)R |

(tср |

tср )R |

|

|||||

q |

|

|

о |

гр |

п |

|

п |

гр |

инт |

, |

(5) |

|

|

|

R R |

R2 |

|

|

|||||

о |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

п |

о |

инт |

|

|

|

|

wheretпср , tоср is an average annual temperature of a heat-carrier in a supply and reverse pipelines, 0С; tгрср is an average temperature of soil at the depth of pipelines and accepted as specified in climate data sources; Rп, R0 is thermal resistance of a supply and reverse pipelines of a heat network respectively, (m К)/Watt; Rинт is extra thermal resistance considering thermal interference of heat pipelines, (m К)/Watt.

Thermal resistances of pipelines are defined as

|

1 |

|

|

d 2 |

из |

|

|

|

1 |

|

|

|

|

2h |

|

|

2h 2 |

|

|

|

|

||

Rп Rо |

|

|

ln |

|

|

|

|

|

|

ln |

|

|

|

|

|

|

1 |

|

, |

(6) |

|||

2 |

|

|

d |

|

2 |

|

|

d |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

d |

|

|

|

|

|

|

|

|||||

|

|

из |

|

|

|

|

|

|

|

гр |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R |

|

1 |

|

ln 1 |

|

2h 2 |

, |

|

|

|

|

|

|

(7) |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

инт |

|

2 гр |

|

|

|

|

s |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

where λиз, λгр is heat conductivity of thermal insulation and soil respectively, Watt/(m К); h is the depth of a pipeline, m; s is a step between the pipes, m.

Inserting the above expressions into a target function, we get

З f ( из). |

(8) |

Specifying some values of δиз1, δиз2, … δизn, we calculate the losses З1, З2, …Зn. The condition З = min is met with an optimal thickness of thermal insulation из изopt [5, 10, 21].

2. Example of operation of a calculation software. A minimum value of specific costs should correspond with an optimal thickness of insulation, mm. Let us identify an area of economic viability for determining the thickness of heat insulation of a structure in heat networks of heat supply systems [22].

As optimization depends on a large number of variables, it should be addressed by means of software. There is currently a whole range of solutions employing software [6, 12].

42

Issue № 4 (40), 2018 |

ISSN 2542-0526 |

Hence, e.g., the calculation software K-PROJECT—2.0 is designed to create multi-purpose engineering systems using technical insulation. For some tasks a calculation software for thermal insulation Armaflex for MS Windows can be employed. The “Insulation” software, which is actually a flagship in Russia’s thermal insulation design, has become widely used. If set up properly, this powerful and incredibly flexible tool reduces design of a thermal insulation structure to specific original data on insulating objects, which is virtually a mouse-click task. There are some investigations of new tools and functions of these software applications [6, 15, 23].

For large designing organizations it is of a lot of relevance, but smaller organizations and individual specialists do not always have access to this kind of software for a number of reasons. Having analyzed a widely available range of software and programming elements, Microsoft Excel appears to be a popular option.

Excel offers opportunities for economic and statistical calculations, graphic tools and macroprogramming language VBA (Visual Basic for Application). One of the great advantages Excel offers is that Visual Basic can be used for coding. There are a lot more of them, but the software is hugely underrated. This code is written using a separate editor and is a go-to option these days [8, 25].

A digital table is managed using a volumetric code and data model. Using this code, data is instantly processed and shown in tables and diagrams (graphs). A table becomes a code interface allowing it to be worked on, modified and managed. Microsoft Excel is part of Microsoft Office and is currently one of the world’s top software.

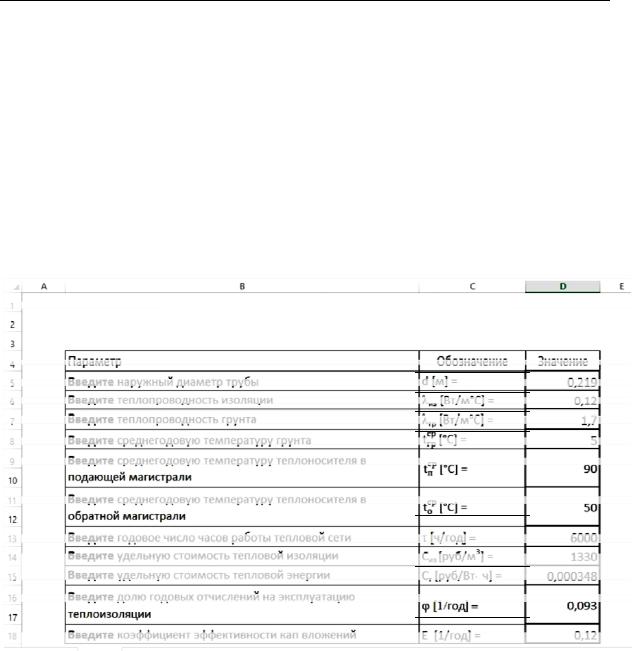

Let us give an example of how software developed for a known dataset operates. Let us identify an optimal thickness of thermal insulation of a two-pipe heat pipeline of a water heat network for the following original data [1, 2, 24]:

1)type of laying a pipeline is channel-free;

2)type of thermal insulation is bitumen pearlite;

3)external diameter of a pipeline: dн = 0.219 m;

4)depth of laying a pipeline is h 0.7 из d /2, m;

5)step between the pipes is S 0.2 2 из d , m;

6)coefficient of heat conductivity of insulation is λиз = 0.12 Watt/(m К);

7)coefficient of heat conductivity of soil is λгр = 1.7 Watt/(m К);

8)average temperature of soil is tгрср = 5 0С;

43

Russian Journal of Building Construction and Architecture

9)average temperature of a heat-carrier is tпср = 90, tоср = 50 0С;

10)annual number of operation hours of a heat network is τ = 6000 h/year;

11)specific cost of thermal insulation is Сиз = 1330 roubles/m3;

12)specific cost of thermal energy is СТ = 348·10−6 roubles/(Watt h);

13)proportion of annual deductions for operation of thermal insulation is φ = 0.093 1/year;

14)coefficient of efficiency of financial investment is Е = 0.12 1/year.

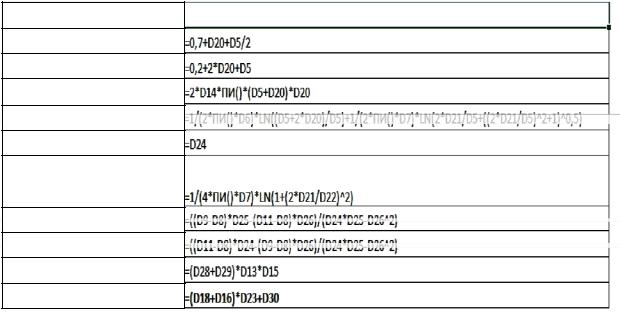

Original data is entered into the “Values” column (Fig. 1). The formulas as seen in table editor Microsoft Excel are presented in Fig. 2.

Determining an optimal thickness of thermal insulation of pipelines of a heat network

Parameter |

|

|

Symbol |

|

Value |

|

|

|

|

||||

|

d (m) = |

|

|

|

||

Enter an external diameter of a pipe |

|

0.219 |

||||

|

λиз (Watt/m oC) = |

|

|

|

||

Enter the heat conductivity of insulation |

|

0.12 |

|

|||

|

λгр (Watt/m oC) = |

|

|

|

||

Enter the heat conductivity of the soil |

|

1.7 |

|

|||

|

грср (oC) = |

|

|

|

||

Enter the average annual temperature of the soil |

|

5 |

|

|||

|

пср(oC) = |

|

|

|

||

Enter the average annual temperature of the heat-carrier |

|

90 |

|

|||

in the supply pipeline |

ср |

o |

|

|

|

|

|

о |

|

|

|

|

|

Enter the average annual temperature of the heat-carrier |

( C) = |

|

50 |

|

||

in the reverse pipeline |

|

|

|

|||

Enter the annual number of the operation hours |

τ (h/year) |

|

6000 |

|

||

of the heat network |

Сиз (roubles/m3) |

|

|

|

||

Enter the specific cost of thermal insulation |

|

1330 |

|

|||

|

Ст(roubles/Watth) |

|

|

|

||

Enter the specific cost of thermal energy |

|

0.000348 |

|

|||

Enter the proportion of annual deductions for the operation |

φ (1/ year) |

|

0.093 |

|

||

of thermal insulation |

Е (1/ year) |

|

|

|

||

Enter the coefficient of efficiency of financial investment |

|

0.12 |

|

|||

|

|

|

|

|

|

|

Fig. 1. Table of specified original data

After entering the original data, the above formulas are used for calculations of all the necessary values for determining an optimal thickness of thermal insulation.

In order to calculate the most optimal thickness of thermal insulation, the method of generalized gradient is used. The main idea of this method is that the dimensionality of a task by excluding dependent (basic) variables should be reduced and a method of specified gradient for determining the direction of descent should be employed as a criterion for identifying optimality as well [11, 18].

44

Issue № 4 (40), 2018 |

ISSN 2542-0526 |

σиз (m) =

h (m) =

s (m) =

Kиз (roubles) =

Rп (moC/Watt) =

Rо (moC/Watt) =

Rинт (moC/Watt) =

qп (Watt/m) =

qо (Watt/m) =

Итп (roubles/year) З (roubles/year)

Fig. 2. Calculation formulas in the table editor Microsoft Excel

The step аk is chosen based on the condition of a minimum of the function f(x) in the direction of descent, i.e.

f xk ak f xk mina 0 f xk af xk .

This indicates that motion along an antigradient occurs till the value of the function f(x) decreases.

From a mathematical point of view, at each iteration it is necessary to solve a task of onedimensional minimization of the following function using а

f xk ak f xk f a .

Gradient methods involve a minimum of a high speed (geometrical progression) for smooth prominent functions. However, in practice minimized functions normally have poorly organized matrices of second variables (Gesse matrices) [11]. The values of such functions along some directions change considerably faster (sometimes by a few orders) than in other directions. Their level surfaces in the simplest case are significantly stretched and these functions themselves are called ravine ones. The direction of an antigradient of these functions can be significantly different from the direction to a minimum point, which causes a convergence speed to slow down.

A convergence speed of gradient methods also largely depends on the accuracy of calculations of a gradient. Loss of accuracy, which is more common in the vicinity of minimum

45

Russian Journal of Building Construction and Architecture

points or in a ravine function, might disrupt convergence of a gradient descent. For the reasons above, gradient methods are commonly used in combination with others that are more effective at the initial stage of solving a task. In this case the point х [0] is far from a minimum point and steps in the direction of an antigradient allow a significant decrease of a function to be achieved [11, 18].

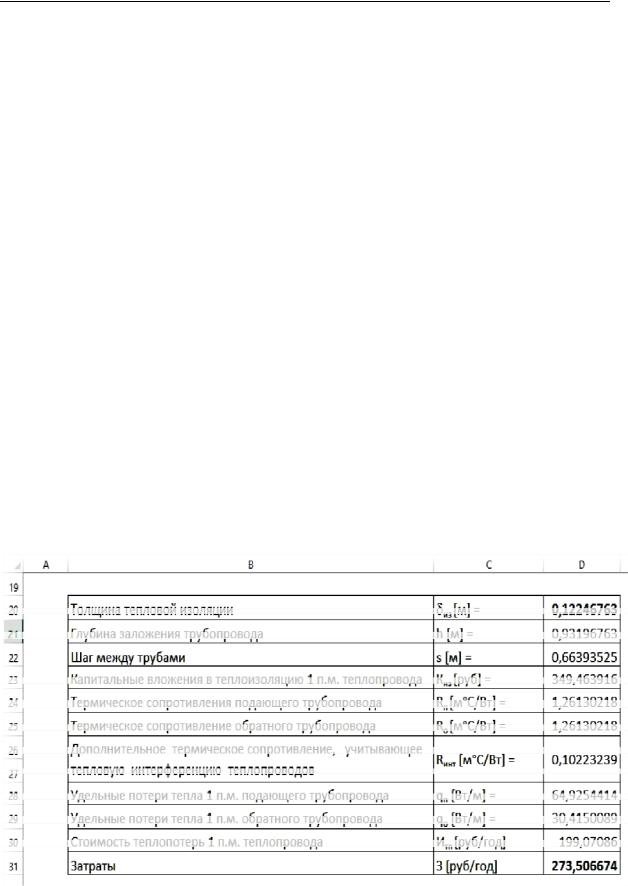

The “Calculate” button enables the thickness of thermal insulation and financial investments into thermal insulation to be computed (Fig. 3).

Processing that takes place after the “Calculate” button written in the VBA language is hit is described below:

Private Sub btnSolve_Click() SolverReset

SolverOK SetCell:=Range ("D31"), MaxMinVal:=2, ByChange:=Range ("D20"), Engine:=1 SolverSolve True

End Sub

As a result of determining an optimal thickness of thermal insulation of a two-pipe heat pipeline of a water network, it was found that an optimal thickness of insulation δиз = 122 mm (Fig. 3) corresponds to minimum limit specified costs Зmin = 273.51 roubles/(year m).

|

Thickness of thermal insulation |

σиз (m) = |

0.12246763 |

|

|

Depth of a pipeline |

h (m) = |

0.93196763 |

|

|

|

|

|

|

|

Step between the pipes |

s (m) = |

0.66393525 |

|

|

|

|

|

|

|

Capital investments into thermal insulation of 1 running |

Kиз (roubles) = |

349.463916 |

|

|

meter of a pipeline |

|

|

|

|

Thermal resistance of a supply pipeline |

Rп(moC/Watt) = |

1.26130218 |

|

|

Thermal resistance of a reverse pipeline |

Rо(moC/Watt) = |

1.26130218 |

|

|

Extra thermal resistance considering thermal interference |

Rинт(moC/Watt)= |

0.10223239 |

|

|

of heat pipelines |

|

|

|

|

|

|

|

|

|

Specific heat losses of 1 running meter of a supply pipeline |

qп (Watt/m) = |

64.9254414 |

|

|

Specificheat lossesof 1 running meterofa reverse pipeline |

qо (Watt/m) = |

30.4150089 |

|

|

Costs of heat losses of 1 running meter of a pipeline |

Итп(roubles/year) |

199.07086 |

|

|

Costs |

З (roubles/year) |

273.506674 |

|

|

|

|

|

|

|

|

|

|

|

Fig. 3. Result of calculating the thickness of thermal insulation

46

Issue № 4 (40), 2018 |

ISSN 2542-0526 |

Conclusions

1.The paper investigates an optimal thickness of thermal insulation of a water heat network considering the criterion of a minimum value of limited specified costs using a known algorithm. As optimization depends on a large number of variables, it is advisable to solve it by means of software.

2.A calculation is performed for similar tasks using programming by means of the digital table editor Microsoft Excel that makes it possible to carry out economic and statistical computations, graphic tools and macroprogramming language VBA. Another advantage offered by Excel is that it allows to code based on Visual Basic for applications. This code is written using a separate table editor as a table becomes a code interface making it easy to work with and manage calculations.

3.The results obtained in the software are instrumental for further engineering calculations.

References

1.Biryuzova E. A., Lomakina L. S. Povyshenie energoeffektivnosti teplovoy seti za schet primeneniya optimal'nogo vida teplovoy izolyatsii [Improving the energy efficiency of the heat network through the use of the optimal type of thermal insulation]. Stroitel'stvo i arkhitektura, 2010, no. 5, pp. 10—19.

2.Gladysheva T. Yu., Petrikeeva N. A. Osnovnye napravleniya rekonstruktsii inzhenernykh sistem zdaniy i sooruzheniy [The main directions of reconstruction of engineering systems of buildings and structures].

Nauchnyy zhurnal. Inzhenernye sistemy i sooruzheniya, 2016, no. 2 (23), pp. 14—21.

3.Zemenkov Yu. D., Moiseev B. V., Dudin S. M., Nalobin N. V. Metodika opredeleniya optimal'noy tolshchiny izolyatsii nazemnykh truboprovodov [Method of determining the optimal insulation thickness of overhead pipelines]. Territoriya Neftegaz, 2014, no. 3, pp. 79—83.

4.Kasatkina S. M., Larina Yu. V., Kulagin S. M., Klyukvin V. V. Optimizatsiya teplovykh poter' v truboprovodakh teplovykh setey [Optimization of heat losses in heat network pipelines]. Molodye uchenye — razvitiyu tekstil'no-promyshlennogo klastera, 2016, no. 1, pp. 495—497.

5.Kornev S. A. Primenenie optimal'nogo materiala teploizolyatsii dlya povysheniya energoeffektivnosti teplovoy seti [Application of the optimal thermal insulation material to improve the energy efficiency of the heat network]. Molodoy uchenyy, 2015, no. 24, pp. 145—146.

6.Kuznetsova T., Lisin S., Korel'shteyn L. «Izolyatsiya»: novye vozmozhnosti unikal'noy programmy ["Insulation": new opportunities for unique programs]. CADMASTER. Proektirovanie promyshlennykh ob"ektov, 2012, no. 3, pp. 82—88.

7.Petrikeeva N. A., Cheremisin A. V., Kopytin A. V. Zadacha tekhniko-ekonomicheskoy optimizatsii pri opredelenii tolshchiny teploizolyatsionnogo sloya teplosetey [The problem of technical and economic optimization in determining the thickness of the thermal insulation layer of heating systems]. Nauchnyy zhurnal stroitel'stva i arkhitektury, 2016, no. 1 (41), pp. 21—28.

47

Russian Journal of Building Construction and Architecture

8.Petrikeeva N. A., Berezkina L. V. Optimizatsiya sistem teplosnabzheniya zdaniy s ispol'zovaniem vozobnovlyaemykh istochnikov energii [Optimization of heating systems of buildings using renewable energy sources]. Nauchnyy zhurnal. Inzhenernye sistemy i sooruzheniya, 2010, no. 2, pp. 128—132.

9.Petrikeeva N. A., Kopytin A. V., Popov N. O. Optimizatsiya stoimostnoy tselevoy funktsii pri opredelenii tolshchiny izolyatsii v sistemakh teplosnabzheniya [Optimization of the cost objective function in determining the insulation thickness in heat supply systems]. Gradostroitel'stvo. Infrastruktura. Kommunikatsii, 2016, no. 2 (3), pp. 26—33.

10.Petrikeeva N. A., Sadovnikov A. N., Nikulin A. V. Puti snizheniya energopotrebleniya zdaniyami [Ways to reduce energy consumption by buildings]. Nauchnyy zhurnal. Inzhenernye sistemy i sooruzheniya, 2012, no. 1, pp. 13—17.

11.Pokornyy Yu. V., Shabrov S. A., Kopytin A. V. [About the features of elastic one-dimensional problems].

Trudy “Sovremennye metody v teorii kraevykh zadach”. Voronezhskiy gosudarstvennyy universitet [Proc. “Modern methods in the theory of boundary value problems”]. Voronezh, 1997, p. 184.

12.Popov N. O., Petrikeeva N. A., Kopytin A. V. Opredelenie optimal'noy tolshchiny teploizolyatsionnogo sloya truboprovodov sistem teplosnabzheniya [Determination of the optimal thickness of the thermal insulation layer of pipelines of heat supply systems]. Nauchnyy zhurnal. Inzhenernye sistemy i sooruzheniya, 2015, no. 1 (18), pp. 15—22.

13.Semenov V. N., Sazonov E. V., Kitaev D. N. e.a. Vliyanie energosberegayushchikh tekhnologiy na razvitie teplovykh setey [The impact of energy-saving technologies on the development of heat networks]. Izvestiya vuzov. Stroitel'stvo, 2013, no. 8 (656), pp. 78—83.

14.Smorodova O. V., Skripchenko A. S. Tekhniko-ekonomicheskoe obosnovanie tolshchiny teplovoy izolyatsii teplovykh setey [Feasibility study of thermal insulation thickness of heat networks]. Innovatsionnaya nauka, 2016, no. 4—3, pp. 151—154.

15.Shoykhet B. M. Pravila rascheta i proektirovaniya teplovoy izolyatsii oborudovaniya i truboprovodov [Rules of calculationanddesignofthermalinsulationofequipmentandpipelines].Energosberezhenie,2013,№2,pp.44—51.

16.Shoykhet B. M. Proektirovanie teplovoy izolyatsii truboprovodov teplovykh setey [Design of thermal insulation of pipelines of thermal networks]. Energosberezhenie, 2015, no. 1, pp. 50—57.

17.Osnovnye polozheniya Energeticheskoy strategii Rossii na period do 2020 goda [Odobreny Pravitel'stvom Rossiyskoy Federatsii (protokol № 39 ot 23 noyabrya 2000 g.)] [Main provisions of the Energy strategy of Russia for the period up to 2020 [Approved by the Government of the Russian Federation (Protocol No. 39 of November 23, 2000)]]. Moscow, GU IES, 2001. 120 p.

18.Matveev M. G., Kopytin A. V., Sirota E. A., Kopytina E. A. Modeling of Nonstationary Distributed Processes on the Basis of Multidimensional Time Series. 3rd International Conference «Information Technology and Nanotechnology», ITNT—2017, 2017, pp. 511—516.

19.Ponomarev S. V., Bulanova V. O., Divin A. G., Bulanov E. V. Optimization of Measurements of the

Thermophysical Properties of Thermally Insulating Materials. Measurement Techniques, 2016, no. 12, pp. 1360—1366.

20. Nenarokomov A. V., Salosina M. О., Alifanov O. M. Optimal Design of Multi-Layer Thermal Protection of Variable Thickness. International Journal of Numerical Methods for Heat and Fluid Flow, 2017, no. 5 (27), pp. 88—100.

48

Issue № 4 (40), 2018 |

ISSN 2542-0526 |

21.Kindras I. N., Vankov A. V., Bogdanov O. V. Insulation Materials and Features of Their Application. Apriori, 2014, no. 6, pp. 21—32.

22.Schiavoni S., D'Alessandro F., Bianchi F. Insulation Materials for the Building Sector: a Review and Com-

parative Analysis. Renewable and Sustainable Energy Reviews, 2016, no. 62, pp. 988—1011, doi: 10.1016/j.rser.2016.05.045.

23.Liu S. Y., Yu Y. X., Qiu Z. X. Determination of Thermal Conduction Coefficient of Refractory and Thermal Insulation Materials. Dongbei Daxue Xuebao (Ziran Kexue Ban), 2006, no. 2, pp. 196—198.

24.Zuboreva M. V., Kitaeva N. K., Skobeev D. A., Sobolev A. V. Solution of Modern Problems of Research of Quality of Thermal Insulation Materials. Ecology, Environment and Conservation, 2017, no. 2, pp. 1162—1168.

25.Jelle B., Gustavsen A., Baetens R. The Path to the High Performance Thermal Building Insulation Materials and Solutions of Tomorrow. Journal of Building Physics, 2010, no. 2, pp. 99—123.

49

Russian Journal of Building Construction and Architecture

DESIGNING AND CONSTRUCTION OF ROADS,SUBWAYS,

AIRFIELDS,BRIDGES AND TRANSPORT TUNNELS

UDC 625.7/.8

A. A. Zadiraka1, N. Ye. Kokodeeva2, A. V. Kochetkov3

PHYSICAL AND MECHANICAL PROPERTIES

OF POLYURETHANE CRUSHED STONE FOR SLOPES OF EMBANKMENTS

AND EXCAVATIONS OF ROADS AND RAILWAYS

Saratov State Technical University Named after Y. A. Gagarin Russia, Saratov, tel.: +7-927-629-13-06, e-mail: alex.zadiraka@mail.ru

1PhD student of the Dept. of Transport Construction

2D. Sc. in Engineering, Assoc. Prof., Head of the Dept. of Transport Construction,

Director of the School of Energy and Transportation

Perm National Research Polytechnic University Russia, Perm, tel.: +7-906-306-95-53, e-mail: soni.81@mail.ru

3 D. Sc. in Engineering, Prof. of the Dept. of Automobiles and Technological Machines

Statement of the problem. It is necessary to determine the nature of the interaction of the polyurethane binder with crushed stone of various fractions and brands. It is also important to carry out a comparative analysis of the physical and mechanical properties of polyurethane and bituminous binders. The issue of the prospects of a possible use of a polyurethane binder on various elements of a road structure, including on the slopes of mounds and excavations ofroads and railways was considered.

Results. Some experiments were conducted to study the adhesion of rubble to polyurethane and bituminous binders. The adhesion indices of the binding materials are investigated with the Vialite instrument. An experiment was also conducted to determine the roughness of the polyurethane crushed stone layer as well as to study the possibility of using this structure as a pavement surfacing.

Conclusions. As a result of the tests, the polyurethane binder was show to interact excellently with rubble compared to bitumen in the same conditions. The experience in determining the macroroughness did not provide an unambiguous answer as to whether it was possible to use the layer under investigation as a covering of the motor road or not.

Keywords: polyurethane binder, bitumen binder, crushed stone, opening of the binding material, adhesion, adhesion with the binder, macroroughness, resin, hardener.

Introduction. One of the key issues is improving transportation and operation performance of transport equipment, i.e. strength and stability of a structure, which depend on weather and climate conditions [3, 8].

© Zadiraka A. A., Kokodeeva N. Ye., Kochetkov A. V., 2018

50