Инновационные процессы в исследовательской и образовательной деятел

..pdfA.A. Kaverin, S.V. Bochkarev

Perm National Research Polytechnic University

RESIDUAL LIFE PREDICTION OF INDUSTRIAL FACILITIES

Working capacity providing and equipment reliability increasing are problem number one at present for the majority of plants of different industry lines. What is more, the issue about optimization of existing MRO system is more important than creation of a new system. Optimized MRO system must provide necessary action for the given equipment at proper time.

Key words: residual life, prediction, life of equipment, MRO, reliability.

A significant part of plant total operating expenses is spent on maintenance of industrial facilities. That is why timely diagnostics of incorporated equipment operating mode plays an important role in exploitation. Diagnostics is realized for determining technical characteristics and residual life estimation. Reliability and life of equipment is growing thanks to good performance because defects and failures can be detected earlier. That gives a possibility of their elimination by maintenance failure exception during the operation and purchase of necessary renewal part by the moment of equipment failure. So, this excludes longtime storage and exploitation of defective equipment which demands a bigger amount of energy of the same power.

All the plant facilities form a big layer for research. Therefore, analysis and optimization of the all facilities are recommended. Electrical equipment is offered to be chosen for better performance as the most optimized for research and results getting. Pilot project realization at the plant allows to correct and adjust the process of determining residual life. This project will be used for the entire equipment in future work.

Equipment record is realized in order to understand what units and types of equipment are used at the plant. A list of equipment is made up in the result of this work. Technical equipment parameters which allow to determine its

“health” are recorded in this record. Technical equipment parameters as it concerns electrical equipment are current, voltage and useful power.

Database is developed for fixing, collecting and processing the technical and static equipment parameters.

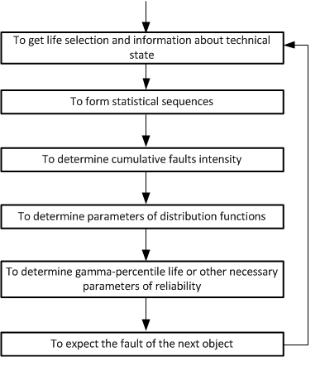

Residual life will be predicted when it is based on statistic data from the database according to the probability theory. For this purpose the database gains such parameters as date of putting it into exploitation equipment, service time, state of equipment. The complete process of analyzing and processing data can be represented as an algorithm based on the method of quantiles which is presented in Figure. The algorithm allows to obtain efficient estimates in exploitation at early stages when first fault has arisen. These estimates are specified by faults of other

31

following equipment. Quantiles method assumes finding the corresponding parameters that allows maximum likelihood of distribution function in accordance with the points calculated with the use of this algorithm.

Fig. Algorithm of estimation

In the result of the work done the software complex will have been realized. It gains statistic data and makes prediction of residual life of equipment. This complex allows the plant to change the method of technical service and maintenance according to state of industrial facilities. It will reduce spontaneous equipment faults and its exploitation caused by defects. This reduces the exploitation expenditures.

References

1.Дружинин Г.В. Надежность автоматизированных систем. – М.:

Энергия, 1977. – 536 с.

2.Технические средства диагностирования / В.В. Клюев, П.П. Пархоменко [и др.]. – М.: Машиностроение, 1989.

3.Бочкарев С.В., Цаплин А.И. Диагностика и надежность автоматизированных систем: учеб. пособие. – Пермь: Изд-во Перм. гос. техн. ун-та, 2006. – 262 с.

4.Гнеденко Б.В., Беляев Ю.К., Соловьев А.Д. Математические методы в теории надежности. – М.: Наука, 1965. – 524 с.

32

S.L. Karanevskiy

Perm National Research Polytechnic University

AUTOMATED TESTING OF AC ELECTRIC MACHINES

WITH MOBILE TESTING STATIONS

The article deal with automatic testing of AC electric machines. Having considered the method of sliding trigonometric approximation and its advantages when testing synchronous AC electric machines, the author suggests and justifies the opportunity of using this method for testing asynchronous AC electric machines.

Key words: AC electric machines, asynchronous AC electric machines, “LabVIEW” development system, virtual instrument, method of sliding trigonometric approximation.

In order to enhance the security of both the entire processing station and production as a whole and avoid emergency situations, AC electric machines, used nowadays in many industries worldwide demand maintenance.

For this purpose, bench tests of AC electric machines are conducted, during which the current performance of the machine, that is, compliance of operating parameters with passport data specified by the manufacturer is checked up [3].

To reveal weaknesses that need to be addressed or to be paid attention to, and to conduct monitoring during operation and maintenance of the machine, the test results are used. The bench tests lead to the improvement of the quality, reliability, and extension of trouble-free operation. Due to the fact that the processes of receiving and processing information in the course of testing are not automated, the testing stations productivity and capacity are low. Mobile testing stations are widely used by service companies when AC electric machines are installed far from industrial areas (e.g., oil and gas pumping stations and oil fields).

In the process of automated information retrieval accurate determination of the current and voltage values in stationary modes and their envelope curves in transient conditions are complicated by interference and noise distortions in the measuring channels. In this connection there is a need for efficient filtering techniques during computer processing.

Providing mobile testing stations with modern software and hardware is a possible solution to this problem. To test synchronous machines, postgraduates of the Electrical and Electromechanical Engineering department developed a set of virtual instruments in software development system “LabVIEW” [2].

The method of sliding trigonometric approximation was used to develop the algorithms of virtual instruments software development system “LabVIEW”.

33

As studies have shown, the virtual instruments developed for synchronous machines by the postgraduates find the basic parameters of the signals and their envelope curves under noise distortion and other kinds of interference in measuring channels more precisely than standard virtual instruments.

After receiving the test results on synchronous AC electric machines [1], the next step is to develop virtual instruments for testing asynchronous AC electric machines.

Development of virtual instruments for testing AC electric machines is sponsored by Russian Foundation for Basic Research №14-07-00104 “The development of the mobile AC electric machines’ station for testing and diagnostics”. Another part of financial support comes for the project statement from the Ministry of Education and Science of the Russian Federation “The development of methodological foundations of adaptive control of autonomous and non-autonomous gas turbine power plants with capacity up to 25 MW”.

References

1.Исцелемов Д.А., Караневский С.Л., Любимов Э.В. Идентификация параметров синхронных электрических машин по результатам автоматизированных стендовых испытаний // Новые информационные технологии: тез. докл. XV Междунар. студ. школы-сем. – М.: Изд-во Моск. гос. ин-та электроники и информатики (Техн. ун-т), 2007. − С. 113.

2.Исцелемов Д.А., Любимов Э.В., Нургатин Р.Ф. Комплекс программ для автоматизации испытаний синхронных турбомашин // Электротехника. –2010. – № 6. – С. 27–32.

3.Жерве Г.К. Промышленные испытания электрических машин. – М.: Госэнергоиздат, 1959. – 575 с.

34

S.L. Kalulin, A.F. Shmakov, V.Ya. Modorsky

Perm National Research Polytechnic University

OPTIMIZATION OF FAN COOLER GFRP SPAR STRUCTURE

IN IOSO PM SOFTWARE

The paper provides structure optimization of the fan cooler spar and an operation technique in IOSO PM application-oriented packet of optimization with integration of Ansys WorkBench. Physical and mathematical design models were constructed. Optimum length of an internal pipe of spar at an admissible optimum thickness of the pipe was found. Optimization parameters were geometrical characteristics of a GFRP spar in the fan blade.

Key words: optimization, Pareto-optimal decision, spar of GFRP fan cooler.

Relocation of aggressive air compounds in air ducts quite often results in the firmness and longevity problem. Materials, air vents are made of, can be exposed to intensive corrosion (steel), temperature deformations (polypropylene, polyethylene), or can exfoliate from the main material (gumming). All these shortcomings can be overcome if the fan is made of chemically resistant Glass Fiber Reinforced Polymer. GFRP fans have found broad application in hostile chemical and corrosive environment and they have a large number of advantages in comparison with noncorrosive steel fans [1, 2, 3].

Statement of the problem to optimize the fan design

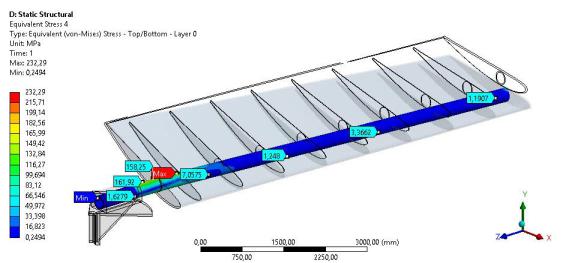

We consider the model problem of optimizing the fan design to develop the operation procedure in IOSO PM optimization software. A constituent element of the design to be optimized is a GFRP spar which is located inside the blade (Fig. 1). As the optimization parameter there has been selected the length of the internal tube which is inserted in the spar with an epoxy resin layer. Only one optimization parameter was chosen to graphically represent the procedure in IOSO PM Software. The optimization criteria were minimizing the maximum von-Mises stress and the tube deflection [4].

Task dimension:

–Total variables: 1;

–Independent variables: 1;

–Criteria: 2;

–Restrictions: 0;

–Quantity of the used cores: 64.

Parameters of the optimization algorithm:

–Maximum number of iterations: 15000;

–Maximum time to solve the task: 100 days 0 hours 0 minutes;

–Solution accuracy: 0.001;

–The set number of Pareto-optimal decisions: 20.

35

Fig. 1. Equivalent von-Mises stresses on the spar surface

Input and output data are described in Table 1.

|

|

|

|

T a b l e 1 |

|

|

Input and output data of algorithm optimization |

|

|||

|

|

|

|

|

|

No. |

Independent variables |

Dependent |

Criteria |

Restrictions |

|

(input data) |

variables |

(output data) |

|||

|

|

||||

1 |

Internal GRFP tube length: |

– |

Von-Mises minimization |

– |

|

1000–9200 mm |

of the maximum tension |

||||

|

|

|

|||

|

|

|

Minimization of the |

|

|

2 |

|

|

maximum deformations |

|

|

|

|

|

(tube bend) |

|

|

Calculations were carried out for three design options using the engineering IOSO PM complex with integration of ANSYS Workbench.

Analysis of calculation results

Data card of optimization calculations for the stress-strain state structure is presented in Table 2.

T a b l e 2 Optimization calculations for the stress-strain state structures

№ |

σ, MPa |

U, mm |

|

min |

/ l |

U |

min |

/ lU |

loptU |

Number of |

, mm |

|

internal tube |

internal tube |

|

opt |

|

opt |

|

running |

internal |

||

|

MPa/mm |

mm/m |

mm |

||||||||

|

|

|

|

||||||||

|

length is |

length is 1700 mm |

tasks in |

tube |

|||||||

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

1700 mm |

(by the design |

|

|

|

|

|

|

|

ANSYS |

thick- |

|

|

|

|

|

|

|

|

|

|

|

|

|

(by the design |

requirements) |

|

|

|

|

|

|

|

(iterations) |

ness |

|

|

|

|

|

|

|

|

|

|

|

|

|

requirements) |

|

|

|

|

|

|

|

|

|

|

1 |

22,3 |

457 |

19/3678 |

250/7009 |

3331 |

43 |

24 |

||||

2 |

21,8 |

444 |

11.7/3679 |

166/5631 |

1952 |

61 |

34 |

||||

3 |

21,6 |

439 |

11.5/3789 |

161/5324 |

1535 |

58 |

49 |

||||

36

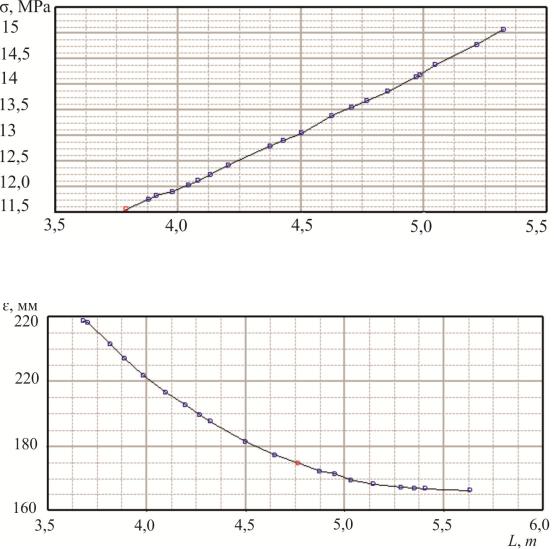

Fig. 2 and 3 show the dependences from the Pareto-optimal set of optimization problem solutions for the GFRP fan spar.

Fig. 2. Von-Mises maximum equivalent stress (MPa) dependence on the internal tube length (mm) from the Pareto-optimal set in IOSO PM (thickness – 34 mm)

Fig. 3. Maximum bend value (m) dependence on the internal tube length (mm) from the Pareto-optimal set in IOSO PM (thickness – 34 mm)

As a result of optimizing calculations of the bend spar problem it was found that at the internal tube thickness of 24 mm, the spar optimum internal tube length scatter is significantly higher, than at 34 and 49 mm. Also, at the internal tube thickness of 34 and 49 mm, minimization indicators of maximum equivalent tension and the maximum bend are close; therefore, to increase the tube thickness higher than 34 mm is inexpedient. The optimum internal tube length of a spar at 34 mm is from 3679 to 5631 mm.

The conducted research was performed by a grant from the Russian Science Foundation (project №14-19-00877).

37

References

1. Пономаренко В.С., Арефьев Ю.И. Градирни промышленных и энергетических предприятий: справ. пособие / под общ. ред. В.С. Пономаренко. – М.: Энергоатомиздат, 1998. – 376 с.

2.Hensley J.C. Cooling tower fundamentals. Compiled from the knowledge and experience of the entire SPX Cooling Technologies staff. SPX Cooling Technologies, Inc. – Overland Park, Kansas USA, 2009.

3.Detlev G. Kröger. Air-cooled heat exchangers and cooling towers. – Tulsa, Oklahoma, PennWell Books, 2004.

4.Калюлин С.Л., Шмаков А.Ф., Модорский В.Я. Оптимизация конструкции крупногабаритного вентилятора из стеклопластика в прикладном пакете IOSO PM // Науч.-техн. вестник Поволжья. – 2014. – № 5. – С. 209–

212.

38

D.N. Krivogina

Die nationale polytechnische Forschungsuniversität Perm

DIE HERAUSBILDUNG VON ÖKOLOGISCHEN

BERUFSKOMPETENZEN BEI STUDENTEN –

KÜNFTIGEN BAUINGENIEUREN

In diesem Artikel betont die Wichtigkeit der ökologischen Befähigung der StudentenBauherren zur Verbesserung der Wettbewerbsfähigkeit der Absolventen. Entwickelt und vorgeschlagen von der Liste der grundlegende berufliche und ökologischen Kompetenzen und ermitteln ihren Inhalt und ihre Zusammensetzung, auch die Möglichkeit, deren Umsetzung in modularen Programme angeboten.

Schlagworte: Kompetenzherangehen, modulare Programme, grundlegende ökologische Fachkompetenz.

Der Kompetenzansatz trägt spürbar zu einer praxisnahen Ausbildung bei [1]. Ob er für verschiedene Studiengänge an den Fachhochschulen annehmbar ist, wird aktiv diskutiert, aber dass er für den Prozess der Ingenieurausbildung erforderlich ist, wird nicht in Frage gestellt. Hervorgehoben sei, dass der Kompetenzansatz bestens zu den Aufgaben einer ökologischen Ausbildung passt.

Die Berücksichtigung der Umweltkomponente ist in der Berufstätigkeit der künftigen Baufachleute außerordentlich wichtig, weil alle auf den Baustellen und Bauobjekten durchzuführenden Arbeiten den Umweltvorschriften entsprechen sollen. Als grundlegende berufliche Umweltkompetenzen der künftigen

Ingenieure gelten:

–die Bereitschaft, sich die Technologien der Gebäudeerrichtung sowie der Herstellung von Baustoffen, Erzeugnissen und Konstruktionen, Maschinen und Ausrüstungen unter der Berücksichtigung der Umweltvorschriften anzueignen;

–die Bereitschaft, neue umweltfreundliche Bautechnologien zu verwenden, die ressourcensparend sind und zur Bewahrung der Ökosysteme beitragen;

–die Bereitschaft, umweltfreundliche technische und organisatorische

Maßnahmen in der zukünftigen Berufstätigkeit zu treffen;

–die Fähigkeit, umweltfreundliche Bauobjekte zu entwerfen;

–die Fähigkeit, einen Notfall auf den Bauobjekten sowie bei der Herstellung von Baustoffen, Erzeugnissen und Konstruktionen zu verhindern.

Die Inhaltskomponente des methodischen Systems zur Entwicklung von

Umweltkompetenzen schließt folgende nötige Aktivitäten ein:

39

1.Es soll ein Ausbildungsinhalt bestimmt und systematisiert werden, der sich auf den Arbeitsschutz bei Bauund Umbauarbeiten sowie bei der Ausbeutung der Bauobjekte bezieht.

2.Bei der Erstellung technischer Unterlagen (Bauzeichnungen, Ausführungspläne, Betriebsvorschriften, eines Kostenüberschlages, Anträge auf Baumaterialen und Ausrüstungen) sowie Berichtsunterlagen sollen die Grundlagen einer sicheren Lebensführung berücksichtigt werden.

3.Es sollen Umweltschutzmaßnahmen getroffen werden, die bei der Entwicklung von Bautechnologien für die Vorbereitung der Bauarbeiten und der Herstellung von Materialen, Produkten, Konstruktionen, Maschinen und Ausrüstungen nötig sind [2].

Das die oben genannten obligatorischen Komponenten der technologischen und ökologischen Berufsbildung einschließende System richtet sich auf die Erreichung wichtiger gesellschaftlicher Ziele, wobei es staatliche Standards in der Ausbildung sichert und berufliche Umweltkompetenzen als eine Komponente der ökologischen Kultur des Menschen herausbildet [3].

Es sei betont, dass die Modulprogramme auch zur Entwicklung der beruflichen Umweltkompetenzen beitragen. Durch diese Programme werden moderne aktivierende Lehrmethoden im Bildungsprozess umgesetzt.

Literaturverzeichnis

1.Зимняя И.А. Ключевые компетентности как результативно-целевая основа компетентностного подхода в образовании / Исследовательский центр проблем качества подготовки специалистов. – М., 2004.

2.Гуреева Е.Г. Формирование базовых профессиональных экологических компетенций у студентов – будущих специалистов общественного

питания [Электронный ресурс]. – URL: http://nauka-pedagogika.com/ pedagogika-13-00-08/dissertaciya-formirovanie-bazovyh-professionalnyh-ekolo- gicheskiy-kompetentsiy-u-studentov-buduschih-spetsialistov-obschest-vennogo- pita#ixzz3l2zyiocc (дата обращения: 17.01.2015).

3. Хуторской А.В. Ключевые компетенции и образовательные стандарты [Электронный ресурс]. – URL: http://www.eidos.ru/journal/2002/

0423.htm (дата обращения: 17.01.2015).

40