Инновационные процессы в исследовательской и образовательной деятел

..pdfO.S. Gladysheva, M.A. Osipenko

Perm National Research Polytechnic University

M.S. Kuyukina

Institute of Ecology and Genetics of Microorganisms, the Ural Branch of the Russian Academy of Sciences

THE MODELING OF WATER TREATMENT FROM OIL POLLUTIONS BY A COLUMN BIOREACTOR

In this paper one of the most effective biological methods of water treatment from oil pollution is considered. This method is based on using Rhodococcus bacteria and the column bioreactor. The bioreactor scheme is shown and the processes occurring in the bioreactor are described. The paper contains the overview of the previous research conducted by other authors. Further prospects for investigating the problem are outlined.

Key words: column bioreactor, Rhodococcus, immobilization, fluidized bed, biodegradation.

The problem of water and soil treatment is urgent, because the cases of oil pollution are quite common nowadays.

Today the biological method is believed to be the most effective one. It is used for water and soil treatment. The method is based on using hydrocarbonoxidizing microorganisms which are fed by oil as one the sources of carbon. Among the hydrocarbon-oxidizing bacteria Rhodococcus bacteria are distinguished and it is these bacteria the paper is concerned with.

As regards polluted objects a lot of physicochemical and biological factors influence on the process of oil biodegradation on the polluted place. If water treatment is carried out putting bacteria into the natural environment, the process of biodegradation might prove to be ineffective. That is why, biotechnical processes are, for the most part, carried out in bioreactors, which provide the necessary conditions for the interaction between bacteria and the environment.

There is a number of theoretical and experimental research which examine how hydrodynamic parameters of the reactor influence the growth and development of bacteria [1]. There are publications [1, 2] discussing phenol biodegradation and the oxygen role in developing the processes which take place in the bioreactor [3]. The process of bacteria immobilization on the solid carrier is considered by Kuyukina [4]. However it is necessary to explore simultaneous biodegradation of different hydrocarbons oil is composed of study the dependence of the degree of some hydrocarbons decomposition of on biodegradation of other hydrocarbons. It is also necessary to work out a mathematical

21

model, which will simulate the process of biodegradation in the reactor with the view to determining the optimal operation parameters of a bioreactor.

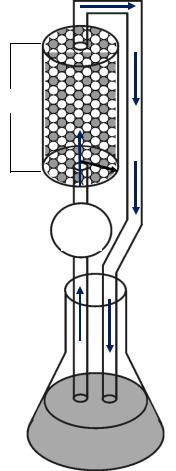

Today column bioreactors are widely used to provide biological processes. The bioreactor consists of the fixed part, which contains the particles of carrier, and circulating fluid, which washes these particles. This provides the best interaction between bacteria and the environment. The scheme of an experimental bioreactor is shown in Fig.

3

Н

R

2

1

Fig. The bioreactor scheme: 1 – circulating fluid; 2 – the peristaltic pump;

3 – the column bioreactor; R – radius of the cylinder; Н – high of the cylinder

To make the process of water treatment as effective as possible, the bacteria cells are first immobilized onto solid carriers. The immobilization allows multiple reusing microbe cells, increases the viability of bacteria and separation makes unnecessary the biomass from the fermentation medium. The process of Rhodococcus bacteria immobilization with hydrophobized pine sawdust used as a carrier was investigated by M. Kuyukina [4]. The process of immobilization is as follow. Rhodococcus suspension is placed into the flask (1), the suspension is pumped by a peristaltic pump (2) to the bioreactor (3), filled with the pine sawdust. The process takes place in a closed cycle. The bacterial cells are

22

fixed on the sawdust and it is its immobilization. After immobilization the bacteria cells may be used for water treatment. The water suspension of model oil (it is the mix of different hydrocarbons) is placated into the flask. This suspension is pumped by the peristaltic pump (2) to the bioreactor (3), where the pine sawdust with immobilized bacteria are located. The process is going on as a closed cycle until the concentration of hydrocarbons reaches a minimum value.

The construction of the bioreactor shown in Fig. is very simple bioreactor. The modern bioreactors used at the moment have a more sophisticated design. They have the aeration system, which supplies the oxygen into the column and the system which maintains the temperature constant. The suspension consisting of water, pine sawdust and bacteria forms the fluidized bed with complex properties.

So far, the problem of simultaneous biodegradation of a large number of hydrocarbons has been considered in only a few works. Relation between biodegradation of different hydrocarbons needs further investigation. The simulation of this process is another urgent problem to be solved. Its solution will result in optimization the bioreactor performance and will enable us to choose the best primers of biodegradation.

References

1.Investigation of hydrodynamic/ biomass growth coupling in a pilot scale granular bioreactor at low pore Reynolds number / M. Karrabi [et al.] // Chemical Engineering Science. – 2011. – No. 66. – P. 1765–1782.

2.Modelling of biological phenol removal in draw-fill reactors using suspended and attached growth olive pulp bacteria / G. Tziotzios [et al.] // International Biodeterioration & Biodegradation. – 2008. – No. 61. – P. 142–150.

3.Simultaneous removal of organic substances and nitrogen in pilot-scale submerged membrane bioreactors treating digested traditional Chinese medicine wastewater / Z. Chen [et al.] // International Biodeterioration & Biodegradation. – 2008. – No. 62. – P. 250–256.

4.Экспериментальное и теоретическое исследование процесса иммобилизации актинобактерий в колоночном биореакторе с псевдоожиженным слоем/ М.С. Куюкина [и др.] // Российский журнал биомеханики. – 2012. – T. 16, № 4. – C. 10–17.

23

V.A. Zhukotsky

Perm National Research Polytechnic University

AUTOMATED FINISHING OF FLOWING PART

OF THE GAS TURBINE ENGINES BLADES

The article considers finishing methods of gas turbine engine blades: electrolyticplasma polishing, magnetic abrasive polishing, robotic grinding and polishing. The main emphasis is on the analysis methods in terms of their universality and adaptability to the uneven allowance on the flow of the blades.

Key words: finishing, polishing, automation, adaptability, electrolytic-plasma polishing, magnetic abrasive polishing, Automation Vision and Robotics.

Operational properties of aircraft gas turbine engines (GTE) are defined by the parameters of blades quality which are subjected to significant and alternating cyclic loads [1, p. 120]. In this case, one of the most important tasks when creating new aircraft engines is the development and production of compressor and turbine blades that have optimum geometry of the flow. Special software packages and mathematical models are used to profile blades with the view to calculating the optimal profile of the blade.

Complex curved profile of the GTE flow makes the production face complex technological problems. Despite the fact that today's multi-axis computer numerical control (CNC) machines can grantee the precision up to a few microns, the required dimensions are achieved manually by means of repetitive cycle: measurement, selection of sites with an increased allowance, processing of the areas, re-measurement [2, p. 8].

This cycle takes a considerable amount of time compared to the total time of the blade processing. It is also worth noting that the manual revision of the blade does not provide dimensional stability, which significantly affects the performance characteristics of the blades. Therefore, there exists the need to automate, grinding, lapping and polishing of GTE blades.

The solution to the problems discussed, being based on of well-developed control algorithms allows us to provide stable process parameters, increase the precision of surface treatment, reduce the roughness of the job surface as well as processing time.

There is a lot of research in this area. One of the methods to solve the problem is to use the electrolytic-plasma polishing (EPP). This method is a highly effective process of handling products made of conductive materials. Another similar method – which enables us to attain the required quality parameters of the treated surface using the same equipment as in EPP – is the electrochemical polishing. But unlike EPP, which uses environmentally friendly aqueous salt so-

24

lutions, electrochemical polishing uses toxic acid components that are more expensive [3, p. 3]. However, EPP also reveals some disadvantages and shortcomings. They are:

–adaptive processing is not possible;

–applicability to only conductive materials;

–inability to make corrections caused by previous operations.

The Zhukovsky National Aerospace University developed the equipment for the magnetic-abrasive polishing (MAP) of details with a complex profile. This is another way to solve the problems under question [4]. Although the method can be used for processing both conductive materials and non-conductive ones, it is not adaptive processing. And the obvious disadvantage of this method is the applicability to only handling blades with small twist amount [4].

A definite advantage of the equipment for magnetic-abrasive polishing is its simplicity, as all operations are performed using one driver [4].

The most comprehensive approach to the problem of automated finishing of GTE blades was suggested by the Canadian company Automation Vision and Robotics (AV&R). They have developed a robotic cell based on robotic arms that allows to perform blades finishing as well as to control blade edges and identify defects [5].

In contrast to the previous methods, this one allows for processing blades made of any material and having any configuration. Besides, it makes the polishing of edges totally adaptive. However, when using this method, the chord width of the blades should meet stringent parameters. As a result, blade grinding is not adaptive.

Considering all said above, the following conclusion can be made. To implement automated and adaptive finishing of GTE blades, new methods of blade geometry monitoring are needed. These methods should provide the information about the allowance on the entire surface of the blade, which will make possible to develop adaptive grinding and polishing techniques for the flow parts of GTE blades. Also, the errors which might occur in the course of previous operations can be eliminated.

The development of such cutting speed control algorithms, in case of uneven allowance distribution on the blade surface and reduced machine parts inertia impact on the constancy of the pressure in the contact zone, will provide higher accuracy of processing in a shorter period of time despite previous technological strains.

References

1. Михайлов Д.А. Некоторые особенности полировки криволинейных поверхностей лопаток ГТД из титановых сплавов // Прогресивні технології і систем и машин обудування. – 2014. – № 3. – С. 120–127.

25

2.Коряжкин А.А. Методология адаптивного управления процессами контактного взаимодействия при ленточном шлифовании лопаток ГТД: автореф. дис. … д-ра техн. наук. – Рыбинск, 2014.

3.Новиков В.И. Повышение эффективности изготовления сложнопрофильных деталей из легированных сталей методом электролитно-плазмен- ного полирования: автореф. дис. … канд. техн. наук. – СПб., 2010.

4.Оборудование для магнитно-абразивной обработки сложнофасонных деталей ГТД / С.Н. Нижник [и др.] // Авиационно-космическая техника и технология. – 2004. – № 7. – С. 220–224

5.Automated edge profiling and vision inspection optimize blade production [Электронный ресурс]. – URL: http://www.cimindustry.com/article/metal wor- king/spatial-profiling (дата обращения: 20.02.2015).

26

Yu.V. Zavizion, N.N. Sliusar

Perm National Research Polytechnic University

ASSESSING DECOMPOSITION LEVEL OF WASTES

WITH DIFFERENT DISPOSAL PERIODS

The paper is aimed at assessing decomposition level of wastes selected from four disposal sites in Perm Krai. Biodegradation stages of wastes with different disposal periods (1–3 years, 2–6 years, 10 years+ and 30 years+) were identified. It was found out that the longer the waste disposal period is, the smaller the values of COD and BOD5 are in wastewater extract, as well as the less organic carbon content and the higher growth of ash content are in the wastes.

Key words: landfill, dump, decomposition level, municipal solid waste (MSW), biodegradation stage.

Introduction

At present waste disposal is the most common method of municipal solid waste (MSW) utilization in Russia. As reported by Rosprirodnadzor, about 35– 40 mln tons of MSW are produced annually, and practically all of them are placed at MSW landfills, both authorized and unauthorized [1].

The impact a landfill has on the environment is caused by leachate and biogas released from waste degradation [2]. Physicochemical properties of landburied MSW are not constant and depend on many factors such as the initial waste composition, landfill age, the temperature in a landfill body, humidity, free oxygen availability, pH, etc., time of MSW exposure to a landfill body being the key factor [3]. Some complex physicochemical, chemical and biochemical processes start to proceed in a landfill body over time. They include compression accompanied by water release, changes in wastes mechanical characteristics, chemical and biochemical degradation and others.

The processes of the disposed waste degradation proceed successively under aerobic and anaerobic conditions. The main stages of waste biodegradation under anaerobic conditions involve hydrolysis, acetogenesis, methanogenesis and the stage of assimilation [4].

The aim of research is to identify the disposed waste biodegradation stage and to assess the level of waste decomposition on the basis of the selected physicochemical parameters (pH, COD, BOD5, organic carbon content, ash content).

Materials and methods

In 2013–2014 a landfill waste sampling was made at four MSW disposal sites in Perm Krai, waste disposal periods being different. Sampling was performed by means of a bucket excavator at the intervals of 0.5 or 1 m.

27

MSW landfill in Krasnokamsk has been operating since 2008. The total area of a disposal site is 13 hectares and the volume of accumulated wastes makes up 142.7 thousand m3. MSW laying capacity is 4–6 m. and the disposed waste age is up to 1–3 years.

„Goliy Mys“ waste landfill has not been in use since 1982; wastes have been dumped in it for over 30 years. Its surface has been recultivated with topsoil cover. The landfill area is 29.75 hectares. The volume of accumulated wastes is 14.900 thousand m.3, the landfill body is 5–8 m high.

The waste dump in Kungur has been used since 1965; its area is 36 hectares; the volume of accumulated wastes amounts to 205,4 thousand m3; the height is 2–8 meters. Waste samples were selected from two sites – the one being in use (with the waste age of 2–6 years) and the other being recultivated (the waste age exceeds 10 years).

The waste dump in Krasnokamsk operated from 1963 to 2008; its area is 10.5 hectares; accumulated waste volume makes up 697.3 thousand m3; and the body height is 7–9 m.

Before the physicochemical analysis of wastes was made they had undergone a preliminary treatment which suggested selecting an inert fraction (glass, metal, stones), its drying, grinding (with a grain size not more than 20 mm) and homogenizing. It is known that waste degradation results in waste ground formation with the properties similar to those of the technical urbanized ground. That is why we used the methods of soil analysis for our purpose.

Wastewater extracts were prepared for the analysis according to GOST 2642385 with the distilled water ratio 1:5. COD was identified in wastewater extracts by means of titrimetric method according to PND F 14.1; 2.100-97. BOD5 was identified by means of manometric method in compliance with MVI 224.01.17.133/2009. The ash content of waste samples was determined according to GOST 27784-88; the organic carbon content was defined by means of oxidometric method as per GOST Standard 26213-91. The results shown exclude a separated inert fraction.

Results and discussion

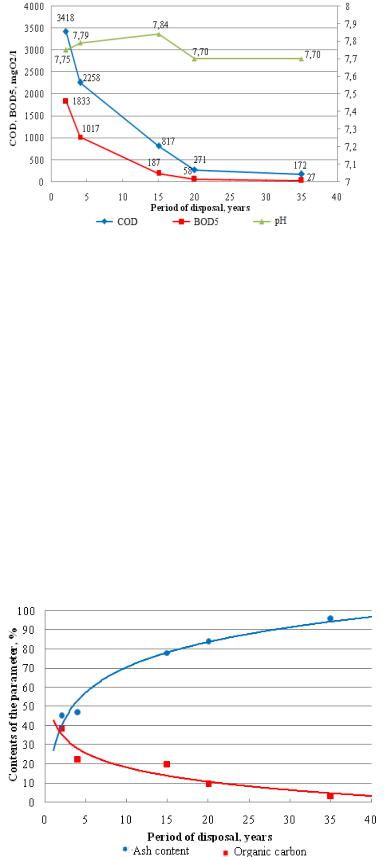

Waste parameters indicating the stage of a landfill life cycle (waste biodegradation stage) include pH, COD and BOD5. The results of waste samples analysis showed wastewater extracts’ pH, COD and BOD5 in relation to a disposal period (Fig.1).

pH medium indicator tends to be a qualitative indicator of the current biodegradation stage. Considering waste disposal period and alkalescent conditions identified for all wastes one can draw a conclusion on whether the methanogenesis stage proceeds in the active or stable phase. A more accurate assessment of the proceeding methanogenesis stage can be made on the basis of wastewater extracts’ COD and BOD5.

28

pH, ед.

Fig. 1. Changes in wastewater extracts’ pH, COD and BOD5 related to a disposal period

COD and BOD5 values of the analyzed wastewater extracts for the disposal periods of 1–3 years (MSW landfill in Krasnokamsk) and 2–6 years (waste dump in Kungur) imply an active methanogenesis stage. Falling values of wastewater extracts’ COD and BOD5 for the disposal period of more than 10 years old (waste dumps in Krasnokamsk and Kungur) show the slowdown of active methanogenesis processes and the transition to a stable methanogenesis phase. Low values of wastewater extracts’ COD and BOD5 for the disposal period of more than 30 years old (waste dump in „Goliy mys“) show the reduction of organic compounds content and stabilization of biochemical processes that is typical of a stable methanogenesis phase completion and the start of assimilation period.

Ash and organic carbon contents are the important indicators of waste decomposition level. Fig. 2 shows the dependence of ash and organic carbon contents in the analyzed waste samples on the waste age.

Fig. 2. Dependence of ash content and organic carbon content in the analyzed samples on the waste disposal period

29

A consistent decline of organic carbon content is observed in the extended waste disposal period. In waste with the disposal period of more than 30 years the content of organic carbon decreases by 6 times as compared to the waste disposed in a landfill body for the period of 1–3 years. As far as the organic carbon content decreases the ash content in waste increases respectively.

As Fig. 2 shows the ash content of waste increases with the increased waste age. Thus, the waste selected in “Goliy mys” (more than 30 years old dump which is closed for receiving wastes) has the ash content value of 94 %, which is more than 2 times higher than the ash content of the “fresh” waste (1–3 years old). The ash content value of wastes dumped in “Goliy Mys” indicates the completion of their decomposition.

Research of the organic carbon and ash contents in MSW resulted in decomposition of organic components which is under way in the wastes with disposal periods of 1–3 years (MSW landfill in Krasnokamsk) and 2–6 years (waste dump in Kungur).These wastes are characterized by a high content of organic carbon and the lowest ash content which indicates the negligible degree decomposition of wastes.

It was also found out that wastes with the disposal period of over 10 years (waste dumps in Krasnokamsk and Kungur) imply a high degree decomposition. These wastes are characterized by less organic carbon content and higher ash content as compared to “young” waste.

Physicochemical analyses showed the reduction of COD and BOD5 values in wastewater extract, decreasing organic carbon content and the growth of ash content in wastes.

References

1.Малышевский А.Ф. Обоснование выбора оптимального способа обезвреживания твердых бытовых отходов жилого фонда в городах России

[Электронный ресурс]. – URL: http://rpn.gov.ru/sites/all/files/users/rpnglavred/ filebrowser/docs/doklad_po_tbo.pdf (дата обращения: 15.02.2015).

2.Barlaz M., Ham R. Methane production from municipal refuse // Critical reviews in environmental control. – 1990. – Vol. 19. – P. 557–584.

3.Получение свалочного газа – экономия первичных природных энергоресурсов / А.М. Шаимова, Л.А Насырова, Г.Г. Ягафарова, Р.Р. Фасхутдинов // Нефтегазопереработка и нефтехимия: сб. тез. междунар. науч.-практ. конф.; г. Уфа, март 2006 г. – Уфа, 2006. – С. 246–248.

4.Управление отходами: сточные воды и биогаз полигонов захоронения твердых бытовых отходов: монография / Я.И. Вайсман [и др.]; под ред. Я.И. Вайсмана. – Пермь: Изд-во Перм. нац. исслед. политехн. ун-

та, 2012. – 259 с.

30