Учебное пособие 800637

.pdf

539.67 : 539.32 : 538.951

NI-FE-GA

. . |

|

|

1, . . |

|

|

2, |

. . |

3, . . |

4 |

|

1 |

|

. |

.- . |

, . . |

., k.sapozhnikov@mail.ioffe.ru |

|

||||

|

|

|

||||||||

- |

|

|

|

. . |

|

. |

, |

- |

, |

|

|

|

|

|

, |

|

- |

|

, |

|

|

|

2 |

. |

.- . |

, . |

. |

., |

. ., nkvlad@inbox.ru |

|

|

|

|

|

|

|

|||||||

|

3 |

. |

.- . |

, . |

. |

., V.Krymov@mail.ioffe.ru |

|

|

||

|

|

|

|

|||||||

- |

|

|

|

. . |

|

. |

, |

- |

, |

|

4 |

|

. |

.- . |

, |

|

|

, Sergey.Kustov@uib.es |

|

||

|

|

|

|

|

||||||

|

|

|

, |

|

|

|

|

, |

, |

|

|

|

|

, |

|

|

|

|

Ni55Fe18Ga27, |

|

|

|

|

|

|

|

|

|

|

100 |

|

|

|

|

12 |

- 370 |

|

|

|

|

|

10-7 - |

10-4. |

|

|

|

|

|

|

|

|

|

, |

|

|

|

|

|

|

|

|

|

, |

. |

|

|

|

|

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

: |

Ni-Fe-Ga, |

|

|

, |

|

, |

, |

|

,.

Ni-Fe-Ga alloys belong to a family of functional ferromagnetic shape memory alloys. Thermal treatment along with composition changes are the simplest means of controlling the

functional properties of Ni-Fe-Ga alloys. Changes in the degree of atomic order and precipita- tion of phase are usually considered as factors determining the properties of Ni-Fe-Ga al-

loys, while the role of point defects, in particular, quenched-in vacancies, is either ignored or analyzed in terms of their impact on the ordering process. However, point defects are among the main factors affecting the mobility of linear and planar defects and thereby the functional properties of alloys. Recently, we have found that quenching of Ni55Fe18Ga27 single crystals from an annealing temperature to the martensitic phase leads to a phenomenon of hyperstabilization of the martensitic phase that has been explained by sweeping of quenched-in point defects by moving interphase boundaries during reverse transformation [1]. It has been also shown that the concentration of vacancies in a Ni-Fe-Ga alloy changes upon thermal treatment in very broad limits and reaches up to 2500 ppm in samples quenched from high tem-

peratures [2].

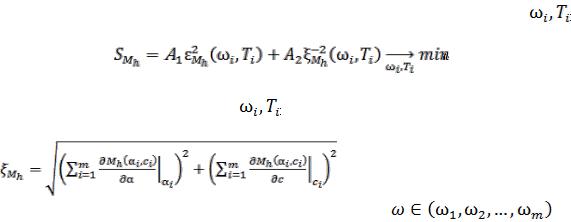

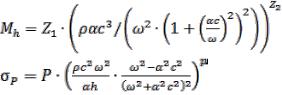

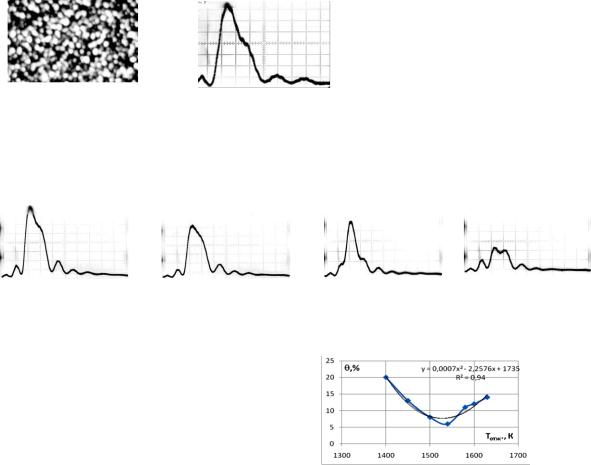

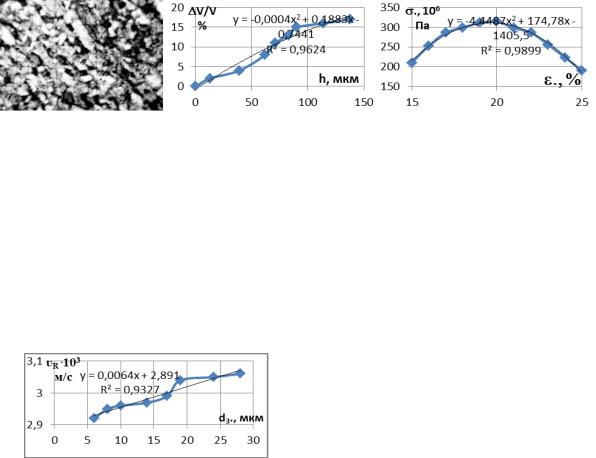

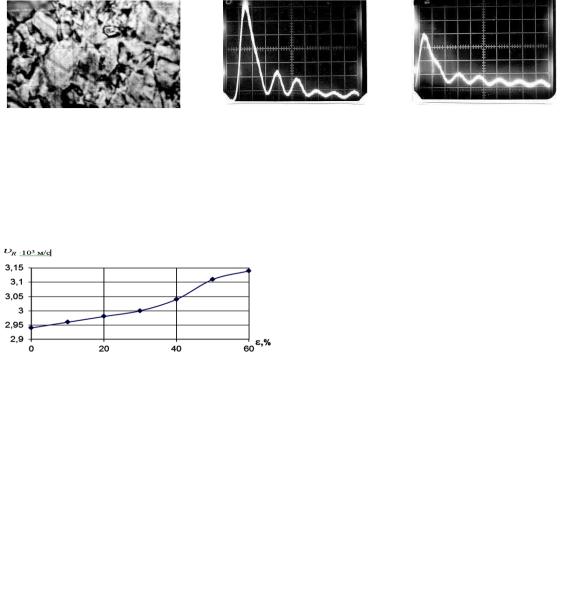

This work is devoted to study of the elastic (effective Young´s modulus) and anelastic

(linear and non-linear internal friction, Young's modulus defect, anelastic strain) properties of Ni55Fe18Ga27 alloy, subjected to different heat treatments, by means of resonant piezoelectric composite oscillator technique at frequencies around 100 kHz, temperatures of 12-370 K and strain amplitudes between 10-7 and 10-4. Samples were cut from rod-shaped Ni55Fe18Ga27 single crystals with [100]A orientation along the rod. After annealing for 20 min. at 970 K, the samples were subjected to three different heat treatments: 1) slow cooling in the air; 2) direct quenching into room-temperature water; 3) step-quenching (quenching into oil at 390 K followed by quenching into room-temperature water). The samples cooled in air were characterized by the forward and reverse martensitic transformation temperatures about 330 and 340 K, respectively, and the Curie temperature of Tc = 290 K. The samples directly quenched into water were in a hyperstabilized state, where a small fraction of martensite exhibited reverse transformation near 400 K, while the main fraction required overheating up to a temperature about 580 K [1]. The magnetic transformation after quenching becomes smeared and shifts to

218