2414

.pdfbreakthrough was making many of the parts interchangeable, and the whole process involved product design.

-------------------------------------------

The capacity decision involves choosing the amount of conversion capacity appropriate for the organization. Determining whether to build a factory capable of making 5,000 or 8,000 units per day is capacity decision. So, too, is deciding whether to build a restaurant with 100 or 150 seats or a bank with 5 or 10 teller stations. The capacity decision is truly a high-risk one, because of the uncertainties of future product demand and the large monetary stakes involved. An organization can build capacity that exceeds its needs and requires resource commitments (capital investment) that may never be recovered. This was the mistake made by many American firms during the 1960s and 1970s. Or an organization can build a facility with a smaller capacity than expected demand. Doing so may result in lost market opportunities, but it may also free capital resources for use elsewhere in the organization.

A key consideration in determining capacity is demand. For example, a company operating in a stable environment with fairly constant monthly demand might build a plant capable of producing an amount each month roughly equivalent to its demand. But if its market is characterized by seasonal fluctuations, it might be better advised to build a smaller plant to meet normal demand and then add extra shifts during peak periods. Likewise, a restaurant that needs 150 seats for Saturday night dinner but never needs more than 100 at any other time during the week would probably be foolish to expand to 150 seats. During the rest of the week, it must still pay to light, heat, cool, and clean the excess capacity. Of course, 150 seats might be a good idea if the manager has good reason to believe that demand will or can be increased in the near future.

III. While listening to the lecture on economics your friend has made some notes but put no full stops. So, he understands nothing. Can you help him? Translate the extract to confirm your decision.

Capacity decisions are aimed at providing the right amount of capacity at the right place at the right time long-range capacity is determined by the size of the physical facilities, which are built in the short run, capacity can sometimes be augmented by subcontracting, extra shifts, or rental of space capacity planning, however, determines not only the size of facilities but also the proper number of people in operations staffing levels are set to meet the needs of market demand and the desire to maintain a stable work force in the short run, available capacity must be allocated to specific tasks and jobs in operations by scheduling people, equipment, and facilities.

83

Workbook Ex. 36– 40on page 117 – 118.

IV. Make up a list of questions for an interview with an Operations Manager of a famous company in order to get information concerning efficient use of their capacity.

Text 17

I. Listen to a native speaker and try to memorize the pronunciation of the words. Try to imitate the pronunciation.

pertain |

[pə´tein] |

принадлежать; иметь отноше- |

|

[ləu´keiʃn] |

ние; подходить |

location |

расположение; размещение |

|

layout |

[´leiaut] |

планировка; расположение |

automate |

[´ɔ:təmeit] |

автоматизировать |

retail |

[´ri:teil] |

розничная продажа |

product layout |

[´prɔdʌkt ´leiaut] |

размещение оборудования для |

|

|

выпуска определенной про- |

|

[ə´sembli ´lain] |

дукции |

assembly line |

конвейерная линия |

|

process layout |

[´prəuses ´leiaut] |

схема технологического про- |

|

[´si:kwəns] |

цесса |

sequence |

последовательность |

|

enormous |

[i´nɔ:məs] |

громадный; огромный |

II. Read about another constituent of operating systems.

II. Read about another constituent of operating systems.

FACILITIES

Facilities are the physical locations where products or services are created, stored, and distributed. Key decisions pertain to location and layout.

Location must be determined by the needs and requirements of the organization. A company that relies heavily on railroads to transport raw materials or finished goods needs to be located close to rail facilities. General Electric decided that it did not need six plants to make circuit breakers, so it invested heavily in automating one plant and closed the other five. Different organizations in the same industry may have different facilities requirements. Benetton uses only one distribution center for the entire world. K mart, in contrast, has several distribution centers in the United States alone. A retail business must choose its location very carefully so as to be convenient for consumers.

The choice of physical configuration, or the layout, of facilities is closely related to decisions on product or service line, capacity, and location.

84

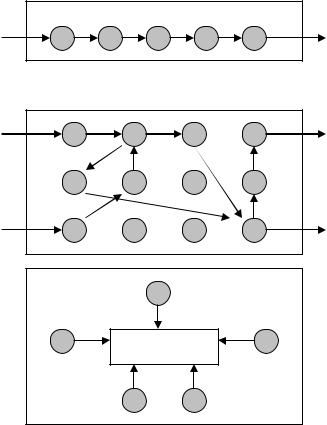

A product layout is appropriate when large quantities of a single product are needed. It makes sense to custom design a straight-line flow of work for a product when a specific task is performed at each workstation as each unit flows past. Most large-scale assembly lines use this format.

Process layouts are used in operations settings that create a variety of products. Auto repair shops and healthcare clinics are good examples. Each automobile and each individual is a separate “product.” Only the general nature of each job is known in advance. Detailed product specifications cannot be known until the customer’s arrival. The needs of each incoming job are diagnosed as it enters the operations system, and the job is routed through the unique sequence of workstations needed to create the desired finished product. In a process layout, each type of conversion task is centralized in a single workstation or department. All welding is done in one designated shop location, and any auto that requires welding is moved to that area. This is in contrast to the product layout, in which several different workstations may perform welding operations if the conversion task sequence so dictates.

The fixed-position layout is used when the organization is creating a few very large and complex products. Aircraft manufacturers like Boeing and shipbuilders like Newport News (subsidiary of Tenneco) use this method. An assembly line capable of moving a 747 would require an enormous plant; so instead the airplane itself remains stationary, and people and machines move around it as it is assembled.

III. Match the numbers to the letters. Use the given words (1 – 6) in the sentences of your own and let your partner specify what you mean using the definitions (a – f).

1 Location

2 Process layout

3 Product layout

4 Fixed-position layout

5 Facilities

6 Layout

services are created, stored, and distributed.

Workbook Ex. 41 on page 118.

IV. What layouts are represented by the following schemes?

All incoming |

Finished |

jobs and |

product |

materials |

|

Incoming |

Finished |

job 1 |

product 1 |

Incoming |

Finished |

job 2 |

product 2 |

Product

Work

Work

station

V. How many questions can you put to the following extract? Ask your partner.

All organizations need to carefully consider where they locate their facilities. To some organizations, however, facilities location decisions are especially important. For example, Luz International operates solar electric generator stations around the world. To be most effective, the stations need to be in locations where there are few clouds and where there are many hours of bright sunshine most days. This station is located in the Mojave Desert.

VI. Write a letter of suggestion with the purpose of changing the equipment of your firm. Mind that such a letter consists of four parts: introductory paragraph; first suggestion; an alternative to this suggestion or a second suggestion; closing paragraph.

86

The following expressions can be helpful for you: I’d like to suggest that…; May I suggest that…; Perhaps we could…; Could you please…; I trust these suggestions have been useful…; Pleases let me know if I can help any further.

Text 18

I. Listen to a native speaker and try to memorize the pronunciation of the words. Try to imitate the pronunciation.

intricacy |

[´intrikəsi] |

запутанность; сложность; |

|

[´veəri] |

лабиринт |

vary |

меняться; изменяться |

|

labor-intensive |

[´leibə in´tensiv] |

трудоемкий |

capital-intensive |

[´kæpitl in´tensiv] |

капиталоемкий |

flexible |

[´fleksəbl |

гибкая производственная |

manufacturing |

ˏmænju´fækʧəriŋ |

система |

system |

´sistəm] |

|

|

[kəm´pju:tə |

автоматизированная сис- |

computer-integrated |

´intigreitid |

тема управления произ- |

manufacturing |

ˏmænju´fækʧəriŋ] |

водством |

|

[kəm´pju:tə ´eidid |

система автоматизирован- |

computer-aided |

di´zain] |

ного проектирования |

design |

[kəm´pju:tə ´eidid |

автоматизированное про- |

|

||

computer-aided |

ˏmænju´fækʧəriŋ] |

изводство |

manufacturing |

[´meinfreim |

главный компьютер вы- |

|

||

mainframe computer |

kəm´pju:tə] |

числительного центра |

accuracy |

[´ækjərəsi] |

точность; тщательность |

|

|

II. Look through the text and find sentences with the words above. Use three words to make sentences.

III. How do you define the word “technology”? Is there any difference between “technology” and “technique”? Read the text and try to answer the questions.

III. How do you define the word “technology”? Is there any difference between “technology” and “technique”? Read the text and try to answer the questions.

TECHNOLOGY

What should the manager know about technology? After all, shouldn’t the matter of technology choice be left to scientists and engineers? How can a

87

manager be expected to master the intricacies of technology when technologists have spent their lifetimes studying the subject? These are important questions, and they reflect the fears that some managers have about technology.

All of us make technological choices in everyday life. We purchase color TVs, microwaves, and automobiles, all of which utilize complex technologies. In making these everyday choices, we concentrate on the performance characteristics of the technology, not the engineering or technical details. When we buy a color TV, we are interested in such performance characteristics as the clarity of the picture, the energy consumption, and the cost. We are not particularly interested in the number of radio frequency stages or the voltage of the picture tube. When we buy an automobile, we are interested in its handling qualities, gas consumption, and possible future repair bills. We are not very interested in the engine’s revolutions per minute or the front-end differential ratio. In the same way, a manager should be concerned with the performance characteristics of a technology, not the technical details.

The decisions of technological choice are of extreme importance and require managerial attention. These decisions, in the end, are not really technical in nature. Technology is only one component of a decision, which involves economics, strategy, products, and all aspects of management responsibility. Thus, managers should be willing to understand enough about technology to be able to integrate their technical knowledge with the management factors involved.

The organization must make decisions about the technology it will employ in creating products or services. The operations technology used can vary along a continuum from highly labor-intensive to highly capital-intensive. A homecleaning service and a football team are highly labor-intensive – people do the work. An automated plant is very capital-intensive – expensive machinery does the work. The degree of mechanization and automation chosen by an organization has a significant impact on output quality, production costs, labor and management skills required, and operations flexibility.

Although the technologies of most service organizations continue to be highly labor-intensive, relatively more capital-intensive options have evolved. Especially with increasing applications of computers, such traditionally laborintensive professional services as medicine, law, and education and other service industries such as commercial banking have adopted new, capital-intensive technologies for creating and delivering their products.

New technologies have also had a significant impact on organizations over the last few years. One approach, called flexible manufacturing systems (FMS) relies on computers to coordinate and integrate automated facilities. This approach is also called computer-integrated manufacturing (CIM). Another new technology involves computer-aided design (CAD), usually used in conjunction with computer-aided manufacturing (CAM). CAD involves the use of computers to design new products and services.

88

IV. Can you find 9 words from the text in the letters?

D |

Q |

W |

E |

I |

M |

P |

A |

C |

T |

O |

|

|

|

|

|

|

|

|

|

|

|

E |

U |

V |

A |

R |

Y |

A |

C |

E |

M |

P |

|

|

|

|

|

|

|

|

|

|

|

C |

D |

E |

S |

I |

G |

N |

C |

O |

L |

E |

|

|

|

|

|

|

|

|

|

|

|

I |

A |

H |

O |

G |

D |

H |

Y |

S |

J |

R |

|

|

|

|

|

|

|

|

|

|

|

S |

F |

F |

M |

X |

N |

O |

P |

D |

H |

A |

|

|

|

|

|

|

|

|

|

|

|

I |

S |

C |

H |

O |

I |

C |

E |

T |

G |

T |

|

|

|

|

|

|

|

|

|

|

|

O |

G |

I |

L |

E |

Z |

K |

T |

V |

F |

I |

|

|

|

|

|

|

|

|

|

|

|

N |

C |

O |

M |

P |

U |

T |

E |

R |

D |

O |

|

|

|

|

|

|

|

|

|

|

|

U |

G |

N |

D |

T |

A |

J |

F |

Q |

R |

N |

|

|

|

|

|

|

|

|

|

|

|

Y |

J |

A |

P |

P |

R |

O |

A |

C |

H |

S |

|

|

|

|

|

|

|

|

|

|

|

P |

K |

H |

A |

E |

F |

S |

Z |

S |

K |

P |

|

|

|

|

|

|

|

|

|

|

|

V.Choose the best item.

1.All of us make technological choices … а) in everyday life.

b) only at work.

c) because we are scientists.

2.In making technological choices, we concentrate … a) on the engineering details.

b)on the performance characteristics of the technology. c) on the technical details.

3.The decisions of technological choice …

a)are not so important as it may seem.

b)are of extreme importance.

c)are important only in particular situations.

4.The operations technology used …

a)can vary from highly labor-intensive to highly capital-intensive.

b)stay invariable in spite of labor-intensiveness or capital-intensiveness of the organization.

c)can never vary from highly labor-intensive to highly capital-intensive.

5.New technologies …

a) have had a significant impact on service organizations.

89

b)have had a significant impact on manufacturing organizations.

c)have had a significant impact on various organizations.

VI. Read the continuation of the text “Technology” and answer the questions:

1.Choosing technology in manufacturing or service industry operations has many parallels to the lawn-mower problem, hasn’t it?

2.What does the lawn-mower example illustrate to managers?

3.Should a manager assess the performance characteristics of the technology along with its economic and managerial implications?

Researchers at the Harvard Business School have illustrated the problem of technology choice as follows:

Consider a simple example of equipment technology, a process for cutting grass, a lawn mower.

A lawn mower could be described to a prospective purchaser as follows: “It costs $128. It has a gasoline engine and cuts a 24-inch wide swath of grass and is well made by a well-known manufacturer.” A technology-aversive prospective buyer might say, “I’ll take it,” only to get home to the 8-inch grass and find that:

The cutting technology was based on a reel moving past a cutter bar. It could not handle grass much higher than one-half of the reel diameter. It simply pushed the 8-inch crop forward and down.

It was self-propelled but had no effective free-wheeling device, so that it was not possible to work close to and around a formal garden.

It took 30 minutes to change the cutting height so that the hillside grass could be cut longer (to cut down on erosion) than lawn grass.

It was not powerful enough to cut wet, thick grass going uphill. It did not mulch leaves.

It had a two-cycle engine, which meant that oil had to be mixed with the gasoline each time the little tank was filled.

This buyer should have purchased an extra-powerful, four-cycle, selfpropelled rotary mower with easy handling for tight maneuvering and with a simple height-adjustment mechanism.

Understanding the equipment and process technology of lawn mowing in order to make a wise purchase of machinery would have required the ownermanager to develop an accurate mental concept or picture of the process of cutting grass with the machine operating on the hillside and on the level, under a variety of physical conditions, with consideration for the operator’s time, money and skills. The most crucial mistake, of course, was in the choice of a reel mower rather than one with a rotary blade. But for a house with low, big glass windows and with close-by neighbors’ houses which were similarly constructed, the buyer would have also needed to consider the danger from flying stones

90

propelled by the rotary mower. In either case, a reasonably good conceptual approximation of the actual grass-cutting action would have suggested enough of the right questions to lead to other useful questions.

VII. Read two extracts and say where computer-integrated manufacturing and where computer-aided design is described.

А) The Alien-Bradley factory in Milwaukee, Wisconsin, is such a facility. This factory makes electric contactors, which are used as motor starters in over 125 different varieties and produced at a rate of 600 contactors per hour.

The most impressive aspect of the Alien-Bradley factory is that it produces each day what was ordered the previous day. This requires the factory to make contactors in lot sizes as small as one and in whatever amount the customer orders. This feat is accomplished by an impressive array of computers and 26 automatic machines. There are no operators in the factory, and only a few maintenance people, a supervisor, and some support people. Material is put into one door of the factory and finished contactors are shipped out of the other door, in a more or less continuous flow.

Each morning the orders from 40 sales offices and 400 distributors around the world are down loaded into the Allen-Bradley main computer. Each order is then scheduled to be produced as the customer ordered it. Before the end of the day the order is produced, packaged, and shipped to the customer. This approach virtually eliminates inventory and allows the facility to turn its inventory in the range of 50 to 100 times a year.

An extensive array of quality checks is also built into the system. Each part is automatically inspected, and equipment is shut down for maintenance if statistical control limits are exceeded. Routine maintenance assures that a high level of system uptime is maintained.

В) Benetton uses this approach in designing new styles and product specifications. A properly designed system can tie directly into a CAM system. Suppose that a Benetton store needs to order some new blue sweaters. The order is transmitted to a Benetton mainframe computer in Italy. The system already knows all the product specifications, because it designed the product. Thus, the reorder is relayed to a knitting machine that actually makes the new sweaters. Meanwhile, another machine is printing out an address label and a copy of the original order. Only when everything is finished does a human being get involved – and only then to provide a final check for quality and accuracy.

Workbook Ex. 42 on page 118.

VII. Look at fig. 8. Have you ever seen this man? Can you imagine his occupation? What is he famous for?

91

Fig. 8

VIII. You are going to listen to the text. Read the following sentences and be ready to fill in not more than three words while listening.

1.He was born near _____________________.

2.At the age of 16 he worked in _________________________.

3.17 years later he built an automobile powered by a gasoline engine using his

___________________.

4.Having organized his own company, he designed and manufactured

_________________.

5.He was able to cut the price of his car by introducing assembly ___________.

6.He increased _____________ and introduced a __________________ plan.

7.He represented _________________, self-reliance and thrift.

8.He contributed more than $40 million to _______________________.

IX. You are going to listen to the text once again. Complete the table using not more than three words while second listening.

1863 |

Henry was 1)__________. |

|

|

1891 |

He began to experiment with 2)___________________. |

|

|

|

92 |