2414

.pdfcomputerized systems to help them provide the best customer service at the lowest possible inventory cost.

Production Control and Scheduling Manager. The production control manager is responsible for developing a production plan and ensuring the best use of resources in meeting that plan. Production control responsibilities include planning schedules; balancing workloads, and making sure that the product is delivered on time. In the service industry, this function is often called scheduling.

Quality Manager. The quality manager is concerned with planning and controlling product quality. Responsibilities include setting quality standards, developing quality control standards, developing quality control systems, and assisting workers in producing quality. The quality manager monitors the quality of the product or service at every stage.

Facility Manager. The facility manager is concerned with the design and control of operations facilities and processes. Responsibilities include work-flow analysis, technology management, facilities choice, facilities location, and equipment planting.

Line Manager. The line manager is concerned with the management of the work force and of operations units. Job titles include first-line supervisor, production superintendent, and unit manager. The line manager is concerned with proper performance of work, personnel development, work organization, and reward Systems.

Operations Planning Analyst. An operations planning analyst deals with the overall planning, budgeting, and control of an operation. A planning analyst serves as staff to the operations manager and may develop models and information systems to support planning and decision-making.

III. Complete the crossword.

1.A programme of work to be done or of planned events.

2.To use something for a practical purpose.

3.A person who manages and controls workers, their work.

4.To have power or authority over somebody or something.

5.A person who is skilled in studying of something by examining its parts and their relationship.

6.The standard of something when compared to other things like it; how good or bad something is.

7.A person who sells food or other small items from a stall in the open air.

8.A detailed list, for example, of goods, furniture or jobs to be done.

9.The activity of buying things.

73

|

7 |

|

|

1 |

|

|

2 |

8 |

3 |

9 |

|

4 |

5 |

6 |

IV. Do you agree with the statements? Use the following expressions for help:

That’s right. That’s right but… . I agree with you. Exactly so. You are wrong. Quite on the contrary.

1. Operations manager is called plant manager in manufacturing organizations. 2. Materials manager is concerned with overall coordination. 3. Purchasing managers work closely with vendors. 4. The purchasing manager negotiates prices and is responsible for budgeting. 5. Inventory managers don’t use computerized systems as it takes much time. 6. The facility manager is concerned with setting quality standards. 7. Personnel development is the responsibility of the scheduling manager.

Workbook Ex. 33on page 116.

V. Try to define an area of management where the speaker works.

1.“Two winches and one crane we are going to buy only next month”.

2.“This machine should be painted once more before shipment”.

3.“For our new project we need two tons of steel”.

4.“If we can’t deliver the equipment in time we shall lose our customer”.

74

5. “One person of our team has to go to Japan to raise the level of his professional skill”.

VI. You are a Purchasing Manager. You are negotiating delivery periods for machines you have ordered with the supplier. Read the dialogue and act it out.

-Well, let’s get started. You know, with this delivery problem I’m sure there’s room for negotiation.

-Let’s see how we get on.

-Right. We can deliver the first machine in ten weeks, and install it four weeks after that.

-Why such a long delivery period?

-Well, these are in fact the usual periods. It’s pretty normal in this kind of operation. Did you expect we could deliver any quicker?

-We need delivery of six weeks maximum, with four weeks for installation.

-That would be very difficult. You see we have a lot of orders to handle at present, and moving just one of these machines is a major operation. Look, if I can promise you delivery in eight weeks, does that help?

-I’m sorry, but I can’t accept eight weeks.

-Ah-ha! Well, look…er… You want the machine in six weeks. Now that is really a very short deadline in this business. You said that you couldn’t take it any later, but couldn’t your engineers find a way to reschedule just a little?

-I’m afraid I can’t increase the delivery period any further. I have my instructions.

-I’ll have to consult with my colleagues and come back to you, but I can’t see what we can do.

-May I make a suggestion? If you can promise delivery in six weeks, then we may be able to talk about a further order.

-Well, on that basis I suppose we might be able to look at some kind of arrangement. In fact, if you can promise another order I think we could accept your terms.

-Let’s go through the terms: six weeks for delivery, four weeks for installation; and the decision about the next order to be taken by the 26th. Agreed?

-Exactly.

VII. Read the poem below. If a student follows all the recommendations, is it possible for him not only to be in a good mood but become a good Purchasing Manager? What pieces of advice are the most important in an effort to fill this position and what rules are unacceptable?

Rules and Regulations

A short direction

75

………………...

To avoid dejection.

………………...

Learn well your grammar, And never stammer, Write well and neatly, And sing most sweetly, Be enterprising,

Love early rising, Go walk of six miles,

Have ready quick smiles, With lightsome laughter, Soft flowing after.

Drink tea, not coffee; Never eat toffy.

Eat bread with butter, And never shutter. Don’t waste your money, Abstain from honey. Shut doors behind you,

(Don’t slam them, mind you.) Drink beer, not porter. Don’t enter the water

Till to swim you are able. Sit close to the table. Take care of a candle.

Shut the door by the handle. Don’t push with your shoulder Until you are older.

Lose not a button. Refuse cold mutton. Starve your Canaries. Believe in fairies.

If you are able, Don’t have a stable With any mangers. Be rude to strangers. Moral: Behave.

Edward Lear

VIII. Give an advertisement for a vacant position of a Purchasing Manager. Do not forget to describe the features of character you need for this person.

76

Text 15

I. Listen to a native speaker and try to memorize the pronunciation of the words. Try to imitate the pronunciation.

efficiency |

[i´fiʃnsi] |

производительность; продуктивность |

effectiveness |

[i´fektivnis] |

эффективность |

myriad |

[´miriəd] |

бесчисленный; несметное число |

regardless |

[ri´gɑ:dlis] |

не считаясь с; не взирая на |

state-of-the-art |

[ˏsteitəvði´ɑ:t] |

достигнутый; реальный, внедренный |

rigorous |

[´rigərəs] |

строгий; точный; тщательный |

specifications |

[ˏspesifi´keiʃnz] |

спецификация; инструкция по обра- |

|

|

щению |

implement |

[´impliment] |

выполнять; осуществлять |

assets |

[´æsets] |

активы; средства; фонды; имущество, |

|

|

собственность |

veer |

[viə] |

менять направление |

parity |

[´pærəti] |

паритет; равенство |

negotiations |

[niˏgəuʃi´eiʃn] |

переговоры |

thorough |

[´θʌrə] |

полный; совершенный; подробный; |

|

|

тщательный |

viable |

[´vaiəbl] |

жизнеспособный |

enhance |

[in´hɑ:ns] |

увеличивать; усиливать; повышать |

anticipate |

[æn´tisipeit] |

ожидать; предвидеть; опережать; |

|

|

предвосхищать |

pursue |

[pə´sju:] |

преследовать; следовать по намечен- |

|

|

ному пути |

personnel |

[ˏpə:sə´nel] |

персонал, штат; кадры |

ongoing |

[´ɔnˏgəuiŋ] |

непрерывный; постоянный; происхо- |

|

|

дящий в настоящее время |

II. Scan the text trying to find the main idea.

II. Scan the text trying to find the main idea.

THE OPERATIONS MANAGEMENT PROCESS

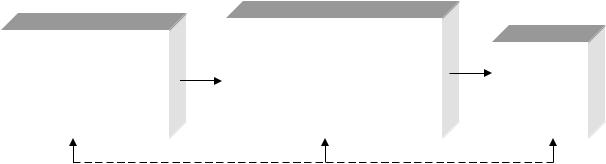

In the process of transforming inputs into goods and services, operations management involves several major elements. For one thing, there is operations strategy, the role played by operations management in both formulating and implementing strategies to achieve organizational goals. For another, operations management includes various operating systems, major methods used to achieve efficiency and effectiveness in manufacturing and service operations.

77

Yet another major element is facilities, the land, buildings, equipment, and other major physical assets that directly affect an organization’s capacity to deliver goods and services. Finally, process technology, the technology used in transforming inputs into goods and services, also is an important ingredient in operations management (Fig. 6).

Operations strategy

Managers face a myriad of decisions that must be integrated with the organization’s strategy. For example, the deceivingly simple strategic decision of whether to stress high quality regardless of cost, lowest possible cost regardless of quality, or some intermediate combination of the two has numerous important implications. The first decision will dictate state-of-the-art technology, rigorous control of product design and materials specifications, and thorough quality checks throughout the production process. The last decision might call for lower-grade technology, less concern about product design and materials specifications, and fewer quality checks.

Just as strategy affects operations management, so too does operations management affects strategy.

INPUTS |

TRANSFORMATION PROCESS |

OUTPUTS |

||||

|

|

|

|

|

|

|

|

|

Operations Management |

|

|

|

|

Raw Materials |

|

|

||||

|

|

Operations strategy |

|

Goods |

|

|

Human Resources |

|

|

|

|||

|

|

Operating systems |

|

and |

|

|

Information |

|

|

|

|||

|

|

Facilities |

|

Services |

|

|

Technology |

|

|

|

|||

|

|

Process technology |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

Fig. 6

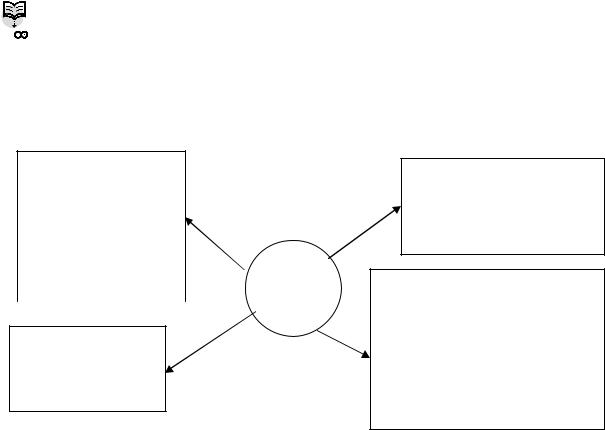

Operations experts Steven C. Wheelwright and Robert H. Hayes argue that operations management plays different roles in determining strategy, depending on an organization’s strategic role stage.

Strategic Role Stages

Stage 1: Minimize Negative Potential. At stage 1, top managers attempt to neutralize any negative impact that internal operations may have on the organization. They take this stance because they regard operations management as essentially neutral in the sense of being incapable of positively affecting the organization’s competitive success. In this mode, top managers typically use detailed measures and controls to be sure that the operations function does not veer to far off track before corrective action is taken. Generally, top managers

78

minimize their involvement with operations areas, except for concerning themselves with major investment decisions (such as new facilities or major equipment purchases) through the vehicle of the capital budgeting process. Many consumer-products and services companies fit in this category.

Stage 2: Achieve Parity with Competition. At stage 2, top managers seek to have operations management maintain parity, or stay even, with the competition. Organizations at this stage typically attempt to maintain equality with the competition by adopting industry practices related to work-force matters (such as labor negotiations), equipment purchases, and upgrades of capacity. They are also very likely to avoid introducing major changes that will disrupt the status quo, to view capital investments in new equipment and facilities as the best means of gaining a temporary jump on the competition, and to consider producing in large amounts as the best source of efficiency. Such industries as steel, autos, and heavy equipment are among the organizations often found in this stage.

Stage 3: Support Overall Organizational Strategy. At stage 3, top managers expect the operations management function to actively support and strengthen the organization’s overall strategy. The role of operations managers, then, is to gain a thorough understanding of the organizational strategy as formulated by top management and to consider innovations that will help implement that strategy effectively. In this mode, top management wants operations managers to be creative and take a longer-term view of the operations management function. In contrast to those at stage 2, organizations at stage 3 see technological progress as a viable option that can enhance an organization’s competitive position. Nonetheless, at this stage, operations managers are involved in implementing and supporting strategy but not in formulating it. The beer industry includes many stage-3 organizations.

Stage 4: Pursue Operations Management-Based Strategy. At stage 4, top managers include operations managers in the strategy development process and formulate a strategy that depends to a significant degree on operations capabilities. Top managers view operations management as a strong strategic resource that can be used a basis for strategy development. At stage 4, managers try to anticipate potential technological advances that could affect operations and to gain the necessary internal expertise well before the implications are obvious. At this stage, organizations attempt to use innovation as a means of making incremental strategic jumps ahead of the competition. Stage 4 is characteristic of all companies that have reached the status of world-class manufacturers. Such companies typically place a great deal of emphasis on ongoing innovations developed within the organization. In operations, these innovations are aimed at improving the processes used to produce goods and services. Because such organizations are at the forefront of new operations processes, they often develop their own innovative production equipment. Such

79

efforts help them keep up with the various operations technologies that can affect their competitive position (Fig. 7).

Normally, organizations have difficulty moving from one stage to higher stages without passing through the stages in between. One reason is that operations management personnel need to acquire new skills to function at each progressive stage. Another reason is that higher stages also require changes in the way that the rest of the organization views operations management and interacts with it.

|

Stage 1 |

|

|

Stage 2 |

|

|

Stage 3 |

|

|

Stage 4 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Minimize |

|

|

|

Achieve |

|

|

|

Support |

|

|

|

Pursue |

|

|

Negative |

|

|

|

Parity with |

|

|

|

Overall |

|

|

|

Operations |

|

|

Potential |

|

|

|

Competition |

|

|

|

Organizational |

|

|

|

Management-Based |

|

|

|

|

|

|

|

|

|

|

Strategy |

|

|

|

Strategy |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Strength of Operations Management Strategic Role |

|||||||||

low |

|

|

|

|

|

|

|

|

|

|

high |

|||

Fig. 7

Workbook Ex. 34, 35on page 116 – 117.

III. Guess the meaning of the words, and then consult your dictionary to see if you are right. Use the words in the sentences of your own.

Process, element, effectiveness, physical, service, ingredient, technology, strategy, combination, materials, product, design, role, organization, neutralize, negative, positively, capital, function, category, budget, steel, formulate, potential, innovation, characteristic, companies, typically, position.

IV. Do you know…

…what major elements operations management involves in the process of transforming inputs into goods and services?

…how strategy affects operations management?

…what organization’s strategic role stages are?

…what top managers do at the 1st stage?

…the difference of the 2nd stage?

…at what stage top management wants operations managers to be creative?

…what companies stage 4 is characteristic of? Why?

…if it is difficult to move from one stage to higher stages without passing through the stages in between?

80

VI. Write a summary of the text.

VII. What is “Motorola” famous for? Have you heard about “Operation Bandit”? What stage has Motorola reached through its “Operation Bandit” robotic production line? If you do not know the answers to the questions above, read the information.

A dominant force in the U.S. market for pocket pagers, Motorola watched as Japanese producers forced out half a dozen other domestic pager makers. Determined to stay competitive, Motorola’s paging division developed a $9 million state-of-the-art manufacturing assembly line that debuted in 1988, operating along one wall of Motorola’s Boynton Beach plant in southern Florida. The production line is called “Operation Bandit” because it borrows heavily from the best legally available manufacturing methods, including those used by Seiko and Honda.

On the Bandit line, robots dominate. The robots receive production orders by computer and then perform all the assembling, adjusting, and checking. They perform all these functions within one-hundredth of the time and with half the defect rate of conventional manufacturing methods. The Bandit robots are aided by about a dozen human employees who monitor the system and load it with sufficient parts to operate for an 8-hour stretch.

The Bandit line is geared to producing one type of pagers, the “Bravo,” which is marketed under several different brand names. Because the pagers work by a unique combination of access codes and ratio frequencies, the Bandit line is able to produce pagers in an astronomical 29 million variations.

It took Motorola 18 months to design and install the Bandit system. In the process, the design team also redesigned the insides of the Bravo pager to make it easier to assemble by robot. The entire Motorola Corporation has a goal of reducing defects and errors in every aspect of its business to three mistakes per million operations within that same time frame. Programs such as Operation Bandit have been crucial to that effort.

Text 16

I. Listen to a native speaker and try to memorize the pronunciation of the words. Try to imitate the pronunciation.

capacity |

[kə´pæsəti] |

объем; способность; мощ- |

|

[kən´və:ʃn] |

ность; производительность |

conversion |

переход на новую систему; |

|

|

|

преобразование; превращение |

monetary stake |

[´mʌnitəri ´steik] |

денежная доля |

commitment |

[kə´mitmənt] |

обязательство |

81

fluctuation |

[ˏflʌktju´eiʃn] |

колебание, неустойчивость |

in the short run |

[in ðə´ʃɔ:t ´rʌn] |

в течение короткого отрезка |

|

[´ɔ:gmənt] |

времени |

augment |

увеличивать, прибавлять |

|

shift |

[ʃift] |

смена, рабочий день; сдвиг; |

|

|

перемещение |

II. In what process are operating systems included? Look at the scheme. Can you describe the constituents? Scan the text. What basic issues are described there?

II. In what process are operating systems included? Look at the scheme. Can you describe the constituents? Scan the text. What basic issues are described there?

OPERATING SYSTEMS

Products and services

-Product line

-Quality

-Cost

- Design |

Key |

|

design |

|

issues |

Facilities

-Location

-Layout

Capacity

-Demand

-Variation

-Flexibility

Technology

-Traditional methods

-FMS (flexible manufacturing systems)

-CAD/CAM (computeraided design/ computeraided manufacturing)

The problems faced by operations managers generally revolve around the acquisition and utilization of resources for conversion. Their goals include both efficiency and effectiveness. In any organization, a number of issues and decisions must be addressed as operations systems are designed. Periodic adjustments and changes are also necessary as circumstances and strategies change. There are four basic issues in designing operating systems.

A natural starting point in designing operations systems is determining the mix and kinds of products and services to be offered. This decision flows from corporate, business, and marketing strategies. Managers have to make a number of decisions about their products and services, starting with how many and what kinds to offer. Procter & Gamble, for example, makes regular control, and gel formulas of Crest toothpaste and packages them in several different sizes of tubes and pumps. Decisions also have to be made regarding the level of quality desired, the optimal cost of each product or service, and exactly how each is to be designed. General Electric, for example, reduced the number of parts in its industrial circuit breakers from 28,000 to 1,275. A key element of this

82