- •T. J. Djankova, a. A. Burinskaja, s. A. Zakharenkov technology of finishing textile materials

- •1. Principal views of textile fibers

- •2. Preparation of cellulose materials for dyeing and printing

- •2.1. Bleaching of cotton textiles

- •2.2. Mercerization

- •3. Application of optical bleaches

- •3.1. Optical bleaching substances

- •3.2. Test on presence of an optical bleach

- •4. Dyeing

- •4.1. Technical classification of dyes

- •4.3. Mordant dyes

- •4.4. Acid metalline dyes

- •The abovementioned recipe and procedure of dyeing are standart and can be changed and specified according to type of the equipment and also kind of coloring material.

- •4.5. Direct dyes Direct dyes may be used for dyeing cotton and other cellulose fibers. Direct dyes simple in application, are suitable for dyeing on any equipment, well combined with each other.

- •4.6. Reactive dyes

- •4.6.1. Cellulose dyeing. Batch methods of dyeing

- •Table 4.1. Dyes Bath Composition and Dyeing Conditions

- •4.6.2. Continuous dyeing

- •4.7. Cationic dyes

- •Dyeing by fast-fixing dyes

- •Dyeing of newly-formed braid

- •4.8. Disperse dyes

- •4.9. Vat dyes

- •Indigo-molecular structure Vat Yellow-molecular structure

- •Dye. . . . . . . . . . . . . . . . . . . . . .3 % from weight of a fiber

- •4.10. Sulfur dyes

- •4.11. Azo dyes synthesized in the fiber

- •5. Printing

- •5.1. Reactive dyes printing

- •5.2. Pigments printing

- •5.3. Thermoprinting of fibrous materials

- •6. Final finishing

- •6.1. Giving to fabrics of properties of water pushing away

- •6. 2. Giving to textile cloths of oil- hidrofobization

- •6.3. Giving to fabrics of fireproof properties

- •6.4. Giving to fabrics of anti-shrinkage chemical properties, form-stable finishing

- •Application Rules

- •7. Dyeing from Emulsions

- •7.1 Auxiliaries solvents

- •7.2 Emulsifiers

- •7.3 Dyeing with water-soluble dyestuffs.

- •7.4. Basic dyeable synthetic fibers

- •7.5. Physic-chemical fundamentals of emulsion technique

- •Influence of the temperature on the stability of an emulsion

- •Influence of additives on the stability of an emulsion

- •The optical properties of a water/perchloroethylene emulsion

- •Vapour pressure of a water/perchloroethylene emulsion

- •7.6 Equipment for dyeing from organic solvents

- •8. Equipment for dyeing and finishing factories.

- •8.1. Machine for washing, bleaching and dyeing “colorado”

- •8.2. Мachine «petra» f. Biancalani For obtaining effects of “worked surface”

- •8.3. High temperature machine mcs comby jigger

- •8.4. Hydraulic drying cylinder machines “jigger jht” by exclusivas tepp s.A. (Spain)

- •8.5. Vertical high-temperature high-pressure yarn dyeing plant

- •8.6. Flow line for combined bleaching and dyeing of fabrics лкб-140

- •Specification

- •8.7. Rapidstretch

- •8.8. Technodye rapid system Main features.

- •8.9. Superflux ne

- •Finally

- •8.7. Rapidstretch 84

4.3. Mordant dyes

For preparation of outer-clothes from wool should be used dyes, giving deep colors and coloration with high fastness to light and wet treatment. Mordant dyes (offered on p.) are met the above requirements.

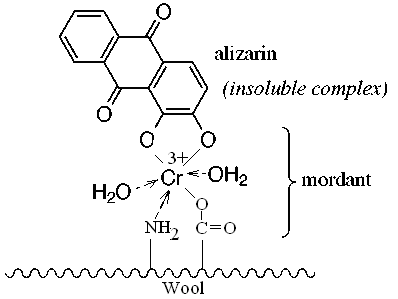

Certain acid dyes form chelated complexes with heavy metals such as copper, chromium, tin, iron, and aluminum. Wool, silk, polyamide fiber can coordinate with these metals. To dye a fabric with a mordant dye, the fabric is treated with a mordant and the salt of a heavy metal. The treated fabric with complexes dye-mordant-fiber, and is thus linked to the fabric. Different metals (mordants) can lead to different colors with the same dye. Alizarin (an anthraquinone dye) is a typical mordant dye, shown in a chelated complex with woll (silk, polyamide) using chromium as the mordant.

Dyeing wool by mordant dyes mainly is carried out by two methods: with simultaneous chromium-plating and with following chromium-plating.

1. Method of dyeing with following chromium-plating

Composition of dyeing bath, % of mass of material:

Dye . . . . . . . . . . . . . . . . . . . .X

Glauber salt. . . . . . . . . . . . 10

Acetic acid (30%). . . . . . . 3-5

Water. . . . . . . . . . . . . . . . . . . Y

Dyeing is started at 30-45°C during 30-45 min. Bath is heated up to boiling and continued dyeing under boiling for 30-45 min. Then under closed steam 1-2% of sulfuric acid (density = 1,84) is added and dye under boiling for additional 20 min. Before to add potassing bichromate (0,5-1,5%) temperature of bath is cooled till 80°C, then bath is heated up to boiling and coat with chromium for 30 min.

2. Method of dyeing with simultaneous chromium-plating

From the offered range of mordant dyes - Mordant green 2-dye wool from weakly acid bath with simultaneous chromium-plating.

Composition of bath, % of mass of material:

Dye . . . . . . . . . . . . . . . . . . . .X

Glauber salt . . . . . . . . . . . . 1,0

Ammonium sulfate . . . . . . .5,0

Potassium bichromate. . . .0,75

Water. . . . . . . . . . . . . . . . . . .Y

Dyeing is started at 30-40°C during 30-45 min.; after temperature is increased up to boiling and continued, dyeing under boiling 45 min.

Recommended recipes and conditions are standard and changed according to type of equipment and character of dyeing material.

4.4. Acid metalline dyes

Chemical Industry offering a Acid and Acid metalline dyes of complex (AMD) 1:1 and 1:2. Acid metalline dyes of complex 1:2 may be used for dyeing polyamide fibers.

AMD of complex 1:2 with one and two sulphodroupes (Delan and Desher respectively), range and color fastness to different physico-chemical influences are shown in table 4.3.

Acid metalline dyes are recommended for dyeing wool at all stages of it treatment, dyeing and printing polyamide fiber and natural silk.

Advantages: brightness and saturation of received colors; high solubility in water; do not damage albuminous fibers during the procedure of dyeing; high color fastness to light and wet treatments; absence of Cromium (Cr)+3 in sewage; simplicity in use. In addition offered dyes well dissemble a structural heterogeneousness of polyamide thread.

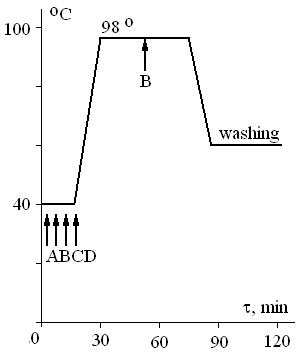

Fig. 4.2. Procedure of dyeing M 1:20

A- Leveling, B- Ammonium sulfate, C- 1/2 of Acetic acid D- Solution of dye.

Dyeing of polyamide fibers

Composition of dyeing bath, %:

Dye. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .X

Leveling (Amsolin F, Kilan, Eline РАМ) . . . 1,0-2,0

Ammonium sulfate. . . . . . . . . . . . . . . . . . . . . . . . 4,0

Acetic acid (30%). . . . . . . . . . . . . . . . . . . . . . 1,0-2,0

Water. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Y

Fixing of color

To reach high color fastness it is recommended Precorezerv NPA or Niofix PA at PH=3,5-4,0 and temperature 70°C for 20 min.