- •T. J. Djankova, a. A. Burinskaja, s. A. Zakharenkov technology of finishing textile materials

- •1. Principal views of textile fibers

- •2. Preparation of cellulose materials for dyeing and printing

- •2.1. Bleaching of cotton textiles

- •2.2. Mercerization

- •3. Application of optical bleaches

- •3.1. Optical bleaching substances

- •3.2. Test on presence of an optical bleach

- •4. Dyeing

- •4.1. Technical classification of dyes

- •4.3. Mordant dyes

- •4.4. Acid metalline dyes

- •The abovementioned recipe and procedure of dyeing are standart and can be changed and specified according to type of the equipment and also kind of coloring material.

- •4.5. Direct dyes Direct dyes may be used for dyeing cotton and other cellulose fibers. Direct dyes simple in application, are suitable for dyeing on any equipment, well combined with each other.

- •4.6. Reactive dyes

- •4.6.1. Cellulose dyeing. Batch methods of dyeing

- •Table 4.1. Dyes Bath Composition and Dyeing Conditions

- •4.6.2. Continuous dyeing

- •4.7. Cationic dyes

- •Dyeing by fast-fixing dyes

- •Dyeing of newly-formed braid

- •4.8. Disperse dyes

- •4.9. Vat dyes

- •Indigo-molecular structure Vat Yellow-molecular structure

- •Dye. . . . . . . . . . . . . . . . . . . . . .3 % from weight of a fiber

- •4.10. Sulfur dyes

- •4.11. Azo dyes synthesized in the fiber

- •5. Printing

- •5.1. Reactive dyes printing

- •5.2. Pigments printing

- •5.3. Thermoprinting of fibrous materials

- •6. Final finishing

- •6.1. Giving to fabrics of properties of water pushing away

- •6. 2. Giving to textile cloths of oil- hidrofobization

- •6.3. Giving to fabrics of fireproof properties

- •6.4. Giving to fabrics of anti-shrinkage chemical properties, form-stable finishing

- •Application Rules

- •7. Dyeing from Emulsions

- •7.1 Auxiliaries solvents

- •7.2 Emulsifiers

- •7.3 Dyeing with water-soluble dyestuffs.

- •7.4. Basic dyeable synthetic fibers

- •7.5. Physic-chemical fundamentals of emulsion technique

- •Influence of the temperature on the stability of an emulsion

- •Influence of additives on the stability of an emulsion

- •The optical properties of a water/perchloroethylene emulsion

- •Vapour pressure of a water/perchloroethylene emulsion

- •7.6 Equipment for dyeing from organic solvents

- •8. Equipment for dyeing and finishing factories.

- •8.1. Machine for washing, bleaching and dyeing “colorado”

- •8.2. Мachine «petra» f. Biancalani For obtaining effects of “worked surface”

- •8.3. High temperature machine mcs comby jigger

- •8.4. Hydraulic drying cylinder machines “jigger jht” by exclusivas tepp s.A. (Spain)

- •8.5. Vertical high-temperature high-pressure yarn dyeing plant

- •8.6. Flow line for combined bleaching and dyeing of fabrics лкб-140

- •Specification

- •8.7. Rapidstretch

- •8.8. Technodye rapid system Main features.

- •8.9. Superflux ne

- •Finally

- •8.7. Rapidstretch 84

8.8. Technodye rapid system Main features.

Storage chambers with capacities of 150 or 225 Kg., provided with a teflon liner. Single size fabric booster, which can be easily removed for cleaning. Large diameter cylindrical inner transport reel, Techno type, specially designed to avoid stretching and scuff marks. Intelligent Regulation 3 (Patented), a system that constantly synchronizes the speed of the reel with the real fabric speed, avoiding friction.

Techno type circulation pump, with electronic regulation, offers a wide range of fabric speeds from 100 up to 600 m/minute. Fabric plaiting system across the width of the chamber insures perfect fabric distribution. Ultra low liquor ratio 1:3 for synthetics up to 1:4 for cellulosic fibers. Automatic machine cleaning with spray heads, programmable from the Microlor control system.

Microlor control system for the total control of all functions, including an automated dye kitchen.

Filling and washing functions programmable in liters, allows an accurate control of the water used.

Fully programmable Modatyc exponential dosing system for the addition of chemicals and dyes (Hoechst license). Automatic and programmable salt dissolution system.

The new RAPID SYSTEM in TECHNODYE dyeing machines increases their productivity between 20% and 40% according to the different dyeing processes.

The RAPID SYSTEM consists of a closed and pressurized vessel with the same capacity to that of the dyeing machine, allowing preparing all necessary products and dyes during the process. The transfer of prepared baths is effected by using the main circulation pump aided with compressed air, on the other hand rapid fill and drain functions are effected by the main pump.

The Technodye dyeing machine is also fitted with a rapid wash system which reduces the final process time substantially.

Fig. 8.18. Main view of machine

Fig. 8.19. TECHNODYE RAPID SYSTEM (Diagram)

1. Machine body; 2. Upper access door; 3. Loading and unloading port; 4. Inner transport reel; 5. 100 mm. diameter booster; 6. Cloth transport tube; 7. Teflon liner; 8. TECHNO type pump; 9. Heat exchanger; 10. Filter; 11. Machine washing valve; 12. Machine fill valve; 13. Machine drain valve; 14. Regulation valve; 15. Machine washing sprays; 16. Preparation tank; 17. Preparation tank filling; 18. Pressure regulator; 19. Preparation tank heat exchanger; 20. Stirring pump; 21. Preparation tank transfer to dyeing machine by circulation pump; 22. Preparation tank draining; 23. Rapid drain by pump.

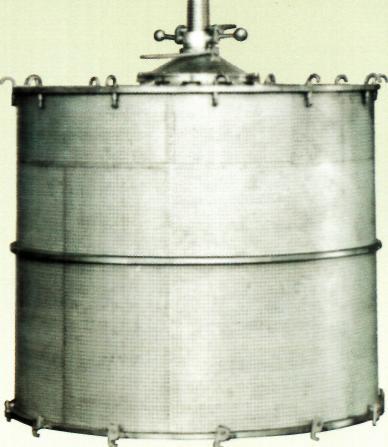

8.9. Superflux ne

Superflux NE is an universal package dyeing machine, entirely built in stainless steel AISI -316, suitable for high temperature operation, maximum 140° C, and specially designed for working at short liquor ratio 1:4 with the additional advantage of being able to operate also at conventional liquor ratio 1:8.

Its high efficiency centrifugal pump with an output of 45 liters/ kilogram/ minute allows a substantial reduction in certain processing times.

The frequency invertor controlled motor of the circulation pump allows, through the Microlor 737XL, the precise programming of the dyebath flow characteristics suitable for each type of fiber.

Static pressure is obtained by means of an air pad.

High productivity coupled with remarkable savings in water, steam, electricity, chemicals, dyestuff, etc., consequence of the ability to successfully operate at short liquor ratios make the Superfiux"NE" a highly profitable investment.

Fig. 8.20. Scheme of apparatus

1 - Low liquor ratio 1:4/1:5; 2 - high liquor ratio 1:8 /1:10; 3 - air pad; 4 - automatic level; 5 - centrifugal pump with frequency converter; 6 - pneumatic actuator; 7 - Additions tank; 8 - introduction pump; 9 - heat exchanger.

Kinds of packages for several textile materials:

Conical

and cylindrical packages

Conical

and cylindrical packages

Compressible

conical and cylindrical packages

Compressible

conical and cylindrical packages

Textured

yarn

Textured

yarn

For

hanks

For

hanks

For

the fiber in the mass

For

the fiber in the mass