- •T. J. Djankova, a. A. Burinskaja, s. A. Zakharenkov technology of finishing textile materials

- •1. Principal views of textile fibers

- •2. Preparation of cellulose materials for dyeing and printing

- •2.1. Bleaching of cotton textiles

- •2.2. Mercerization

- •3. Application of optical bleaches

- •3.1. Optical bleaching substances

- •3.2. Test on presence of an optical bleach

- •4. Dyeing

- •4.1. Technical classification of dyes

- •4.3. Mordant dyes

- •4.4. Acid metalline dyes

- •The abovementioned recipe and procedure of dyeing are standart and can be changed and specified according to type of the equipment and also kind of coloring material.

- •4.5. Direct dyes Direct dyes may be used for dyeing cotton and other cellulose fibers. Direct dyes simple in application, are suitable for dyeing on any equipment, well combined with each other.

- •4.6. Reactive dyes

- •4.6.1. Cellulose dyeing. Batch methods of dyeing

- •Table 4.1. Dyes Bath Composition and Dyeing Conditions

- •4.6.2. Continuous dyeing

- •4.7. Cationic dyes

- •Dyeing by fast-fixing dyes

- •Dyeing of newly-formed braid

- •4.8. Disperse dyes

- •4.9. Vat dyes

- •Indigo-molecular structure Vat Yellow-molecular structure

- •Dye. . . . . . . . . . . . . . . . . . . . . .3 % from weight of a fiber

- •4.10. Sulfur dyes

- •4.11. Azo dyes synthesized in the fiber

- •5. Printing

- •5.1. Reactive dyes printing

- •5.2. Pigments printing

- •5.3. Thermoprinting of fibrous materials

- •6. Final finishing

- •6.1. Giving to fabrics of properties of water pushing away

- •6. 2. Giving to textile cloths of oil- hidrofobization

- •6.3. Giving to fabrics of fireproof properties

- •6.4. Giving to fabrics of anti-shrinkage chemical properties, form-stable finishing

- •Application Rules

- •7. Dyeing from Emulsions

- •7.1 Auxiliaries solvents

- •7.2 Emulsifiers

- •7.3 Dyeing with water-soluble dyestuffs.

- •7.4. Basic dyeable synthetic fibers

- •7.5. Physic-chemical fundamentals of emulsion technique

- •Influence of the temperature on the stability of an emulsion

- •Influence of additives on the stability of an emulsion

- •The optical properties of a water/perchloroethylene emulsion

- •Vapour pressure of a water/perchloroethylene emulsion

- •7.6 Equipment for dyeing from organic solvents

- •8. Equipment for dyeing and finishing factories.

- •8.1. Machine for washing, bleaching and dyeing “colorado”

- •8.2. Мachine «petra» f. Biancalani For obtaining effects of “worked surface”

- •8.3. High temperature machine mcs comby jigger

- •8.4. Hydraulic drying cylinder machines “jigger jht” by exclusivas tepp s.A. (Spain)

- •8.5. Vertical high-temperature high-pressure yarn dyeing plant

- •8.6. Flow line for combined bleaching and dyeing of fabrics лкб-140

- •Specification

- •8.7. Rapidstretch

- •8.8. Technodye rapid system Main features.

- •8.9. Superflux ne

- •Finally

- •8.7. Rapidstretch 84

6. 2. Giving to textile cloths of oil- hidrofobization

Repellane KFC is a fluorineacrilic derivative, is used from water solutions for giving of effects ole- to fibrous materials of various structure (cellulose, polyester, polyamide, woolen and mixed).

Application for polyester and polyamide fabrics:

Repellane KFC - 30-50 г/л

Processing mode: impregnation, отжим - 40 %, drying and thermal processing - 30 with at temperature 170-180 °С.

For giving of repellent effect steady a dirt (for cotton cloths) it is recommended to use Repellane in quantity to 4 % from weight of a material. Conducting: impregnation, dehydration - 70 %, drying and thermal processing at temperature 150 °С - 4 min.

6.3. Giving to fabrics of fireproof properties

Reception of fireproof and nonflammable fabrics from natural and chemical fibers, and also application of various ways of giving of fire resistance to ready fabrics of household and technical appointment is of great importance.

The materials steady against action of heats concern fire-resistant (fireproof) materials and capable to provide full or partial protection against fire. The scope of such fabrics is very wide. It is overalls a fire ных, steelmakers, founders, decorative materials for salons of courts, cars, planes and fire-prevention covers.

Pirofix used to communicate fire-proof properties and stability against multiple washings to the cellulose-containing textile materials.

Composition A preparation based on phosphorus-containing pre-baker of the thermoreactive resin. Low-dangerous substance. Mass fraction of phosphorus: 11-13 %; mass fraction of free formaldehyde: not more than1%.

Application Rules

To communicate the fire-proof properties it is recommended to add the following chemicals into the impregnation solution (g/1):

- pirofix 350-400;

- metazin 6U 60- 80

6.4. Giving to fabrics of anti-shrinkage chemical properties, form-stable finishing

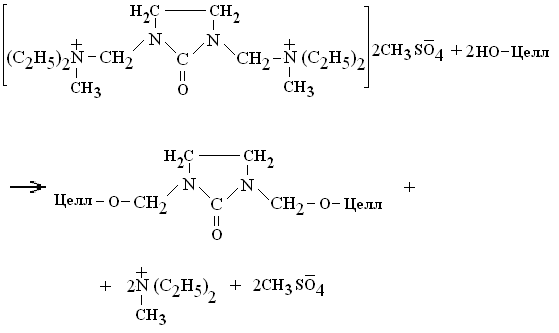

Process of form-stable finishing are accompanied by following reactions (on an example of preparation based on dimethylene urea Карбамол МТ-2):

![]()

Carbamol МТ-2 - low-dangerous preparation based on dimethylene urea for the final of cellulose-containing textile fabrics with low formaldehyde content. Mass fraction of the basic substance 65 ± 3%; Mass fraction of free formaldehyde: not more than - 0,15 %.

Recommended concentrations (g/1) for the following finish processes:

- with weakly washing-off finishing agent based on thermoreactive resins (WWTR, WW) 40 - 60;

- anti-shrinkage chemical finish (ASCF) 0-120;

- schreiner-silky finish (SSF) 120 - 150;

- stable calendaring effects ( embossing, glossing) 40 - 140.

Metazin 6U - Stabilized mixture of methylol melamine Derivatives for high-quality finish of the fabrics made of cotton and artificial fibers, binder for pigment printing; for the backing of non-woven materials, carpets and floor covering. Mass fraction of the basic substance: 68-70 %; mass fraction of free formaldehyde: not more than 0,75 %. Metazin 6U - moderately dangerous substance.

Application rules

Recommended concentrations (g/1) for the following finish processes:

- with weakly washing-off finishing agent based on thermoreactive resins(WWTR, WW) 50-70;

- anti-shrinkage chemical finish (ASCF) 30-100;

- stable calendaring effects ( embossing, glossing) 80-150;

- form-stable finish of curtain-lace and knitted fabrics 50-250. Recommended concentrations of the preparation in pigment printing 100-150 g/kg.

Recommended concentrations for the backing of non-woven materials, carpets and floor covering materials 10-20 % mass.

Glikazin - mixture of methylol melamine derivatives for the final finish of cellulose-containing fabrics, binder for pigment printing, a preparation for the backing of non-woven materials, carpets and floor covering materials. Mass fraction of free formaldehyde: not more than - 0,9 %; mass fraction of the basic: substance 40 %.

Recommended concentrations (g/1) for the following finish processes:

- with weakly washing-off finishing agent based on thermoreactive resins (WWTR, WW) 50 - 70;

- anti-shrinkage finish (ASCF) 30 -100;

- stable calendaring effects (embossing, glossing) 80 -150;

- form-stable finish of curtain-lace and knitted fabrics 50 - 250. Recommended concentrations of the preparation in pigment printing 100-150 g/kg.

Recommended concentrations for the backing of non-woven materials, carpets and floor covering materials 10-20 % mass.

Carbamol GL - low-dangerous preparation based on methylolated derivative of hydroxyehtylene urea for the final finishing of cellulose-containing textile materials. Mass fraction of free formaldehyde: not more than1 %; mass fraction of the basic substance: 45 ±2 %.