Lecture Part II

.pdfLecture 2

The Art of Print

A print is an image obtained from any printing element. Originally, this was either a metal plate, engraved in intaglio, or a wood block (or metal plate) cut in relief. From the beginning of the XIXth century, lithographic stones were included. Contemporary fine art printmaking is concerned with the production of images by varying methods of replication onto paper, parchment, fabric or other supports.

Prints are multiple originals. The development of printmaking was connected to the development of movable type and the printing press in the XVth century, although woodblock printing had been done on textiles since ancient times.

Prints in color require two or more blocks, plates, screens or stones, one for each color, printed sequentially on top of each other to produce the final work of art. This process is called registration.

Prints can be classified according to the type of surface used to make them. Those with raised printing surfaces are known as relief prints; woodcuts are the most common type of relief print. When the printing surface is below the surface of the plate, the print technique is classified as intaglio. Planographic and stencil methods are also used, and print from a surface that is at the same level as the nonprinting surface.

Prints are made from a single original plate or surface, called a 'matrix'. There are several different types of matrix, including: plates of metal, typically copper or zinc which are used for engravings or etchings; stone, which is used to make lithographs; wood blocks, employed for woodcuts; linoleum, used for linocuts; fabric plates, used in screen-printing, and others. Conventional fine prints are usually produced in limited edition sets, each print being numbered and signed by the artist.

History

Following its invention by Chinese art many centuries previously, fine art printmaking became established during the German Renaissance (1430-1580), during the early period of the Northern Renaissance. Its leading exponents were the Old Masters Albrecht Durer (1471-1528), Martin Schongauer (1448-91), Rembrandt (160669) and Goya (1746-1828). Technical and artistic developments which paved the way for new types of fine print, included the following.

The invention of the screw printing press in 1450, by the German Johann Gutenberg, along with an oil-based ink, metal prism matrices, punch-stamped typeface molds and a functional metal alloy to mold the type. Astonishingly, only minor improvements were made to Gutenberg's press design until about 1800.

1799, the invention of lithography (using a matrix of fine-grained limestone) by the Austrian printer Alois Senefelder.

1803, the invention of machine made paper (made from linen and cotton rags) by the Frenchman Nicholas Louis Robert.

1800s, the replacement of Gutenberg's wooden screw press with an iron framed lever press, by Lord Stanhope, and the appearance of Frederich Koenig's steam printing machine.

1840, the invention of the revolving perfecting press by American Richard March Hoe, (followed in 1846 by the first rotary press) and the manufacture of paper from wood pulp.

1859, the invention of photo-lithography by the French lithographer, Firmin Gillot, followed in 1872 by his son's invention of zincography, combining photography with etching.

Relief Printing

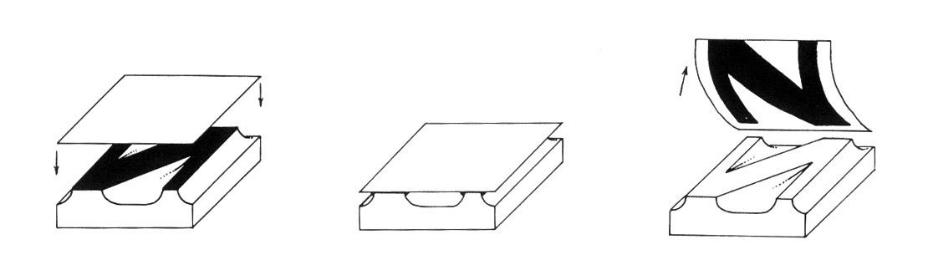

A printing process in which the impression is created by the uncarved areas or the unprepared surface of the PRINTING ELEMENT, which has been inked with a ROLLER, BRAYER, or other tool. WOODCUT and LINOCUT are usually used for relief printing. In all relief techniques it is the surface of the block that is inked and printed and, given perfect printing, all lines or surfaces will be equally dark. Woodcuts are made by cutting into the broad face of a plank of wood, usually with a knife (the linocut is made the same way, except that linoleum is substituted for wood). In working the block, the artist cuts away areas not meant to print. These cut away areas appear in the finished print as the white parts of the design while the ink adheres to the raised parts.

Wood engravings are made by engraving a block of endgrain, extremely hard wood (usually boxwood). The block, being naturally much harder, enables the artist to engrave (rather than cut) a much finer line than is possible on the softer plank surface used for woodcut.

ANTHONISZ, Cornelis Henry VIII of England on Horseback, c. 1538 Hand-coloured woodcut, 403 x 295 mm Rijksmuseum, Amsterdam

Chiaroscuro Woodcut - The design is divided among several blocks, each to print a different color, with or without overlaps. Those areas cut away in all blocks will not print at all and thus provide highlights of the natural color of the paper used, the light of the "light-dark" technique. The blocks must be carefully matched in placement of the design (registration) and the paper must pass through as many printings as there are blocks.

BURGKMAIR, Hans Portrait of Jacob Fugger,1510-12 Chiaroscuro woodcut using two blocks, 210 x 145 mm

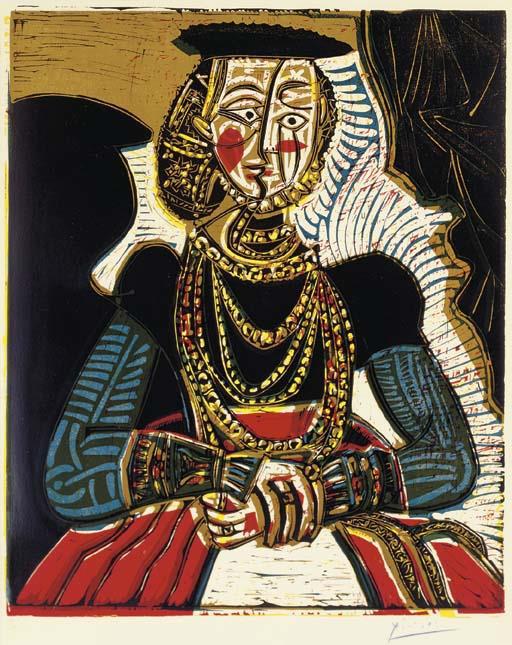

Linocut or linoleum cut - the technique is a derivation of the woodcut but owing to the supple, relatively soft properties of the material, linocuts have different characteristics. The material takes all types of lines, but is most suited to large designs with contrasting dark and light flat tints. The material is cut with small pen-like tools which have a mushroomshaped handle. As on a woodcut, the relief parts of the block are inked. Color printing is done with several linoleum blocks.

Pablo Picasso Buste de Femme d'apres Cranach le Jeune, 1958.

Linocut in colors, signed in blue crayon, numbered 38/50; 648 x 533 mm.

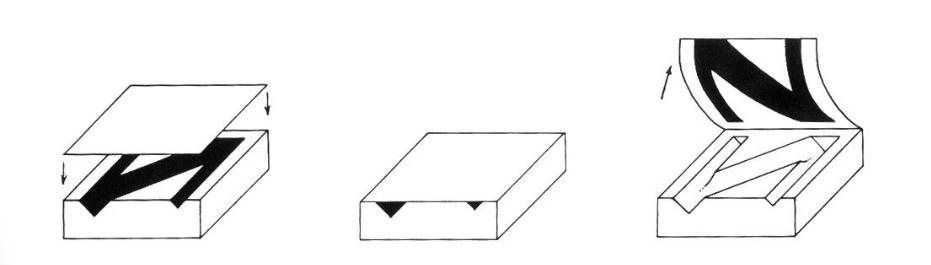

Intaglio Printing

A printing process in which the image is incised or etched into a metal plate using a variety of techniques and tools.

Intaglio printing involves the use of a metal plate. In printing, the ink settles in the sunken areas and the smooth surface of the plate is wiped clean. The plate, in contact with damp paper, is passed through a roller press under pressure. The paper is forced into the sunken areas to receive the ink.