Environmental Biotechnology - Theory and Application - G. M. Evans & J. C. Furlong

.pdf

134 Environmental Biotechnology

the total active biomass content in an activated sludge system, which is termed the mixed liquor suspended solids (MLSS), is an important factor in process efficacy. Accordingly, it is routinely measured at sewage works being important in the calculation of the F/M ratio, which can be more properly defined as:

flow rate(m3/d) × BOD(kg/m3)

F/M =

volume of sludge tank(m3) × MLSS(kg/m3)

Although the preceding systems are the most common forms likely to be seen in use, a number of other systems exist which may sometimes be encountered, some of which will be briefly outlined for the sake of completeness.

Deep Shaft Process

In many respects this is an activated sludge derivative, which was borne out of ICI’s work on the production of proteins from methanol in the 1970s. Figure 6.5 shows the main features of the system, which is based around a shaft 50 – 100 metres deep.

Figure 6.5 ICI deep shaft process

Aerobes and Effluents 135

The shaft contains the wastewater to be treated, compressed air being blown in at the base, which travels up the central section, setting up an opposing counter flow in the outer part of the shaft. Screened secondary effluent is allowed to settle and a portion of the sludge produced is returned to the input zone, just as in a traditional activated sludge tank, though degassing is required to remove nitrogen and carbon dioxide bubbles from the floc to allow for proper sedimentation.

The high pressures at the base force far more oxygen into solution than normal, which aids aeration enormously and allows the process to achieve an oxygen utilisation of around 90%, which is some 4.5 times better than conventional activated sludge systems. The bubble contact time produced, averaging 90 seconds or more, is over 6 times longer than in standard diffused air systems. It has a low footprint, making it ideal for use in restricted areas.

Pure Oxygen Systems

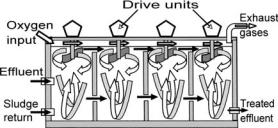

With process efficacy so closely dependent on aeration and the ability to support a high microbial biomass, the use of pure oxygen to enhance the effective levels of the gas dissolved in the effluent has an obvious appeal. The UNOX process, which was developed by the Union Carbide Corporation is probably amongst the best known of the pure oxygen activated sludge systems and Figure 6.6 shows the general layout of the bioreactor vessels.

Pure oxygen obviously gives a better oxygen transfer rate per unit volume of the bioreactor than can be achieved using conventional aeration methods. In turn, this allows a heavier organic loading per unit volume to be treated compared with ordinary air-fed systems, which enables this system to be used to deal with stronger effluents and permits a high throughput where space is restricted. Typically these systems are fed using liquid oxygen tanks.

Despite their clear advantages, pure oxygen systems suffer with some major drawbacks. For one thing, the capital costs involved in installing them in the first place are considerable, as are their running costs and maintenance requirement. The pure oxygen itself represents an explosion risk, thus necessitating intrinsically

Figure 6.6 The UNOX pure oxygen system

136 Environmental Biotechnology

safe operational procedures and, in addition, leads to accelerated corrosion of the equipment used. However, for some applications and for certain kinds of effluents, they can prove particularly appropriate.

The Oxidation Ditch

This is a sometimes used for sewage treatment and is characterised by a constructed ellipsoidal ditch, in which the effluent is forced to circulate around the channel by brush aerators. The ditch itself is trapezoidal in cross-section to maintain uniform effluent velocity throughout the channel. Effluent is fed into the system without any prior primary sedimentation and typically gives rise to only 50% of the surplus sludge produced by a typical activated sludge process.

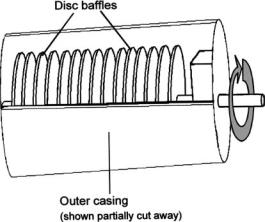

The Rotating Biological Contactor

This system, shown in Figure 6.7, is a derivative of the biological filter. It effectively combines the advantages of this previously described approach, like the absence of a complicated settlement system for sludge return and a low maintenance requirement with the smaller footprint and long microbial exposure characteristic of the active sludge process.

They have submerged internal disc baffles which act as sites for the attached growth of biomass, which are slowly turned by electric motor causing the microbes to be alternately aerated and immersed in the effluent. Rotating biological contactors are typically used for small installations, and are particularly useful for applications with high seasonal variations like caravan site sewage systems.

Figure 6.7 Rotating biological contactor

Aerobes and Effluents 137

Membrane Bioreactors

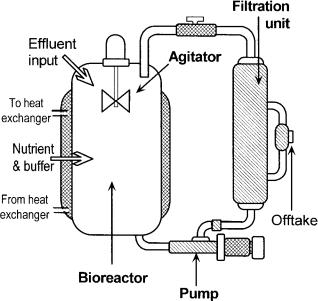

This system, instead of utilising conventional methods of gravity settlement, achieves the desired biomass retention by means of a cross-flow filtration process, as shown in Figure 6.8.

The development of effective methods of microand ultra-filtration has opened up the potential for using membrane bioreactor technology on various forms of domestic and industrial effluents. There are three general types of reactor systems which have been developed, namely solid/liquid separation, gas permeable and extractive systems. The membrane element allows the passage of small molecules, but retains the total resident microbial population. As a result, the cumulative overall bioactivity and the resultant speed of remediation is boosted, since not only are micro-organisms no longer lost with wash-out flow, but also, conditions for even the slowest-growing member species of the microbial community are able to be adequately enhanced. This is of particular relevance to xenobiotics and the more recalcitrant components of wastewaters, as their biological breakdown is often brought about by bacteria which themselves have a relatively long establishment period within the population. The high biomass levels within the bioreactor itself obviously necessitate abundant readily available oxygen, though the high organic loading and efficient intrasystem microbial conservation combine to make the hydraulic retention time entirely independent of the solids

Figure 6.8 Schematic membrane bioreactor

138 Environmental Biotechnology

themselves. Since the membrane allows gaseous transport while constraining the biological phase, there is provision within the reactor for bubbleless aeration and oxygenation consequently can take place over a relatively large surface area, thereby improving the efficiency of this process. In addition, the membrane itself may become an attachment zone for biofilm formation.

Thus, the membrane bioreactor can offer a greater degradation capacity for persistent chemicals, making possible the biological removal of benzene, nitrobenzene, dichloroaniline and polyaromatic hydrocarbons (PAHs), for example, which represent a significant risk, both to the environment and human health, due to their high toxicity. Removal efficiency for these substances can approach 99%.

The membrane bioreactor has proved its suitability as an efficient system for degradation of recalcitrant compounds and significantly higher biomass concentrations and utilisation rates are routinely achieved than in corresponding alternative treatment systems. In common with most operational, rather than experimental, biological detoxification processes, not all of the contaminants present in the effluent are typically completely converted into carbon dioxide and water, a certain percentage being turned into metabolic byproducts instead, though this can amount to less than 5% in a well-managed bioreactor system. Part of this involves the gradual and controlled introduction of novel wastewater elements, to ensure that acclimatisation is maximised and any potential tendency for ‘shock loadings’ avoided. This is a clear example of the value of permitting optimised microbial adaptation to the individual application.

These systems are, of course, more expensive than the conventional activated sludge or trickling filters, but produce a much smaller quantity of excess sludge for subsequent disposal of treatment. In addition, they produce an elevated COD removal and would seem particularly well suited to use in small-scale plants where the production of high-quality final effluent is a priority.

Cellulose Ion-Exchange Media

For effluents requiring a highly selective removal of high molecular weight proteins, cellulose ion-exchange media provide an example of treatment involving the use of isolated biologically derived materials. The ion exchange medium is replenished with brine as required, and the proteins collected are removed in the resulting saline solution, for subsequent coagulation and drying. This enables a valuable material to be recovered, typically for use as an animal foodstuff, while reducing the wastewater BOD by 90% or more.

Sludge Disposal

Many of the treatment processes described in this chapter give rise to primary or secondary sludges. Typically, these byproducts require disposal and, like many

Aerobes and Effluents 139

forms of solid waste, a proportion have been consigned to either landfill or incineration. For some treated sludges, especially those derived from domestic sewage or food residuals, agricultural use has been an option, often requiring additional treatments to ensure its freedom from human pathogens, before land spreading or injection beneath the surface. The effectiveness of microbes in metal sequestration means, inevitably, that most treated sludges have a degree of heavy metal contamination, which itself makes possible the accumulation of these contaminants in soils exposed to these products. In addition, there are increasingly stringent controls on the release of nitrogen to the environment, particularly within escalating European Union legislation regarding nitrogen vulnerable zones. It would seem, then, that the future land use of ‘spent’ sludges is likely to be somewhat more heavily regulated than previously.

Closing Remarks

In many respects, the treatment of effluents by biological means is of particular importance to any consideration of environmental biotechnology, since it represents the central point of the previously mentioned intervention triangle, having simultaneous relevance to manufacturing, waste management and pollution control. The majority of manufacturing companies produce wastewaters that contain organic contaminants of one form or another and the traditional route previously in common use: discharge to sewer, watercourse or the sea, is becoming less attractive due to environmental legislation and rising disposal costs. As a result, for an increasing number of companies there is a growing requirement to treat their own effluents and biotechnological processes can often prove the most cost-effective means to achieve this goal.

References

European Commission’s Directorate General for Environment, (2001) Survey of Wastes Spread on Land – Final Report, Office for Official Publications of the European Communities, Luxembourg: (a) p. 2; (b) p. 55.

Hardman, D., McEldowney, S. and Waite, S. (1994) Pollution: Ecology and Bioreatment, Longman, Essex: pp. 81 – 2.

Case Study 6.1 Mollusc Biofilters (Rhode Island, USA)

Maintaining or improving the quality of coastal water, particularly around areas of high tourist or amenity value is an increasing concern in many parts of the world. While restricting polluting discharges at their source remains the ideal solution to the problem, various biological interventions have been suggested to deal with the problem directly and the potential of some of these may be developed in future years.

Continued on page 140

140 Environmental Biotechnology

Continued from page 139

One particularly interesting example, put forward by the University of Rhode Island, involves utilising the intrinsic abilities of bivalve molluscs such as clams, mussels and oysters, to act as natural biofilters of estuarine waters. These species derive most of their nutritional requirements by sifting the water, actively discriminating between particles, ingesting food while depositing rejects onto the substrate. There is also evidence to suggest that microbial and chemical processes in the sediment convert a number of substances present in this matter to less biologically active forms.

Increasing the local population of suitable shellfish, possibly in artificial aquaculture units, could contribute to a significant reduction in turbidity and improved removal of nitrogen and other nutrients. One of the main advantages of this approach would be that the waters are continually cleaned and at little or no cost. In addition, the system might also be harnessed to offer a boost to the local economy, providing a crop to be harvested or potentially supporting larger commercial ventures.

Even for areas where it would be inappropriate to establish intensive shell fisheries of this kind, initiatives to restore and conserve indigenous mollusc species could prove a cost-effective complement to conservation projects or coastal management strategies, especially those designed to mitigate the impacts of eutrophication.

Case Study 6.2 Flexible Sewage Treatment (Takoradi, Ghana)

Often one of the key features of biological effluent treatment is its simplicity. As the Takoradi raw sewage treatment plants in Ghana show, for many parts of the world, when resources or skilled labour are in short supply, this can be a major advantage.

The work, which involved dealing with the effluent from military barracks, was carried out by Naston of Weybridge, England. Both of the systems supplied were designed on the basis of a population equivalent of 5000, with a daily throughput of up to 1 million litres. Each site was equipped with twin aeration tanks 19 metres in diameter, containing integral settlement chambers, aeration and excess sludge removal systems, together with associated 6 metre diameter sludge-holding tanks. The use of two treatment cells, rather than a single, large one, enables the plant to be operated for maximum efficiency, allowing one of them to be shut down if the population falls below half its design capacity for extended periods.

Since both facilities are in remote areas and were built under supervision by unskilled labour, the design deliberately minimised the civil engineering requirement. Other aspects of the plants were, likewise, kept simple to ensure that the system is easy to operate, involving no daily maintenance and little more than a routine periodic servicing to the pumps and aerators.

Thus the wastewater collects at the pumping facilities and is transferred directly to the aeration tanks, where it is processed by the rich complement of microorganisms growing in the well-oxygenated environment. After the aeration phase, the mixed liquor of treated sewage and active microbes is transferred at a constant rate to the clarifiers, which helps to achieve a good separation and the resulting

Continued on page 141

Aerobes and Effluents 141

Continued from page 140

offtake is typically of high quality. The excess biomass arising is dewatered and tankered off site, while the supernatant liquor is returned as an inoculant to the aeration tank.

It is a particularly simple system in principle and clearly illustrates that practical ‘biotech’ solutions do not have to be technologically complex or highly engineered. However, operational success is only possible given a thorough appreciation of the biological processes involved and the constraints imposed by particular local circumstances.

7

Phytotechnology

and Photosynthesis

From a practical standpoint, phytotechnology is the use of plants in environmental biotechnology applications, and draws on many of the characteristics which have already been described. In this respect, it does not represent a single unified technology, or even application, but rather is a wider topic, defined solely by the effector organisms used. Thus the fundamental scope of this chapter is broader and the uses and mechanisms described somewhat more varied than for many of the preceding biotechnologies discussed.

Plants of one kind or another can be instrumental in the biological treatment of a large number of substances which present many different types of environmental challenges. Accordingly, they may be used to remediate industrial pollution, treat effluents and wastewaters or solve problems of poor drainage or noise nuisance. The processes of bioaccumulation, phytoextraction, phytostabilisation and rhizofiltration are collectively often referred to as phytoremediation. Although it is sometimes useful to consider them separately, in most functional respects, they are all aspects of the same fundamental plant processes and hence there is much merit in viewing them as parts of a cohesive whole, rather than as distinctly different technologies. It is important to be aware of this, particularly when reading a variety of other published accounts, as the inevitable similarities between descriptions can sometimes lead to confusion. Moreover, the role of phytotechnology is not limited solely to phytoremediation and this discussion, as explained above, is more deliberately inclusive of wider plant-based activities and uses.

Despite the broad spectrum of potential action exhibited by plants in this respect, there are really only three basic mechanisms by which they achieve the purpose desired. In essence, all phytotechnology centres on the removal and accumulation of unwanted substances within the plant tissues themselves, their removal and subsequent volatisation to atmosphere or the facilitation of in-soil treatment. Plant-based treatments make use of natural cycles within the plant and its environment and, clearly, to be effective, the right plant must be chosen. Inevitably, the species selected must be appropriate for the climate, and it must, obviously, be able to survive in contact with the contamination to be able to accomplish its goal. It may also have a need to be able to encourage localised microbial growth.